Chains

Chains

Chains

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Conveyor<br />

Design<br />

www.bergab.ru Берг АБ bergab@ya.ru Тел. (495)-228-06-21, факс (495) 223-3071<br />

Straight Running and Sideflexing <strong>Chains</strong><br />

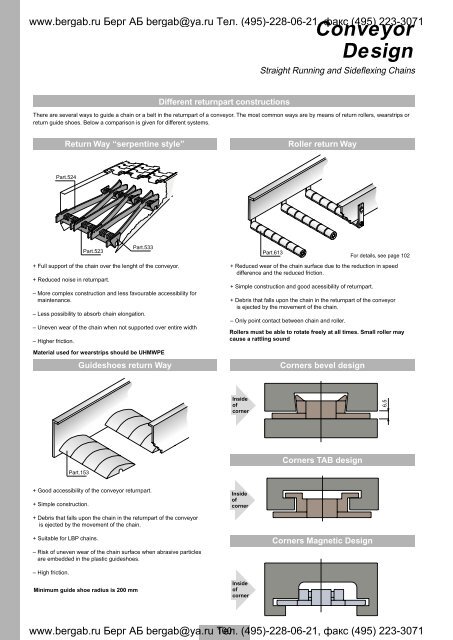

Different returnpart constructions<br />

There are several ways to guide a chain or a belt in the returnpart of a conveyor. The most common ways are by means of return rollers, wearstrips or<br />

return guide shoes. Below a comparison is given for different systems.<br />

Return Way “serpentine style”<br />

Roller return Way<br />

Part.524<br />

Part.523<br />

Part.533<br />

+ Full support of the chain over the lenght of the conveyor.<br />

+ Reduced noise in returnpart.<br />

– More complex construction and less favourable accessibility for<br />

maintenance.<br />

– Less possibility to absorb chain elongation.<br />

– Uneven wear of the chain when not supported over entire width<br />

– Higher friction.<br />

Material used for wearstrips should be UHMWPE<br />

Guideshoes return Way<br />

Part.613<br />

For details, see page 102<br />

+ Reduced wear of the chain surface due to the reduction in speed<br />

difference and the reduced friction.<br />

+ Simple construction and good acessibility of returnpart.<br />

+ Debris that falls upon the chain in the returnpart of the conveyor<br />

is ejected by the movement of the chain.<br />

– Only point contact between chain and roller.<br />

Rollers must be able to rotate freely at all times. Small roller may<br />

cause a rattling sound<br />

Corners bevel design<br />

Inside<br />

of<br />

corner<br />

6,5<br />

Corners TAB design<br />

Part.153<br />

+ Good accessibility of the conveyor returnpart.<br />

+ Simple construction.<br />

Inside<br />

of<br />

corner<br />

+ Debris that falls upon the chain in the returnpart of the conveyor<br />

is ejected by the movement of the chain.<br />

+ Suitable for LBP chains.<br />

– Risk of uneven wear of the chain surface when abrasive particles<br />

are embedded in the plastic guideshoes.<br />

Corners Magnetic Design<br />

– High friction.<br />

Minimum guide shoe radius is 200 mm<br />

Inside<br />

of<br />

corner<br />

www.bergab.ru Берг АБ bergab@ya.ru Тел. 100 (495)-228-06-21, факс (495) 223-3071