Use of biofuels in the district heating system of Riga - rehva

Use of biofuels in the district heating system of Riga - rehva

Use of biofuels in the district heating system of Riga - rehva

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Articles<br />

In summer period only <strong>the</strong> operation <strong>of</strong> <strong>the</strong> bi<strong>of</strong>uel<br />

fired boilers is envisaged <strong>in</strong> <strong>the</strong> heat plants<br />

„Daugavgrīva” and „Vecmīlgrāvis”. For <strong>the</strong> purpose<br />

<strong>of</strong> ensur<strong>in</strong>g <strong>the</strong> compensation for <strong>the</strong> daily chang<strong>in</strong>g<br />

heat loads - heat accumulators were <strong>in</strong>stalled <strong>in</strong> <strong>the</strong><br />

heat plants and <strong>the</strong>y are cover<strong>in</strong>g <strong>the</strong> heat loads dur<strong>in</strong>g<br />

<strong>the</strong> peak hours and charge <strong>the</strong> load <strong>of</strong> <strong>the</strong> boilers<br />

dur<strong>in</strong>g night hours.<br />

The development measures implemented at <strong>the</strong> heat<br />

plant „Vecmīlgrāvis” permitted to improve <strong>the</strong> operational<br />

efficiency <strong>of</strong> this heat source and has <strong>in</strong>creased <strong>the</strong><br />

share <strong>of</strong> use <strong>of</strong> <strong>the</strong> bi<strong>of</strong>uel <strong>in</strong> <strong>the</strong> total production scope<br />

from 2.4% to 6.4%.<br />

Fur<strong>the</strong>r development<br />

<strong>of</strong> <strong>the</strong> bi<strong>of</strong>uel usage<br />

By <strong>in</strong>creas<strong>in</strong>g <strong>the</strong> share <strong>of</strong> use <strong>of</strong> <strong>the</strong> bi<strong>of</strong>uel, <strong>the</strong> impact<br />

<strong>of</strong> <strong>the</strong> <strong>in</strong>crease <strong>of</strong> natural gas prices upon <strong>the</strong> heat<br />

production costs will be reduced. Currently two modernisation<br />

projects have been <strong>in</strong>itiated provid<strong>in</strong>g for <strong>the</strong><br />

<strong>in</strong>stallation <strong>of</strong> highly efficient heat production units us<strong>in</strong>g<br />

bi<strong>of</strong>uel:<br />

• a cogeneration unit produc<strong>in</strong>g up to 22 MW<br />

heat and 4 MW electricity with <strong>the</strong> total<br />

efficiency rate up to 97% will be <strong>in</strong>stalled at <strong>the</strong><br />

heat plant “Ziepniekkalns”;<br />

• <strong>the</strong> <strong>in</strong>stallation <strong>of</strong> <strong>the</strong> water heat<strong>in</strong>g boiler with<br />

<strong>the</strong> capacity <strong>of</strong> 20 MW and <strong>the</strong> fluidised bed<br />

furnace allow<strong>in</strong>g to burn a wide range <strong>of</strong> bi<strong>of</strong>uel<br />

is planned <strong>in</strong> <strong>the</strong> modernisation project <strong>of</strong> <strong>the</strong><br />

heat plant “Zasulauks”.<br />

In both above mentioned projects <strong>the</strong> flue gas utilisation<br />

technologies (flue gas condensers) will be <strong>in</strong>stalled ensur<strong>in</strong>g<br />

<strong>the</strong> efficiency rate <strong>of</strong> <strong>the</strong> boiler operation close to<br />

100%. The maximum automation level and construction<br />

<strong>of</strong> <strong>the</strong> automated storage <strong>of</strong> bi<strong>of</strong>uel is planned to be<br />

placed at <strong>the</strong> boiler houses. The implementation <strong>of</strong> <strong>the</strong><br />

projects will permit to save <strong>the</strong> natural gas consumption<br />

<strong>of</strong> approximately 11.2 mill. n.m³/year, at <strong>the</strong> same time<br />

<strong>in</strong>creas<strong>in</strong>g <strong>the</strong> consumption <strong>of</strong> bi<strong>of</strong>uel by approximately<br />

112 thous. loose m³/year.<br />

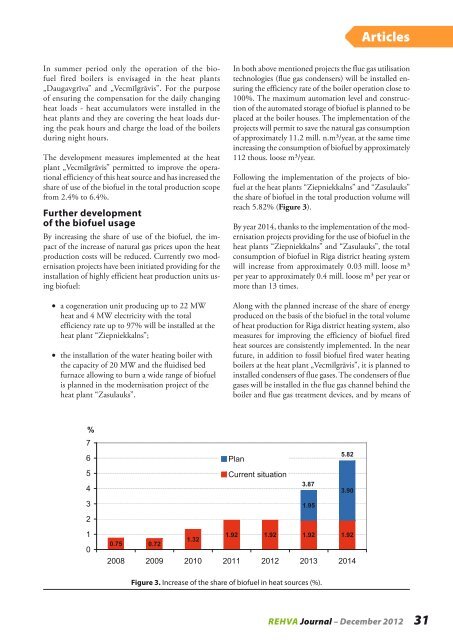

Follow<strong>in</strong>g <strong>the</strong> implementation <strong>of</strong> <strong>the</strong> projects <strong>of</strong> bi<strong>of</strong>uel<br />

at <strong>the</strong> heat plants “Ziepniekkalns” and “Zasulauks”<br />

<strong>the</strong> share <strong>of</strong> bi<strong>of</strong>uel <strong>in</strong> <strong>the</strong> total production volume will<br />

reach 5.82% (Figure 3).<br />

By year 2014, thanks to <strong>the</strong> implementation <strong>of</strong> <strong>the</strong> modernisation<br />

projects provid<strong>in</strong>g for <strong>the</strong> use <strong>of</strong> bi<strong>of</strong>uel <strong>in</strong> <strong>the</strong><br />

heat plants “Ziepniekkalns” and “Zasulauks”, <strong>the</strong> total<br />

consumption <strong>of</strong> bi<strong>of</strong>uel <strong>in</strong> <strong>Riga</strong> <strong>district</strong> heat<strong>in</strong>g <strong>system</strong><br />

will <strong>in</strong>crease from approximately 0.03 mill. loose m³<br />

per year to approximately 0.4 mill. loose m³ per year or<br />

more than 13 times.<br />

Along with <strong>the</strong> planned <strong>in</strong>crease <strong>of</strong> <strong>the</strong> share <strong>of</strong> energy<br />

produced on <strong>the</strong> basis <strong>of</strong> <strong>the</strong> bi<strong>of</strong>uel <strong>in</strong> <strong>the</strong> total volume<br />

<strong>of</strong> heat production for <strong>Riga</strong> <strong>district</strong> heat<strong>in</strong>g <strong>system</strong>, also<br />

measures for improv<strong>in</strong>g <strong>the</strong> efficiency <strong>of</strong> bi<strong>of</strong>uel fired<br />

heat sources are consistently implemented. In <strong>the</strong> near<br />

future, <strong>in</strong> addition to fossil bi<strong>of</strong>uel fired water heat<strong>in</strong>g<br />

boilers at <strong>the</strong> heat plant „Vecmīlgrāvis”, it is planned to<br />

<strong>in</strong>stalled condensers <strong>of</strong> flue gases. The condensers <strong>of</strong> flue<br />

gases will be <strong>in</strong>stalled <strong>in</strong> <strong>the</strong> flue gas channel beh<strong>in</strong>d <strong>the</strong><br />

boiler and flue gas treatment devices, and by means <strong>of</strong><br />

%<br />

7<br />

6<br />

Plan<br />

5.82<br />

5<br />

4<br />

Current situation<br />

3.87<br />

3.90<br />

3<br />

1.95<br />

2<br />

1<br />

0<br />

1.92 1.92 1.92 1.92<br />

1.32<br />

0.75 0.72<br />

2008 2009 2010 2011 2012 2013 2014<br />

Figure 3. Increase <strong>of</strong> <strong>the</strong> share <strong>of</strong> bi<strong>of</strong>uel <strong>in</strong> heat sources (%).<br />

REHVA Journal – December 2012 31