High Performance Highway Structures - RIBAProductSelector.com

High Performance Highway Structures - RIBAProductSelector.com

High Performance Highway Structures - RIBAProductSelector.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

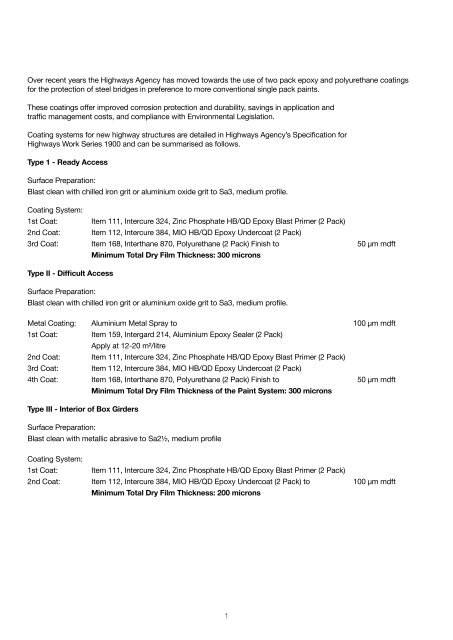

Over recent years the <strong>High</strong>ways Agency has moved towards the use of two pack epoxy and polyurethane coatings<br />

for the protection of steel bridges in preference to more conventional single pack paints.<br />

These coatings offer improved corrosion protection and durability, savings in application and<br />

traffic management costs, and <strong>com</strong>pliance with Environmental Legislation.<br />

Coating systems for new highway structures are detailed in <strong>High</strong>ways Agency’s Specification for<br />

<strong>High</strong>ways Work Series 1900 and can be summarised as follows.<br />

Type 1 - Ready Access<br />

Surface Preparation:<br />

Blast clean with chilled iron grit or aluminium oxide grit to Sa3, medium profile.<br />

Coating System:<br />

1st Coat: Item 111, Intercure 324, Zinc Phosphate HB/QD Epoxy Blast Primer (2 Pack)<br />

2nd Coat: Item 112, Intercure 384, MIO HB/QD Epoxy Undercoat (2 Pack)<br />

3rd Coat: Item 168, Interthane 870, Polyurethane (2 Pack) Finish to 50 μm mdft<br />

Minimum Total Dry Film Thickness: 300 microns<br />

Type II - Difficult Access<br />

Surface Preparation:<br />

Blast clean with chilled iron grit or aluminium oxide grit to Sa3, medium profile.<br />

Metal Coating: Aluminium Metal Spray to 100 μm mdft<br />

1st Coat: Item 159, Intergard 214, Aluminium Epoxy Sealer (2 Pack)<br />

Apply at 12-20 m²/litre<br />

2nd Coat: Item 111, Intercure 324, Zinc Phosphate HB/QD Epoxy Blast Primer (2 Pack)<br />

3rd Coat: Item 112, Intercure 384, MIO HB/QD Epoxy Undercoat (2 Pack)<br />

4th Coat: Item 168, Interthane 870, Polyurethane (2 Pack) Finish to 50 μm mdft<br />

Minimum Total Dry Film Thickness of the Paint System: 300 microns<br />

Type III - Interior of Box Girders<br />

Surface Preparation:<br />

Blast clean with metallic abrasive to Sa2½, medium profile<br />

Coating System:<br />

1st Coat: Item 111, Intercure 324, Zinc Phosphate HB/QD Epoxy Blast Primer (2 Pack)<br />

2nd Coat: Item 112, Intercure 384, MIO HB/QD Epoxy Undercoat (2 Pack) to 100 μm mdft<br />

Minimum Total Dry Film Thickness: 200 microns<br />

1