Cooled Injection System CIS 6

Cooled Injection System CIS 6

Cooled Injection System CIS 6

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Cooled</strong> <strong>Injection</strong> <strong>System</strong><br />

<strong>CIS</strong> 6<br />

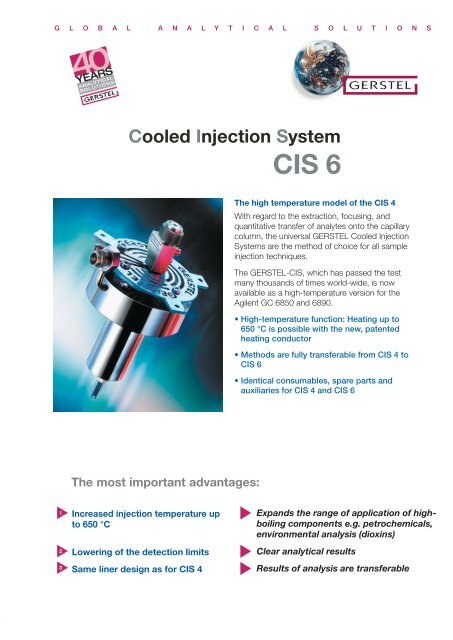

The high temperature model of the <strong>CIS</strong> 4<br />

With regard to the extraction, focusing, and<br />

quantitative transfer of analytes onto the capillary<br />

column, the universal GERSTEL <strong>Cooled</strong> <strong>Injection</strong><br />

<strong>System</strong>s are the method of choice for all sample<br />

injection techniques.<br />

The GERSTEL-<strong>CIS</strong>, which has passed the test<br />

many thousands of times world-wide, is now<br />

available as a high-temperature version for the<br />

Agilent GC 6850 and 6890.<br />

• High-temperature function: Heating up to<br />

650 °C is possible with the new, patented<br />

heating conductor<br />

• Methods are fully transferable from <strong>CIS</strong> 4 to<br />

<strong>CIS</strong> 6<br />

• Identical consumables, spare parts and<br />

auxiliaries for <strong>CIS</strong> 4 and <strong>CIS</strong> 6<br />

The most important advantages:<br />

1<br />

2<br />

3<br />

Increased injection temperature up<br />

to 650 °C<br />

Lowering of the detection limits<br />

Same liner design as for <strong>CIS</strong> 4<br />

Expands the range of application of highboiling<br />

components e.g. petrochemicals,<br />

environmental analysis (dioxins)<br />

Clear analytical results<br />

Results of analysis are transferable

Further advantages of the GERSTEL <strong>CIS</strong> 6<br />

4<br />

Universal use<br />

5<br />

Septumless injection head<br />

6<br />

Patented heating conductor system<br />

7<br />

8<br />

Variable sample introduction temperatures<br />

due to different cooling option<br />

Solvent Venting<br />

9<br />

Large volume injection up to 1000 µl<br />

10<br />

Selective extraction of low and high-boiling components<br />

11<br />

Control via the GERSTEL-MAS* Controller 506<br />

The patented heating conductor<br />

system, with free programmable<br />

heating rates, ensures optimal<br />

transfer also of thermolabile<br />

sensitive substances to the<br />

separating column.<br />

12<br />

Can be used to upgrade existing GC<br />

Ask us about your own individual benefit!<br />

600 µl PCB / Pesticide standard<br />

<strong>Injection</strong> temperature: 25 °C<br />

Solvent Venting<br />

with Stop Flow<br />

Total flow: 200 ml / min<br />

<strong>Injection</strong> rate:<br />

115 µl / min<br />

30 m x 0,25 mm x 0.25 µm HP-5 MS<br />

* MAS = Modular Analytical <strong>System</strong>s

Only one injection system for all injection techniques, split/splitless <strong>Injection</strong>,<br />

Large Volume and On-Column injection techniques<br />

No falsification of results by partition particles or bleeding; no loss of<br />

analytes; low maintenance requirement<br />

Optimal transfer of analytes onto the column, even for thermobile<br />

unstable substances, using free programmable heating rates;<br />

better separating performance due to better peak shape<br />

Protected Sample introduction<br />

Better chromatographic separation; protection of the capillary column and<br />

the detectors<br />

Lowering of detection limits and time-saving due to less<br />

sample preparation steps<br />

Selective transfer of components onto the column<br />

Cost-effective system upgrades possible for GERSTEL sample<br />

preparation systems<br />

Suitable for all Agilent GC 6850/ 6890; no new investment<br />

in GC equipment required<br />

<strong>CIS</strong> On-column<br />

injection insert<br />

Polywax 655<br />

On-column injection<br />

at 30 °C with<br />

0.5 °C / s 400 °C<br />

12 m x 0.53 mm x<br />

0.15 µm HT5

Cooling Options<br />

4<br />

1 LN 2<br />

Cooling<br />

For applications with injection temperatures up to - 150 °C. The Dewar vessel<br />

required for this purpose can also be provide by GERSTEL.<br />

2 LCO 2<br />

Cooling<br />

For applications with injection temperatures up to - 50 °C.<br />

3 Cryostat Cooling<br />

Preferably for applications with injection temperatures up to - 40 °C, for which a<br />

Peltier cooling system is not sufficient, but for which cooling with LCO 2<br />

or LN 2<br />

is<br />

not required. Peltier and cryostat cooling systems can be upgraded with an LN 2<br />

-<br />

option.<br />

4 Patented Peltier Cooling<br />

Preferably for applications with injection temperatures up to + 30 °C (with an<br />

initial oven temperature of 60 °C), for which cooling with LCO 2<br />

or LN 2<br />

is not required.<br />

Technical Data on <strong>CIS</strong> 6<br />

Temperatur<br />

emperature e ranges<br />

with LN 2<br />

cooling – 150 to + 650 °C<br />

with LCO 2<br />

cooling – 50 to + 650 °C<br />

with cryostat cooling – 40 to + 650 °C<br />

with Peltier cooling + 30 to + 650 °C *<br />

Heating rate<br />

Split-flow<br />

0,5 to 18 °/s<br />

adjustable to 400 ml/min,<br />

depending on the type of<br />

carrier gas and GC<br />

GERSTEL Controller 506<br />

The Controller 506 is a permanent feature<br />

of every <strong>CIS</strong> 6 and controls all<br />

GERSTEL modules.<br />

Transfer modes<br />

Split/split-less<br />

Solvent Venting<br />

Solvent Venting<br />

with stop-flow<br />

LAN interface Suitable for networks<br />

* at 60°C initial oven temperature<br />

GERSTEL MAESTRO Software<br />

The proven GERSTEL MAESTRO Software provides a comfortable means of<br />

controlling the <strong>CIS</strong> 6 and the GERSTEL modules. This software is compatible<br />

with MS Windows 2000/XP and has automatic hardware recognition<br />

Information, descriptions and specifications in this<br />

publication are subject to change without notice.<br />

GERSTEL, GRAPHPACK and TWISTER are registered<br />

tradenames of GERSTEL GmbH & Co. KG.<br />

© Copyright by GERSTEL GmbH & Co. KG