HVO 2009 Annual Environmental Management Report - Final

HVO 2009 Annual Environmental Management Report - Final

HVO 2009 Annual Environmental Management Report - Final

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

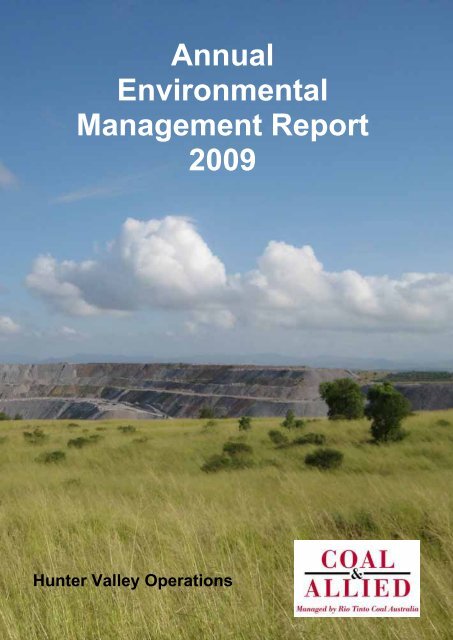

<strong>Annual</strong><br />

<strong>Environmental</strong><br />

<strong>Management</strong> <strong>Report</strong><br />

<strong>2009</strong><br />

Hunter Valley Operations

This page has been intentionally left blank<br />

Cover: Photo of Rehabilitation at Cheshunt Pit

Coal & Allied – Hunter Valley Operations<br />

TABLE OF CONTENTS<br />

1 INTRODUCTION ....................................................................................................................................... 1<br />

1.1 SCOPE............................................................................................................................................. 1<br />

1.1.1 Background Development................................................................................................... 1<br />

1.1.2 Corporate <strong>Environmental</strong> <strong>Management</strong> Strategies............................................................. 2<br />

1.2 CONSENTS, LEASE AND LICENCES............................................................................................ 5<br />

1.2.1 Current Approvals ............................................................................................................... 5<br />

1.2.2 Compliance Audits ............................................................................................................ 21<br />

1.2.3 Amendments over the <strong>Report</strong>ing Period........................................................................... 21<br />

1.2.4 Proposed Developments................................................................................................... 22<br />

1.3 MINE CONTACTS ......................................................................................................................... 23<br />

1.4 ACTIONS REQUIRED AFTER REVIEW OF 2008 AEMR ............................................................ 24<br />

2 OPERATIONS DURING THE REPORTING PERIOD ............................................................................ 27<br />

2.1 EXPLORATION AND RESOURCE UTILISATION ........................................................................ 27<br />

2.1.1 Current Exploration ........................................................................................................... 27<br />

2.1.2 Reserve/Resource Status ................................................................................................. 28<br />

2.1.3 Estimated Mine Life........................................................................................................... 28<br />

2.2 LAND PREPARATION................................................................................................................... 28<br />

2.2.1 Vegetation Clearing........................................................................................................... 29<br />

2.2.2 Topsoil <strong>Management</strong>.........................................................................................................29<br />

2.3 CONSTRUCTION .......................................................................................................................... 29<br />

2.4 MINING .......................................................................................................................................... 29<br />

2.4.1 Changes during the <strong>Report</strong>ing Period............................................................................... 30<br />

2.4.2 Mining Equipment ............................................................................................................. 30<br />

2.5 MINERAL PROCESSING .............................................................................................................. 30<br />

2.5.1 Product and Market........................................................................................................... 31<br />

2.5.2 Production and Waste Summary ...................................................................................... 32<br />

2.6 WASTE MANAGEMENT................................................................................................................ 32<br />

2.6.1 Hydrocarbon Disposal.......................................................................................................32<br />

2.6.2 Sewage Treatment/Disposal............................................................................................. 32<br />

2.6.3 Non Hazardous Wastes .................................................................................................... 32<br />

2.6.4 Processing Plant Residues/Rejects <strong>Management</strong>............................................................ 34<br />

2.6.5 Monitoring and Maintenance of Tailings Containment Facilities ...................................... 34<br />

2.7 ORE AND PRODUCT STOCKPILES ............................................................................................ 37<br />

2.7.1 Stockpile Capacity............................................................................................................. 37<br />

2.7.2 Changes or Additions to Process or Facilities during <strong>2009</strong> .............................................. 37<br />

2.7.3 Changes in Product Transport .......................................................................................... 37<br />

2.8 WATER MANAGEMENT ............................................................................................................... 38<br />

2.8.1 Water Balance................................................................................................................... 38<br />

2.8.2 Improvements to Mine Water <strong>Management</strong>...................................................................... 43<br />

AEMR <strong>2009</strong><br />

ii

Coal & Allied – Hunter Valley Operations<br />

2.8.3 Mine Water <strong>Management</strong> System..................................................................................... 43<br />

2.8.4 Hunter River Salinity Trading Scheme.............................................................................. 44<br />

2.8.5 Flooding ............................................................................................................................ 44<br />

2.9 HAZARDOUS MATERIAL MANAGEMENT................................................................................... 49<br />

2.9.1 Status of Licences............................................................................................................. 49<br />

2.9.2 Inventory of Material <strong>Management</strong> ................................................................................... 49<br />

2.9.3 Fuel Containment.............................................................................................................. 49<br />

2.9.4 Oil and Grease Containment and Disposal ...................................................................... 49<br />

2.10 OTHER INFRASTRUCTURE MANAGEMENT.............................................................................. 50<br />

3 ENVIRONMENTAL MANAGEMENT AND PERFORMANCE ................................................................. 51<br />

3.1 METEOROLOGICAL ..................................................................................................................... 51<br />

3.1.1 <strong>Environmental</strong> <strong>Management</strong> ............................................................................................. 51<br />

3.1.2 <strong>Environmental</strong> Performance ............................................................................................. 51<br />

3.1.3 Rainfall .............................................................................................................................. 52<br />

3.2 AIR QUALITY................................................................................................................................. 55<br />

3.2.1 <strong>Environmental</strong> <strong>Management</strong> ............................................................................................. 55<br />

3.2.2 <strong>Environmental</strong> Performance ............................................................................................. 57<br />

3.3 EROSION AND SEDIMENT MANAGEMENT ............................................................................... 71<br />

3.3.1 <strong>Environmental</strong> <strong>Management</strong> ............................................................................................. 71<br />

3.3.2 <strong>Environmental</strong> Performance ............................................................................................. 71<br />

3.4 SURFACE WATER QUALITY........................................................................................................71<br />

3.4.1 <strong>Environmental</strong> <strong>Management</strong> ............................................................................................. 71<br />

3.4.2 <strong>Environmental</strong> Performance ............................................................................................. 73<br />

3.5 GROUNDWATER QUALITY..........................................................................................................89<br />

3.5.1 <strong>Environmental</strong> <strong>Management</strong> ............................................................................................. 89<br />

3.5.2 <strong>Environmental</strong> Performance ............................................................................................. 92<br />

3.6 CONTAMINATED POLLUTED LAND.......................................................................................... 117<br />

3.6.1 <strong>Environmental</strong> <strong>Management</strong> and Performance .............................................................. 117<br />

3.7 THREATENED FLORA AND FAUNA.......................................................................................... 118<br />

3.7.1 <strong>Environmental</strong> <strong>Management</strong> ........................................................................................... 118<br />

3.7.2 <strong>Environmental</strong> Performance ........................................................................................... 118<br />

3.7.3 Flora and Fauna Monitoring............................................................................................ 119<br />

3.8 WEEDS ........................................................................................................................................ 120<br />

3.8.1 <strong>Environmental</strong> <strong>Management</strong> ........................................................................................... 120<br />

3.8.2 <strong>Environmental</strong> Performance ........................................................................................... 120<br />

3.9 BLASTING.................................................................................................................................... 123<br />

3.9.1 <strong>Environmental</strong> <strong>Management</strong> ........................................................................................... 123<br />

3.9.2 <strong>Environmental</strong> Performance ........................................................................................... 126<br />

3.10 OPERATIONAL NOISE ............................................................................................................... 130<br />

3.10.1 <strong>Environmental</strong> <strong>Management</strong> ........................................................................................... 130<br />

AEMR <strong>2009</strong><br />

iii

Coal & Allied – Hunter Valley Operations<br />

3.10.2 <strong>Environmental</strong> Performance ........................................................................................... 133<br />

3.10.3 Noise Predictions for 2010.............................................................................................. 137<br />

3.11 VISUAL, STRAY LIGHT............................................................................................................... 138<br />

3.11.1 <strong>Environmental</strong> <strong>Management</strong> ........................................................................................... 138<br />

3.11.2 <strong>Environmental</strong> Performance ........................................................................................... 138<br />

3.12 ARCHAEOLOGY AND CULTURAL HERITAGE ......................................................................... 138<br />

3.12.1 Relations with the Local Aboriginal Community.............................................................. 138<br />

3.12.2 <strong>Management</strong> of Archaeology and Cultural Heritage....................................................... 139<br />

3.12.3 Archaeology and Cultural Heritage Performance ........................................................... 141<br />

3.12.4 Historic Heritage.............................................................................................................. 143<br />

3.13 NATURAL HERITAGE................................................................................................................. 144<br />

3.14 SPONTANEOUS COMBUSTION ................................................................................................ 144<br />

3.14.1 <strong>Environmental</strong> <strong>Management</strong> ........................................................................................... 144<br />

3.14.2 <strong>Environmental</strong> Performance ........................................................................................... 144<br />

3.15 BUSHFIRE ................................................................................................................................... 145<br />

3.15.1 <strong>Environmental</strong> <strong>Management</strong> ........................................................................................... 145<br />

3.15.2 <strong>Environmental</strong> Performance ........................................................................................... 145<br />

3.16 MINE SUBSIDENCE.................................................................................................................... 146<br />

3.17 HYDROCARBON CONTAMINATION ......................................................................................... 146<br />

3.17.1 <strong>Environmental</strong> <strong>Management</strong> ........................................................................................... 146<br />

3.17.2 <strong>Environmental</strong> Performance ........................................................................................... 146<br />

3.18 METHANE DRAINAGE/VENTILATION ....................................................................................... 147<br />

3.18.1 <strong>Environmental</strong> <strong>Management</strong> and Performance .............................................................. 147<br />

3.19 ACID ROCK DRAINAGE ............................................................................................................. 147<br />

3.19.1 <strong>Environmental</strong> <strong>Management</strong> ........................................................................................... 147<br />

3.19.2 <strong>Environmental</strong> Performance ........................................................................................... 147<br />

3.20 PUBLIC SAFETY ......................................................................................................................... 148<br />

3.20.1 <strong>Environmental</strong> <strong>Management</strong> ........................................................................................... 148<br />

3.20.2 <strong>Environmental</strong> Performance ........................................................................................... 148<br />

3.21 REPORTABLE ENVIRONMENTAL INCIDENTS ........................................................................ 148<br />

3.21.1 <strong>Environmental</strong> <strong>Management</strong> ........................................................................................... 148<br />

3.21.2 <strong>Environmental</strong> Performance ........................................................................................... 148<br />

3.22 FURTHER IMPROVEMENTS AND TARGETS........................................................................... 151<br />

3.22.1 <strong>2009</strong> Performance against Targets................................................................................. 151<br />

3.23 TRIALS AND RESEARCH........................................................................................................... 152<br />

3.23.1 Commercial Forestry Trials............................................................................................. 152<br />

3.23.2 Biosolids Trial.................................................................................................................. 154<br />

3.23.3 Meteorological Data Measurement and Assessment ..................................................... 154<br />

3.23.4 Blast Vibration Studies.................................................................................................... 154<br />

3.23.5 Contribution of Mining Emissions to NO 2 and PM 10 in the Upper Hunter ....................... 155<br />

AEMR <strong>2009</strong><br />

iv

Coal & Allied – Hunter Valley Operations<br />

3.24 CLIMATE CHANGE ..................................................................................................................... 156<br />

3.24.1 Efforts to Address Climate Change................................................................................. 156<br />

3.24.2 <strong>Environmental</strong> Performance ........................................................................................... 158<br />

3.25 ENVIRONMENTAL EQUIPMENT DELAYS ................................................................................ 160<br />

3.25.1 <strong>Environmental</strong> <strong>Management</strong> ........................................................................................... 160<br />

3.25.2 <strong>Environmental</strong> Performance ........................................................................................... 160<br />

3.26 CARRINGTON BILLABONG........................................................................................................ 161<br />

3.26.1 <strong>Environmental</strong> <strong>Management</strong> ........................................................................................... 161<br />

3.26.2 <strong>Environmental</strong> Performance ........................................................................................... 161<br />

4 COMMUNITY RELATIONS ................................................................................................................... 162<br />

4.1 ENVIRONMENTAL COMPLAINTS.............................................................................................. 162<br />

4.1.1 Listing of Complaints for the <strong>Report</strong>ing Period ............................................................... 162<br />

4.1.2 Complaint Resolution...................................................................................................... 162<br />

4.2 COMMUNITY LIAISON................................................................................................................ 163<br />

4.2.1 External Relations ........................................................................................................... 163<br />

4.2.2 Community Consultation................................................................................................. 163<br />

4.2.3 Community Consultative Committees............................................................................. 164<br />

4.2.4 Aboriginal Relationships.................................................................................................. 164<br />

4.3 SOCIAL/ECONOMIC CONTRIBUTION AND ACHIEVEMENTS ................................................ 166<br />

4.3.1 Involvement in the Community........................................................................................ 166<br />

4.4 RECOGNITION AND SHARING SUCCESS ............................................................................... 169<br />

4.4.1 Coal & Allied Community Trust ....................................................................................... 169<br />

4.4.2 Community Partnerships................................................................................................. 171<br />

4.5 EMPLOYMENT STATUS AND DEMOGRAPHY......................................................................... 173<br />

5 REHABILITATION ................................................................................................................................. 175<br />

5.1 BUILDINGS.................................................................................................................................. 175<br />

5.2 REHABILITATION OF DISTURBED LAND ................................................................................. 175<br />

5.2.1 Assessment of Land Capability....................................................................................... 175<br />

5.2.2 Rehabilitation Material Characteristics............................................................................ 175<br />

5.2.3 Method of Land Shaping................................................................................................. 175<br />

5.2.4 Characteristics of Cover Material.................................................................................... 175<br />

5.2.5 Methods, Thickness and Compaction of Cover Material ................................................ 176<br />

5.2.6 Drainage and Erosion Control......................................................................................... 176<br />

5.2.7 <strong>Final</strong> landform Profile Slopes .......................................................................................... 176<br />

5.2.8 Soil Treatment................................................................................................................. 176<br />

5.2.9 Vegetation Species and Establishment .......................................................................... 177<br />

5.2.10 Native Seed Strategy ...................................................................................................... 180<br />

5.2.11 Habitat Audit.................................................................................................................... 180<br />

5.2.12 Water Containment, Control and Distribution ................................................................. 180<br />

5.2.13 Feral Animal Control ....................................................................................................... 181<br />

AEMR <strong>2009</strong><br />

v

Coal & Allied – Hunter Valley Operations<br />

5.3 OTHER INFRASTRUCTURE....................................................................................................... 183<br />

5.4 REHABILITATION STATUS AT END OF REPORTING PERIOD............................................... 183<br />

5.4.1 West Pit........................................................................................................................... 183<br />

5.4.2 South (Riverview, Cheshunt, Lemington South Pits)...................................................... 184<br />

5.4.3 North (Carrington and North Pits) ................................................................................... 184<br />

5.4.4 Review of Rehabilitation Monitoring and Performance................................................... 185<br />

5.4.5 Decommissioning Closure Plans and Schedules ........................................................... 186<br />

5.4.6 <strong>Final</strong> Void ........................................................................................................................ 187<br />

5.5 FURTHER DEVELOPMENT OF THE FINAL REHABILITATION PLAN..................................... 187<br />

6 ACTIVITIES PROPOSED IN THE NEXT AEMR PERIOD .................................................................... 188<br />

6.1 PLANS FOR THE 2010 REPORTING PERIOD .......................................................................... 188<br />

AEMR <strong>2009</strong><br />

vi

Coal & Allied – Hunter Valley Operations<br />

LIST OF FIGURES<br />

Figure 1: <strong>HVO</strong> Regional Proximity....................................................................................................................... 3<br />

Figure 2: <strong>HVO</strong> Mine Site Layout.......................................................................................................................... 4<br />

Figure 3: Coal & Allied <strong>Environmental</strong> Services Organisation Chart for <strong>2009</strong> .................................................. 24<br />

Figure 4: Coal & Allied Product Coal Destinations <strong>2009</strong> ................................................................................... 31<br />

Figure 5: Schematic of the Material Recycling Facility at Thornton .................................................................. 33<br />

Figure 6: Waste Statistics for <strong>HVO</strong> in <strong>2009</strong>....................................................................................................... 33<br />

Figure 7: <strong>2009</strong> <strong>HVO</strong> Waste Streams ................................................................................................................. 34<br />

Figure 8: Location and Status of Tailings Dams at <strong>HVO</strong>................................................................................... 36<br />

Figure 9: <strong>HVO</strong> Water Balance Schematic ......................................................................................................... 40<br />

Figure 10: <strong>HVO</strong> Salt Balance Schematic Diagram............................................................................................ 41<br />

Figure 11: <strong>HVO</strong> West Pit Water <strong>Management</strong> Structures ................................................................................. 45<br />

Figure 12: <strong>HVO</strong> North Pit Water <strong>Management</strong> Structures ................................................................................ 46<br />

Figure 13: <strong>HVO</strong> South Pit Water <strong>Management</strong> Structure.................................................................................. 47<br />

Figure 14: Location and Status of Levee Banks at <strong>HVO</strong>................................................................................... 48<br />

Figure 15: Rainfall Summary for 2007 to <strong>2009</strong>.................................................................................................. 52<br />

Figure 16: Maximum and Minimum Temperatures for the <strong>2009</strong> Period............................................................ 53<br />

Figure 17: <strong>2009</strong> <strong>Annual</strong> Wind Rose................................................................................................................... 54<br />

Figure 18: Quarterly Average Wind Roses for <strong>HVO</strong> in <strong>2009</strong> (Clockwise from top left; January to March, April to<br />

June, July to September, and October to December)....................................................................... 54<br />

Figure 19: Ambient Air Monitoring Network at <strong>HVO</strong> in <strong>2009</strong>............................................................................. 56<br />

Figure 20: Dust Depositional <strong>Annual</strong> Average 2007 to <strong>2009</strong> ............................................................................ 58<br />

Figure 21: Dust Depositional <strong>Annual</strong> Average Increase 2008 to <strong>2009</strong> ............................................................. 58<br />

Figure 22: Dust Isopleth <strong>Annual</strong> Average Dust Deposition January <strong>2009</strong> – December <strong>2009</strong> (g/m2/month<br />

insoluble matter) at gauges on private and Coal & Allied owned land.............................................. 61<br />

Figure 23: <strong>Annual</strong> Average HVAS TSP Results 2007 to <strong>2009</strong>.......................................................................... 64<br />

Figure 24: Monthly Mean TSP and Rainfall at <strong>HVO</strong> in <strong>2009</strong>............................................................................. 64<br />

Figure 25: <strong>Annual</strong> Average HVAS PM 10 Results 2007 to <strong>2009</strong>......................................................................... 65<br />

Figure 26: Monthly Mean PM 10 and Rainfall at <strong>HVO</strong> in <strong>2009</strong>............................................................................ 66<br />

Figure 27: PM 10 Results for <strong>2009</strong> against 24 Hour Impact Assessment Criteria .............................................. 68<br />

Figure 28: Surface Water Monitoring Network at <strong>HVO</strong> in <strong>2009</strong> ........................................................................ 72<br />

Figure 29: Hunter River Mean pH, EC and TSS ............................................................................................... 76<br />

Figure 30: Hunter River pH Trends ................................................................................................................... 76<br />

Figure 31: Hunter River EC Trends ................................................................................................................... 77<br />

Figure 32: Hunter River TSS Trends ................................................................................................................. 78<br />

Figure 33: Wollombi Brook pH Trends .............................................................................................................. 79<br />

Figure 34: Wollombi Brook EC Trends.............................................................................................................. 79<br />

Figure 35: Wollombi Brook TSS Trends............................................................................................................ 80<br />

Figure 36: Other Tributaries pH Trends............................................................................................................. 81<br />

Figure 37: Other Tributaries EC Trends ............................................................................................................ 82<br />

AEMR <strong>2009</strong><br />

vii

Coal & Allied – Hunter Valley Operations<br />

Figure 38: Other Tributaries TSS Trends .......................................................................................................... 82<br />

Figure 39: <strong>HVO</strong> Site Dams pH Trends .............................................................................................................. 83<br />

Figure 40: <strong>HVO</strong> Site Dams EC Trends.............................................................................................................. 84<br />

Figure 41: <strong>HVO</strong> Site Dams TSS Trends............................................................................................................ 84<br />

Figure 42: Groundwater Monitoring Network at <strong>HVO</strong> in <strong>2009</strong>........................................................................... 90<br />

Figure 43: Carrington Bore Monitoring Network in <strong>2009</strong> ................................................................................... 91<br />

Figure 44: Cheshunt Bore Monitoring Network <strong>2009</strong> ........................................................................................ 91<br />

Figure 45: Carrington Groundwater pH Trends................................................................................................. 96<br />

Figure 46: Carrington Groundwater EC Trends ................................................................................................ 97<br />

Figure 47: Carrington Groundwater SWL Trends.............................................................................................. 98<br />

Figure 48: North Pit and Alluvial Lands Groundwater pH Trends ................................................................... 101<br />

Figure 49: North Pit and Alluvial Lands Ground EC Trends............................................................................ 101<br />

Figure 50: North Pit Alluvial Lands Groundwater SWL Trends ....................................................................... 102<br />

Figure 51: Hobden's Gully and South Facilities Groundwater pH Trends....................................................... 103<br />

Figure 52: Hobden's Gully and South Facilities Groundwater EC Trends ...................................................... 103<br />

Figure 53: Hobden's Gully and South Facilities Groundwater SWL Trends ................................................... 104<br />

Figure 54: Alluvial Levee Bank Groundwater pH Trends ................................................................................ 105<br />

Figure 55: Alluvial Levee Bank Groundwater EC Trends................................................................................ 106<br />

Figure 56: Alluvial Levee Bank Groundwater SWL Trends............................................................................. 107<br />

Figure 57: Cheshunt Stage 1 Groundwater pH Trends................................................................................... 110<br />

Figure 58: Cheshunt Stage 1 Groundwater EC Trends .................................................................................. 110<br />

Figure 59: Cheshunt Stage 1 Groundwater SWL Trends................................................................................ 111<br />

Figure 60: Cheshunt Stage 2 Groundwater pH Trends................................................................................... 111<br />

Figure 61: Cheshunt Stage 2 Groundwater EC Trends .................................................................................. 112<br />

Figure 62: Cheshunt Stage 2 Groundwater SWL Trends................................................................................ 112<br />

Figure 63: Lemington Groundwater pH Trends............................................................................................... 113<br />

Figure 64: Lemington Groundwater EC Trends .............................................................................................. 114<br />

Figure 65: Lemington Groundwater SWL........................................................................................................ 114<br />

Figure 66: West Pit Groundwater pH Trends .................................................................................................. 115<br />

Figure 67: West Pit Groundwater EC Trends.................................................................................................. 116<br />

Figure 68: West Pit Groundwater SWL Trends ............................................................................................... 116<br />

Figure 69: <strong>HVO</strong> Weed Control Areas for <strong>2009</strong>................................................................................................ 122<br />

Figure 70: Location of Version 6 Blast Monitors for <strong>HVO</strong> in <strong>2009</strong>................................................................... 124<br />

Figure 71: Moses Crossing Blast Monitoring Results <strong>2009</strong>............................................................................. 126<br />

Figure 72: Jerrys Plains Blast Monitoring Results <strong>2009</strong>.................................................................................. 127<br />

Figure 73: Cheshunt East Blast Monitoring Results <strong>2009</strong>............................................................................... 127<br />

Figure 74: Maison Dieu Blast Monitoring Results <strong>2009</strong> .................................................................................. 128<br />

Figure 75: Wandewoi Blast Monitoring Results <strong>2009</strong>...................................................................................... 128<br />

Figure 76: Warkworth Blast Monitoring Results <strong>2009</strong> ..................................................................................... 129<br />

Figure 77: <strong>HVO</strong>'s Equipment Noise Reduction Plan ....................................................................................... 131<br />

AEMR <strong>2009</strong><br />

viii

Coal & Allied – Hunter Valley Operations<br />

Figure 78: <strong>HVO</strong> Noise Monitoring Locations <strong>2009</strong>. ......................................................................................... 132<br />

Figure 79: Breakdown of <strong>Environmental</strong> Complaints by Issue for <strong>2009</strong> ......................................................... 162<br />

Figure 80: Coal & Allied Shopfronts and Community Information Line ........................................................... 167<br />

Figure 81: Coal & Allied Community Development Investment in <strong>2009</strong>.......................................................... 169<br />

Figure 82: Coal & Allied Aboriginal Development Consultative Committee Investment in <strong>2009</strong> .................... 170<br />

Figure 83: Locations of Feral Animal Control in <strong>2009</strong> ..................................................................................... 182<br />

AEMR <strong>2009</strong><br />

ix

Coal & Allied – Hunter Valley Operations<br />

LIST OF TABLES<br />

Table 1: <strong>HVO</strong> Approvals...................................................................................................................................... 5<br />

Table 2: <strong>HVO</strong> Licences and Permits ................................................................................................................... 8<br />

Table 3: <strong>HVO</strong> Water Licences ........................................................................................................................... 10<br />

Table 4: <strong>HVO</strong> Mining Tenements ...................................................................................................................... 18<br />

Table 5: <strong>HVO</strong> Other Approvals.......................................................................................................................... 20<br />

Table 6: Actions Required After <strong>Annual</strong> <strong>Environmental</strong> Inspection................................................................... 25<br />

Table 7: <strong>HVO</strong> Mining Equipment Used in <strong>2009</strong>................................................................................................. 30<br />

Table 8: Total Product Coal at <strong>HVO</strong> in <strong>2009</strong> ..................................................................................................... 31<br />

Table 9: Production and Waste Summary for <strong>HVO</strong> <strong>2009</strong>.................................................................................. 32<br />

Table 10: Tailings Storage Facilities.................................................................................................................. 35<br />

Table 11: Stockpile Capacities .......................................................................................................................... 37<br />

Table 12: Coal Transported at <strong>HVO</strong> during <strong>2009</strong>.............................................................................................. 38<br />

Table 13: <strong>2009</strong> <strong>HVO</strong> Water Balance ................................................................................................................. 39<br />

Table 14: Modelled or Measured Groundwater Contribution from Connected Hunter River Alluvium.............. 42<br />

Table 15: Summary of <strong>Environmental</strong> Impacts Risk Register........................................................................... 51<br />

Table 16: Rainfall Summary for <strong>2009</strong> ................................................................................................................ 52<br />

Table 17: <strong>Annual</strong> Average Insoluble Matter Deposition Rates at <strong>HVO</strong> Dust Gauges 2007 to <strong>2009</strong>................. 59<br />

Table 18: Selected High Results in <strong>2009</strong> .......................................................................................................... 59<br />

Table 19: TSP Monitoring Results for <strong>HVO</strong> in <strong>2009</strong>.......................................................................................... 63<br />

Table 20: <strong>Annual</strong> Average HVAS PM 10 Results 2007 to <strong>2009</strong>.......................................................................... 65<br />

Table 21: PM 10 Maximum Over 24 Hour Against Acquisition Criteria ............................................................... 66<br />

Table 22: <strong>HVO</strong> South Project <strong>Environmental</strong> Assessment Cumulative Predictions for 2006 and 2010 against<br />

<strong>2009</strong> <strong>Annual</strong> Averages for TSP Data ................................................................................................ 69<br />

Table 23: <strong>HVO</strong> South <strong>Environmental</strong> Assessment Cumulative Predictions for 2006 and 2010 against <strong>2009</strong><br />

<strong>Annual</strong> Averages for PM 10 Data ........................................................................................................ 69<br />

Table 24: <strong>HVO</strong> South <strong>Environmental</strong> Assessment Cumulative Predictions for 2006 and 2012 against <strong>2009</strong><br />

<strong>Annual</strong> Averages for Dust Deposition Data....................................................................................... 70<br />

Table 25: <strong>HVO</strong> Surface Water Monitoring Data Recovery for <strong>2009</strong>.................................................................. 73<br />

Table 26: Surface Water Results from Hunter River Sites for <strong>2009</strong>.................................................................. 75<br />

Table 27: Surface Water Results from Wollombi Brook Sites for <strong>2009</strong>............................................................. 78<br />

Table 28: Surface Water Results from Other Tributaries Sites for <strong>2009</strong>........................................................... 81<br />

Table 29: Surface Water Results from <strong>HVO</strong> Site Dams for <strong>2009</strong>...................................................................... 83<br />

Table 30: Water Quality during Discharge from Lake James............................................................................ 86<br />

Table 31: Discharge Record for Lake James .................................................................................................... 87<br />

Table 32: Representative Water Quality for West Pit........................................................................................ 88<br />

Table 33: <strong>HVO</strong> Ground Water Monitoring Data Recovery for <strong>2009</strong> .................................................................. 92<br />

Table 34: Ground Water Results from <strong>HVO</strong> Carrington Groundwater’s for <strong>2009</strong> ............................................. 96<br />

Table 35: Groundwater Results from North Pit & Alluvial Lands for <strong>2009</strong> ...................................................... 100<br />

Table 36: Groundwater Results from Hobden’s Gully and South Facilities for <strong>2009</strong> ...................................... 102<br />

AEMR <strong>2009</strong><br />

x

Coal & Allied – Hunter Valley Operations<br />

Table 37: Groundwater Results from Alluvial Lands Levee Bank Groundwater for <strong>2009</strong>............................... 105<br />

Table 38: Groundwater Results from Cheshunt Stage 1 Groundwater’s for <strong>2009</strong>.......................................... 108<br />

Table 39: Groundwater Results from Cheshunt Stage 2 Groundwater’s for <strong>2009</strong>.......................................... 109<br />

Table 40: Groundwater Results from Lemington for <strong>2009</strong> .............................................................................. 113<br />

Table 41: Groundwater Results from West Pit Groundwater’s for <strong>2009</strong> ......................................................... 115<br />

Table 42: Carrington groundwater results ....................................................................................................... 117<br />

Table 43: <strong>HVO</strong> Internal Meteorological Limits................................................................................................. 125<br />

Table 44: LAeq Greater than Allowable Noise Levels Generated by <strong>HVO</strong> ..................................................... 133<br />

Table 45: <strong>HVO</strong> North (West Pit EIS, 2003) – Day Period LAeq...................................................................... 134<br />

Table 46: <strong>HVO</strong> North (West Pit EIS, 2003) – Night Period LAeq.................................................................... 134<br />

Table 47: <strong>HVO</strong> South (Cheshunt Extension SEE, July 2005) – Day Period LAeq.......................................... 135<br />

Table 48: <strong>HVO</strong> South (Cheshunt Extension SEE, July 2005) – Night Period LAeq ....................................... 135<br />

Table 49: <strong>HVO</strong> South (South Coal Project EA, 2006) – Night Period LAeq.................................................... 136<br />

Table 50: Equipment Planned to be used in Mining Areas in 2010 ................................................................ 137<br />

Table 51: <strong>HVO</strong> Objectives and Target Performance <strong>2009</strong> and 2010.............................................................. 151<br />

Table 52: Electricity Energy Usage and Greenhouse Gas Emissions <strong>2009</strong> ................................................... 158<br />

Table 53: Diesel Energy Usage and Greenhouse Gas Emissions <strong>2009</strong>......................................................... 158<br />

Table 54: Total Energy Usage <strong>2009</strong>................................................................................................................ 159<br />

Table 55: Total Greenhouse Gas Emissions <strong>2009</strong>.......................................................................................... 159<br />

Table 56: Equipment Delays for <strong>2009</strong> ............................................................................................................. 160<br />

Table 57: <strong>HVO</strong> – Demographic Breakdown in <strong>2009</strong> ....................................................................................... 173<br />

Table 58: <strong>HVO</strong> – Occupational and Gender Breakdown in <strong>2009</strong>.................................................................... 173<br />

Table 59: Rio Tinto Coal Australia HVS – Demographic Breakdown in <strong>2009</strong>................................................. 174<br />

Table 60: Rio Tinto Coal Australia HVS – Occupational and Gender Breakdown in <strong>2009</strong> ............................. 174<br />

Table 61: Pasture Species and Seeding Rates at <strong>HVO</strong>.................................................................................. 178<br />

Table 62: Tree Species and Seeding Rates at <strong>HVO</strong>....................................................................................... 179<br />

Table 63: Vertebrate Pest Control Summary <strong>2009</strong> ......................................................................................... 181<br />

Table 64: Sand pad Abundance Calculations – <strong>2009</strong> ..................................................................................... 181<br />

Table 65: <strong>2009</strong> MOP Commitments and Performance – Rehabilitation and Disturbance .............................. 183<br />

Table 66: 2010 MOP Commitments and Planned Rehabilitation and Disturbance ........................................ 188<br />

AEMR <strong>2009</strong><br />

xi

Coal & Allied – Hunter Valley Operations<br />

LIST OF PHOTOGRAPHS<br />

Photograph 1:<br />

Establishment Technique Trial, 12 Nov 2008 (part of minimum till plot with<br />

comparatively poor growth)<br />

Photograph 2: Establishment Technique Trial – Mounded Plot, 12 Nov 2008 (height stick at 3m)<br />

Photograph 3 & 4:<br />

Photograph 5:<br />

Photograph 6 & 7:<br />

Local residents learn more about Coal & Allied at Community Information Sessions in<br />

<strong>2009</strong>.<br />

The Coal & Allied Rescue Helicopter in full flight<br />

Through Coal & Allied’s Community Alliance, the Newcastle Knights continue to work<br />

with Indigenous students at Singleton High School in <strong>2009</strong>.<br />

AEMR <strong>2009</strong><br />

xii

Coal & Allied – Hunter Valley Operations<br />

LIST OF APPENDICIES<br />

Appendix 1<br />

Appendix 2<br />

Appendix 3<br />

Appendix 4<br />

Appendix 5<br />

Appendix 6<br />

Appendix 7<br />

Appendix 8<br />

Appendix 9<br />

Appendix 10<br />

Appendix 11<br />

Appendix 12<br />

Appendix 13<br />

Appendix 14<br />

Appendix 15<br />

Appendix 16<br />

Appendix 17<br />

Appendix 18<br />

Rio Tinto Coal Australia Health, Safety & Environment Policy<br />

<strong>2009</strong> <strong>Environmental</strong> Complaints<br />

<strong>2009</strong> <strong>Environmental</strong> Incidents<br />

Community Newsletter<br />

Meteorological Data<br />

Air Quality Monitoring Data<br />

Real Time Air Quality Monitoring Data<br />

Surface Water Monitoring Data<br />

Comparison of <strong>2009</strong> Water Balance with the 2004 West Pit EIS Water Balance Prediction<br />

Groundwater Monitoring Data<br />

Blast Monitoring Data<br />

Noise Monitoring Data – Attended<br />

Real Time Noise Monitoring Data – Unattended Noise Monitoring<br />

Environment Protection Licence<br />

Environment Protection Licence – <strong>Annual</strong> Return<br />

Development Consent Compliance Tables<br />

Rehabilitation Schedules<br />

Department of Industry and Investment Review of 2008 <strong>HVO</strong> AEMR<br />

AEMR <strong>2009</strong><br />

xiii

Coal & Allied – Hunter Valley Operations<br />

LIST OF ABBREVIATIONS<br />

ACARP – Australian Coal Association Research Programme<br />

ADCC – Aboriginal Development Consultative Committee<br />

AECOM – AECOM Australia Pty. Ltd.<br />

AEMR – <strong>Annual</strong> <strong>Environmental</strong> <strong>Management</strong> <strong>Report</strong><br />

AHMP – Aboriginal Heritage <strong>Management</strong> Plan<br />

AHIMS – Aboriginal Heritage Information <strong>Management</strong> System<br />

AHIP – Aboriginal Heritage Impact Plan<br />

ALRA – Alluvial Lands Reinstatement Area<br />

ANZECC – Australian and New Zealand Environment Conservation Council<br />

AS – Australian Standard<br />

ASNZS – Australian and New Zealand Standard<br />

AWS – <strong>Annual</strong> Works Schedule<br />

CCAP – Climate Change Action Plan<br />

CCC – Community Consultative Committee<br />

CCL – Consolidated Coal Lease<br />

CHIMA – Cultural Heritage Indigenous <strong>Management</strong> Agreement<br />

CHMP – Cultural Heritage <strong>Management</strong> Plan<br />

CHMS – Cultural Heritage <strong>Management</strong> System<br />

CHSF – Cultural Heritage Storage Facility<br />

CHWG – Cultural Heritage Working Group<br />

CHZP – Cultural Heritage Zone Plan<br />

CMA – Catchment <strong>Management</strong> Authority<br />

CML – Consolidated Mining Lease<br />

CPP – Coal Preparation Plant<br />

CSIRO – Commonwealth Scientific and Industrial Research Organisation<br />

DA – Development Application<br />

DAP – Diammonium Phosphate<br />

dB (L) – Decibels (Linear Peak)<br />

DC – Development Consent<br />

DECC – Department of Environment and Climate Change<br />

DECCW – Department of Environment, Climate Change and Water<br />

DEUS – Department of Energy Utilities and Sustainability<br />

DEWHA – Department of Environment, Water, Heritage and the Arts<br />

DII – Department of Industry and Investment New South Wales<br />

DNR – Department of Natural Resources<br />

DNV – Det Norske Veritas<br />

DoP – Department of Planning<br />

DPI – Department of Primary Industries<br />

AEMR <strong>2009</strong><br />

xiv

Coal & Allied – Hunter Valley Operations<br />

DPI – MR – Department of Primary Industry – Mineral Resources<br />

DTI – Department of Transport and Infrastructure<br />

DTL4B – Dare to Lead for Business<br />

DWE – Department of Water and Energy<br />

EC – Electrical Conductivity<br />

EEO – Energy Efficiency Opportunity<br />

EIS – <strong>Environmental</strong> Impact Statement<br />

EMP – <strong>Environmental</strong> <strong>Management</strong> Plan<br />

EMS – <strong>Environmental</strong> <strong>Management</strong> System<br />

ENSR – ENSR Australia Pty Ltd<br />

EP&A Act – <strong>Environmental</strong> Planning and Assessment Act<br />

EPBC Act – <strong>Environmental</strong> Protection and Biodiversity Conservation Act<br />

EPL – Environment Protection Licence<br />

ESAP – Energy Savings Action Plan<br />

EWU – Early Warning Units<br />

FFMP – Flora and Fauna <strong>Management</strong> Plan<br />

g/m² – Grams per metre squared<br />

GDP – Ground Disturbance Permit<br />

GGE – Greenhouse Gas Emissions<br />

GHG – Greenhouse Gases<br />

GIS – Geographic Information System<br />

GPR – Ground Penetrating Radar<br />

ha – Hectares<br />

HMRI – Hunter Medical Research Institute<br />

HRSTS – Hunter River Salinity Trading Scheme<br />

HS&E – Health Safety and Environment<br />

HSEQ – Health Safety Environment and Quality<br />

HVAS – High Volume Air Samplers<br />

HVCPP – Hunter Valley Coal Preparation Plant<br />

HVLP – Hunter Valley Load Point<br />

<strong>HVO</strong> – Hunter Valley Operations<br />

HVRF – Hunter Valley Research Foundation<br />

HVS – Hunter Valley Services<br />

IA – Inaudible<br />

IJM – Indigenous Jobs Market<br />

INP – Industrial Noise Policy<br />

kg – Kilograms<br />

km – Kilometres<br />

LCPP – Lemington Coal Preparation Plant<br />

AEMR <strong>2009</strong><br />

xv

Coal & Allied – Hunter Valley Operations<br />

LGA – Local Government Area<br />

LIDAR – Light Detecting and Ranging<br />

L/s – Litres per second<br />

LODB – Limit of Disturbance Boundary<br />

Mbcm – Million Bank Cubic Metres<br />

MCH – McCardle Cultural Heritage Pty Ltd<br />

ML – Megalitres<br />

ML – Mining Lease<br />

MLP – Mine Life Plan<br />

mm – Millimetres<br />

mm/s – Millimetres/second<br />

MOP – Mining Operations Plan<br />

MRF – Materials Recycling Facility<br />

MSC – Muswellbrook Shire Council<br />

MSDS – Material Safety Data Sheet<br />

MTW – Mount Thorley Warkworth<br />

N/A – Not Applicable<br />

NATA – National Association of Testing Authorities<br />

NAIDOC – National Aboriginal Islander Day Observance Committee<br />

NCPP – Newdell Coal Preparation Plan<br />

NLP – Newdell Load Point<br />

NM – Non-Measurable<br />

NOW – New South Wales Office of Water<br />

NPW Act – National Parks and Wildlife Act<br />

NPWS – National Parks and Wildlife Service<br />

NRL – National Rugby League<br />

NSW – New South Wales<br />

OCE – Open Cut Examiner<br />

PaL – Parents and Learning<br />

PFF – Graham (Polly) Farmer Foundation<br />

pH – Measure of the hydrogen ion concentration, [H + ]<br />

PM10 – Particulate Matter < 10 micron units<br />

PAD – Potential Archaeological Deposits<br />

RFS – Rural Fire Service<br />

ROM – Run Of Mine<br />

RTA – Roads and Traffic Authority<br />

s90 – Section 90<br />

s87 – Section 87<br />

SEE – Statement of <strong>Environmental</strong> Effects<br />

AEMR <strong>2009</strong><br />

xvi

Coal & Allied – Hunter Valley Operations<br />

SEM – Scanning Electron Microscopy<br />

SSC – Singleton Shire Council<br />

SWL – Standing Water Level<br />

t – Tonnes<br />

TEM – Transmission Electron Microscopy<br />

TEOM – Tapered Element Oscillating Microbalance<br />

TSC Act – Threatened Species Conservation Act<br />

TSP – Total Suspended Particulates<br />

TSS – Total Suspended Solids<br />

TWMS – Total Waste <strong>Management</strong> System<br />

UHSDC – Upper Hunter Skills Development Centre<br />

UNE – University of New England<br />

Uv-DOAS – Ultra violet – Differential Optical Absorption Spectroscopy<br />

WAL – Water Access Licence<br />

WONS – Weeds Of National Significance<br />

WOOP – Western Out Of Pit<br />

μS/cm – Micro Siemens per Centimetre<br />

μ – Microns<br />

< – Less than<br />

> – Greater than<br />

AEMR <strong>2009</strong><br />

xvii

Coal & Allied – Hunter Valley Operations<br />

1 INTRODUCTION<br />

1.1 SCOPE<br />

This <strong>Annual</strong> <strong>Environmental</strong> <strong>Management</strong> <strong>Report</strong> (AEMR) has been compiled to review the environmental<br />

performance of Hunter Valley Operations (<strong>HVO</strong>) during the <strong>2009</strong> reporting period. The <strong>Report</strong> has been<br />

prepared in accordance with New South Wales Department of Industry & Investment (DII) agreed format and<br />

government guidelines to meet the conditions of <strong>HVO</strong> Development Consents.<br />

This report is distributed to:<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

NSW Department of Planning (DoP);<br />

NSW Department of Industry & Investment (DII);<br />

NSW Department of Environment, Climate Change and Water (DECCW);<br />

Singleton Shire Council (SSC) and Singleton Library;<br />

Muswellbrook Shire Council (MSC) and Muswellbrook Library;<br />

<strong>HVO</strong> Community Consultative Committee (CCC);<br />

NSW Rural Fire Service;<br />

Hunter Central Rivers Catchment <strong>Management</strong> Authority (CMA);<br />

Mine Subsidence Board; and<br />

Neighbouring mines – Wambo Mining Corporation, United Collieries and Ravensworth Operations.<br />

The reporting period extends from 1 January <strong>2009</strong> to 31 December <strong>2009</strong>.<br />

1.1.1 Background Development<br />

Rio Tinto Coal Australia has an agreement to provide management services to Coal & Allied Operations Pty<br />

Limited. <strong>HVO</strong> is managed by Coal & Allied and is situated in the Upper Hunter Valley between Singleton and<br />

Muswellbrook, approximately 24km north west of Singleton, and approximately 100km north west of<br />

Newcastle (see Figure 1). The integration of various pits and associated facilities forms <strong>HVO</strong> and has enabled<br />

improved operational efficiency, rationalisation of infrastructure and improved resource utilisation. <strong>HVO</strong><br />

consists of the following areas (as shown in Figure 2):<br />

<br />

<br />

<br />

<br />

<br />

West Pit (previously Howick Pit), including the Howick Coal Preparation Plant (HCPP), Newdell Coal<br />

Preparation Plant (NCPP) and Newdell Load Point (NLP);<br />

North Pit and Alluvial Lands (previously Hunter Valley Number 1), including the Hunter Valley Load Point<br />

(HVLP) and the Hunter Valley Coal Preparation Plant (HVCPP);<br />

Carrington Pit;<br />

Cheshunt and Riverview Pits, incorporating the new Cheshunt Development and the former Lemington<br />

Pit, as well as the Riverview Pit (previously South Pit or Hunter Valley Number 2) and Lemington Coal<br />

Preparation Plant (LCPP); and<br />

Lemington South Pit.<br />

West Pit is one of the oldest established pits in the Hunter Valley, where mining first commenced in 1952. Rio<br />

Tinto Coal assumed management of the pit in 1997 following the merger of Rio Tinto Zinc and Conzinc Rio<br />

Tinto of Australia. Seven seams (with up to 21 splits) are mined, with consent to mine up to 12 million tonnes<br />

per annum Run Of Mine (ROM) coal. Seams dip at an average of 7.5 degrees to the south east with an<br />

overburden to coal ratio average of 5.5:1.<br />

North Pit commenced coal recovery in 1979 and mining was extended to the alluvial floodplain in 1993, until<br />

its conclusion in 2003. Rehabilitation of the area between the Hunter River and the final void was completed in<br />

2008 with the filling of the final void with tailings to be completed in approximately 2020.<br />

AEMR <strong>2009</strong> 1

Coal & Allied – Hunter Valley Operations<br />

Carrington Pit is located on the western boundary of North Pit and commenced operations in November 2000.<br />

The seams mined are the Broonies and Bayswater and the pit has consent to mine up to 10 million tonnes per<br />

year ROM coal, with all seams dipping at an average of three degrees to the south east. The overburden to<br />

coal ratio averages 3.5:1.<br />

Cheshunt Pit incorporates the former Lemington North Pit, where the new strip alignment commenced in<br />

November 2001. Seams mined in the Cheshunt Pit are Warkworth, Mt Arthur, Piercefield and Vaux seams<br />

and the pit has a combined consent with the Riverview Pit to mine up to eight million tonnes per year of ROM<br />

coal. Seams predominantly dip at two degrees to the south east with an overburden to coal ratio of around<br />

4:1. Following the grant of the <strong>HVO</strong> South consent in <strong>2009</strong>, the Deep Cheshunt development was<br />

commenced. This involves the extraction of Piercefield, Broonies and Bayswater seams with the first strip of<br />

Bayswater coal expected to be extracted in early 2011.<br />

Riverview Pit commenced mining operations in 1991 and a modification to consent in 2001 allowed for the<br />

introduction of a dragline. Coal is extracted from the Glen Munro, Woodlands Hill, Arrowfield and Bowfield<br />

seams. The combined consent with Cheshunt Pit allows annual ROM coal production of up to eight million<br />

tonnes per year. Predominantly, seams dip at three degrees to the south east and the current overburden to<br />

coal strip ratio is approximately 6:1.<br />

Lemington South Pit is located on the southern side of the Wollombi Brook and is consented to produce up to<br />

4.4 million tonnes per year of product coal. Mining operations are currently suspended within the Lemington<br />

South Pit.<br />

1.1.2 Corporate <strong>Environmental</strong> <strong>Management</strong> Strategies<br />

All of Coal & Allied’s Hunter Valley mining operations operate under an <strong>Environmental</strong> <strong>Management</strong> System<br />

(EMS) which is certified to the international standard ISO14001 (2004) by Det Norske Veritas (DNV). The<br />

EMS relies upon an environmental policy, a series of regulatory required management plans, a monitoring<br />

programme and environmental standards and procedures. The EMS forms the basis for rigorous and<br />

consistent environmental management.<br />

The EMS is reviewed annually and was audited on three separate occasions during <strong>2009</strong>. The effectiveness<br />

of the system has been demonstrated through audits, which have shown a consistent trend in environmental<br />

improvement throughout the business.<br />

As part of the EMS, <strong>HVO</strong> also has in place a robust <strong>Environmental</strong> Impacts Risk Register which systematically<br />

identifies all the activities related to the mine that could cause environmental harm and applies a risk ranking<br />

to these aspects. Those aspects which are subsequently identified with a high level of risk are appropriately<br />

managed through procedures, management plans or <strong>Environmental</strong> Improvement Plans.<br />

At the commencement of each calendar year a set of environmental objectives and targets are developed to<br />

ensure continuous improvement in environmental performance. Targets and status for <strong>2009</strong>, along with those<br />

set for 2010, are detailed in Section 3.22. Performance against these targets is reported monthly to<br />

employees and contractors.<br />

Coal & Allied operates under the Rio Tinto Coal Australia Health, Safety and Environment Policy Statement<br />

(Appendix 1).<br />

AEMR <strong>2009</strong> 2

Coal & Allied – Hunter Valley Operations<br />

Figure 1: <strong>HVO</strong> Regional Proximity<br />

AEMR <strong>2009</strong> 3

Coal & Allied – Hunter Valley Operations<br />

Figure 2: <strong>HVO</strong> Mine Site Layout<br />

AEMR <strong>2009</strong> 4

Coal & Allied – Hunter Valley Operations<br />

1.2 CONSENTS, LEASE AND LICENCES<br />

<strong>HVO</strong> operates under a number of different approvals including:<br />

<br />

Development Consents and approvals issued by the Department of Planning, SSC and Muswellbrook<br />

Shire Council;<br />

Environment Protection Licence issued by the DECCW (see Appendix 13 and Section 1.2.3);<br />

Dangerous Goods Licences issued by WorkCover;<br />

<br />

<br />

<br />

<br />

<br />

Section 87 and 90 permits issued by the DECCW;<br />

Water Licences issued by NOW (New South Wales Office of Water);<br />

Mining tenements issued by DII;<br />

Mining Operations Plans (MOP) approved by DII; and<br />

Dam Licences issued by the Dam Safety Committee.<br />

The following sections describe the current approvals.<br />

1.2.1 Current Approvals<br />

The status of <strong>HVO</strong> development consents, licences and relevant approvals are listed in Table 1 to Table 5.<br />

Table 1: <strong>HVO</strong> Approvals<br />

Approval Number Description Issue Date Expiry Date<br />

<strong>HVO</strong> North<br />

450-10-2003 West Pit consolidated consent 12/06/2004 12/06/2025<br />

450-10-2003 M1* Modification to HVLP 16/08/2005 12/06/2025<br />

450-10-2003 M2* Carrington Pit extension 25/06/2006 12/06/2025<br />

884/2004 Relocation of Energy Australia access road 02/02/2005 02/02/2010<br />

6/2001 Pikes Gully Creek realignment 28/03/2001 N/A<br />

6/2001 M1*<br />

Amendment to Pikes Gully Creek<br />

realignment consent<br />

05/08/2003 N/A<br />

117/93 Newdell enhancement project 26/11/1993 N/A<br />

420/2000 Lemington Road Realignment Carrington 10/11/2000 N/A<br />

627/2006 Carrington Mine Extended Flood Levees 08/02/2007 N/A<br />

<strong>HVO</strong> South – Cheshunt and Riverview<br />

PA 06_0261<br />

PA 06_0261 M1*<br />

Hunter Valley Operations – South Coal<br />

Project<br />

Modification 1 to PA 06 – 0261 - Raising<br />

Lake James<br />

24/03/<strong>2009</strong> 24/03/2030<br />

17/12/<strong>2009</strong> 24/03/2030<br />

AEMR <strong>2009</strong> 5

Coal & Allied – Hunter Valley Operations<br />

Approval Number Description Issue Date Expiry Date<br />

85/27 Hunter Valley No. 2 Coal Mine 04/05/1986 06/03/2010<br />

81/828 (85/27 M1)* Modifications to DA 85/27 12/11/1990 06/03/2010<br />

37/90<br />

Western out of pit emplacement and<br />

realignment of Jerrys Plains Road<br />

18/10/1990 N/A<br />

144/96 Extension to Hunter Valley South Mine 24/01/1997 06/03/2010<br />

144/96 (37) M1* Modification to DA 144/96 27/08/1997 06/03/2010<br />

114-12-98 Hunter Valley No. 1 Mine South Pit 15/03/2000 15/03/2021<br />

14-01-01-M1*<br />

114-12-98-M2*<br />

114-12-98-M3*<br />

114-12-98-M4*<br />

Modification to DA 114-12-98 – change to<br />

mining schedule<br />

Modification 2 to DA 114-12-98 – change to<br />

mining sequence<br />

Modification 3 to DA 114-12-98 – extension<br />

to blasting hours<br />

Modification 4 to DA 114-12-98 – Riverview<br />

Pit extension<br />

02/11/2001 15/03/2021<br />

11/03/2002 15/03/2021<br />

23/01/2003 15/03/2021<br />

11/05/2006 15/03/2021<br />

181-8-05 Cheshunt Pit extension 31/03/2006 31/03/2021<br />

628/2006 Cheshunt Mine Extended Flood Levees 08/02/2007 N/A<br />

<strong>HVO</strong> South – Lemington<br />

N/A Lemington Open Cut Development Consent 24/06/1971 N/A<br />

N/A Lemington Open Cut Extension to Mining 05/03/1976 N/A<br />

88/76 Mining in No. 2 complex and LCPP 24/02/1976 N/A<br />

79/48 Expansion Buchanan Lemington Colliery 17/06/1980 N/A<br />

80/71 Extension of Lemington Open Cut (3 Mt) 24/11/1980 N/A<br />

80/70*<br />

Modification to DA 80/71 - Extension of<br />

Lemington Open Cut (Vary Conditions)<br />

10/08/1981 N/A<br />

83/145 Office block No. 2 03/01/1984 N/A<br />

83/153 Overburden dump 10/02/1984 N/A<br />

80/961 (equivalent<br />

to DA 84/115)<br />

84/115 M1<br />

(equivalent to DA<br />

80/961)<br />

Northern Lemington open cut extension 29/07/1981 N/A<br />

Extension of Lemington Mine 19/08/1985 N/A<br />

AEMR <strong>2009</strong> 6

Coal & Allied – Hunter Valley Operations<br />

Approval Number Description Issue Date Expiry Date<br />

87/42 Lemington Mine 18/12/1987 N/A<br />

84/115 M2* Modification to DA 84/115 06/01/1998 N/A<br />

86/75 Bathhouse 24/07/1986 N/A<br />

86/104 Extension to No. 2 Mine workshop 04/11/1986 N/A<br />

86/119 Carport 04/11/1986 N/A<br />

115/90 Laboratory 20/09/1990 N/A<br />

73/91 Building extension 10/07/1991 N/A<br />

101/92 Offices 09/07/1992 N/A<br />

225/92<br />

215/97<br />

Coarse reject conveyor & rehabilitation of old<br />

portal<br />

South Lemington open cut and highwall<br />

mining<br />

29/01/1993 N/A<br />

17/07/1998 17/07/2019<br />

405/98 Increase in production tonnage 11/01/1999 17/07/2019<br />

215/97.2 and<br />

405/98.2<br />

Modification of DA 215/97 and 405/98 09/01/2001 17/07/2019<br />

651/2001 Temporary Shovel Crossing 13/02/2002 13/07/2007<br />

396/2001<br />

Temporary Crossing and relocate Dragline &<br />

Electric Shovel<br />

22/10/2001 22/10/2006<br />

215/97.2 and<br />

405/98.2<br />

Modification of DA 215/97 and 405/98 22/11/2002 17/07/2019<br />

195/2000 Hay shed 06/02/2001 N/A<br />

58/2007 Installation of production bore 27/02/2007 27/02/2012<br />

*Modification to previous consent<br />

Note: Hunter Valley Operations – South Coal Project Approval (PA 06_0261) will consolidate all other<br />

previous <strong>HVO</strong> South – Cheshunt, Riverview and Lemington approvals, once they are surrendered by 24<br />

March 2010, as per Condition 10 of the project approval.<br />

AEMR <strong>2009</strong> 7

Coal & Allied – Hunter Valley Operations<br />

Table 2: <strong>HVO</strong> Licences and Permits<br />

Licence No. Description Expiry Date<br />

<strong>Environmental</strong> Protection Authority<br />

EPL 640<br />

Dangerous Goods<br />

Environment Protection Licence<br />

1 April (Anniversary) Review<br />

Date 27/02/2011<br />

35/037852 Dangerous Goods Licence <strong>HVO</strong> 27/09/2010<br />

Radiation Licence<br />

28724 Radiation Licence 15/08/2011<br />

Section 87 Care and Control Permit<br />

2491 Cheshunt Pit Extension 11/07/2011<br />

2863<br />

AHIP Care and Control Permit<br />

(extended for a further three<br />

years on 16/1/<strong>2009</strong>)<br />

16/01/2013<br />

Section 90 Consent to Destroy Permit<br />

3393 West Pit (Howick) 19/08/1988<br />

798 Hunter Valley No. 2 19/03/1990<br />

370005 Hunter Valley No. 1 04/02/1993<br />

431<br />

North west CNR of Lemington<br />

Colliery Lease<br />

N/A<br />

512 Hunter Valley 1-37-5-63 28/12/1993<br />

566<br />

656<br />

657<br />

Hunter Valley 37-5-63 SW<br />

Portion<br />

Hunter Valley No.1 37-5-63 North<br />

East Portion<br />

Hunter Valley No. 1 Stage 1 37-<br />

5-0063<br />

08/11/1995<br />

09/09/1996<br />

15/09/1996<br />

734 North Pit Alluvial Stage 2 N/A<br />

SZ245<br />

Hunter Valley No. 1 Salvage<br />

Stage for 37-5-0063<br />

11/02/2001<br />

254 Lemington South 26/05/2001<br />

SZ300 Howick 04/08/2002<br />

SZ288 Howick April 2000<br />

AEMR <strong>2009</strong> 8

Coal & Allied – Hunter Valley Operations<br />

Licence No. Description Expiry Date<br />

SZ311 Carrington Mine Lease 25/09/2002<br />

SZ315<br />

South Pit (issued 22/01/01 &<br />

reissued 5/09/02)<br />

22/01/2003<br />

2086 West Pit Mine July 2005<br />

2091<br />

Carrington Pit – Substation<br />

Access Road<br />

20/05/2004<br />

2114 Newdell Borrow Pit 22/02/2007<br />

2488 Cheshunt Pit Extension 11/07/2011<br />

2547 Carrington Pit Extension 09/03/2012<br />

2804 West Pit Extension 31/10/<strong>2009</strong><br />

1102084 Riverview Pit 11/06/2011<br />

AEMR <strong>2009</strong> 9

Coal & Allied – Hunter Valley Operations<br />

Table 3: <strong>HVO</strong> Water Licences<br />

Licence Number<br />

Type of<br />

License<br />

Purpose Legislation Description Renewal Date<br />

20AL201237 (see<br />

WAL 962)<br />

Water Access<br />

Licence<br />

Water Access<br />

Licence<br />

Water <strong>Management</strong> Act 2000<br />

<strong>HVO</strong> North – HVCPP River Pump – Water<br />

Access Licence<br />

Perpetuity<br />

20AL201254 (see<br />

WAL 969)<br />

Water Access<br />

Licence<br />

Water Access<br />

Licence<br />