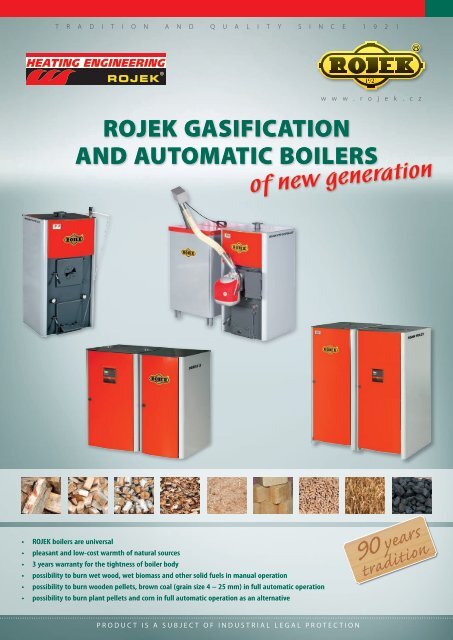

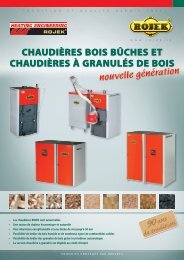

ROJEK GASIFICATION AND AUTOMATIC BOILERS

ROJEK GASIFICATION AND AUTOMATIC BOILERS

ROJEK GASIFICATION AND AUTOMATIC BOILERS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

T r a d i t i o n a n d Q u a l i t y s i n c e 1 9 2 1<br />

w w w . r o j e k . c z<br />

<strong>ROJEK</strong> <strong>GASIFICATION</strong><br />

<strong>AND</strong> <strong>AUTOMATIC</strong> <strong>BOILERS</strong><br />

of new generation<br />

• <strong>ROJEK</strong> boilers are universal<br />

• pleasant and low-cost warmth of natural sources<br />

• 3 years warranty for the tightness of boiler body<br />

• possibility to burn wet wood, wet biomass and other solid fuels in manual operation<br />

• possibility to burn wooden pellets, brown coal (grain size 4 – 25 mm) in full automatic operation<br />

• possibility to burn plant pellets and corn in full automatic operation as an alternative<br />

PRODUCT IS A SUBJECT OF INDUSTRIAL LEGAL PROTECTION

1921 2011<br />

Tradition and Quality<br />

since 1921<br />

The family joint-stock company <strong>ROJEK</strong> woodworking<br />

machinery has a 90 years tradition in production<br />

of woodworking machinery. Its head office is in<br />

Častolovice in the region of Hradec Králové. Its turnover<br />

for sold products and services reached 10 millions EUR<br />

in 2010. In Častolovice there is also a <strong>ROJEK</strong> Heating<br />

and Woodworking Centre, while the production plant<br />

is situated in Kostelec nad Orlicí. The company was<br />

founded by Josef Rojek in 1921.<br />

Josef <strong>ROJEK</strong>, Company´s founder<br />

He was very successful with his woodworking machines of his own construction<br />

even in the period of the economic crisis and<br />

in the war years. The tradition was interrupted<br />

only in 1948. Many machines of that period are<br />

still functional and in spite of some technical<br />

and moral wear they are still in operation.<br />

Head office a.s. <strong>ROJEK</strong><br />

in Častolovice<br />

Mgr. Jiří <strong>ROJEK</strong><br />

general manager and chairman of the board of directors<br />

The family company of Josef Rojek was<br />

restored by his grandson Mgr. Jiří Rojek<br />

in 1991. Again it was started from almost<br />

nothing. The returned plant was in a very<br />

bad state and without any competitive<br />

product. At present the joint-stock<br />

company <strong>ROJEK</strong> is an important world<br />

producer in its branch and has its dealers<br />

in more than 65 countries of the whole<br />

world.<br />

Production plant of the company<br />

in Kostelec nad Orlicí<br />

Mgr. Jiří Rojek is a general manager and a chairman of<br />

the board of directors of the joint-stock company. His<br />

son, Evžen Rojek, is a co-owner of the company and is in<br />

position of an executive manager and a member of board<br />

of directors. Produced machines and heating technology<br />

are presented in important world fairs and exhibitions.<br />

The interest in <strong>ROJEK</strong> products is growing continuously.<br />

The range of products is continuously being enlarged and innovated in order to have a good solution for the customer. At present we offer NEWS of our own<br />

construction in all production ranges. In the production range of <strong>ROJEK</strong> HEATING ENGINEERING it concerns quite new <strong>ROJEK</strong> <strong>AUTOMATIC</strong> <strong>BOILERS</strong> FOR<br />

BIOMASS <strong>ROJEK</strong> KTP 20 PELLET, KTP 25 PELLET, KTP 30 PELLET, <strong>ROJEK</strong> A 15, <strong>ROJEK</strong> TKA 15, <strong>ROJEK</strong> TKA 25, <strong>ROJEK</strong> TKA 45 and <strong>ROJEK</strong> TKA 80<br />

for automatic combustion of pellets, even of lower quality as well as plant pellets, corn and coal according to the execution and boiler model. We further offer<br />

innovated gasification boilers <strong>ROJEK</strong> KTP 20-80 for wood with extraordinary useful features completed by pellet burners. We produce innovated wood crushers<br />

with bag filling attachment. The crushers produce short piece wood, a cheap and available fuel with high efficiency.<br />

All mentioned products are made by means of new production technologies included in the innovated production process by the company <strong>ROJEK</strong>. This production<br />

process is co-financed from the project of European Funds for Regional Development and the Ministry of Industry and Trade of the Czech Republic. This tends to<br />

the increase of productivity of labour, reduction of costs for made products and maintenance of price and supplier stability of the <strong>ROJEK</strong> brand for the future.<br />

SMALL WOODWORKING MACHINERY<br />

COMBINED WOODWORKING MACHINERY<br />

ST<strong>AND</strong>ARD WOODWORKING MACHINERY<br />

HEATING ENGINEERING<br />

EXCLUSIVE TRADE REPRESENTATION<br />

FOR THE CZECH REPUBLIC

<strong>ROJEK</strong> KTP Gasification Boilers for Fire Wood<br />

<strong>ROJEK</strong> KTP gasification boilers are designed for<br />

burning of fire wood, short piece wood, fresh saw<br />

dust, wet chips and other wet biomass. Another<br />

possible alternative fuel is brown and hard coal.<br />

The fuels can be mixed. This is enabled by an<br />

original design of boiler fireplace using double<br />

stage combustion enabling a perfect fuel using and<br />

and burn-up. Combustion of different kinds of fuels<br />

has no effect on warranty conditions of boilers. Dry<br />

wood is not necessary.<br />

But fuel efficiency and boiler output are influenced<br />

by higher moisture content of fuels.<br />

Warranty for tightness of boiler body is 3 years,<br />

complying with operation conditions.<br />

KTP 20<br />

KTP 30<br />

Technical Description of Boilers<br />

KTP 49<br />

<strong>ROJEK</strong> KTP gasification boilers for fire wood and other solid fuels are<br />

a welded structure made of steel boiler plate. All walls of the boiler<br />

body are doubled, filled with water, including the grate made of<br />

heat resistant pipes enabling an effective use of heat produced by<br />

burning.<br />

The inlets of both the primary and<br />

secondary air can be easily adjusted and<br />

reach a good combustion and a long<br />

time for burn-up of the fuel. Although<br />

heat transfer surfaces do not get fouled,<br />

the boiler is provided by a door for easy<br />

cleaning.<br />

The boiler body is provided by insulated<br />

covering and sheet covering. The top plate<br />

has a built-in temperature and pressure<br />

indication.<br />

Boilers are designed for a smaller chimney draught up to 12 Pa. No other<br />

additional devices increasing costs for their fitting are needed.<br />

By an optimum adjustment of convection of primary (chimney draught<br />

10 - 12 Pa) and secondary air a specially favourable time for fuel burnup<br />

can be reached.<br />

Fuel<br />

Orientation time for fuel burn-up<br />

Time<br />

Soft wood up to 5 hours *<br />

Hard wood up to 6 hours *<br />

Brown coal up to 8 hours *<br />

Hard coal up to 10 hours *<br />

*) in economy operation it can differ dependent<br />

on combustion conditions and moisture content<br />

Combustion Model<br />

1. combustion chamber<br />

2. inlet of secondary air<br />

3. water-cooled grate<br />

4. feeding door<br />

5. cleaning door<br />

6. door for inlet and regulation of<br />

primary air<br />

7. door for boiler cleaning<br />

8. ash pan<br />

9. outlet of combustion gases to the chimney<br />

10. inlet of return water to boiler<br />

11. outlet of heating water from boiler<br />

12. boiler covering<br />

13. sheet covering<br />

14. blue colour indicates water in boiler<br />

15. cooling loop<br />

Connection Diagram<br />

- Back Sight<br />

2<br />

1<br />

4<br />

5<br />

Combustion<br />

Spaliny<br />

gases<br />

Water outlet<br />

Výstup vody<br />

15<br />

11<br />

15<br />

1<br />

3<br />

6<br />

7<br />

2<br />

7<br />

4<br />

12<br />

13<br />

1. valve sensor<br />

4. inlet of cooling water<br />

14<br />

2. thermometer and manometer<br />

5. thermostatic valve<br />

Water inlet<br />

Vstup vody<br />

sensor<br />

6. outlet of cooling water<br />

3. chimney<br />

7. outlet<br />

10 9 3 2 6 5<br />

8 3<br />

UNIQUE HEATING TECHNOLOGY WITH CONSIDERABLE COSTS SAVINGS

Combustion of different kinds and also wet fuels is enabled by an<br />

original design of fireplace. This enables the best and perfect combustion<br />

of fuel and stops to make harmful emissions and condensates.<br />

This effect is achieved due to the fact that a volatile combustible comes<br />

loose of the layer of burning fuel which is collected under the arch of<br />

fireplace and mixed with secondary air and by the effect of chimney<br />

draught this mixture is drawn through the glowing layer of burning<br />

fuel to be burnt-up with high temperature. In the contact place of this<br />

mixture and burning fuel further secondary air is supplied. The inlet of all<br />

secondary air can be controlled.<br />

Boiler output is controlled by the quantity<br />

of primary air supplied under the grate. The<br />

adjustment is controlled either manually or using<br />

a thermal output control.<br />

The temperature of return water can be<br />

reduced up to 40°C as the return water goes<br />

back to the boiler near the grate. Due to this fact<br />

high financial costs for a mixing device can be<br />

saved.<br />

Boiler description<br />

Legend:<br />

1. cleaning space<br />

2. loading space<br />

3. inlet of secondary air<br />

4. ash pan<br />

5. outlet valve<br />

6. insulation<br />

7. thermometer<br />

8. manometer<br />

9. sensor of thermostatic valve<br />

10. inlet of cooling water<br />

11. outlet of cooling water<br />

12. cooling loop<br />

13. water outlet<br />

14. escape of combustion gases<br />

15. water inlet<br />

Technical Data of <strong>ROJEK</strong> KTP Gasification Boilers<br />

Data Unit KTP 20 KTP 25 KTP 30 KTP 40 KTP 49 KTP 80<br />

Adjustable power kW 12 - 20 15 - 25 18 - 30 24 - 40 29 - 49 48 - 80<br />

Width A mm 605 605 605 745 745 748<br />

Depth B mm 495 595 695 670 800 1556<br />

Height C mm 1165 1165 1165 1260 1260 1372<br />

Grate depth D mm 326 426 526 496 626 1060<br />

Chimney height E mm 1005 1005 1005 1120 1120 1269<br />

Chimney diam. F mm 159 159 159 219 219 219<br />

Height of water inlet G mm 215 215 215 225 225 170<br />

Installation depth H mm 685 785 885 945 1075 1565<br />

Water inlet and outlet diam. DN G 2”<br />

Max. diam/length of wood cm 20/30 20/40 20/50 23/47 23/60 23/100<br />

Volume of combustion chamber l 43 57 70 95 120 200<br />

Boiler weight kg 235 270 310 380 420 785<br />

Efficiency % 75 - 78<br />

Volume of combustion gases with nominal<br />

power<br />

m 3 /h 146 160 174 202 230 320<br />

Heat loss mbar 0,4 0,6<br />

Size of loading opening:<br />

Half circle – width x height<br />

mm 245/230 245/230 245/230 395 x 295 395 x 295 395 x 295<br />

Water volume in boiler l 98 109 120 126 166 262<br />

Max. water overpressure bar 2<br />

Min. water overpressure bar 0,5<br />

Water testing overpressure bar 4<br />

Max. operation temperature °C 90<br />

Specified chimney draught Pa 8 - 12 25 - 32<br />

Temperature of combustion gases with<br />

nominal power<br />

°C 220 - 300<br />

UNIQUE HEATING TECHNOLOGY WITH CONSIDERABLE COSTS SAVINGS

<strong>ROJEK</strong> Automatic Boilers<br />

<strong>ROJEK</strong> KTP 20 PELLET, <strong>ROJEK</strong> KTP 25 PELLET, <strong>ROJEK</strong> KTP 30 PELLET<br />

<strong>ROJEK</strong> KTP 20 PELLET<br />

Application of a pellet burner<br />

<strong>ROJEK</strong> KTP 25 PELLET<br />

<strong>ROJEK</strong> KTP 30 PELLET<br />

Automatic boilers <strong>ROJEK</strong> KTP 20, 25, 30 PELLET are a combination of gasification boilers KTP 20,<br />

25 and 30 with a pellet burner for high quality white wooden pellets. In gasification boilers it is<br />

possible to burn fire wood, short piece wood, fresh saw dust, wet chips and other wet biomass.<br />

Pellet burners can be mounted into gasification boilers on customer´s wish on the front hinged<br />

door with right or left opening direction according to the position of the fuel tank. Such boilers<br />

burn high quality white wooden pellets 6 – 8 mm diam. in automatic operation. They comply<br />

with class 3 in accordance with the Norm ČSN EN 303-5.<br />

Thanks to the fuel tank, electronic regulation and the burner with worm feeder the boiler is able<br />

to work even several days long in automatic operation. The electronic regulation can be connected<br />

with room regulator. It is further possible to connect it with parent heating regulation.<br />

Technical Data of Automatic Boilers <strong>ROJEK</strong> KTP 20, 25, 30 PELLET<br />

Data Unit KTP 20 PELLET KTP 25 PELLET KTP 30 PELLET<br />

Adjustable pellet power kW 5,1 - 20 5,5 - 25 5,5 - 32<br />

Pellet efficiency % 87 87 87<br />

Boiler class in accordance with the Norm<br />

ČSNEN303-5<br />

3 3 3<br />

Temperature of combustion gases °C 220 - 300 220 - 300 220 - 300<br />

Size (W x H x D) mm 605 x 1165 x 960 605 x 1165 x 1060 605 x 1165 x 1160<br />

Chimney height mm 1005 1005 1005<br />

Chimney diam. mm 159 159 159<br />

Volume of fuel tank l 300 300 300<br />

Water volume in boiler body l 98 109 120<br />

Connection diam. for water inlet and outlet DN G 2”<br />

Connection voltage V / Hz 230 / 50 230 / 50 230 / 50<br />

Electric input W 400 400 400<br />

Boiler weight kg 246 281 321

Automatic Boilers<br />

<strong>ROJEK</strong> A 15, <strong>ROJEK</strong> TKA 15, <strong>ROJEK</strong> TKA 25, <strong>ROJEK</strong> TKA 45, <strong>ROJEK</strong> TKA 80<br />

Automatic boiler <strong>ROJEK</strong> A 15 is designed for heating buildings with low<br />

heat loss. The adjustable power is 3,6 – 14 kW for pellets 6 – 8 mm diam.,<br />

both high quality white pellets and pellets of lower quality with bark<br />

mixture, and brown coal, in automatic operation.<br />

Automatic boiler <strong>ROJEK</strong> TKA 15, TKA 25, TKA 45 and TKA 80 enable to<br />

burn both high quality white wooden pellets 6 – 8 mm diam. (TKA 15)<br />

or 6 – 10 mm (TKA 25, 45, 80) and also pellets of lower quality with bark<br />

mixture and brown coal – grain size 4 - 25 mm. Retort burner enables to<br />

burn also lower quality plant pellets and corn using a special adapter.<br />

With an additional grate of cast iron it is possible to burn piece wood,<br />

biomass and other solid fuels in manual operation.<br />

In automatic operation with wooden pellets and brown coal 4 - 25 mm<br />

the boilers comply with class 3 in accordance with the Norm ČSN EN<br />

303-5.<br />

Thanks to the fuel tank, electronic regulation and the burner with spiral<br />

feeder the boiler is able to work in automatic operation even for several<br />

days. The electronic control can be connected with circular pump and<br />

room regulator. It is further possible to connect it with parent heating<br />

regulation.<br />

A 15 Optional design<br />

The retort burner is installed in the lower part of boiler body. It<br />

is designed for lower fuel loading and the combustion process<br />

can be compared with a blacksmith hearth. From the tank the<br />

fuel is feeded by spiral feeder to the retort knee. Here it is forced<br />

out up to a round grate.<br />

TKA 25 Optional design<br />

Both the grate and the retort are made of high quality cast iron. The retort<br />

is placed in a converter to which the air is blown by a blower. Through<br />

the slots between the retort and the grate the air is then driven to the<br />

burning fuel layer.<br />

TKA 45 Standard design

Combustion in retort burner<br />

Sketch of retort burner<br />

Retort burners can be mounted to automatic boilers on customer´s wish in the<br />

right or left execution including the fuel tank.<br />

Technical Data of Automatic Boilers A 15 and <strong>ROJEK</strong> TKA<br />

Data Unit A 15 TKA 15 TKA 25 TKA 45 TKA 80<br />

Adjustable pellet power kW 3,6 - 14 3,5 - 15 7,5 - 25 13,5 - 45 22 - 80<br />

Adjustable brown coal power kW 3,4 - 14,8 3,5 - 15 7,5 - 25 12,9 - 45 20 - 78<br />

Brown coal / pellet efficiency % 84 / 86 83 / 86 83 / 86 83 / 86 86 / 89<br />

Boiler class in accordance with the Norm ČSN<br />

EN 303-5<br />

3 3 3 3 3<br />

Temperature of combustion gases °C max. 180 max. 190 max. 190 max. 210 max. 210<br />

Size (W x H x D) mm 1130 x 1105 x 780 1271 x 1530 x 770 1222 x 1530 x 910 1565 x 1642 x 1043 1605 x 1772 x 1552<br />

Chimney height mm 945 1434 1424 1549 1669<br />

Chimney diam. mm 129 159 159 219 219<br />

Volume of fuel tank l 300 300 300 500 800<br />

Water volume in boiler body l 106 77 108 156 262<br />

Connection diam. for water inlet and outlet DN G 2“<br />

Connection voltage V / Hz 230 / 50 230 / 50 230 / 50 230 / 50 3x400 / 50<br />

Electric input W 100 100 100 100 350<br />

Boiler weight kg 300 395 465 605 1025

<strong>ROJEK</strong> Worldwide<br />

Boiler designing in 3D<br />

Laser cutting<br />

CNC robot welding<br />

ALGERIA<br />

IREL<strong>AND</strong><br />

REUNION<br />

AUSTRALIA<br />

ITALY<br />

ROMANIA<br />

AUSTRIA<br />

ISRAEL<br />

RUSSIA<br />

BELGIUM<br />

JAPAN<br />

GREECE<br />

BANGLADESH<br />

SOUTH AFRICA<br />

SAUDI ARABIA<br />

BELARUS<br />

CANADA<br />

SLOVENIA<br />

BOSNIA & HERZEGOVINA<br />

KAZAKHSTAN<br />

SRI LANKA<br />

BOTSWANA<br />

KOREA<br />

SINGAPORE<br />

Component assembly<br />

DENMARK<br />

COSTA RICA<br />

SPAIN<br />

ECUADOR<br />

LITHUANIA<br />

SWEDEN<br />

ESTONIA<br />

LATVIA<br />

SWITZERL<strong>AND</strong><br />

ETHIOPIA<br />

HUNGARY<br />

THAIL<strong>AND</strong><br />

PHILIPPINES<br />

MACEDONIA<br />

TURKEY<br />

FINL<strong>AND</strong><br />

MALTA<br />

UG<strong>AND</strong>A<br />

FRANCE<br />

MEXICO<br />

UKRAINE<br />

GHANA<br />

MOLDOVA<br />

USA<br />

GEORGIA<br />

NIGERIA<br />

UNITED ARAB<br />

Boiler assembly<br />

NETHERL<strong>AND</strong>S<br />

HONDURAS<br />

GERMANY<br />

NORWAY<br />

EMIRATES<br />

UNITED KING-<br />

CROATIA<br />

INDIA<br />

INDONESIA<br />

IRAN<br />

NEW ZEAL<strong>AND</strong><br />

PAKISTAN<br />

POL<strong>AND</strong><br />

PORTUGAL<br />

DOM<br />

VENEZUELA<br />

ZIMBABWE<br />

Studio eMD.cz 2-2011<br />

Automated stock system<br />

Data and pictures in this leaflet have informative character. Technical and optical changes are possible without previous advise.<br />

<strong>ROJEK</strong> dřevoobráběcí stroje a.s.<br />

Masarykova 16, 517 50 Častolovice<br />

Czech Republic<br />

Your dealer:<br />

w w w . r o j e k . c z<br />

Tel.: +420 494 339 140, Fax: +420 494 323 341<br />

e-mail: export@rojek.cz<br />

THE EUROPEAN REGIONAL DEVELOPMENT FUND <strong>AND</strong> THE MINISTRY OF INDUSTRY<br />

<strong>AND</strong> TRADE OF THE CZECH REPUBLIC SUPPORT INVESTMENT IN YOUR FUTURE.