International Elastomer Conference - Rubber Division

International Elastomer Conference - Rubber Division

International Elastomer Conference - Rubber Division

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Wabash MPI/Carver, Inc.* ............................. 2208<br />

1569 Morris St.<br />

Wabash, IN 46992<br />

Ph: 260 563-1184; Fx: 260 563-1396<br />

Email: wabashmpi@corpemail.com<br />

www.wabashmpi.com<br />

Wabash MPI/Carver Inc. manufactures standard<br />

and custom presses for production and laboratory<br />

applications from .5 to 1,200 tons. Wabash/Carver<br />

features the widest variety of hydraulic and electric<br />

compression, transfer, vacuum, and laminating<br />

presses for an array of materials, including com-<br />

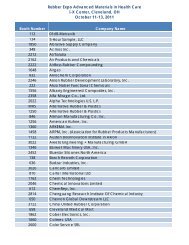

Company Name Booth No. Company Name Booth No. Company Name Booth No.<br />

www.mrpvalleyprocessing.com<br />

Valley Processing is part of Mitchell <strong>Rubber</strong><br />

Products, a growing $60+ million company with<br />

200+ employees, founded in 1939 and in its third<br />

generation of family leadership. Valley Processing<br />

is the western US’s market leader in custom-mixed<br />

rubber-based compounds, serviced via its California<br />

operations, and has expanded to serve Midwestern<br />

and Eastern customers through its new facility in<br />

Bedford, Virginia. The company is ISO 9001 certified,<br />

with diagnostic labs in both its California and<br />

Virginia operations testing and validating every<br />

batch. Valley Processing compounds meet the<br />

exacting needs of oil field, mining, transportation,<br />

electrical, construction, medical and other industries.<br />

for the tire and rubber industries. People feel a real<br />

pride when they create technical innovations that<br />

keep manufacturers ahead in their markets. That’s<br />

the passion behind the VMI Group and our work<br />

with tire and rubber manufacturers and processors.<br />

And the reason VMI is the market leader in complex<br />

production machinery. We employ more than 800<br />

people around the world, with production facilities<br />

in the Netherlands, Germany, the USA, China and<br />

Brazil. These are people who dedicate constant<br />

effort to developing new products and solutions to<br />

meet current - and future - manufacturing demands.<br />

Booth personnel: Harm Voortman, Arie Kroeze, Dirk<br />

Reurslag, Gerry Pol, Roy te Boome, Mike Slone,<br />

Ralph Parise, Dave Grepp, Ashok Bisoen<br />

posites, rubber, LSR, plastic, and more. Wabash/<br />

Carver will display a Genesis ASTM press with the<br />

ACCU-HEAT premium uniformity platen system.<br />

The booth will also feature products from our ACS<br />

Group sister companies; AEC, Cumberland and<br />

Sterling, featuring auxiliary equipment such as; air/<br />

water cooled chillers, oil/water TCUs and grinding/<br />

granulating equipment.<br />

Let the ACS Group companies help with all of your<br />

press and auxiliaries needs.<br />

Booth personnel: Nancy Jones, Bobbi Palmer, David<br />

Singer, and Mike Hedberg<br />

Vanderbilt Chemicals, LLC ............................. 2814<br />

30 Winfield St.<br />

Norwalk, CT 06855<br />

Ph: 203 853-1400<br />

Email: rubber@vanderbiltchemicals.com<br />

www.vanderbiltchemicals.com<br />

Vanderbilt Chemicals, LLC is a wholly owned<br />

subsidiary of R.T. Vanderbilt Holding Company, Inc.,<br />

whose roots date to 1916. Vanderbilt Chemicals<br />

provides more than 500 products: accelerators, antioxidants<br />

crosslinking agents, mineral fillers, polymer<br />

stabilizers and process aids to the rubber and<br />

plastics industries. The company operates chemical<br />

manufacturing plants in Connecticut and Kentucky,<br />

and in addition to our internally manufactured products,<br />

distributes the products of many prominent<br />

companies under continuing contracts dating as far<br />

back as the 1920s. Vanderbilt Chemicals sells products<br />

worldwide, both through distribution and direct<br />

sales, with offices in the United States, Switzerland<br />

and China.<br />

Booth personnel: Dan Berigan, Roger Burtraw, Jennifer<br />

Forgue, Chris Nola, Tom Mroczkowski, Marty<br />

Sheridan and Wayne Vanderhoof<br />

Walther Trowal GmbH & Co. KG ............... 636<br />

4540 East Paris Ave., Suite F<br />

Grand Rapids, MI 49512<br />

Ph: 616 455-8940<br />

Email: v.mathews@walther-trowal.com<br />

www.walther-trowal.com<br />

The Rotamat specializes in the coating of small<br />

mass produced parts made of metal, elastomers,<br />

and plastic. Applications for the Rotamat include<br />

decorative coating, corrosion protection, improvement<br />

of sliding characteristics, preparation of<br />

parts for rubber coating, and electrical insulation.<br />

The Rotamat machine uses a hot air process,<br />

where small parts are spray coated in a closed<br />

elliptical shaped drum. The rolling behavior of the<br />

INFINITY RUBBER<br />

TECHNOLOGY GROUP<br />

ISO 9002.2000 Certified: A2LA Accredited Lab<br />

Exhibitor List<br />

Venango Machine Co., Inc.* ......................... 1236<br />

14118 Rt. 8 - 89<br />

Wattsburg, PA 16442<br />

Ph: 814 739-2211<br />

Email: nvogel@venangomachine.com<br />

www.venangomachine.com<br />

Venango Machine Company specializes in manufacturing<br />

and refurbishing platens for the rubber<br />

molding industry. We are the largest and oldest<br />

exclusive platen manufacturer in the world. We offer<br />

design and engineering expertise in all types of<br />

platens. We build and supply replacement platens<br />

for all original equipment presses.<br />

VMI Group ............................................................ 2228<br />

4670 Allen Rd.<br />

Stow, OH 44224<br />

330 929-6800; Fx: 330 929-7254<br />

Email: sales@vmi-rubber.com<br />

www.vmi-group.com<br />

VMI - The market leader in production machinery<br />

•Custom Mixing and Compounding - Colors and Black<br />

•Wide Variety of Polymers and Applications<br />

•Various Product Forms and Packaging Options<br />

•Calendering and Slitting Available<br />

•Compound Development and Problem Solving<br />

Contact: Tom Lennox - Sales • Glen Spooner - Technical<br />

www.infinityrubber.com • e-mail tlennox@infinityrubber.com<br />

Infinity <strong>Rubber</strong> Technology Group<br />

170 North Queen St. Toronto, ON M9C 1A8<br />

PH (416) 626-0701 - FAX (416) 626-5156<br />

INTERNATIONAL ELASTOMER CONFERENCE 49