Download - Sampe

Download - Sampe

Download - Sampe

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2009 SAMPE<br />

Fall Technical Conference & Exhibition<br />

Century II Convention Center, Wichita, Kansas<br />

October 19-22, 2009<br />

Co-Located with ASTM-D30 Conference<br />

Final Program and Exhibitors Guide<br />

Global Material Technology: Soaring to New Horizons<br />

Hosted by SAMPE’s New Jersey and Wichita Chapters

Welcome to Wichita and the 2009 SAMPE Fall Technical Conference, co-located with the ASTM D-30 conference. SAMPE’s Wichita and New<br />

Jersey chapters are pleased to present this conference, whose theme is “Global Material Technology: Soaring to New Horizons.”<br />

The conference features 41 technical sessions with over 175 papers, two keynote presentations, three featured lectures, and six panels. Eight<br />

tutorial sessions are offered on Monday, along with a multi-scale modeling workshop on Thursday. Also on Thursday, tours are offered of<br />

the Spirit AeroSystems manufacturing facility, and laboratories of the National Institute for Aviation Research at Wichita State University. The<br />

exhibit hall will showcase over 100 exhibitors.<br />

You are invited to network with your fellow conference attendees at the Welcome Reception on Tuesday evening, and at morning and afternoon<br />

coffee breaks Tuesday and Wednesday. Wednesday evening’s entertainment will feature a Kansas Saloon, with a barbecue and calf roping. In<br />

addition, the SAMPE awards luncheon will be held Thursday.<br />

Wichita, a city of more than 400,000 people, is the heart of industry and commerce in the state of Kansas. Known as the “air capitol of the<br />

world,” it is the local presence of six major aerospace companies: Airbus, Boeing, Bombardier/Learjet, Cessna, Hawker Beechcraft, and Spirit<br />

AeroSystems.<br />

We hope you enjoy the conference and your stay in Wichita.<br />

Benjamin Rasmussen and Melanie Violette, General Co-Chairs, 2009 Fall Technical Conference<br />

SAMPE Thanks Our Organizing Committee:<br />

General Co-Chairs<br />

Ben Rasmussen, BMR Associates<br />

Melanie Violette, Wichita State University<br />

Technical Program Co-Chairs<br />

Timothy Chavez, Spirit AeroSystems<br />

Howard Kliger, HS Kliger & Associates Inc.<br />

Brad Lucht, Honeywell Federal Manufacturing & Technologies<br />

Louis Pilato, Consultant<br />

Volunteers Chairs<br />

Ralph Carson, Retired<br />

Yeow Ng, National Institute for Aviation Research<br />

AV Support Chair<br />

Tracee Friess, National Institute for Aviation Research<br />

Financial Chairs<br />

John Osterndorf, US Army RDECOM-ARDEC<br />

Bill Washburn, Spirit AeroSystems<br />

Exhibits Chair<br />

Tony Constantino, Fiber-Line Inc.<br />

Sponsors Chair<br />

Borys Schafran, Evonik Degussa<br />

Attention SAMPE Conference Attendees!<br />

w This year’s SAMPE Fall Technical Conference is colocated<br />

with the ASTM D30 Meeting. The ASTM D30<br />

meeting requires separate registration from the SAMPE<br />

Conference. ASTM D30’s registration area is located in<br />

the Stimson/Santa Fe Room, Hyatt Regency Hotel.<br />

w Also, SAMPE Fall Technical Conference and Exhibition attendees<br />

will be able to attend, at no charge, the Wichita Industrial Trade Show<br />

(WITS) which is also being held in the Bob Brown hall of the Century<br />

II Convention Center.<br />

The WITS show hours are:<br />

Tuesday, October 20 1:00 – 7:00 PM<br />

Wednesday, October 21 10:00 AM – 7:00 PM<br />

Thursday, October 22 10:00 AM – 4:00 PM<br />

w Join us for the 2009 SAMPE Technical Communities Meeting. Discuss<br />

ways SAMPE’s Technical Communities can work better for you. This<br />

meeting will take place on Wednesday, October 21, 2009 from 4:30<br />

– 5:30 PM in the Chisholm Room at the Hyatt Regency Hotel.<br />

w Tour registration is not available onsite. Tours are available only<br />

to attendees who registered and confirmed their attendance by Sept.<br />

30.<br />

A Special Thank You to Our Conference Sponsors!<br />

A d i v i s i o n o f T e c I n d u s t r i e s , L L C<br />

www.sampe.org 1

Century II Convention Center and Hyatt Regency Hotel Layout<br />

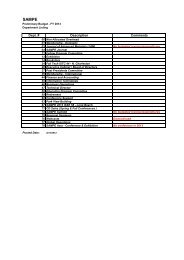

SAMPE<br />

registration<br />

SAMPE<br />

EXHIBITS<br />

W.I.T.S. Exhibits<br />

Hyatt Regency Meeting Rooms<br />

Exhibits Hours<br />

Tuesday<br />

10:00 AM - 4:00 PM<br />

Wednesday<br />

10:00 AM - 4:00 PM<br />

Coffee Breaks<br />

Tuesday and Wednesday<br />

Complimentary coffee will be available in the<br />

exhibition hall, sponsored by Evonik Jayhawk Fine<br />

Chemicals, during these breaks.<br />

10:40 – 11:00 AM<br />

2:55 – 3:25 PM<br />

<br />

SAMPE Fall Tech Conference & Exhibits–Wichita, KS

2009 SAMPE Fall Technical<br />

Monday, October 19<br />

Registration 7:30 AM - 5:00 PM<br />

Tutorials (Tutorials require additional fees)<br />

9:00 AM – 12:00 PM<br />

• Tooling for Composite Materials–Room 204<br />

• Composites Damage Tolerance: Materials & Structures–Room 205<br />

• Composite Materials Overview–Room 207<br />

• Design & Analysis of Composite Materials & Structures–Room 208<br />

Tutorials require a fee separate from conference registration.<br />

ITAR<br />

*Sessions include ITAR restricted presentations.<br />

Tuesday, October 20<br />

Registration 7:30 AM - 5:00 PM<br />

8:00 AM – Keynote<br />

• Global Materials Technology–Room 209A<br />

9:00 AM – Panels<br />

• Benchmarking of Composite Technology for Aircraft Structures Europe<br />

vs. USA–Room 204<br />

• Damage Resistance of Composite Sandwich Structures–Room 206<br />

(Joint SAMPE and ASTM D-30 Program)<br />

9:00 AM - 12:00 PM – Sessions<br />

• Resin & Plastics Technology - Non-Epoxy Systems–Room 207<br />

ITAR<br />

•Advances in Manufacturing & Out-of-Autoclave I*<br />

Room 209B<br />

• Sensors in Aerospace Systems–Room 205<br />

10:40 AM – Coffee Break sponsored by<br />

11:00 AM - 12:00 PM – Session<br />

• Design & Analysis of Composite Structures I–Room 208<br />

• Epoxy Resin Technology I–Room 207<br />

11:00 AM – Featured Lecture/Session<br />

• The Role of Education in Composites Engineering–Room 205<br />

No Exhibits<br />

Exhibits 10:00 AM - 4:00 PM<br />

2:00 – 5:00 PM<br />

• Thermoset Resins Technology–Room 204<br />

• Testing of Composite Materials–Room 205<br />

• Composites Repair Technology & Issues–Room 207<br />

• Composites Fabrication & Manufacturing Overview–Room 208<br />

Coffee Breaks - Sponsored by<br />

Tuesday and Wednesday<br />

10:40 – 11:00 AM<br />

and<br />

2:55 – 3:25 PM<br />

Complimentary coffee will be available<br />

in the exhibition hall.<br />

1:15 - 5:00 PM – Panel<br />

• Energy Issues in Aviation–Room 204<br />

1:15 - 3:15 PM Session<br />

•Advances in Manufacturing & Out-of-Autoclave II*<br />

ITAR<br />

Room 209B<br />

1:15 - 5:00 PM – Sessions<br />

• Epoxy Resin Technology II–Room 207<br />

• Design & Analysis of Composite Structures II–Room 208<br />

• 3-D Nanostructured Advanced Composites–Room 206<br />

• Damage Tolerance & Fracture Mechanics–Room 205<br />

2:55 PM – Coffee Break sponsored by<br />

3:15 - 5:00 PM – Sessions<br />

• Tooling Advancements–Room 209B<br />

• Ballistic Composites–Room 204<br />

4:15 - 5:00 PM – Sessions<br />

• Automated Tape Placement/Automated Fiber Placement–Room 204<br />

5:00 - 6:00 PM – Welcome Reception–Upper Gallery<br />

<br />

SAMPE Fall Tech Conference & Exhibits–Wichita, KS

Conference At-A-Glance<br />

Wednesday, October 21<br />

Registration 7:30 AM - 5:00 PM<br />

8:00 AM – Keynote<br />

• Materials, Processing and Manufacturing Technology:<br />

A Rich History and Promising Future–Room 209A<br />

9:00 AM - 12:00 PM – Panel<br />

• Commercializing Composites: The Outlook for High-Volume,<br />

Sustainable Material Applications–Room 206<br />

9:00 AM - 12:00 PM – Sessions<br />

• Testing & Qualification of Materials–Room 208<br />

• Technologies to Assist Composite Manufacturers I–Room 209B<br />

• Nanocomposites & Multifunctional Materials–Room 204<br />

• Composite Foams–Room 205<br />

9:00 - 10:40 AM – Session<br />

• Epoxy Resin Technology III–Room 207<br />

10:40 AM – Coffee Break sponsored by<br />

11:00 AM – Featured Lecture<br />

• Metal Composite Hybrid Materials & Products–Room 205<br />

11:00 AM - 12:00 PM – Session<br />

• Bio-, Natural & Innovative Materials I–Room 207<br />

Exhibits 10:00 AM - 4:00 PM<br />

Thursday, October 22<br />

Registration 7:30 AM - 1:30 PM<br />

8:15 AM – Featured Lecture<br />

• Acoustic Emission (AE) Offers New Horizons for Composites–<br />

Room 205<br />

8:45 AM - 5:00 PM – AFOSR Workshop<br />

• Multiscale Modeling for Polymer Matrix Composites–Room 208<br />

9:00 AM - 10:40 AM – Session<br />

ITAR<br />

ITAR<br />

•Manufacturing with Nano-modified Composites*–Room 209B<br />

•Lightning Strike Protection*–Room 206<br />

9:00 AM - 12:00 PM – Sessions<br />

ITAR<br />

•EMI Shielding, Conductive Materials*–Room 205<br />

• Nano-Enhanced Resins for Aerospace Applications I–Room 204<br />

ITAR<br />

•High Temperature Resins & Composites I*–Room 207<br />

10:40 AM – Brief Session Break–Room 209A<br />

11:00 AM - 12:00 PM - Sessions<br />

• Filament Winding & Pultrusion I–Room 209B<br />

• Infusion Technology - Processing Effects–Room 206<br />

12:15 PM – SAMPE Awards Luncheon–Room 210B<br />

No Exhibits<br />

1:15 - 2:55 PM – Panel<br />

• Design & Analysis Tool Demonstration–Room 206<br />

1:40 - 2:55 PM – Sessions<br />

• Technologies to Assist Composite Manufacturers II–Room 209B<br />

• Infusion Technology – Applications–Room 205<br />

1:40 - 5:00 PM – Session<br />

• Bio-, Natural & Innovative Materials II–Room 207<br />

• Nanofiber Technology, Uses–Room 204<br />

• Core & Sandwich Materials–Room 208<br />

2:55 PM – Coffee Break sponsored by<br />

3:15 - 5:00 PM – Panel<br />

• Technologies to Assist Composite Manufacturers–Room 206<br />

3:15 - 5:00 PM – Sessions<br />

• Building Blocks to Advanced Materials Applications–Room 209B<br />

• Infusion Technology - Resins/Preforms–Room 205<br />

4:30 PM – Technical Communities Meeting<br />

6:00 PM<br />

Night on the Kansas Prairie–Eagle Ballroom, Hyatt Regency Hotel<br />

1:45 - 5:00 PM – Tours<br />

(Registration closed)<br />

• National Institute of Aviation Research, Wichita State University<br />

• Spirit AeroSystems<br />

Meet in Hyatt Regency Hotel lobby at 1:45 sharp<br />

1:45 - 3:35 PM – Sessions<br />

• POSS Resin Systems–Room 206<br />

ITAR<br />

ITAR<br />

•Nano-Enhanced Resins for Aerospace Applications II*<br />

Room 204<br />

• High Temperature Resins & Composites II–Room 207<br />

1:45 - 5:00 PM – Session<br />

• Filament Winding & Pultrusion II–Room 209B<br />

3:25 PM – Brief Session Break<br />

3:45 - 5:00 PM – Sessions<br />

• Automation & Optimization of Autoclave Cure–Room 204<br />

• POSS Resin Systems Round Table–Room 206<br />

• Nondestructive Evaluation & Inspection*–Room 207<br />

www.sampe.org 5

Monday, October 19<br />

Tutorials<br />

Tutorials are half-day courses that require a separate cost from the conference registration. Depending upon the tutorial, either a printed<br />

handout or electronic handout will be included.<br />

Prices are: $150 with conference registration, $75 for students, $199 for other registrants.<br />

9:00 AM – Noon<br />

Tooling for Composites–Room 204<br />

Robert Stratton, Stratton Composite Solutions<br />

Composites Damage Tolerance: Materials & Structures–Room 205<br />

Dr. Keshavanarayana Raju, Wichita State University<br />

Composite Materials Overview–Room 207<br />

Dr. Linda Clements, C&C Innovation Strategies Inc.<br />

Design & Analysis of Composite Materials & Structures–Room 208<br />

Dr. Dan Adams, University of Utah<br />

2:00 – 5:00 PM<br />

Thermoset Resin Matrices–Room 204<br />

Dr. James Senger, Cytec Engineered Materials<br />

Testing of Composite Materials–Room 205<br />

Dr. Don Adams, Wyoming Test Fixtures<br />

Composites Repair Technology & Issues–Room 207<br />

Louis Dorworth, Abaris Training Resources Inc.<br />

Composites Fabrication & Manufacturing Overview–Room 208<br />

Dr. James C. Leslie, ACPT Inc.<br />

Important session information for all attendees.<br />

SAMPE Restricted Papers —ITAR Regulations Session Admittance<br />

ITAR<br />

(REVISED PROCEDURES 6/05)<br />

Several papers to be presented at this conference will be restricted papers governed by ITAR (International Traffic in Arms Regulations). The U.S.<br />

citizens SAMPE list used at previous conferences will not be available. If you plan to attend any presentations restricted by ITAR, you must bring proof<br />

of citizenship plus the other verification documents as shown below. Please note that only U.S. citizens and U.S. Resident Aliens can be considered<br />

for attendance at these restricted presentations.<br />

Admittance to restricted sessions and access to restricted technical papers is implemented and controlled by U.S. International Traffic in Arms Regulations<br />

(ITAR). All restricted session attendees MUST abide by the procedures and submittal of verification documents as noted below – no exceptions:<br />

ATTENDEE CLASSIFICATION<br />

U.S. Government Employees<br />

U.S. Citizens<br />

Resident Aliens (U.S.)<br />

IDENTIFICATION & PROOF OF EMPLOYMENT REQUIREMENTS<br />

1. Proof of Citizenship (for example, passport, birth certificate, voters registration card,<br />

naturalization papers), and,<br />

2. Personal photographic identification (passport, driver’s license, corporate ID, etc.)<br />

1. Proof of Citizenship (for example, passport, birth certificate, voters registration<br />

card, naturalization papers), and,<br />

2. Personal photographic identification (passport, driver’s license, corporate ID, etc.), and,<br />

3. Certification credentials based on DD Form 2345 (see below for details)<br />

1. Resident Alien Card, and,<br />

2. Personal photographic identification (passport, driver’s license, corporate ID, etc.), and,<br />

3. Certification credentials based on DD Form 2345 (see below for details)<br />

DD Form 2345 individual certification credentials (required for U.S. & Resident Aliens) must be from one of the following:<br />

1. Copy of an approved and active DD Form 2345 for the individual, or,<br />

2. Copy of an approved and active DD Form 2345 for the individual’s employer PLUS evidence of current employment status<br />

with that employer (corporate ID, business card, etc.), or,<br />

3. A listing of the individual’s employer in the most recent DoD quarterly Qualified U.S. Contractor Access<br />

List PLUS evidence of current employment status with that employer (corporate ID, business card, etc.).<br />

DD Form 2345 may be downloaded and completed online in order to apply for approval to be listed on the Qualified U.S. Contractor List, www.<br />

dlis.dla.mil/jcp/. Allow at least 4 weeks prior to the SAMPE symposia or technical conference dates for this process.<br />

How to get your ITAR Clearance:<br />

Bring all of the above listed identification, proof of employment and certification credentials to the to the SAMPE Clearance counter at the SAMPE<br />

Registration area. Your documents will be verified and you will be provided with a stamp indicating your ITAR clearance. Photo ID will be checked<br />

against your ITAR badge before admittance is granted to any ITAR presentation.<br />

<br />

SAMPE Fall Tech Conference & Exhibits–Wichita, KS

Tuesday, October 20<br />

8:00 – 9:00 AM • Room 209A<br />

SAMPE Keynote Presentation<br />

Global Materials Technology<br />

Presenter: John Pilla: Senior VP/General Manager,<br />

Propulsion Segment, Spirit AeroSystems<br />

The aviation industry is embarking upon a<br />

historic transformation from all metallic fuselages to light-weight<br />

composite aero-structures. In the decades past there has been a<br />

six-fold increase in air traffic provided by the U.S. aviation system,<br />

while there has been a 60 percent improvement in fuel efficiency.<br />

Concerned with the spiraling fossil fuel consumption and its debilitating<br />

environmental impact, we are focusing on a new paradigm shift<br />

toward the development of disruptive, energy efficient (“green”),<br />

global material technology for effective energy utilization and efficient<br />

manufacturing. These emerging technologies for advanced material<br />

and process are paving way for the future of aviation. Also, in this<br />

era of globalization, we are growing our diverse business portfolio<br />

through open innovations and leveraged collaborations for the costeffective<br />

and rapid implementation of these technologies. As the<br />

premier aero-structure producer and system integrator of the aviation<br />

industry, Spirit AeroSystems is actively and strategically engaged in<br />

this Global Material Technology revolution.<br />

9:00 AM • Room 204<br />

Panel: Benchmarking of Composite Technology for Aircraft and<br />

Marine Structures: Europe vs. USA<br />

Moderator: Len Poveromo - Director, Northrop Grumman<br />

Panelists:<br />

• Charlie Rowe – Technical Director, SCRA<br />

• Tom Carstenson – Chief, Air Frame Development Program, Sikorsky<br />

• Nick Melillo – Senior Manager Structures Technology, Boeing<br />

• Paul Oldroyd – Bell Helicopter<br />

• Bob Gray – President, Maverick Corp.<br />

• Scott Lewit – President, Structural Composites, Inc.<br />

• Chris Hicks – Northrop Grumman<br />

• Danna Kelley-Haddad - Chairwoman of The Composite Consortium (TCC)<br />

9:00 AM • Room 206<br />

Panel: Damage Resistance of Composite Sandwich Structures<br />

Moderator: Carl Rousseau - ASTM D30 Committee and Lockheed Martin<br />

Aeronautics<br />

The purpose of this combined presentation/panel session will be to<br />

bring together subject-matter-experts in the area of durability, damage<br />

resistance, and damage tolerance of aerospace sandwich structures<br />

and discuss near-term needs for standardized test methods, practices,<br />

and/or guides. Brief presentations will be given on recent sandwich<br />

structure DaDT certification requirements, methods of compliance, and<br />

related field service history and repair. A panel discussion will follow,<br />

which will focus on a strategy for development of sandwich DaDT<br />

standards and a recommended path/plan for development. Notes will<br />

be taken and subsequently distributed, along with presentations, to<br />

attendees. Possible resulting new work items for ASTM Sub-Committee<br />

D30.09 (Sandwich Structures) will then be addressed in the D30.09<br />

meeting that afternoon.<br />

Panelists:<br />

• Dr. Dan Adams, University of Utah<br />

• Mr. Mark Chris, Bell Helicopter Textron<br />

• Mr. Wade Jackson, NASA Langley Research Center<br />

• Dr. Paul Lagace, Massachusetts Institute of Technology<br />

• Dr. Alan Nettles, NASA Marshall Space Flight Center<br />

• Mr. Adam Sawicki, Boeing Company<br />

• Dr. K. Suresh Raju, Wichita State University<br />

Coffee Breaks - Sponsored by<br />

Technical Program<br />

Tuesday and Wednesday<br />

10:40 – 11:00 AM and 2:55 – 3:25 PM<br />

Complimentary coffee will be available in the exhibition hall.<br />

www.sampe.org 7

Tuesday, October 20<br />

Room 209B<br />

Advances in Manufacturing & Out-of-Autoclave I<br />

Session Chairs: Gail Hahn, The Boeing Company - Phantom Works; John<br />

Russell, AFRL/RXMT; and Amit Vyas, Spirit AeroSystems Inc.<br />

9:00 AM – 2 nd Place Winner<br />

Advanced Composite Cargo Aircraft, J. D. Russell, Air<br />

Force Research Laboratory, Wright-Patterson Air Force Base,<br />

OH; B. Shenk, R. Holzwarth, Air Force Research Laboratory,<br />

Wright-Patterson Air Force, Base, OH; M. Swanson, D. Paige,<br />

M. Tresnak, S. Ames, Lockheed Martin Aeronautics Company,<br />

Palmdale, CA; P. Neumeier, Lockheed Martin Aeronautics<br />

Company, Marietta, GA<br />

9:25 AM<br />

Prototype Fabrication and Assembly of Large Scale Integrated<br />

Out-of-Autoclave (OOA) Structures, G. Rossi, J. D. Russell, Air<br />

Force Research Laboratory, Wright-Patterson AFB, OH<br />

9:50 AM<br />

Properties of an Out-of-Autoclave Prepreg Material: Oven Versus<br />

Autoclave, J. Courter, J. Dustin, A. Ritchey, R. B. Pipes, Purdue University,<br />

West Lafayette, IN; L. Sargent, W. Purcell, Applied Composites Engineering,<br />

Indianapolis, IN<br />

10:15 AM<br />

Non-autoclave Prepreg Manufacturing Technology for Primary<br />

Aerospace Structure, G. Hahn, G. G. Bond, The Boeing Company,<br />

Berkeley, MO<br />

11:00 AM<br />

Low Cost, Short Lead Tooling for Limited Use and Lower Temperatures,<br />

N. Froeschner, J. M. Griffith, The Boeing Company, St. Louis, MO<br />

11:25 AM<br />

Advanced Materials and Technologies for Wide-body Aircraft<br />

Structures, L. B. Rosa, F. D. R. Amado, UESC – Universidade Estadual de<br />

Santa Cruz, Brazil<br />

11:50 AM<br />

Morphing Mold Tools, B. Halford, Surface Generation Ltd, London, UK<br />

Room 205<br />

Sensors in Aerospace Systems<br />

Session Chair: Anindya Ghoshal, United Technologies Research Center<br />

9:00 AM<br />

Structural Health Monitoring of Carbon Fiber Composites Using<br />

Inherently Conducting Polymeric Films, A. K. Singh, D. Kim, H. Yang,<br />

B. W. Pitts, G. J. Tregre, Crosslink, Hattiesburg, MO; P. J. Kinlen, Crosslink,<br />

St. Louis, MO<br />

9:25 AM<br />

Metallized Carbon Nanofiber Based Nanocomposites for<br />

Electrochemical Sensing, L. Li, K. Lafdi, University of Dayton Research<br />

Institute, Dayton, OH<br />

9:50 AM<br />

Visibility of Viscoelastic Properties During Processing of Fiber<br />

Reinforced Thermoset Resin Systems, L. Dorworth, Abaris Training<br />

Resources Inc., Reno, NV<br />

10:15 AM<br />

The Embedding of Optical Fibre Sensors for SHM, M. Volanthen, L.<br />

Rumsey, R. Caesley, Insensys, Fareham, UK; A. Ghoshal, G. Welsh, United<br />

Technologies Research Center, East Hartford, CT; N. Bordick, US Army<br />

RDECOM, Fort Eustis, VA<br />

<br />

ITAR<br />

Room 207<br />

Resin & Plastics Technology - Non-Epoxy Systems<br />

Session Chairs: Axel Böettcher, Boettcher Consult; Jeff Wiggins, University of<br />

Southern Mississippi; and Volker Altstädt, Universitaet Bayreuth<br />

9:00 AM<br />

Impact of Cure Environment on Mechanical Properties and Network<br />

Morphology of Vinyl Ester Resin Systems, J. Swanson, J. W. Rawlins,<br />

University of Southern Mississippi, Hattiesburg, MS<br />

9:25 AM<br />

New Developments in Polyaryl Ether Amide Resin Technology, F.-A.<br />

von Itter, B. Schafran, Evonik Degussa GmbH, Marl, Germany<br />

9:50 AM<br />

Reactive Rotational Molding of Thermoset Polyurethane: Application<br />

to H2 Storage Liner Production, J. Viale, F. Nony, L. Delnaud, P.<br />

Mazabraud, CEA Le Ripault, Monts, France; J.-F. Gerard, UMR 5223<br />

– INSA Lyon, Villeurbanne, France; A. Tcharkhtchi, PIM – ENSAM Paris,<br />

Paris, France; A. Baron, Raigi, Rouvray St. Denis, France<br />

10:15 AM<br />

Benzoxazine Resins for Composite Materials - Recent Developments,<br />

R. Schönfeld, S. Kreiling, C. Sawaryn, A. Taden, Henkel AG & Co. KGaA,<br />

Düsseldorf, Germany<br />

11:00 AM<br />

Effects of Annealing on Mechanical Properties of Uniaxial Oriented<br />

Polypropylene Film, M. Deevey, B. Chen, J. Chung, Frontier Performance<br />

Polymers Corporation, Dover, NJ; J. Song, M. Sennett, US Army, RDECOM<br />

- NSRDEC, Natick, MA; T. Woo, US Army, RDECOM - ARDEC, Picatinny<br />

Arsenal, NJ<br />

Room 207<br />

Epoxy Resin Technology I<br />

Session Chairs: Axel Böettcher, Boettcher Consult; Jeff Wiggins, University of<br />

Southern Mississippi; and Volker Altsadt, Universitaet Bayreuth<br />

11:25 AM<br />

Atomistic Modelling of Crosslinked Epoxy Polymer, A. Bandyopadhyay,<br />

P. K. Valavala, G. M. Odegard, Michigan Technological University,<br />

Houghton, MI<br />

11:50 AM<br />

Near IR Kinetics and Correlation of Cure of Epoxy Resins, M.<br />

Pramanik, J. O. Swanson, J. A. Scott, S. K. Mendon, J. W. Rawlins, The<br />

University of Southern Mississippi, Hattiesburg, MS<br />

Tuesday 10:00 AM - 4:00 PM<br />

Wednesday 10:00 AM - 4:00 PM<br />

Coffee Breaks - Sponsored by<br />

Technical Program<br />

Visit our 120+ exhibitors in the<br />

Century II Convention Hall!<br />

Tuesday and Wednesday<br />

10:40 – 11:00 AM and 2:55 – 3:25 PM<br />

Complimentary coffee will be available in the exhibition hall.<br />

SAMPE Fall Tech Conference & Exhibits–Wichita, KS

Tuesday, October 20<br />

11:00 AM • Room 205<br />

Featured Lecture - The Role of Education in<br />

Composites Engineering<br />

Lecturer: Beckry Abdel-Magid: Chair, Composite<br />

Materials Engineering, Winona State University<br />

In the early 1990s, leaders in the composite<br />

materials industry declared that the major<br />

problem with composite materials was neither technical nor economic,<br />

but rather educational, and called for shifting the emphasis in the<br />

academic community from focusing on research and development to<br />

educating and graduating large numbers of engineers with broad<br />

and in-depth knowledge in composite materials.<br />

A number of universities responded by developing strong programs<br />

in composites engineering both at the undergraduate and graduate<br />

levels. In the subsequent two decades, graduates of these programs<br />

were in the forefront of a second revolution not only in new applications<br />

in myriad products and industries, but also in the material and<br />

processing technologies of composite materials. This presentation<br />

will highlight the role of education in taking composite materials from<br />

artisan fabrication and laboratory research to advanced technology<br />

and applications ranging from aerospace, to consumer goods and<br />

nano-scale materials. A review of the current state of education in<br />

composites engineering in the United States and other industrial<br />

nations will also be presented.<br />

Panelists:<br />

• John L. Graham, Ph.D., University of Dayton Research Institute<br />

• Donald Minus, Fuels & Energy Branch, AFRL<br />

• Omar Mendoza, Materials Engineer, AFRL<br />

• Tim Edwards, Fuels & Energy Branch, AFRL<br />

• James Hileman, Research Engineer, Massachusetts Institute of Technology<br />

• Kevin Trayer, USAF Reserves, Air Mobility Command Fuel Efficiency Office<br />

• Gregory L. Rhoads, Fuels & Energy Branch, AFRL<br />

Room 209B<br />

Advances in Manufacturing & Out-of-Autoclave II<br />

Session Chairs: Gail Hahn, The Boeing Company - Phantom Works; John<br />

Russell, AFRL/RXMT; and Amit Vyas, Spirit AeroSystems Inc.<br />

1:40 PM<br />

ITAR<br />

Technical Program<br />

The Cure Cycle Reduction of Advanced High Temperature<br />

Polyimide, E. Stone, B. Pinkerton, A. Arhelger, Vought Aircraft<br />

Industries, Dallas, TX<br />

2:05 PM<br />

Optimization of Composite Ply Kits, J. A. Petermeier, R. P. Willardson,<br />

K. R. Wilkinson, eServ, A Perot Systems Company, Plano, TX<br />

2:30 PM<br />

Experimental Study of Milling Bifurcations, A. Radhakrishnan, J.<br />

Kennedy, R. Fales, University of Missouri - Columbia, Columbia, MO<br />

Room 205<br />

The Role of Education in Composites Engineering<br />

Session Chair: Brad Jorgenson, South Dakota School of Mines & Technology<br />

11:50 AM<br />

Experimental Characterization of Composite Materials Across<br />

the Curriculum, B. Abdel-Magid, M. Grami, S. Ziaee, Winona State<br />

University, Winona, MN<br />

Room 208<br />

Design & Analysis of Composite Structures I<br />

Session Chairs: Brian Kitt, Spirit AeroSystems Inc.; Phil Sears, eServ; and<br />

Walter Horn, Wichita State University<br />

11:00 AM<br />

Scatter Analysis of Composites and Adhesive Joints for Substantiation<br />

of Modern Aircraft Structures, W. Seneviratne, J. S. Tomblin, National<br />

Institute for Aviation Research, Wichita, KS<br />

11:25 AM<br />

The Buckling Response of Tapered Composite Plates Based on Thirdorder<br />

Theory, S. Akhlaque-E-Rasul, R. Ganesan, Concordia University,<br />

Montreal, Canada<br />

11:50 AM<br />

Asymmetric and Tension-shear Coupling Model Based on Non-<br />

Orthogonal Constitutive Law for Dry Fabric Composites, W. Lee, M.-<br />

K. Um, J.-H. Byun, KIMS, Changwon, South Korea<br />

1:15 PM • Room 204<br />

Panel: Energy Issues in Aviation<br />

Moderators: Wade Adams - Director of the Center for Nanoscale Science and<br />

Technology, Rice University; Don Erbschloe - Chief Scientist, Air Mobility Command;<br />

and Gregory L. Rhoads - AFRL Propulsion and Power Directorate.<br />

This panel presentation and discussion will cover the broad issues in<br />

energy needs, availability and opportunities for aviation, including<br />

new technologies and applications, alternative fuels, operational<br />

strategies for conservation, and climate change issues.<br />

www.sampe.org 9

Tuesday, October 20<br />

Room 208<br />

Design & Analysis of Composite Structures II<br />

Session Chairs: Brian Kitt, Spirit AeroSystems Inc.; Phil Sears, eServ; and<br />

Walter Horn, Wichita State University<br />

1:40 PM<br />

Simple Analytical Techniques for Laminated Cylinders and Plates, T.<br />

Fronk, S. L. Folkman, E. Clark, Utah State University, Logan, UT<br />

2:05 PM<br />

21 st Century Analysis and Design of Composite Flight Vehicle<br />

Structures Using an FEA-Based Electronic Handbook, S. J. Leemans,<br />

Advatech Pacific, Tempe, AZ<br />

2:30 PM<br />

Bridging the Gap Between Physics and Large-scale Structural<br />

Analysis: A Novel Method for Fatigue Life Prediction of Composites,<br />

R. Fertig III, Firehole Technologies, Laramie, WY<br />

3:25 PM<br />

Simulating Impact Damage to Composite Structures, A. Hsu, NEi<br />

Software Inc., Westminster, CA<br />

3:50 PM<br />

Composite Aircraft Assemblies: The Complete Solution, O. Guillermin,<br />

Vistagy, Waltham, MA<br />

4:15 PM<br />

Quantitative Microstructural Analysis of a Nylon 6,6/E-Glass Long<br />

Fiber Thermoplastic Composite, V. S. Chevali, U. K. Vaidya, G. M.<br />

Janowski, The University of Alabama at Birmingham, Birmingham, AL<br />

4:40 PM<br />

Design and Analysis Methods for Composite Load Introduction<br />

Fittings, P. Middendorf, M. Siemetzki, T. Havar, K. Zimmermann, EADS<br />

Deutschland GmbH, Innovation Works, Munich, Germany<br />

Room 205<br />

Damage Tolerance & Fracture Mechanics<br />

Session Chairs: Waruna Seneviratne, National Institute for Aviation Research;<br />

and Rick Willardson, eServ<br />

1:40 PM<br />

Computational Simulation of Progressive Damage in Composite<br />

Stiffened Panels with Discrete Source Damage, H. Zhang, F. Abdi,<br />

Alpha STAR Corporation, Long Beach, CA<br />

2:05 PM<br />

Robust Design of Assembled Composite Joining Concepts, a<br />

Combined Durability-Reliability Evaluation, F. Abdi, F. Rognin, Alpha<br />

STAR Corporation, Long Beach, CA; J. Housner, Analytical Enterprises,<br />

Newport News, VA; K. Nikbin, Imperial College of London, UK<br />

2:30 PM<br />

Load Rate Effects on the Crush Response of Laminated Corrugated<br />

Beams, S. Keshavanarayana, K. Y. Tan, S. F. Elyas, Wichita State<br />

University, Wichita, KS<br />

3:25 PM<br />

Rate Sensitivity of Fracture Toughness of Laminated Composites, S.<br />

Keshavanarayana, P. N. Nandakumar, Wichita State University, Wichita,<br />

KS<br />

3:50 PM<br />

Damage Tolerance of Full-scale Notched Composite Sandwich<br />

Panels, Keshavanarayana, J. Tomblin, Wichita State University, Wichita,<br />

KS; P. Shyprykevich, C. Davies, FAA William J. Hughes Technical Center,<br />

Atlantic City, NJ<br />

Technical Program<br />

Room 206<br />

3-D Nanostructured Advanced Composites<br />

Session Chairs: Brian Wardle, MIT; and Larry Drzal, Michigan State<br />

University<br />

1:40 PM<br />

Health Monitoring of Aligned Carbon Nanotube (CNT) Enhanced<br />

Composites, D. M. Barber, S. S. Wicks, B. L. Wardle, Massachusetts<br />

Institute of Technology, Cambridge, MA; A. Raghavan, C. T. Dunn, S. S.<br />

Kessler, Metis Design Corporation, Cambridge, MA<br />

2:05 PM<br />

Towards Multifunctional Enhancement of Composite Aerostructures<br />

via the Incorporation of Aligned Carbon Nanotubes, M. S. Tsai, R.<br />

Guzman de Villoria, B. L. Wardle, Massachusetts Institute of Technology,<br />

Cambridge, MA<br />

2:30 PM<br />

Polymer-based Carbon Nanotube Composites in the Space<br />

Environment, L. Daniel, MIT, Boston, MA; M. Chipara, The University of<br />

Texas Pan American, Edinburg, TX<br />

3:25 PM<br />

Investigation of Nanostructure Effects and Interactions on the Elastic<br />

Properties of Buckypaper-polymer Nanocomposites, C. Tsai, C.<br />

Zhang, A. Vanli, B. Wang, Florida State University, Tallahassee, FL<br />

3:50 PM<br />

Processing and Properties of Functionalized Graphite Nanoplatelet/<br />

Epoxy Composites, Z. Wang, H. T. Hahn, UCLA, Los Angeles, CA; D.<br />

Wang, L.-S. Tan, Air Force Research Laboratory, Wright-Patterson AFB,<br />

OH<br />

4:15 PM<br />

Optimal Matching of Thermal Vibrations into Carbon Nanotubes,<br />

K.G.S.H Gunawardana, K. Mullen, The University of Oklahoma, Norman,<br />

OK<br />

Room 207<br />

Epoxy Resin Technology II<br />

Session Chairs: Axel Böettcher, Boettcher Consult; Jeff Wiggins, University of<br />

Southern Mississippi; and Volker Altstädt, Universitaet Bayreuth<br />

1:40 PM<br />

Effect of Amine Isomerism on Glass Transition and Free Volume<br />

of Epoxy-Amine Network Based on Glycidyl Ether of Bisphenol-<br />

F (DGEBF) and Diaminodiphenyl Suffone (DDS), M. Kaushik, M.<br />

B. Jackson, S. R. Heinz, J. S. Wiggins, S. Nazarenko, The University of<br />

Southern Mississippi, Hattiesburg, MS<br />

2:05 PM<br />

Measuring Compression Strain Recovery in Thermoset Matrices<br />

Using Digital Image Correlation, S. Heinz, J. Wiggins, The University<br />

of Southern Mississippi, Hattiesburg, MS<br />

2:30 PM<br />

Mechanical Properties and Network Structure of Blended Epoxy<br />

Resins, M. Pramanik, J. O. Swanson, J. A. Scott, S. K. Mendon, J. W.<br />

Rawlins, The University of Southern Mississippi, Hattiesburg, MS<br />

3:25 PM<br />

Characterizing Fortified Epoxy Amine Matrixes with Latent Uretdione<br />

Crosslinking Agents, J. Rawlins, K. Davis, The University of Southern<br />

Mississippi, Hattiesburg, MS<br />

3:50 PM<br />

The Effect of Different Matrix Materials on the Properties of Structural<br />

Composites Fabricated from Waste Carpet, A. Jain, G. Pandey, R.<br />

Vaidyanathan, R. P. Singh, Oklahoma State University, Stillwater, OK<br />

10 SAMPE Fall Tech Conference & Exhibits–Wichita, KS

Tuesday, October 20<br />

Technical Program<br />

4:15 PM<br />

Specialty Anhydrides for High-Performance Composites, K. Shah,<br />

Evonik Jayhawk Fine Chemicals Corporation, Galena, KS<br />

4:40 PM<br />

Technical Advances in Epoxy Technology for Wind Turbine Blade<br />

Composite Fabrication, G. C. Jacob, B. Hoevel, H. Q. Pham, M. L. Dettloff,<br />

N. E. Verghese, R. H. Turakhia, G. Hunter, Dow Chemical Co., Freeport,<br />

TX; J. F. Mandell, D. D. Samborsky, Montana State University, Bozeman, MT<br />

Room 209B<br />

Tooling Advancements<br />

Session Chairs: Carl Fiegenbaum and Jeff Priest, Spirit AeroSystems Inc.<br />

3:25 PM<br />

Rapid Manufacturing of Large Master Models and High Temperature<br />

Resistant Tools, W. L. Miller, P. D. Christou, D. Howland, Huntsman<br />

Advanced Materials, The Woodlands, TX<br />

3:50 PM – 1 st Place Winner<br />

900°F Glass Transition Temperature Material for Structural<br />

Composites and High Temperature Composite Tooling<br />

Applications, J. E. Lincoln, Z. McHale, R. J. Jurek, S. L. Hout, D.<br />

B. Curliss, Performance Polymer Solutions Inc., Moraine, OH<br />

4:15 PM<br />

Machining, Bonding, Sealing, and Venting of Carbon Foam for<br />

Production Tooling, D. M. Kaschak, R. Shao, G. D. Shives, A. J. Francis,<br />

GrafTech International, Parma, OH<br />

4:40 PM<br />

Nanocomposite Mold Fabrications and Applications, K. Han, B.<br />

Rice, J. Hickey, T. Glenchur, D. Johnson, J. Hartings, University of Dayton<br />

Research Institute, Dayton, OH<br />

Room 204<br />

Ballistic Composites<br />

Session Chair: John F. Osterndorf, USA, RDECOM-ARDEC<br />

3:25 PM<br />

Low and Medium Speed Multi-axial Impact Responses of Fiber<br />

Reinforced Thermoplastic and Thermoset Composites, B. Chen, O.<br />

Kizhner, O. Chainani, J. Chung, Frontier Performance Polymers Corporation,<br />

Dover, NJ; T. Woo, L. Moy, J. Osterndorf, D. Prillaman, US Army, RDECOM-<br />

ARDEC; R. Basavaraju, US Army, TARDEC; J. Song, US Army, NSRDEC; B.<br />

Liaw, F. Delale, City College of New York, New York, NY<br />

3:50 PM<br />

The Ballistic Impact Resistance of Polypropylene Composites,<br />

R. Roylance, T. Godfrey, E. Welsh, US Army Natick Soldier Research<br />

Development & Engineering Center, Natick, MA<br />

Room 204<br />

Automated Tape Placement/Automated Fiber Placement<br />

Session Chair: Brice Johnson, Boeing Phantom Works<br />

4:15 PM<br />

Machine-Independent Automated Fiber Placement Programming<br />

and Simulation, J. Schule, CGTech, Irvine, CA<br />

4:40 PM<br />

Tow Steered CFRP Aircraft Parts – Preforming and Mechanical<br />

Properties, K. Hazra, K. Potter, M. Wisnom, ACCIS, University of Bristol,<br />

Bristol, UK<br />

5:00 – 6:00 PM Upper Gallery<br />

Welcome Reception<br />

Join us for the Welcome Reception, an excellent place to network<br />

with new and existing colleagues and business partners.<br />

www.sampe.org 11

Wednesday, October 21<br />

8:00 – 9:00 AM • Room 209A<br />

SAMPE Keynote Presentation<br />

Materials and Processing & Manufacturing<br />

Technology: A Rich History and Promising Future<br />

Presenter: Persis A. Elwood - Division Chief,<br />

Materials & Manufacturing Directorate, WPAFB<br />

As the world has gotten flatter, the defense industry has gotten<br />

smaller. Globalization and decreased demand have impacted many<br />

industries that supply the Air Force and DoD. There is also increased<br />

competition for critical commodities – energy and specialty metals,<br />

for example. Internal to the Air Force the two communities, materials<br />

and processing and manufacturing technology, have shared a very<br />

productive relationship. The communities share the same customer<br />

base, and the breadth of products and disciplines are the same.<br />

We are different links in the same chain. In order for materials and<br />

processing to deliver to their potential, it is essential that manufacturing<br />

readiness be considered earlier than ever before in the development<br />

cycle. By partnering more effectively we can help ensure scale up and<br />

timely transition of new capabilities.<br />

9:00 AM • Room 206<br />

Panel: Commercializing Composites: The Outlook for High-<br />

Volume, Sustainable Material Applications<br />

Moderator: Sara Black - Technical Editor, Gardner Publications, CompositesWorld<br />

The focus of this panel will be successful real-world, non-aerospace<br />

applications of composite materials. While the composites industry<br />

has been challenged by the design and manufacturing demands of<br />

lucrative, high-volume markets, the barriers are starting to break<br />

down — particularly as alternative energy sources, infrastructure<br />

upgrades, and new industrial technologies begin to shape policy<br />

decisions. Panelists will address application areas including wind<br />

energy, offshore oil exploration and production, infrastructure,<br />

pressure vessels for fuel and compressed gas storage, automotive<br />

components and composite design. They will describe how composite<br />

materials, processing and design concepts are being used in specific<br />

market areas, in innovative ways — and how the material or process<br />

or design approach is helping to facilitate composites’ growth, in light<br />

of the current difficult economy.<br />

Panelists:<br />

• Dr. Vistaph Karbhari, University of Alabama, Huntsville<br />

• Paul Oldroyd, Bell Helicopter Textron<br />

• James Patterson, HyPerComp Engineering<br />

• Chris Red, Composite Market Reports<br />

• Andrew Rich, Plasan Carbon Composites<br />

• Thomas Royle, Gurit<br />

Visit our 120+ exhibitors in the<br />

Century II Convention Hall!<br />

Tuesday 10:00 AM - 4:00 PM<br />

Wednesday 10:00 AM - 4:00 PM<br />

Technical Program<br />

Room 209B<br />

Technologies to Assist Composite Manufacturers I<br />

Session Chairs: Jim Leslie, ACPT Inc.; Linda Clements, C&C Innovation<br />

Strategies Inc.<br />

9:00 AM<br />

Technology Gained from Composite Development Programs, J. C.<br />

Leslie, Advanced Composite Products & Technology, Huntington Beach,<br />

CA<br />

9:25 AM<br />

New Low/No VOC Coating Technologies for Composite<br />

Applications, M. O. Wells, K. A. Wood, S. Lacock, Arkema Inc., King<br />

of Prussia, PA<br />

9:50 AM<br />

Nano-fiber Reinforced Enhancements in Composite Polymer<br />

Matrices, C. Chamis, NASA Glenn Research Center, Cleveland, OH<br />

10:15 AM<br />

Specialty Building Blocks for Composites: An Overview, K. Shah,<br />

Evonik Jayhawk Fine Chemicals Corporation, Galena, KS; T.-P. Sauer,<br />

Evonik Degussa GmbH, Marl, Germany<br />

11:00 AM<br />

Developing Breakdown Tooling from Initial Concept Stage Through<br />

Final Production, R. Starck, Paragon D&E, Grand Rapids, MI<br />

11:25 AM<br />

Cleaning for Effective Coating of Composites, B. Kanegsberg, E.<br />

Kanegsberg, BFK Solutions LLC, Pacific Palisades, CA<br />

11:50 AM<br />

Tooling for Composite Materials: Problems and Solutions, L. L.<br />

Clements, J. L. Crowley, C&C Innovation Strategies Inc., Dayton, NV<br />

Room 208<br />

Testing & Qualification of Materials<br />

Session Chairs: Beth Clarkson, NASA National Center for Advanced Materials<br />

Performance<br />

9:00 AM<br />

Multivariate Equivalence Testing for Composite Materials, E.<br />

Clarkson, National Institute for Aviation Research, Wichita, KS<br />

9:25 AM<br />

Evaluation of Cubic Specimens for Compression Testing at Different<br />

Strain Rates, J.F. Acosta, K. S. Raju, Wichita State University, Wichita,<br />

KS<br />

9:50 AM<br />

Mechanical Behavior of Woven Thermoplastic Composites Under<br />

Varying Strain Rates, U. Sharma, G. Reyes, University of Michigan-<br />

Dearborn, Dearborn, MI<br />

10:15 AM<br />

Modified Coefficient of Variation Approach to set Basis Values for<br />

Newly Developed Composite Materials, E. Clarkson, Y. Ng, Wichita<br />

State University, Wichita, KS<br />

11:00 AM<br />

Impact Strength of Hybrid Fiber-Reinforced Polymers at Cryogenic<br />

Temperatures, M. Lambert, E. A. Clark, T. H. Fronk, Utah State University,<br />

Logan, UT; J. Noorda, HyPerComp Engineering Inc., Brigham City, UT<br />

11:25 AM<br />

Representing Viscoelastic Response of a Curing Laminate, M. Stover,<br />

B. Kelpine, AvPro Inc., Norman, OK<br />

12 SAMPE Fall Tech Conference & Exhibits–Wichita, KS

Wednesday, October 21<br />

11:50 AM<br />

Simple Destructive Test Methodology to Determine the Mechanical<br />

Bond Strength of Coatings on Ceramic Fibers, J. Lincoln, R. J. Jurek,<br />

D. B. Curliss, M. Grigsby, M. Napoli, Performance Polymer Solutions Inc.,<br />

Moraine, OH; M. Rich, L. T. Drzal, B. Rook, Michigan State University, East<br />

Lansing, MI<br />

Room 204<br />

Nanocomposites and Multifunctional Materials<br />

Session Chair: Bob Minaie, Wichita State University<br />

9:00 AM<br />

Multifunctional Carbon Fiber Epoxy-matrix Composites for Energy<br />

Harvesting, S. Han, S. Wang, D. D. L. Chung, State University of New<br />

York, Buffalo, NY<br />

9:25 AM<br />

Nanotube Buckypaper Composite Actuators for Morphing Structure<br />

Applications, S.-Y. Tsai, I.-W. Chen, Z. Liang, B. Wang, C. Zhang, FAMU-<br />

FSU College of Engineering, Tallahassee, FL; S. Walsh, Army Research<br />

Laboratory (ARL), Aberdeen Proving Ground, MD<br />

9:50 AM<br />

Thermoplastic Polyurethane Elastomer-Clay and -Carbon Nanofiber<br />

Nanocomposites: Flammability Studies, J. H. Koo, K. C. Nguyen, J. C.<br />

Lee, W. K. Ho, M. C. Bruns, O. A. Ezekoye, University of Texas at Austin,<br />

Austin, TX<br />

10:15 AM<br />

Influence of Nanoparticles on the Thermal and Mechanical Properties<br />

of PMR-15 and Candidate Replacement Resins, S. G. Miller, NASA<br />

Glenn Research Center, Cleveland, OH; P. Heimann, Ohio Aerospace<br />

Institute, Cleveland, OH; M. Maryanski, University of Akron, Akron, OH; J.<br />

Bauer, University of Michigan, Ann Arbor, MI<br />

11:00 AM<br />

Dispersion Optimization of Exfoliated Graphite Nanoplatelets in<br />

Polyetherimide Nanocomposites: Extrusion vs Precoating vs Solid<br />

State Ball Milling, H. Wu, B. Rook, L. T. Drzal, Michigan State University,<br />

Lansing, MI<br />

11:25 AM<br />

Multifunctional Exfoliated Graphite Nanoplatelets/High Density<br />

Polyethylene Nanocomposites, X. Jiang, L. T. Drzal, Michigan State<br />

University, Lansing, MI<br />

11:50 AM<br />

Composite Films Prepared by Deposition of Manganese Dioxide<br />

and Polypyrrole on In-Situ Grown Carbon Nanotubes for<br />

Supercapacitors, L. Li, K. Lafdi, University of Dayton Research Institute,<br />

Dayton, OH<br />

Room 205<br />

Composite Foams<br />

Session Chairs: David Kaschak, Graftech; James Klett, Oak Ridge National<br />

Laboratory; and Ed Semmes, Consultant<br />

9:00 AM<br />

Flexible Molded Polyurethane Foams with Clay and Silica Nano-<br />

Fillers, I. Javni, K. Song, J. Lin, Z. S. Petrovic, Kansas Polymer Research<br />

Center, Pittsburg State University, Pittsburg, KS<br />

9:25 AM<br />

Graphite Foam Performance in Heat Exchanger Applications, P. G.<br />

Stansberry, E. Pancost, Y. Xiong, J. Norley, GrafTech International Holdings<br />

Inc., Parma, OH<br />

9:50 AM<br />

Tensile Strength of Aluminum Foam-Polypropylene Interpenetrating<br />

Phase Composites, J. Hadley, N. Rayess, N. Dukhan, University of Detroit<br />

Mercy, Detroit, MI; D. Q. Houston, Ford Motor Company, Dearborn, MI<br />

10:15 AM<br />

Coal Derivatives for Sprayable Carbon Foams, E. B. Kennel, M. E.<br />

Heavner, M. Mukka, O. A. Olajide, C. Prasad, P. Subramanian, A. H.<br />

Stiller, West Virginia University, Morgantown, WV<br />

Room 207<br />

Epoxy Resin Technology III<br />

Session Chairs: Axel Böettcher, Boettcher Consult; Jeff Wiggins, University of<br />

Southern Mississippi; and Volker Altstädt, Universitaet Bayreuth<br />

9:00 AM<br />

A Nanoscale Investigation of Epoxy Resin Nodule Development, C.<br />

Sahagun, S. Morgan, University of Southern Mississippi, Hattiesburg, MS<br />

9:25 AM<br />

Fast Composite Production with Reactive Epoxy Resins, M. Döring,<br />

U. Arnold, A. Schmidt, Karlsruhe Research Center, Baden-Wuerttemberg,<br />

Germany<br />

9:50 AM<br />

Aspects of High-volume Series Production with High Performance<br />

Fibre-reinforced Plastics, V. Altstädt, J. Krämer, B. Uwe, University of<br />

Bayreuth, Bayreuth, Germany<br />

11:00 AM • Room 205<br />

Featured Lecture - Metal Composite Hybrid<br />

Materials and Products<br />

Lecturer: Jim Stevenson - Corporate Composite Fellow,<br />

Honeywell Aerospace<br />

Technical Program<br />

A hybrid metal-composite structure has the<br />

potential advantages of combining the best properties of metals<br />

and composite materials–synergies that can lead to exceptional<br />

performance–along with the challenges of interfacing these dissimilar<br />

materials. This talk will examine the rationale for hybrids and several<br />

applications: fiber metal laminates and 3D structures including turbine<br />

blades, flow control valves, structural housings, avionics chassis and<br />

molten metal bonded links.<br />

Room 207<br />

Bio-, Natural and Innovative Materials I<br />

Session Chairs: Borys Schafran, Evonik Degussa Corporation; and Warren<br />

Hatfield, Hawker Beechcraft<br />

11:00 AM<br />

New Bio-based Polyurethane Resins for Composites and Polymeric<br />

Concrete, I. Javni, M. Ionescu, D. P. Hong, Z. S. Petrovic, Pittsburg State<br />

University, KPRC, Pittsburg, KS<br />

11:25 AM<br />

Novel Monomer Process for Parylene Coating Applications, C. Lee,<br />

A. Kumar, Dielectric Systems Inc., Fremont, CA; M. Capalongan, Stratamet<br />

Inc., Fremont, CA<br />

11:50 AM<br />

Structure-Properties Relationship of Polyimides Derived from<br />

Different Composition of Diamines and Dianhydrides, Q. Luo, N. Bilic,<br />

Z. Petrovic, Kansas Polymer Research Center, Pittsburg State University,<br />

Pittsburg, KS<br />

www.sampe.org 13

Wednesday, October 21<br />

1:15 – 2:55 PM Room 206<br />

Panel: Design and Analysis Tool Demonstration<br />

Moderator: DeWayne Howell, President, Peak Composites Inc.<br />

Every trade has its tools. Carpenters use hammer and saw, painters the<br />

brush and roller, and plumbers the wrench and torch. As engineers in<br />

the field of composites, we also require tools to do our job. In particular,<br />

we rely on our software tools to help us analyze laminates, process<br />

materials, and design structures. It would be quite a benefit if there<br />

were one place you could go to see a variety of these software tools<br />

in action and have a chance to compare them versus your specific<br />

needs. Panelists will present their respective software packages for<br />

you to review and give you the opportunity to get your questions<br />

answered by the experts.<br />

Panelists:<br />

• Craig Collier, Collier Research Corporation<br />

• John Tierney, University of Delaware Center for Composite Materials<br />

• Jason Gies and Dr. Ray Fertig, Firehole Technologies Inc.<br />

• Dr. Sungk Ha, Think Composites<br />

• DeWayne Howell, Peak Composites Inc.<br />

Room 208<br />

Core & Sandwich Materials<br />

Session Chair: Abhishek K. Singh, Crosslink<br />

1:40 PM<br />

Mechanical Properties of Laser-Welded Grade 9 Titanium<br />

Honeycomb Core, G. Jones, Benecor Incorporated, Wichita, KS<br />

2:05 PM<br />

Electrically Conductive Hollow Carbon Microspheres in a Polymer<br />

Matrix, C. Walls, A. Simpson, BAM Inc., Knoxville, TN<br />

2:30 PM<br />

Interfacial Fracture Properties of Novel Carbon Foam Sandwich Structures,<br />

S. Rangaraj, G. Reyes, University of Michigan Dearborn, Dearborn, MI<br />

3:25 PM<br />

Effect of Core Shear Modulus on the Transmission Loss of Composite<br />

Honeycomb Panels, T. Wang, J. Maxon, D. Hornick, A. Foose, J. Fila,<br />

Gulfstream Aerospace Corporation, Savannah, GA<br />

3:50 PM<br />

Mechanical Properties of Sandwich Composites from Recycled Tires,<br />

A. Bhadra, G. Pandey, R. Vaidyanathan, R. P. Singh, Oklahoma State<br />

University, Stillwater, OK<br />

Room 204<br />

Nanofiber Technology, Uses<br />

Session Chair: Frank Ko, University of British Columbia<br />

Technical Program<br />

1:40 PM<br />

Recent Progress in Carbon Nanotube Fibers and Yarns, F. Ko, Y.<br />

Wan, AMPEL, The University of British Columbia, Vancouver, Canada<br />

2:05 PM<br />

Nanoclay Reinforced Flax Nanocomposite by Electrospinning, C. Wang,<br />

F. K. Ko, M. Alcock, The University of British Columbia, Vancouver, Canada<br />

2:30 PM<br />

Manufacturing Neat SWCNT Fibers from Reduced SWCNT in DMSO,<br />

J. Guan, L. Tay, B. Simard, National Research of Canada, Ottawa, Canada<br />

3:25 PM<br />

Superhydrophobic Behavior of Electrospun Micro and Nanofibers,<br />

M. Ceylan, R. Asmatulu, W. Khan, Wichita State University, Wichita, KS;<br />

N. Nuraje, Massachusetts Institute of Technology, Cambridge, MA<br />

3:50 PM<br />

Properties of Recycled PVC and PS Nanocomposite Fibers at Various<br />

NiZn Ferrite Loadings, R. Asmatulu, V. Dandin, W. Khan, Wichita State<br />

University, Wichita, KS<br />

Room 207<br />

Bio-, Natural and Innovative Materials II<br />

Session Chairs: Borys Schafran, Evonik Degussa Corporation; and Warren<br />

Hatfield, Hawker Beechcraft<br />

1:40 PM<br />

Chopped Prepregs - A Compelling Performance and Cost Alternative<br />

Material Form, J. D. Fudge, Blackbird Composites, San Ramon, CA<br />

2:05 PM<br />

Biobased Adhesives for Wood and Metal, A. Zlatanic, Z. S. Petrovic,<br />

Kansas Polymer Research Center, Pittsburg, KS<br />

2:30 PM<br />

Examination of a Low Temperature Paste Adhesive as an Alternative<br />

to Film Adhesives for Process Cost Reduction, D. Klapprott, Henkel<br />

Aerospace, Bay Point, CA<br />

3:25 PM<br />

Vegetable Oil Based Epoxy Resins, D. P. Hong, I. Javni, Z. S. Petrovic,<br />

Pittsburg State University, KPRC, Pittsburg, KS<br />

3:50 PM<br />

Creep Friction of Neoprene on Graphite Epoxy, S. J. Mills, United<br />

Launch Alliance, Trinity, AL<br />

4:15 PM<br />

Thermal and Mechanical Studies of Wood Flour Reinforced<br />

Polyurethane Composites, G. T. Strawder, M. V. Hosur, S. Jeelani, Y.<br />

Zhou, Tuskegee University, Tuskegee, AL<br />

Coffee Breaks - Sponsored by<br />

Tuesday and Wednesday<br />

10:40 – 11:00 AM and 2:55 – 3:25 PM<br />

Complimentary coffee will be available in the exhibition hall.<br />

Room 209B<br />

Technologies to Assist Composite Manufacturers II<br />

Session Chairs: Jim Leslie, ACPT Inc; Linda Clements, C&C Innovation<br />

Strategies Inc.<br />

1:40 PM<br />

A Comparison of the Environmental Attributes of Thermoplastic vs. Thermoset<br />

Composites, M. Favaloro, Ticona Engineering Polymers, Amesbury, MA<br />

2:05 PM<br />

The Basics of Materials Engineering, S. Peters, Process Research,<br />

Mountain View, CA<br />

2:30 PM<br />

Performance of New Repair Adhesives in State-of-Art Structural<br />

Composite Repairs, S. Lehmann, O. Lammerschop, Henkel Corporation,<br />

Bay Point, CA<br />

14 SAMPE Fall Tech Conference & Exhibits–Wichita, KS

Wednesday, October 21<br />

Room 205<br />

Infusion Technology - Applications<br />

Session Chair: Dirk Heider, University of Delaware<br />

1:40 PM<br />

A New Empirical Approach to Predict Microcracking in Composites<br />

– Resin and Fiber Preform Effects, Y. Yoon, X. Fang, W. W. Lin, GE<br />

Global Research, Niskayuna, NY; J. A. Woods, The Boeing Company,<br />

Seattle, WA<br />

2:05 PM<br />

Design and Fabrication of VARTM Fabricated Skin Panels with<br />

Integrated Hollow Stiffeners, D. Heider, P. Schulze, J. Tierney, J. W.<br />

Gillespie, Jr., University of Delaware, Newark, DE<br />

2:30 PM<br />

Cost Effective Production and Lightweight Transportation Frames<br />

Made in Tri Dimensional Composite Materials, J. Verhaeghe, G.<br />

Nouwen, J. Kustermans, Acrosoma NV, Lokeren, Belgium<br />

3:25 – 5:00 PM Room 206<br />

Panel: Technologies to Assist Composite Manufacturers<br />

Moderator: Linda Clements - Chief Executive Officer, C&C Innovation<br />

Strategies<br />

Many exciting technologies have emerged in recent years that may<br />

be of significant assistance in the manufacturing of composites.<br />

Unfortunately, in many cases a manufacturer with a problem now<br />

either does not have access to details of these technologies or finds<br />

that they are not yet ready for practical application. This panel of<br />

experts is here to address your questions about manufacturing with<br />

practical solutions.<br />

Panelists:<br />

•Dr. Jim Leslie, ACPT Inc.<br />

•Louis Dorworth, Abaris Training Inc.<br />

•Dr. Frances Abrams, US Air Force Research Laboratory<br />

•Dr. Tracy Colwell, Lockheed Martin Space Systems<br />

Room 205<br />

Infusion Technology - Resins/Preforms<br />

Session Chair: Dirk Heider, University of Delaware<br />

3:25 PM<br />

High Service Temperature Polymer Matrix Composite Process<br />

Development, C. Homrighausen, A. Mereness, Eltron Research &<br />

Development Inc., Boulder, CO<br />

3:50 PM<br />

Chopped Carbon Fiber Airplane Propeller Spinner, M. Janney,<br />

E. Geiger, Jr., T. Gunder, N. Baitcher, R. Johnson, Materials Innovation<br />

Technologies LLC, Fletcher, NC<br />

4:15 PM<br />

Continuous Process Chain for Robot Stitched Preforms, J. Filsinger,<br />

EADS Deutschland GmbH, Munich, Germany<br />

4:40 PM<br />

Cost-efficient Preforming Process for Complex High-performance<br />

Fibre-reinforced Composites: Mechanical Properties, U. Beier, J.<br />

K. W. Sandler, V. Altstädt, Polymer Engineering, University of Bayreuth,<br />

Bayreuth, Germany; H. Spanner, C. Weimer, Eurocopter Deutschland<br />

GmbH, Munich, Germany<br />

SAMPE Technical Communities Meeting<br />

Join us on Wednesday, October 21, 2009 from 4:30 – 5:30 PM in<br />

the Chisholm Room at the Hyatt Regency Hotel. Discuss ways SAMPE’s<br />

Technical Communities can work better for you.<br />

Room 209B<br />

Building Blocks to Advanced Materials Applications<br />

Session Chair: Michael Knight, Teijin Aramid USA<br />

3:25 PM<br />

Prosthetics and Orthotics Manufacturing Initiative (POMI): Composite<br />

Socket Testing and Novel Design and Fabrication Paradigm, C. W.<br />

Norfolk, J. Osborn, SCRA / ARDI, Anderson, SC<br />

3:50 PM<br />

Toxicity of Nanomaterials and Recent Developments in Protection<br />

Methods, R. Asmatulu, E. Asmatulu, A. Yourdkhani, Wichita State<br />

University, Wichita, KS<br />

4:15 PM<br />

Increasing the Efficiency of Pharmaceutical Drugs for Magnetic<br />

Targeted Drug Delivery, H.L. Wamocha, R. Asmatulu, M. M. El-Tabey,<br />

H. Misak, J. S. Gopu, B. Cooper, J. Ho, and H. H. Hamdeh, Wichita State<br />

University, Wichita, KS<br />

4:40 PM<br />

ImpacGard® for Long Lasting Protection in Transportation<br />

Applications, M. Kubota, J. W. Long, Kubota Research Associates Inc.,<br />

Hockessin, DE; S. Yarlagadda, University of Delaware, Newark, DE<br />

6:00 - 8:00 PM Hyatt Regency Hotel, Eagle Ballroom<br />

SAMPE’s Night on the Kansas Prairie<br />

Prepare for a “genuine, honest-to-goodness, sky’s the limit, good<br />

time” at our “Kansas Saloon”.<br />

Join us for food, fun and entertainment. The fun begins on Wednesday<br />

from 6:00 – 8:00 PM at the Hyatt Regency’s Eagle Ballroom.<br />

Tickets are included with a full-package registration. Additional<br />

tickets can be purchased for $55 at the Additional Purchases Counter<br />

in the SAMPE Registration Area.<br />

Producer of high quality,<br />

affordable<br />

carbon nanofibers.<br />

Pyrograf Products, Inc.<br />

Cedarville, Ohio<br />

937-766-2020 x139 • dburton@apsci.com<br />

www.pyrografproducts.com<br />

See us in booth 1003<br />

Technical Program<br />

www.sampe.org 15

Thursday, October 22<br />

8:15 – 8:45 AM • Room 205<br />

Featured Lecture - Acoustic Emission (AE)<br />

Offers New Horizons for Composites<br />

Lecturer: Adrian Pollock - Principal Scientist,<br />

Mistras Group<br />

Acoustic emission (AE) is an excellent tool for<br />

detecting damage in composites at the moment it is occurring. AE<br />

testing can also be used to recognize the presence of pre-existing<br />

damage. It can be used to locate the sites where damage is developing<br />

early in the fatigue life of a structure; and near the end of the structure’s<br />

life, it can be used to give a direct warning of incipient failure. As a<br />

nondestructive testing method, AE works even better on composites<br />

than on metals, because composites are more generous in their<br />

emitting properties. Applications include fatigue testing of prototypes<br />

(to prevent premature failure), routine maintenance inspection (of<br />

bucket trucks, for example), and materials characterization.<br />

This presentation will discuss these capabilities, give examples to show<br />

what can be done with AE today, review the technical elements that<br />

must be in place for successful AE testing, and indicate directions for<br />

future growth. The horizons of material technology can indeed be<br />

expanded by the use of this method.<br />

8:45 AM – 3:00 PM • Room 208<br />

AFOSR Workshop: Multiscale Modeling for Polymer Matrix<br />

Composites<br />

Moderator: Charles Lee, Program Manager, AFOSR and Tia Benson-Tolle,<br />

Air Force Research Laboratory/Materials and Manufacturing Directorate<br />

This panel/workshop is focused on one of the many links in the<br />

multiscale modeling of Fiber Reinforced Composites, specifically<br />

between the molecular scale modeling and the micromechanics scale<br />

modeling. Efforts to directly link these two scales are needed to make a<br />

rudimentary prediction of composite structure behaviors based on the<br />

consituent’s properties. A direct linkage between these two scales will<br />

lead to better prediction of new resin chemistry on the performance<br />

of the composite structures. This linkage can also lead to prediction of<br />

cure cycle effects and chemical aging effects on the properties of the<br />

composite structures.<br />

Panel members are drawn from researchers who are in the<br />

micromechanics and molecular scale modeling areas that are offering<br />

potential possibilities for this linkage.<br />

Panelists:<br />

8:45 AM – Charles Lee, AFOSR<br />

9:00 AM – Steve Christensen, Boeing<br />

9:25 AM – Jon Gosse, Boeing<br />

9:50 AM – Sung Ha, HanHang University and Prof. Steve Tsai, Stanford<br />

University<br />

10:15 AM – Tom Clancy, National Inst of Aerospace Associates<br />

11:00 AM – Rajev Berry, Materials Laboratory<br />

11:25 AM – Prof. Reinhold Daustadkt, Stanford University<br />

11:50 AM – Ray Fertig , Firehole Technologies Inc.<br />

1:45 PM – Soumya Patniak, AFRL/RX<br />

2:10 PM – Greg Odegard, Michigan Tech University<br />

2:35 PM – Kishore Pochiraju, Stevens Institute<br />

Room 205<br />

Nano and Conductivity/EMI<br />

Session Chair: Nate Hansen, Conductive Composites Company<br />

9:00 AM<br />

ITAR<br />

9:25 AM<br />

ITAR<br />

Technical Program<br />

Lightweight Highly Effective Shielding Veil for Conductive<br />

Composites, G. Hansen, N. Hansen, Conductive Composites<br />

Company, Midway, UT<br />

Electromagnetically Shielding Spray Paints Using<br />

Commercial-off-the-Shelf Polymer Systems, G. Hansen, N.<br />

Hansen, Conductive Composites Company, Midway, UT<br />

9:50 AM<br />

Highly Electrical Conductive Multi-walled Carbon Nanotube/BMI<br />

Composites, Q. Cheng, J. G. Park, J. Bao, Z. Liang, C. Zhang, B. Wang,<br />

FAMU-FSU College of Engineering, Tallahassee, FL<br />

10:15 AM<br />

Eliminating Tradeoffs in Conductive Composites via Novel<br />

Heterogeneous Structures, T. Fornes, N.D. Huffman, S.B. Carruthers,<br />

LORD Corporation, Cary, NC<br />

11:00 AM<br />

Electrically-conductive Skins for Morphing UAVs, E. S. Handy, GVD<br />

Corporation, Cambridge, MA; T. Sanderson, Raytheon Missile Systems,<br />

Tucson, AZ; R. Justice, Air Force Research Laboratory, Wright-Patterson<br />

AFB, OH<br />

11:25 AM<br />

Integrated EMI Coatings for Composites Through Engineered Use of<br />

Nanofillers, A. Morgan, T. J. Stonecash, J. L. Pierce, University of Dayton<br />

Research Institute, Dayton, OH<br />

11:50 AM<br />

Preparation of Hollow Metallic Fibers for Electromagnetic Wave<br />

Absorbing Materials, J. Woo Yi, S. Bok Lee, J. Bong Kim, S. Kwan Lee, K.<br />

Yeon, Park, Korea Advanced Institute of Science and Technology, Daejeon,<br />

Korea; M. Keun Yoon, South Dakota School of Mines & Technology, Rapid<br />

City, SD<br />

Room 204<br />

Nano-Enhanced Resins for Aerospace Applications I<br />

Session Chair: Ming C. Liu, Spirit AeroSystems Inc.<br />

9:00 AM<br />

Carbon Nanotube Enhanced Composite Materials, W. Wang,<br />

F. Meyer, Y. Wang, G. Miller, S. Potluri, Zyvex Performance Materials,<br />

Columbus, OH<br />

9:25 AM<br />

Development of Boron Cage Compound Nanocomposite Elastomers,<br />

M. F. Hawthorne, M. W. Lee, Jr., University of Missouri–Columbia<br />

International Institute of Nano and Molecular Medicine, University of<br />

Missouri – Columbia, Columbia, MO; D. E. Bowen III, E. A. Eastwood,<br />

National Nuclear Security Administration’s Kansas City Plant Honeywell<br />

Federal Manufacturing & Technologies, Kansas City, MO<br />

9:50 AM<br />

Development of Epoxy and Urethane Boron Cage Compound<br />

Nanocomposites, M. F. Hawthorne, M. W. Lee, Jr., University of<br />

Missouri–Columbia International Institute of Nano and Molecular Medicine,<br />

University of Missouri – Columbia, Columbia, MO; E. A. Eastwood, D. E.<br />

Bowen III, National Nuclear Security Administration’s Kansas City Plant<br />

Honeywell Federal Manufacturing & Technologies, Kansas City, MO<br />

16 SAMPE Fall Tech Conference & Exhibits–Wichita, KS

Thursday, October 22<br />

10:15 AM<br />

Carbon Nanofibers Toughened AS-4/EPON862 Prepreg and its<br />

Laminate Properties, K.-T. Hsiao, J. Ryals, University of South Alabama,<br />

Mobile, AL; P. H. Wu, M. C. Liu, Chief Scientist Office, Spirit AeroSystems<br />

Inc., Wichita, KS<br />

11:00 AM<br />

Nano-scale Resin Modifications in Fiberglass Laminates Containing<br />

Ply Drops, S. L. Donaldson, University of Dayton, Dayton, OH; T. J.<br />

Stonecash, S. Sihn, University of Dayton Research Institute, Dayton, OH<br />

11:25 AM<br />

Dispersion of Short and Long Nanotubes Using Microfluidic Method<br />

for Composite Applications, Y. Tian, C. Zeng, Z. Liang, C. Zhang, B.<br />

Wang, FAMU-FSU College of Engineering, Tallahassee, FL<br />

11:50 AM<br />

Shape Memory Polymer Nanocomposites with Carbon Nanofiber<br />

Paper, H. Lu, Y. Tang, E. Chew, J. Gou, University of Central Florida,<br />

Orlando, FL; H. Lu, J. Leng, S. Du, Harbin Institute of Technology, Harbin,<br />

China<br />

Room 207<br />

High Temperature Resins & Composites I<br />

Session Chair: Kenny Johnson, Air Force Research Laboratory<br />

9:00 AM<br />

ITAR<br />

9:25 AM<br />

ITAR<br />

Thermal Oxidative Barrier Coating for Polymer Matrix<br />

Composites, T. Bullions, W. Ronk, GE Aviation, Cincinnati, OH<br />

Improving the Manufacturability and Durability of Thick<br />

Polyimide Matrix Composites, J. Lincoln, S. Hout, D. B. Curliss,<br />

Performance Polymer Solutions Inc., Moraine, OH<br />

9:50 AM<br />

High Temperature Structural Adhesives for Wide Area Bonding<br />

Applications, J. Lincoln, A. Javorina, D. B. Curliss, Performance Polymer<br />

Solutions Inc., Moraine, OH<br />

10:15 AM<br />

ITAR<br />

11:00 AM<br />

ITAR<br />

11:25 AM<br />

ITAR<br />

Moisture Effects on Silicon Carbide-reinforced Imide Matrix<br />

Composites with High-temperature Finishes, R. E. Allred, J.-<br />

M. Gosau, J. P. Barlow, H. Wang, Adherent Technologies Inc.,<br />

Albuquerque, NM<br />

Effect of Stacking Sequence on Oxidation Behavior of<br />

Polymeric Matrix Composites, G. Tandon, University of Dayton<br />

Research Institute, Dayton, OH; K. V. Pochiraju, Stevens Institute of<br />

Technology, Hoboken, NJ; R. B. Hall, Materials and Manufacturing<br />

Directorate, Air Force Research Laboratory, WPAFB, OH<br />

Alternate Monomer Suppliers for AFR-PE-4, J. Magato, R. A.<br />

Gray, Maverick Corporation, Blue Ash, OH<br />

11:50 AM<br />

Compimide® P500: A New Bismaleimide Powder for Advanced<br />

Composites, S. Evsyukov, B. Kramer, T. Pohlmann, H. D. Stenzenberger,<br />

Evonik Technochemie GmbH, Dossenheim, Germany<br />

Room 206<br />

Lightening Strike Protection<br />

Session Chair: Yulia Kostogorova-Beller, National Institute for Aviation Research<br />

9:00 AM<br />

ITAR<br />

Carbon Nanomembrane for Lightning Strike Protection, J.<br />

Ravine, NanoTechLabs Inc., Kettering, OH; R. Czerw, NanoTechLabs<br />

Inc., Yadkinville, NC; J. Schultz, National Composite Center,<br />

Kettering, OH<br />

9:25 AM<br />

Damage Response of Carbon/Epoxy Composite Plates Subjected<br />

to Mechanical Impact and Simulated Lightning Strike, P. Feraboli, H.<br />

Kawakami, University of Washington, Seattle, WA<br />

9:50 AM<br />

Hole Protection with Expanded Grommets in Carbon Fiber<br />

Reinforced Plastic, J. Ransom, M. Wehrmeister, D. Bakken, Fatigue<br />

Technology, Seattle, WA<br />

10:15 AM<br />

Carbon Nanofiber Paper for Lightning Strike Protection of<br />

Composite Materials via Hybrid Carbon Nanofiber Paper, F. Liang,<br />

Y. Tang, J. Gou, University of Central Florida, Orlando, FL; D. Firsich,<br />

Inorganic Specialists Inc., Miamisburg, OH; J. Fielding, Air Force Research<br />

Laboratory, Wright-Patterson Air Force Base, OH<br />

Room 209B<br />

Manufacturing with Nano-modified Composites<br />

Session Chair: Susan Robitaille, Renegade Materials Corp.<br />

Technical Program<br />

9:00 AM<br />

Field Emission Improvement of Carbon Nanotube Buckypaper by<br />

Laser Post-treatment, H. Y. Miao, Department of Electrical Engineering,<br />

Tunghai University, Taichung, Taiwan; Y. Chen, M. Zhang, R. Liang, C.<br />

Zhang, B. Wang, Florida State University, Tallahassee, FL; S. Walsh, Army<br />

Research Laboratory Aberdeen Proving Ground, MD<br />

9:25 AM<br />

The Distribution and Flow of Nickel Powder and Carbon Nanotubes<br />

Mixed in an Aluminum Matrix via Friction Stir Welding, H. E. Misak,<br />

C. A. Widener, D. A. Burford, R. Asmatulu, Wichita State University,<br />

Wichita, KS<br />

9:50 AM<br />

Novel Core Shell Rubber Particles for High Performance Thermosets,<br />

D. Sober, R. Nishimura, S. Walsh, Kaneka Texas Corp., Pasadena, TX<br />

10:15 AM<br />

Mechanical Characterization of Unidirectional Thermoplastic<br />

Nanocomposites, K. Narasimhan, S. Roy, The University of Alabama,<br />

Tuscaloosa, AL<br />

Thursday Breaks<br />

10:40 – 11:00 AM* and 3:25 – 3:35 PM<br />

*Complimentary coffee in the SAMPE Registration area<br />

sponsored by SAMPE Asia.<br />

19-20 January 2010 • Kuala Lumpur, Malaysia<br />

www.sampe.org 17

Thursday, October 22<br />

Room 206<br />

Infusion Technology - Processing Effects<br />

Session Chair: Dirk Heider, University of Delaware<br />

11:00 AM<br />

Pressure Behavior During Vacuum Assisted Processing (VAP), Ö.<br />

Eksik, TUBITAK Marmara Research Center, Material Institute, Kocaeli,<br />

Gebze, Turkey; S. Chandrabalan, Ö. Eksik, H. Deffor, P. Simacek, J. W.<br />

Gillespie, Jr., S. Advani, D. Heider, University of Delaware, Newark, DE<br />

11:25 AM<br />

Spring-In Prediction for Cylindrical Composite Specimens Manufactured<br />

with VARTM, K. Jin Teoh, K.-T. Hsiao, University of South Alabama,<br />

Mobile, AL<br />

11:50 AM<br />

Use of Controlled Radical Polymerization in Elevated Temperature<br />

Vacuum Infusion of Large Parts, M. O. Wells, A. Cocquyt, Arkema Inc.,<br />

King of Prussia, PA<br />

Room 209B<br />

Filament Winding and Pultrusion I<br />

Session Chairs: John Green, GSG Inc.; Anand Rau, Toray; and Clem Hiel,<br />

Composites Support and Solutions<br />

11:00 AM – 3 rd Place Winner<br />

Improvements in FEA of Composite Overwrapped Pressure<br />

Vessels, R. Willardson, eServ, a Perot Systems Company, Plano,<br />

TX; D. Gray, Dassault Systemes Simulia Corp., Lewisville, TX; T.<br />

Delay, NASA, MSFC, Huntsville, AL<br />

11:25 AM<br />

Mechanical Property Characterization and Finite Element Analysis<br />

of Pultruded I-beam, M. Saha, J. Anderson, University of Oklahoma,<br />

Norman, OK<br />

11:50 AM<br />

Polyurethane Resins for Pultrusion, R. A. Cageao, J. Hayes, C. Snyder,<br />