PCD2.H32.. MOTION CONTROL MODULES - SBC-support

PCD2.H32.. MOTION CONTROL MODULES - SBC-support

PCD2.H32.. MOTION CONTROL MODULES - SBC-support

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

PCD1<br />

PCD2<br />

xx7<br />

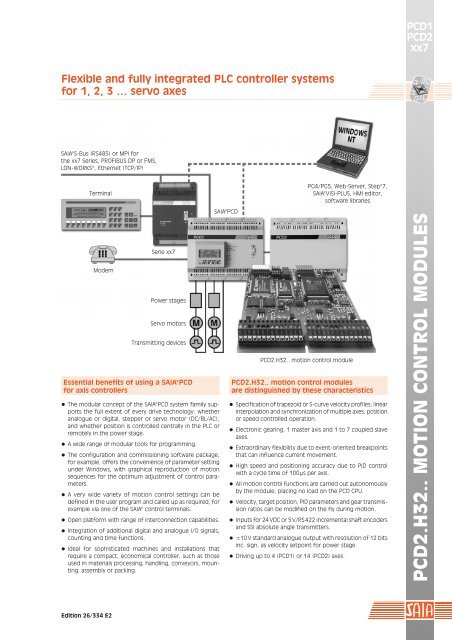

Flexible and fully integrated PLC controller systems<br />

for 1, 2, 3 … servo axes<br />

SAIA®S-Bus (RS485) or MPI for<br />

the xx7 Series, PROFIBUS DP or FMS,<br />

LON-WORKS®, Ethernet (TCP/IP)<br />

Terminal<br />

PG4/PG5, Web-Server, Step®7,<br />

SAIA®ViSi-PLUS, HMI editor,<br />

software libraries<br />

Modem<br />

Serie xx7<br />

Power stages<br />

Servo motors<br />

Transmitting devices<br />

Essential benefits of using a SAIA®PCD<br />

for axis controllers<br />

¬ The modular concept of the SAIA®PCD system family <strong>support</strong>s<br />

the full extent of every drive technology: whether<br />

analogue or digital, stepper or servo motor (DC/BL/AC),<br />

and whether position is controlled centrally in the PLC or<br />

remotely in the power stage.<br />

¬ A wide range of modular tools for programming.<br />

¬ The configuration and commissioning software package,<br />

for example, offers the convenience of parameter setting<br />

under Windows, with graphical reproduction of motion<br />

sequences for the optimum adjustment of control parameters.<br />

¬ A very wide variety of motion control settings can be<br />

defined in the user program and called up as required, for<br />

example via one of the SAIA® control terminals.<br />

¬ Open platform with range of interconnection capa bilities.<br />

¬ Integration of additional digital and analogue I/O signals,<br />

counting and time functions.<br />

¬ Ideal for sophisticated machines and installations that<br />

require a compact, economical controller, such as those<br />

used in materials processing, handling, conveyors, mounting,<br />

assembly or packing.<br />

SAIA®PCD<br />

<strong>PCD2.H32.</strong>. motion control module<br />

<strong>PCD2.H32.</strong>. motion control modules<br />

are distinguished by these characteristics<br />

¬ Specification of trapezoid or S-curve velocity profiles; linear<br />

interpolation and synchronization of multiple axes; position<br />

or speed controlled operation.<br />

¬ Electronic gearing, 1 master axis and 1 to 7 coupled slave<br />

axes.<br />

¬ Extraordinary flexibility due to event-oriented breakpoints<br />

that can influence current movement.<br />

¬ High speed and positioning accuracy due to PID control<br />

with a cycle time of 100 µs per axis.<br />

¬ All motion control functions are carried out autonomously<br />

by the module, placing no load on the PCD CPU.<br />

¬ Velocity, target position, PID parameters and gear transmission<br />

ratios can be modified on the fly during motion.<br />

¬ Inputs for 24 VDC or 5 V/RS 422 incremental shaft encoders<br />

and SSI absolute angle transmitters.<br />

¬ ±10 V standard analogue output with resolution of 12 bits<br />

inc. sign, as velocity setpoint for power stage.<br />

¬ Driving up to 4 (PCD1) or 14 (PCD2) axes.<br />

<strong>PCD2.H32.</strong>. <strong>MOTION</strong> <strong>CONTROL</strong> <strong>MODULES</strong><br />

Edition 26/334 E2

PCD1<br />

PCD2<br />

xx7<br />

Ultimate controller integration for the most sophisticated<br />

motion functions<br />

With the <strong>PCD2.H32.</strong>. motion control<br />

module, each axis can be operated fully<br />

independently of any other and previously<br />

selected profiles can be modified<br />

on the fly.<br />

Position control mode<br />

The trapezoidal velocity profile is standard<br />

for many applications. It enables<br />

acceleration and deceleration to be set<br />

differently.<br />

v1<br />

v2<br />

v<br />

The S-surve velocity profile permits<br />

smooth motion sequences. The profile is<br />

predefined. Acceleration and deceleration<br />

have identical values.<br />

v<br />

v1<br />

24 V<br />

24 V<br />

24 V<br />

LS1<br />

24 V LS2<br />

24 V Ref<br />

24Vor5V<br />

M<br />

SSI-Data<br />

SSI-Data<br />

SSI-Clk<br />

SSI-Clk<br />

s1<br />

POWER<br />

AMPLIFIER<br />

SI<br />

SO<br />

A<br />

B<br />

IN<br />

±10V<br />

IN<br />

IN<br />

B<br />

B<br />

Destination<br />

position<br />

s2<br />

Speed control mode<br />

Acceleration, velocity and deceleration<br />

can be modified on the fly. A “Stop“<br />

command can be used to travel through<br />

a predefined deceleration ramp.<br />

9 LED PROM<br />

ENCODER-<br />

INTERFACE<br />

s<br />

Destination<br />

position<br />

s1<br />

s<br />

Electronic gearing<br />

Position information from the master<br />

axis serves to control the slave axis.<br />

This position information can be delivered<br />

either directly from the master axis<br />

transmitter or through the control of<br />

the master module. The transmission<br />

ratio extends from 1:65 535 to 65 535:1<br />

and can be modified on the fly.<br />

Breakpoints<br />

Each axis has two programmable breakpoints,<br />

each with 5 parameters and<br />

8 conditions. This allows specific functions<br />

to be integrated and parameters<br />

(e. g. target position, velocity, etc.) to<br />

be modified depending on axis status<br />

(e. g. position of another axis, velocity,<br />

time, etc.).<br />

Synchronization<br />

SI/SO inputs/outputs are deployed in<br />

connection with breakpoints.<br />

Flying cut<br />

This function is easy to realize, thanks to<br />

the module‘s great flexibility. It involves<br />

the insertion of on-the-fly connection<br />

or disconnection of electronic gearing<br />

and breakpoints.<br />

Status registers<br />

Each axis has registers available of 3 × 16<br />

bits to record certain states, events,<br />

motions, etc., which can be queried via<br />

the user program or which can directly<br />

influence the module.<br />

<strong>MOTION</strong><br />

PROCESSOR<br />

CHIP-SET<br />

(DSP+ASIC)<br />

TRAJECTORY<br />

GENERATION<br />

PID-<br />

REGULATION<br />

CLOCK<br />

40 MHz<br />

<strong>PCD2.H32.</strong>.<br />

<strong>CONTROL</strong> SIGNALS<br />

HOST DATABUS<br />

DATABUS<br />

TRACE<br />

MEMORY<br />

FIELD PRO-<br />

GRAMMABLE<br />

GATE ARRAY<br />

BUS-<br />

INTERFACE<br />

SERIAL/<br />

PARALLEL<br />

CONVERSION<br />

SSI-<br />

INTERFACE<br />

PCD1/2-BUS<br />

Motion parameters<br />

Registers with 32 bits are used for target<br />

position, velocity, acceleration and<br />

deceleration.<br />

Position: metric entry (unit selectable between<br />

1 µm and 1 m) or encoder pulses<br />

Velocity: metric entry (unit selectable<br />

between 1 µm/s and 1 m/s) or encoder<br />

pulses/s<br />

Acceleration: metric entry (unit selectable<br />

between 1 µm/s² and 1 m/s²) or<br />

encoder pulses/s²<br />

PID controller: sampling interval 100 µs<br />

per axis, proportional, integrative and<br />

derivative factors programmable, sampling<br />

interval for derivative part programmable<br />

separately, feed-forward for<br />

velocity and acceleration<br />

Trace memory<br />

This RAM memory of 2 × 256 kBit per<br />

module allows motions to be stored of<br />

1 s to 100 min, with up to 4 para me ters<br />

and max. 2000 data points (4 para meters<br />

with 500 each). This data can then be<br />

read and displayed graphically.<br />

Other functions<br />

These include stop commands, compensation<br />

voltage for vertical axes, openloop<br />

mode and automatic limit switch<br />

monitoring.<br />

PROCESSOR PCD1/2<br />

Block diagram<br />

of a servodrive for 1 axis<br />

(2 axes per module)<br />

PERFORMANCE OVERVIEW

PCD1<br />

PCD2<br />

xx7<br />

Comfortable configuring, programming and commissioning<br />

of the positioning modules<br />

This software package runs under Windows 98, 2000 and NT.<br />

In summary, it offers the following capabilities:<br />

¬ Direct, easy access to all basic functions<br />

¬ Effortless entry, testing and storage for a variety of motion<br />

parameters<br />

¬ Tracing and graphical representation of motion<br />

sequences<br />

¬ Comprehensive diagnostic functions<br />

¬ The PCD utilities, PG5, also allow the automatic integration<br />

of software libraries, initialization for programming and<br />

use of the new CSF instructions, which guarantee very fast<br />

processing of user cycles in the SAIA®PCD.<br />

The package can either be run as a stand-alone program,<br />

or integrated into the PG5 PCD utilities, or used together<br />

with Siemens‘ STEP®7 programming software. The following<br />

is intended to present some of the dialog boxes in more<br />

detail, various of which can also be used simultaneously.<br />

Entry of motion parameters<br />

This dialog box allows control parameters to be entered online,<br />

updated directly in the ..H32.. module and stored as<br />

backup. The right-hand column contains current values, which<br />

can be modified in the left-hand column.<br />

Diagnostic function<br />

The “Watch Window” offers the possibility of displaying online<br />

all data from the PCD (registers, flags, counters, etc.) and<br />

those of the ..H32.. module.<br />

Programming and testing different<br />

motion sequences<br />

With this dialog box it is possible, for example, quite simply<br />

to define a motion on-line and then process it (without<br />

knowledge of any programming language). Parameters and<br />

the motion sequence are entered and then the process type<br />

is selected.<br />

Recording control parameters and<br />

evaluating them graphically<br />

This dialog box defines which motion parameters to record<br />

in trace memory and how (up to 4 parameters per module).<br />

«One Time» means that tracing will end as soon as the memory<br />

is full. «Rolling Buffer» is used to refresh data in the memory<br />

continuously. The start and end of a trace can be set manually<br />

or event-controlled (e.g. by a breakpoint or state, such as<br />

«Target velocity reached»).<br />

The graphical display of motion follows automatically.<br />

PROGRAMMING AND COMMISSIONING

PCD1<br />

PCD2<br />

xx7<br />

Technical data and ordering details<br />

Path recording with incremental shaft encoders _ _ _<br />

Number of inputs 6 per axis; A, B, IN and A, B, IN for ..H325<br />

Input signal 24 V or non-equivalent 5 V inputs, according to RS 422<br />

Count frequency max. 125 kHz with shaft encoder 24 V<br />

max. 250 kHz with shaft encoder 5 V/RS 422<br />

Count mode<br />

fourfold evaluation of input signals<br />

Encoder supply external or internal for ..H325<br />

Error detection possible with ..H325: cable break, encoder failure<br />

Path recording with SSI absolute angle transmitters<br />

SSI interfaces<br />

per axis 1 data input RS 422 (electrically isolated)<br />

and 1 clock output RS 422 (electrically connected)<br />

Resolution<br />

data bits selectable from 8 to 26 bits<br />

control bits selectable from 0 to 2 bits<br />

Count frequency 1 MHz (cable length þ20 m), 500 kHz (cable length 50 m),<br />

250 kHz (cable length 100 m)<br />

Data refresh<br />

every 100 µs at 1 MHz, 200 µs at 500 kHz,<br />

500 µs at 250kHz<br />

Data format<br />

gray or binary code<br />

Read mode<br />

normal (simple)<br />

Error detection transmitter failure (with 30 µs timeout)<br />

Digital inputs<br />

Number of inputs<br />

Input current<br />

Signal level<br />

Input delay<br />

Digital outputs<br />

Number of outputs<br />

Breaking capacity<br />

Potential drop<br />

Output delay<br />

Analogue outputs<br />

Number of channels<br />

Output signal<br />

Load resistance<br />

Ordering details<br />

Type<br />

Description<br />

per axis: 2 limit switches (LS1/LS2), 1 reference switch<br />

(Ref) and 1 input for synchronization (SI)<br />

8, electrically connected, negative logic<br />

7 mA at 24 V<br />

low = –30…5 V, high = 15…32 V<br />

300 µs at 24 V<br />

1 output per axis for synchronization (SO)<br />

2, electrically connected, short-circuit protected,<br />

source operation<br />

max. 0.5 A in range 6…32 VDC<br />

max. 0.3 V at 0.5 A<br />

typically 100 µs, max. 500 µs, under resistive load<br />

1 output per axis as velocity setpoint for driving the<br />

power amplifier<br />

2, electrically connected, with short-circuit protection<br />

±10 V, resolution 12 bit inc. sign bit<br />

ÿ3 kÞ<br />

LEDs for status indication and diagnosis<br />

Number of LEDs 8 per axis, indication of A, B, IN, Ref, LS1, LS2, SI, SO<br />

2 per module, indication of Power and OK<br />

Power supply<br />

External supply<br />

Internal supply<br />

Operating conditions<br />

Ambient temperature<br />

6…32 VDC smoothed, residual ripple max.10%, max.1 A<br />

(for outputs), without reverse battery protection<br />

5 VDC: 190…250 mA + shaft encoder supply for the<br />

..H325: max. 400 mA (electrically connected,<br />

with short-circuit protection)<br />

15 VDC: 10…16 mA<br />

operating: 0…+50 °C without forces ventilation<br />

storage: –20…+85 °C<br />

Noise emission CE mark according to EN 50081-1<br />

Noise immunity CE mark according to EN 50082-2<br />

Motion control modules for servodrives<br />

PCD2.H320 for 2 axes with incremental shaft encoders 24 VDC<br />

PCD2.H325 for 2 axes with incremental shaft encoders 5 V/RS 422<br />

or SSI absolute angle transmitters<br />

PCD2.H322 for 1 axis as slave with incremental shaft encoders 24 VDC<br />

PCD2.H327 for 1 axis as slave with incremental shaft encoders 5 V/RS 422<br />

or SSI absolute angle transmitters (only as slave)<br />

PCD8.Hx E Software package under Windows 95, 98, 2000, NT<br />

26/772 E Manual <strong>PCD2.H32.</strong>. for PCD<br />

PCD9.H32 E Software library with function blocks<br />

26/778 E Manual <strong>PCD2.H32.</strong>. for xx7<br />

Saia-Burgess<br />

Saia-Burgess Controls Ltd.<br />

Bahnhofstrasse 18<br />

CH-3280 Murten / Switzerland<br />

Telephone ++41 26 672 72 72<br />

Telefax ++41 26 672 74 99<br />

E-mail: pcd@saia-burgess.com<br />

Homepage: www.saia-burgess.com<br />

Your local contact:<br />

TECHNICAL DATA<br />

Printed in Switzerland 26/334 E2 06. 2001 TA20 Subject to change without notice.