VAV500 Multi-functional variable air volume controller, analogue ...

VAV500 Multi-functional variable air volume controller, analogue ...

VAV500 Multi-functional variable air volume controller, analogue ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

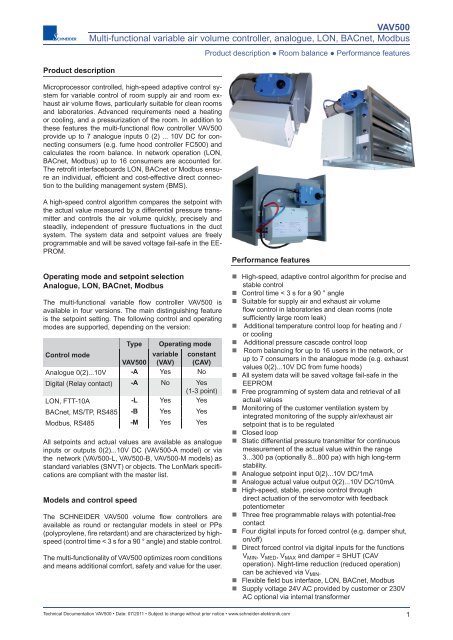

Product description<br />

<strong>VAV500</strong><br />

<strong>Multi</strong>-<strong>functional</strong> <strong>variable</strong> <strong>air</strong> <strong>volume</strong> <strong>controller</strong>, <strong>analogue</strong>, LON, BACnet, Modbus<br />

Microprocessor controlled, high-speed adaptive control system<br />

for <strong>variable</strong> control of room supply <strong>air</strong> and room exhaust<br />

<strong>air</strong> <strong>volume</strong> fl ows, particularly suitable for clean rooms<br />

and laboratories. Advanced requirements need a heating<br />

or cooling, and a pressurization of the room. In addition to<br />

these features the multi-<strong>functional</strong> fl ow <strong>controller</strong> <strong>VAV500</strong><br />

provide up to 7 <strong>analogue</strong> inputs 0 (2) ... 10V DC for connecting<br />

consumers (e.g. fume hood <strong>controller</strong> FC500) and<br />

calculates the room balance. In network operation (LON,<br />

BACnet, Modbus) up to 16 consumers are accounted for.<br />

The retrofi t interfaceboards LON, BACnet or Modbus ensure<br />

an individual, effi cient and cost-effective direct connection<br />

to the building management system (BMS).<br />

Product description ● Room balance ● Performance features<br />

A high-speed control algorithm compares the setpoint with<br />

the actual value measured by a differential pressure transmitter<br />

and controls the <strong>air</strong> <strong>volume</strong> quickly, precisely and<br />

steadily, independent of pressure fl uctuations in the duct<br />

system. The system data and setpoint values are freely<br />

programmable and will be saved voltage fail-safe in the EE-<br />

PROM.<br />

Operating mode and setpoint selection<br />

Analogue, LON, BACnet, Modbus<br />

The multi-<strong>functional</strong> <strong>variable</strong> fl ow <strong>controller</strong> <strong>VAV500</strong> is<br />

available in four versions. The main distinguishing feature<br />

is the setpoint setting. The following control and operating<br />

modes are supported, depending on the version:<br />

Type Operating mode<br />

Control mode<br />

<strong>variable</strong> constant<br />

<strong>VAV500</strong> (VAV) (CAV)<br />

Analogue 0(2)...10V -A Yes No<br />

Digital (Relay contact) -A No Yes<br />

(1-3 point)<br />

LON, FTT-10A -L Yes Yes<br />

BACnet, MS/TP, RS485 -B Yes Yes<br />

Modbus, RS485 -M Yes Yes<br />

All setpoints and actual values are available as <strong>analogue</strong><br />

inputs or outputs 0(2)...10V DC (<strong>VAV500</strong>-A model) or via<br />

the network (<strong>VAV500</strong>-L, <strong>VAV500</strong>-B, <strong>VAV500</strong>-M models) as<br />

standard <strong>variable</strong>s (SNVT) or objects. The LonMark specifi -<br />

cations are compliant with the master list.<br />

Models and control speed<br />

The SCHNEIDER <strong>VAV500</strong> <strong>volume</strong> fl ow <strong>controller</strong>s are<br />

available as round or rectangular models in steel or PPs<br />

(polyproylene, fi re retardant) and are characterized by highspeed<br />

(control time < 3 s for a 90 ° angle) and stable control.<br />

The multi-<strong>functional</strong>ity of <strong>VAV500</strong> optimizes room conditions<br />

and means additional comfort, safety and value for the user.<br />

Performance features<br />

• High-speed, adaptive control algorithm for precise and<br />

stable control<br />

• Control time < 3 s for a 90 ° angle<br />

• Suitable for supply <strong>air</strong> and exhaust <strong>air</strong> <strong>volume</strong><br />

fl ow control in laboratories and clean rooms (note<br />

suffi ciently large room leak)<br />

• Additional temperature control loop for heating and /<br />

or cooling<br />

• Additional pressure cascade control loop<br />

• Room balancing for up to 16 users in the network, or<br />

up to 7 consumers in the <strong>analogue</strong> mode (e.g. exhaust<br />

values 0(2)...10V DC from fume hoods)<br />

• All system data will be saved voltage fail-safe in the<br />

EEPROM<br />

• Free programming of system data and retrieval of all<br />

actual values<br />

• Monitoring of the customer ventilation system by<br />

integrated monitoring of the supply <strong>air</strong>/exhaust <strong>air</strong><br />

setpoint that is to be regulated<br />

• Closed loop<br />

• Static differential pressure transmitter for continuous<br />

measurement of the actual value within the range<br />

3...300 pa (optionally 8...800 pa) with high long-term<br />

stability.<br />

• Analogue setpoint input 0(2)...10V DC/1mA<br />

• Analogue actual value output 0(2)...10V DC/10mA<br />

• High-speed, stable, precise control through<br />

direct actuation of the servomotor with feedback<br />

potentiometer<br />

• Three free programmable relays with potential-free<br />

contact<br />

• Four digital inputs for forced control (e.g. damper shut,<br />

on/off)<br />

• Direct forced control via digital inputs for the functions<br />

V MIN , V MED , V MAX and damper = SHUT (CAV<br />

operation). Night-time reduction (reduced operation)<br />

can be achieved via V MIN .<br />

• Flexible field bus interface, LON, BACnet, Modbus<br />

• Supply voltage 24V AC provided by customer or 230V<br />

AC optional via internal transformer<br />

Technical Documentation <strong>VAV500</strong> • Date: 07/2011 • Subject to change without prior notice • www.schneider-elektronik.com<br />

1

<strong>VAV500</strong><br />

<strong>Multi</strong>-<strong>functional</strong> <strong>variable</strong> <strong>air</strong> <strong>volume</strong> <strong>controller</strong>, <strong>analogue</strong>, LON, BACnet, Modbus<br />

Functional description • Variable <strong>volume</strong> fl ow <strong>controller</strong> (<strong>VAV500</strong>), <strong>analogue</strong> setpoint control<br />

Volume flow measurement with a static differential<br />

pressure transmitter<br />

Using a suitable measuring device (maintenance-free measuring<br />

system, venturi measuring tube, orifi ce ring, measuring<br />

tube or measuring cross) the differential pressure is<br />

determined by a differential pressure transmitter. Measurement<br />

is very accurate and stable over the entire measuring<br />

range of 3...300 pa (optionally 8...800 pa), making it possible<br />

to regulate a <strong>volume</strong> fl ow range of 10:1.<br />

Unlike the thermo-anemometric measuring principle, <strong>air</strong><br />

does not fl ow through the static differential pressure transmitter,<br />

making it particularly suitable for measuring in dusty<br />

and contaminated (corrosive) media (its suitability should<br />

be checked in individual cases. The suitability of the thermo-anemometric<br />

measuring principle for such media is very<br />

limited, as the sensor becomes dirty or is affected by corrosive<br />

<strong>air</strong> and thus measurement may be very imprecise or<br />

inaccurate.<br />

Volume flow settings V MIN , V MED , V MAX<br />

Setting of the <strong>volume</strong> fl ow (programming) is done via the<br />

service module SVM100 or the Laptop (with software<br />

PC2500). The desired <strong>volume</strong> fl ow is entered as a numeric<br />

value in m 3 /h.<br />

Function Volume flow Demand signal w<br />

V MIN minimum 0(2) ≤ w ≤ 10V DC<br />

V MED median value 0(2) ≤ w ≤ 10V DC<br />

V MIN ≤ V MED ≤ V MAX<br />

V MAX maximum w = 10V DC<br />

The allocation of the <strong>analogue</strong> demand signal w to the <strong>volume</strong><br />

fl ow V MIN and V MAX accentuates the VAV curve (<strong>variable</strong><br />

operating mode).<br />

The <strong>volume</strong> fl ow value V MED is only available in constant<br />

operating mode (see CAV curve) and is digitally controlled<br />

(e.g. via relay contacts). V MED must always lie between<br />

V MIN and V MAX .<br />

Demand signal w (setpoint setting via<br />

<strong>analogue</strong> input A8-In)<br />

With the demand signal w (setpoint selection), the <strong>volume</strong><br />

fl ow can be constantly switched between V MIN and V MAX , at<br />

which the following is always true:<br />

0m 3 /h = 0(2)V DC, V MAX = 10V DC<br />

The regulated <strong>volume</strong> fl ow actual value (A2-Out) is available<br />

as 0(2)...10V DC output voltage. Various master/slave<br />

operating modes can be implemented with this signal.<br />

Shield factor (C value)<br />

The shield factor is the geometry-dependent constant of the<br />

measuring device used (construction of the damming body<br />

and geometric dimensions).<br />

The <strong>volume</strong> fl ow is calculated according to the following<br />

formula:<br />

Function Meaning Notes<br />

V MIN<br />

.<br />

V MAX<br />

Shield<br />

factor<br />

Type<br />

default<br />

V MED<br />

Offset<br />

V = c .<br />

p<br />

Programming of the <strong>volume</strong> flow <strong>controller</strong><br />

Using the service module SVM100 or the Laptop the <strong>volume</strong><br />

fl ow <strong>controller</strong> is programmed as follows:<br />

minimum <strong>volume</strong><br />

fl ow<br />

maximum <strong>volume</strong><br />

fl ow<br />

measuring device<br />

constant<br />

<strong>controller</strong><br />

confi guration<br />

interim value<br />

V MIN ≤ V MED ≤ V MAX<br />

fi xed +/- value for<br />

constant loads<br />

shield factor<br />

S * 1,5 (rule of thumb)<br />

shield factor<br />

S * 16 (rule of thumb)<br />

10...2000<br />

<strong>analogue</strong> (VAV)<br />

digital (CAV)<br />

digital operating mode<br />

only (CAV)<br />

+9990 m 3 /h to<br />

- 9990 m 3 /h<br />

Type default (setpoint value = <strong>analogue</strong> or digital)<br />

The <strong>controller</strong> configuration specifi es the operating mode<br />

(<strong>analogue</strong> or digital).<br />

In <strong>analogue</strong> operating mode (<strong>variable</strong> <strong>volume</strong> fl ow <strong>controller</strong><br />

= VAV) the <strong>volume</strong> fl ow is regulated linearly based on<br />

the <strong>analogue</strong> demand signal w (setpoint value via <strong>analogue</strong><br />

input A8-In).<br />

In digital operating mode (constant <strong>volume</strong> fl ow <strong>controller</strong> =<br />

CAV) the <strong>volume</strong> fl ow is regulated in stages based on the<br />

digital inputs (In2, In3 and In4). Up to four different <strong>volume</strong><br />

fl ows (V MIN , V MED and V MAX and V EMERGENCY ) can be regulated.<br />

An <strong>analogue</strong> demand signal is not required.<br />

In both operating modes (VAV and CAV) pressure fl uctations<br />

in the duct system are recognized and automatically<br />

regulated.<br />

Offset for integrating constant loads<br />

.<br />

V = <strong>air</strong> <strong>volume</strong><br />

c = geometrical constant<br />

(shield factor)<br />

p = differential pressure<br />

= <strong>air</strong> density<br />

With the offset value a fi xed value is programmed (+9990<br />

to - 9990 m3/h) that is added to the <strong>volume</strong> fl ow setpoint (+<br />

offset = increases the <strong>volume</strong> fl ow setpoint, - offset decreases<br />

the <strong>volume</strong> fl ow setpoint). This makes it possible to<br />

integrate constant loads.<br />

A constant difference between supply and exhaust <strong>air</strong> is<br />

therefore possible in master/slave mode. This function is<br />

particularly important in <strong>air</strong>tight rooms (e.g. clean rooms).<br />

2 Technical Documentation <strong>VAV500</strong> • Date: 07/2011 • Subject to change without prior notice • www.schneider-elektronik.com

<strong>VAV500</strong><br />

<strong>Multi</strong>-<strong>functional</strong> <strong>variable</strong> <strong>air</strong> <strong>volume</strong> <strong>controller</strong>, <strong>analogue</strong>, LON, BACnet, Modbus<br />

Operating modes • Variable <strong>volume</strong> flow <strong>controller</strong> (VAV) • Constant <strong>volume</strong> flow <strong>controller</strong> (CAV)<br />

Notes on <strong>controller</strong> dimensioning (dimensions and <strong>volume</strong><br />

flow)<br />

0 = contact open (no current)<br />

1 = contact closed (under current)<br />

Due to measurement accuracy it must be ensured that at<br />

the minimum <strong>volume</strong> fl ow V MIN the fl ow velocity in the <strong>volume</strong><br />

fl ow <strong>controller</strong> does not fall below 2 m/s.<br />

Due to noise development, in laboratory applications it must<br />

be ensured that at the maximum <strong>volume</strong> fl ow V MAX the fl ow<br />

velocity in the <strong>volume</strong> fl ow <strong>controller</strong> does not exceed 7,5<br />

m/s.<br />

The <strong>volume</strong> fl ows V MIN , V MED , V MAX are freely programmable<br />

within the range 50...25.000 m 3 /h, but care must be<br />

taken to ensure suitable <strong>volume</strong> fl ow <strong>controller</strong> dimensions<br />

with regard to the <strong>volume</strong> fl ow range while at the same time<br />

taking the fl ow velocity into account.<br />

See the terminal diagram on page 23 for wiring information.<br />

Determination <strong>volume</strong> flow for laboratory applicationstaking<br />

the flow velocity v into account<br />

Volume flow<br />

Flow velocity v<br />

V MIN v ≥ 2 m/s<br />

V MAX v ≤ 7,5 m/s<br />

Analogue operating mode<br />

Variable <strong>volume</strong> flow <strong>controller</strong> (VAV)<br />

Diagram 1: <strong>variable</strong> <strong>volume</strong> flow control (VAV)<br />

[V]<br />

V MAX<br />

10<br />

[V]<br />

10<br />

In <strong>variable</strong> <strong>volume</strong> fl ow operating mode the desired <strong>volume</strong><br />

fl ow is predefi ned by a demand signal w (setpoint setting).<br />

The value range of the demand signal is 0(2)...10V DC.<br />

The <strong>volume</strong> fl ow can be constantly controlled between V MIN<br />

und V MAX with the demand signal w, at which the following<br />

is always true:<br />

Leading signal w (A-In1)<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

V MIN<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

Air <strong>volume</strong> actual value (A-Out1)<br />

0m 3 /h = 0(2)V DC<br />

0(2) ≤ V MIN ≤ 10V DC<br />

V MAX = 10V DC<br />

1<br />

0<br />

0 200 400 600 800 1000 [m 3 /h]<br />

1<br />

0<br />

Always note:<br />

1. Minimum control value VMIN = shield factor B * 1.5<br />

2. Values

<strong>VAV500</strong><br />

<strong>Multi</strong>-<strong>functional</strong> <strong>variable</strong> <strong>air</strong> <strong>volume</strong> <strong>controller</strong>, <strong>analogue</strong>, LON, BACnet, Modbus<br />

Master / slave sequence control • Equal percentage ratio • Constant difference<br />

Digital operating mode<br />

Constant <strong>volume</strong> flow <strong>controller</strong> (CAV)<br />

In constant <strong>volume</strong> fl ow operating mode (digital operating<br />

mode) the desired <strong>volume</strong> fl ow is controlled based on the<br />

digital inputs.<br />

The available operating stages are shown in diagram 2 and<br />

Table 2. 1 point, 2 point, 3 point or 4 point operation can<br />

easily be implemented by direct control of the digital inputs.<br />

The <strong>volume</strong> fl ows are programmed to the values V MIN = 875<br />

m 3 /h, V MED = 1750 m 3 /h and V MAX = 2150 m 3 /h. V MED must<br />

always lie between V MIN and V MAX . The <strong>volume</strong> fl ow actual<br />

value signal (A2--Out) correlates with the regulated <strong>volume</strong><br />

fl ow.<br />

The following is valid for the <strong>volume</strong> fl ow actual value:<br />

SHUT = 0m 3 /h = 0(2)V DC<br />

0(2) ≤ V MIN ≤ 10V DC<br />

V MIN ≤ V MED ≤ V MAX<br />

V MAX = 10V DC<br />

See above and the terminal diagram on page 23 for information<br />

on the digital input wiring.<br />

Master-slave sequence control with equal<br />

percentage ratio in VAV operation<br />

This master-slave sequence control is always used when<br />

room pressure must be maintained at an equal percentage<br />

ratio of supply and exhaust <strong>air</strong>. Suffi cient replacement fl ow<br />

of the difference between the supply and exhaust <strong>air</strong> must<br />

be ensured in this operating mode.<br />

The master <strong>controller</strong> is programmed with the <strong>volume</strong> fl ow<br />

values V MIN and V MAX and the demand signal w is added<br />

on directly. The <strong>volume</strong> fl ow actual value of the master <strong>controller</strong><br />

provides the demand signal for the slave <strong>controller</strong>,<br />

which can be programmed with other V MIN and V MAX <strong>volume</strong><br />

fl ow values depending on the application.<br />

If the master <strong>controller</strong> is mounted in the supply <strong>air</strong> and<br />

the slave <strong>controller</strong> in the exhaust <strong>air</strong> and positive (+) room<br />

pressure is required, the slave <strong>controller</strong> must be programmed<br />

with the lower percentage <strong>volume</strong> fl ow values V MIN<br />

and V MAX in relation to the master <strong>controller</strong>.<br />

If negative (-) room pressure is required, the slave <strong>controller</strong><br />

must be programmed with the lower percentage <strong>volume</strong><br />

fl ow values V MIN and V MAX in relation to the master <strong>controller</strong>.<br />

Sample settings for master/slave <strong>controller</strong>s:<br />

Slave (+) Master Slave(-)<br />

V MIN 240 300 360<br />

V MAX 600 750 900<br />

Diagram 2: Constant <strong>volume</strong> flow control (CAV)<br />

Function Input 1 Input 2<br />

V MAX 0 0<br />

V MED 1 1<br />

V MIN 1 0<br />

SHUT 0 1<br />

Table 2:<br />

Digital inputs<br />

Funktion In 2 In 3 In4<br />

V MAX 0 0 0<br />

V MIN 1 0 0<br />

V MED 0 1 0<br />

V EMERGENCY or damper SHUT 0 0 1<br />

Contact open = 0, contact closed = 1.<br />

The digital input In1 is the highest priority and switches the<br />

fl ow <strong>controller</strong> <strong>VAV500</strong> ON or OFF.<br />

Schematic diagram: Master-slave sequence control<br />

in VAV operation<br />

Room supply<br />

VAV<br />

dp M<br />

<strong>VAV500</strong><br />

Master<br />

Leading signal w<br />

SHUT<br />

Air <strong>volume</strong> actual value<br />

0 500 1000 1500 2000 2500 [m 3 /h]<br />

Damper position<br />

SHUT<br />

V MIN<br />

V MIN<br />

Forced control VAV operation in<br />

digital operating mode (CAV)<br />

T<br />

Room exhaust<br />

VAV<br />

V MED<br />

V MED<br />

dp M<br />

<strong>VAV500</strong><br />

Slave<br />

V MAX<br />

V MAX<br />

Air <strong>volume</strong><br />

actual value<br />

Air <strong>volume</strong><br />

Building Management<br />

System<br />

System network<br />

DDC<br />

substation<br />

The master slave sequence control applies for both equal<br />

percentage ratio and constant difference between supply<br />

and exhaust <strong>air</strong>. The demand signal w (A8-In) is added on<br />

to the master <strong>controller</strong> and the <strong>volume</strong> fl ow actual value<br />

(A2-Out) provides the demand signal for the slave <strong>controller</strong>.<br />

This ensures that the slave <strong>controller</strong> always follows the<br />

master <strong>controller</strong>. For safety reasons, master/slave sequence<br />

control must always be given preference over parallel<br />

control.<br />

[V]<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

Air <strong>volume</strong> actual value (A-Out1)<br />

4 Technical Documentation <strong>VAV500</strong> • Date: 07/2011 • Subject to change without prior notice • www.schneider-elektronik.com

<strong>VAV500</strong><br />

<strong>Multi</strong>-<strong>functional</strong> <strong>variable</strong> <strong>air</strong> <strong>volume</strong> <strong>controller</strong>, <strong>analogue</strong>, LON, BACnet, Modbus<br />

In the sample settings, the <strong>volume</strong> fl ow values VMIN und<br />

VMAX of the slave (+) <strong>controller</strong> were programmed to -20%<br />

(negative room pressure) in relation to the <strong>volume</strong> fl ow values<br />

of the master <strong>controller</strong>. For negative room pressure<br />

the <strong>volume</strong> fl ow values V MIN and V MAX of the slave (-) <strong>controller</strong><br />

must be programmed to +20% in relation to the <strong>volume</strong><br />

fl ow values of the master <strong>controller</strong>.<br />

The equal percentage ratio between supply and exhaust <strong>air</strong><br />

is maintained throughout the entire <strong>volume</strong> fl ow range of<br />

V MIN to V MAX .<br />

Master / slave sequence control • Application examples<br />

Diagram 3: Sequence control (master/slave) in<br />

equal percentage ratio<br />

Leading signal w (A-In1)<br />

[V]<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

[V]<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

Air <strong>volume</strong> actual value (A-Out1)<br />

V MIN<br />

V MAX<br />

V MAX<br />

Master/slave sequence control with constant<br />

difference in VAV operating mode<br />

1<br />

0<br />

1<br />

0<br />

This form of master/slave sequence control is used when<br />

room pressure with a constant difference between supply<br />

and exhaust <strong>air</strong> is required. This operating mode is selected<br />

for <strong>air</strong>tight rooms (e.g. clean rooms).<br />

The master <strong>controller</strong> is programmed with the <strong>volume</strong> fl ow<br />

values V MIN and V MAX and the demand signal w is added<br />

on directly. The <strong>volume</strong> fl ow actual value of the master <strong>controller</strong><br />

provides the demand signal for the slave <strong>controller</strong>,<br />

which is programmed with the same <strong>volume</strong> fl ow values<br />

V MIN and V MAX , depending on the application.<br />

In addition, the offset is also programmed in the slave <strong>controller</strong>.<br />

If the master <strong>controller</strong> is mounted in the supply <strong>air</strong><br />

and the slave <strong>controller</strong> in the exhaust <strong>air</strong> and positive (+)<br />

room pressure is required, the slave <strong>controller</strong> must be programmed<br />

with a negative offset.<br />

[V]<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

0 200 400 600 800 1000 [m 3 /h]<br />

V MIN<br />

V MIN<br />

V MIN<br />

V MAX<br />

V MAX<br />

Air <strong>volume</strong>-Master<br />

Air <strong>volume</strong>-Slave(-)<br />

Air <strong>volume</strong>-Slave(+)<br />

Diagram 4: Sequence control (master / slave) with<br />

constant difference<br />

konstante<br />

Differenz<br />

Zu-/Abluft<br />

[V]<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

If negative (-) room pressure is required, the slave <strong>controller</strong><br />

must be programmed with a positive offset.<br />

3<br />

2<br />

1<br />

3<br />

2<br />

1<br />

Sample settings for master/slave <strong>controller</strong>s:<br />

0<br />

0<br />

0 200 400 600 800 1000 [m 3 /h]<br />

Slave (+) Master Slave(-)<br />

V MIN<br />

V MAX<br />

Volumenstrom-Master<br />

V MIN 300 300 300<br />

V MAX 750 750 750<br />

Offset - 150 0 + 150<br />

V MIN<br />

V MIN<br />

V MIN<br />

V MAX<br />

V MAX<br />

V MAX<br />

Volumenstrom-Slave(-)<br />

Volumenstrom-Slave(+)<br />

In this example, the <strong>volume</strong> fl ow values V MIN and V MAX of<br />

the slave (+) <strong>controller</strong> and the slave (-) <strong>controller</strong> were programmed<br />

with the <strong>volume</strong> fl ow values of the master <strong>controller</strong>.<br />

For negative room pressure the offset of the slave (-)<br />

<strong>controller</strong> must be programmed with +150 m 3 /h.<br />

The constant difference between supply and exhaust <strong>air</strong><br />

is maintained over the entire <strong>volume</strong> fl ow range of V MIN to<br />

V MAX .<br />

Master / slave sequence control in CAV operating<br />

mode<br />

In CAV operating mode the digital inputs of the master <strong>controller</strong><br />

are wired to control the different operating stages<br />

(see table 2). The <strong>volume</strong> fl ow actual value (A2-Out) of the<br />

master <strong>controller</strong> provides the demand signal for the slave<br />

<strong>controller</strong>.<br />

DDC / BMS control<br />

If the master <strong>controller</strong> is controlled via a DDC/BMS (demand<br />

signal w or digital control) the <strong>volume</strong> fl ow actual value<br />

of the slave <strong>controller</strong> can be added on as feedback and<br />

therefore used to monitor the functioning of both <strong>volume</strong><br />

fl ow <strong>controller</strong>s (master and slave).<br />

Technical Documentation <strong>VAV500</strong> • Date: 07/2011 • Subject to change without prior notice • www.schneider-elektronik.com<br />

5

<strong>VAV500</strong><br />

<strong>Multi</strong>-<strong>functional</strong> <strong>variable</strong> <strong>air</strong> <strong>volume</strong> <strong>controller</strong>, <strong>analogue</strong>, LON, BACnet, Modbus<br />

Master / slave sequence control • Application examples<br />

Connection plan VAV operation<br />

The <strong>analogue</strong> demand signal is added on by the signal<br />

transmitter (e.g. temperature sensor, setpoint device) or by<br />

the DDC or BMS. The <strong>volume</strong> fl ow actual value of the master<br />

VAV in turn provides the demand signal for the slave<br />

VAV.<br />

The <strong>volume</strong> fl ow actual value signal of the slave VAV can be<br />

added on to the DDC or BMS as a feedback signal, which<br />

makes it possible to check the <strong>functional</strong>ity of the entire master/slave<br />

sequence control. Forced control via terminal X2<br />

is also possible and is shown in table 1 on page 3.<br />

Connect<br />

via safety<br />

transformer<br />

Master<br />

Slave<br />

X8<br />

X8<br />

X8<br />

24V AC<br />

supply<br />

voltage<br />

N<br />

N<br />

10...20 VA<br />

20 19<br />

22 21<br />

X30<br />

max. 10 VA<br />

20 19<br />

X30<br />

L<br />

L<br />

X11<br />

X11<br />

Leading signal w<br />

0(2)...10V DC<br />

105 104<br />

48 47<br />

0(2)...10V DC<br />

GND<br />

105 104<br />

48 47<br />

GND<br />

RAM500<br />

<strong>VAV500</strong><br />

Air <strong>volume</strong><br />

actual value<br />

RAM500<br />

<strong>VAV500</strong><br />

GND<br />

0(2)...10V DC<br />

Air <strong>volume</strong><br />

actual value<br />

from source,<br />

DDC/GLT<br />

to<br />

DDC/GLT<br />

Connection plan<br />

VAV operation<br />

Connection plan CAV operation<br />

The various CAV operating stages are shown in table 2 on<br />

page 4.<br />

When both digital inputs (input 1 and input 2) are not under<br />

current, i.e. the contacts are open, the <strong>volume</strong> fl ow V MAX is<br />

regulated. When both inputs are under current the <strong>volume</strong><br />

fl ow V Med is regulated.<br />

Connect<br />

via safety<br />

transformer<br />

Master<br />

Slave<br />

20 19<br />

X8<br />

X8<br />

24V AC<br />

supply<br />

voltage<br />

N<br />

22 21<br />

X11<br />

N<br />

10...20 VA<br />

max. 10 VA<br />

20 19<br />

X8 X30<br />

L<br />

L<br />

CAV operating modes<br />

X11<br />

X11<br />

In2<br />

48 47<br />

0(2)...10V DC<br />

GND<br />

105 104<br />

48 47<br />

In3<br />

In4<br />

39 40 41 42 43 44<br />

<strong>VAV500</strong><br />

Air <strong>volume</strong><br />

actual value<br />

RAM500<br />

<strong>VAV500</strong><br />

CAV-operating mode (digital)<br />

VAV-operating mode (<strong>analogue</strong>)<br />

Connection plan<br />

CAV operation<br />

The master is controlled in CAV operating mode and the<br />

slave in VAV operating mode. Here the slave also follows<br />

the actual value of the master. Feedback of the <strong>volume</strong> fl ow<br />

actual value to the DDC/BMS is also possible.<br />

GND<br />

0(2)...10V DC<br />

Air <strong>volume</strong><br />

actual value<br />

to<br />

DDC/GLT<br />

Room plan 1 ● Variable <strong>volume</strong> fl ow <strong>controller</strong>, <strong>analogue</strong> setpoint value via group <strong>controller</strong> GC10<br />

Room plan 1 shows the interconnection of up to 10 FC500<br />

fume hood <strong>controller</strong>s (Ain1 to Ain10) with the GC10 group<br />

<strong>controller</strong>. The group <strong>controller</strong> can control up to four freely<br />

confi gurable VAV-A <strong>volume</strong> fl ow <strong>controller</strong>s for room supply/<br />

exhaust <strong>air</strong> (Aout1 to Aout4). The internal transformer (optional)<br />

provides the supply voltage for the <strong>volume</strong> fl ow <strong>controller</strong>s<br />

24V AC, which simplifi es planning and makes implementation<br />

more cost-effi cient. The <strong>analogue</strong> inputs Ain1 to<br />

Ain10 are summated, can be combined in any number of<br />

groups on the <strong>analogue</strong> outputs Aout1 to Aout4 and provide<br />

an <strong>analogue</strong> setpoint value for the <strong>variable</strong> <strong>volume</strong> fl ow<br />

<strong>controller</strong>. A room by room LON connection to the building<br />

services management system is optionally possible.<br />

For a detailed description, see the technical documentation<br />

GC10 or for extended <strong>functional</strong>ity LCO500.<br />

Legend:<br />

FC<br />

Fume hood #1<br />

FC<br />

Fume hood #2<br />

Fume hood<br />

#3 bis #9<br />

FC<br />

Fume hood #10<br />

Optional:<br />

Room control panel<br />

RBG100<br />

LED-Night operation<br />

Button cancel night operation<br />

FC<br />

GC10<br />

LON300<br />

RBG100<br />

<strong>VAV500</strong>-A<br />

= Fume hood <strong>controller</strong>, fully <strong>variable</strong>,<br />

<strong>analogue</strong> Output 0(2)...10V DC<br />

= Group <strong>controller</strong>, 10 <strong>analogue</strong> inputs<br />

= LON-module, FTT-10A (optional)<br />

= Room control panel for canceling the night<br />

operation (optional)<br />

= high speed <strong>VAV500</strong> with <strong>analogue</strong> input<br />

0...10V DC<br />

cable type: IY(St)Y 4x2x0,8<br />

cable type: IY(St)Y 4x2x0,8<br />

Ain1 … Ain10 = 10 <strong>analogue</strong> inputs 0...10V DC<br />

Sin1 … Sin10 = 10 alarm inputs<br />

T/N<br />

= Day/Night operation fume hood (roomwise)<br />

Room supply<br />

VAV<br />

dp<br />

M<br />

Ain1 Ain2<br />

Sin1 Sin2<br />

T/N T/N<br />

Aout1<br />

24V AC<br />

Ain3<br />

Sin3<br />

T/N<br />

…<br />

…<br />

...<br />

Ain10<br />

Sin10<br />

T/N<br />

Room group <strong>controller</strong><br />

GC10<br />

Din1<br />

K2<br />

Aout2<br />

24V AC<br />

Room exhaust<br />

VAV<br />

dp<br />

M<br />

Din1<br />

= Digital input button cancel night operation<br />

K2<br />

= Relay contact for LED-Day/Night<br />

Aout1 … Aout4 = <strong>analogue</strong> outputs 0...10V DC<br />

24V AC = 24V AC supply voltage for VAV-A<br />

Attention! Wires for LON A/B must be twisted p<strong>air</strong>.<br />

Don´t exceed max. cable lenght.<br />

<strong>VAV500</strong>-A<br />

cable type: IY(St)Y 4x2x0,8<br />

Optional:<br />

Transformer<br />

T = 24V AC/<br />

30 VA<br />

Optional:<br />

LON300<br />

LON-module<br />

FT-X1 (FTT-10A)<br />

free topology<br />

<strong>VAV500</strong>-A<br />

cable type: IY(St)Y 4x2x0,8<br />

mains<br />

230V AC +-10%<br />

Room fault alarm<br />

Day/Night operation<br />

(roomwise)<br />

Building Management<br />

System<br />

LON-NETWORK, FT-X1 (FTT-10A), LON A/B<br />

cable type: IY(St)Y 2x2x0,8<br />

6 Technical Documentation <strong>VAV500</strong> • Date: 07/2011 • Subject to change without prior notice • www.schneider-elektronik.com

<strong>VAV500</strong><br />

<strong>Multi</strong>-<strong>functional</strong> <strong>variable</strong> <strong>air</strong> <strong>volume</strong> <strong>controller</strong>, <strong>analogue</strong>, LON, BACnet, Modbus<br />

<strong>Multi</strong>-<strong>functional</strong> applications in <strong>analogue</strong>- or network operation • Heating and/or Cooling<br />

<strong>Multi</strong><strong>functional</strong> applications in <strong>analogue</strong> or<br />

network operation (LON, BACnet, Modbus)<br />

In addition to those described in the following pages classic<br />

fl ow control modes such as <strong>variable</strong> <strong>volume</strong> fl ow <strong>controller</strong>,<br />

3-point constant fl ow regulators, balancing <strong>volume</strong><br />

<strong>controller</strong> and room fl ow difference <strong>controller</strong> in <strong>VAV500</strong>-A<br />

or <strong>VAV500</strong>-LON are implemented following additional multi<strong>functional</strong><br />

applications:<br />

• actual value of pressure measuring<br />

• own temperature control loop for heating<br />

and / or cooling<br />

• own pressure cascade control loop<br />

(<strong>VAV500</strong>-LON only)<br />

Actual value of pressure measuring<br />

Pressure measuring or other <strong>analogue</strong> values can be connected<br />

to the <strong>analogue</strong> inputs A1-in to A7-in (value range:<br />

0(2)...10V DC) and are available as standard <strong>variable</strong><br />

(SNVT) via the LON network.<br />

Network <strong>functional</strong>ity (LON, BACnet, Modbus)<br />

The control (temperature and pressure cascade) on the<br />

LON network with the appropriate LON <strong>variable</strong>s (SNVTs)<br />

is described as an example. The same control principle is<br />

even valid for the supported networks BACnet and Modbus,<br />

and differ only in the <strong>variable</strong> types and <strong>variable</strong> names.<br />

The LON functions of fl ow <strong>controller</strong> <strong>VAV500</strong>-LON are implemented<br />

according to LonMark specifi cation 8010 „VAV<br />

<strong>controller</strong>s (Variable Air Volume)“. In implementing the <strong>functional</strong>ity,<br />

not all functions of the LonMark specifi cation 8010<br />

„VAV <strong>controller</strong>“ were considered due to the <strong>functional</strong>ity of<br />

the pressure cascade control. See SNVT list on page 9 to<br />

13<br />

Self temperature control loop for heating<br />

and/or cooling<br />

The multi-<strong>functional</strong> fl ow control or <strong>VAV500</strong>-LON or<br />

<strong>VAV500</strong>-A has a built-in temperature control. The temperature<br />

is controlled by a change in the nominal <strong>volume</strong> fl ow<br />

and/or an additional heating or cooling coil.<br />

The multi-<strong>functional</strong> fl ow control <strong>VAV500</strong> supports three different<br />

temperature control modes:<br />

1. External increase of the set <strong>volume</strong> flow (temperature<br />

control by the BMS over the network)<br />

Via the LON <strong>variable</strong> nviFlowTempAddon the value of this<br />

<strong>variable</strong> is added to the calculated setpoint fl ow value and<br />

thus raised. The temperature control is taking over by the<br />

building management system (BMS), which of course also<br />

requires the actual value of the room temperature.<br />

2. Independent temperature control (actual<br />

temperature value via the network)<br />

In this temperature control mode the actual room temperature<br />

value of an external LON temperature sensor is transmitted<br />

to the multi-<strong>functional</strong> fl ow <strong>controller</strong> <strong>VAV500</strong>-LON<br />

via the LON-<strong>variable</strong> nviTemperature. The room temperature<br />

setpoint is set with the LON-constant (nciTemperature).<br />

Bit0 of the LON constant nciDeviceState determines<br />

whether heating (Bit0 = 0) or cooling (Bit0 = 1) is selected.<br />

During cooling is:<br />

If the room temperature actual value nviTemperature exceeds<br />

the setpoint nciTemperature, the nominal <strong>volume</strong><br />

fl ow will be increased by the LON-constant value nciTempOffset<br />

per degree exceeding.<br />

During heating is:<br />

If the room temperature actual value nviTemperature falls<br />

below the setpoint nciTemperature, the nominal <strong>volume</strong><br />

fl ow will be increased by the LON-constant value nciTempOffset<br />

per degree exceeding.<br />

The multi-<strong>functional</strong> fl ow control <strong>VAV500</strong>-LON can be connected<br />

directly to an <strong>analogue</strong> thermosensor KTY81. The<br />

measured value is as a LON <strong>variable</strong> nvoTemperature<br />

available.<br />

3. Independent temperature control (<strong>analogue</strong> or<br />

via the network)<br />

The independent temperature control needs a temperature<br />

sensor, which is connected to the <strong>VAV500</strong>. As a standard<br />

sensor, a sensor is implemented with a range from 0 ° C<br />

to 50 ° C at 0 V to 10 V output voltage. The heating and/or<br />

cooling coil can be controlled via the <strong>analogue</strong> outputs of<br />

A3-Out and A4-Out with the voltage range 0(2)...10V DC.<br />

When the independent temperature control is activated, the<br />

pressure cascade control can not be used.<br />

3.1.1 Activation via the network<br />

The independent temperature control system is activated or<br />

deactivated via the LON <strong>variable</strong> nciTempActiv. The control<br />

cycle is defi ned by nciControlTime and the P component is<br />

defi ned by the nciControlFactor.<br />

The setpoint is specifi ed via nciTemperature either static,<br />

or can be set dynamically via nviTemperature. In this case,<br />

nciTemperature must be set to 0.<br />

Bit0 of the LON constant nciDeviceState determines<br />

whether heating (Bit0 = 0) or cooling (Bit0 = 1) is selected.<br />

3.1.2 Analogue mode<br />

In addition to the temperature sensor, the temperature setpoint<br />

value as 0(2)...10V DC signal can be connected, thus<br />

allows a dynamic temperature control.<br />

Technical Documentation <strong>VAV500</strong> • Date: 07/2011 • Subject to change without prior notice • www.schneider-elektronik.com<br />

7

<strong>VAV500</strong><br />

<strong>Multi</strong>-<strong>functional</strong> <strong>variable</strong> <strong>air</strong> <strong>volume</strong> <strong>controller</strong>, <strong>analogue</strong>, LON, BACnet, Modbus<br />

<strong>Multi</strong>-<strong>functional</strong> applications in <strong>analogue</strong>- or network operation • Pressure cascade control loop<br />

The setpoint setting is therefore <strong>variable</strong> and constantly<br />

changeable.<br />

A constant temperature reference is given via the SVM100<br />

or the PC2500 PC software and is voltage fail-safe stored<br />

in EEPROM.<br />

Own pressure cascade control loop<br />

1. In <strong>analogue</strong> mode, the pressure cascade control is<br />

not currently implemented.<br />

2. Pressure cascade control in network operation<br />

The pressure cascade control via the LON network with the<br />

appropriate LON <strong>variable</strong>s (SNVTs) is described examplary.<br />

The same control principle is even valid for the supported<br />

networks BACnet and Modbus, and differs only in the <strong>variable</strong><br />

types and <strong>variable</strong> names.<br />

With the pressure cascade control, a <strong>volume</strong> fl ow-prioritized<br />

pressure control is realized.<br />

All the following information applies to a supply <strong>air</strong>. For exhaust<br />

<strong>air</strong> the specifi ed logic is inverted.<br />

First, the nominal fl ow rate is determined, for example the<br />

addition of the actual values of the exhaust <strong>air</strong> fl ow <strong>volume</strong>s.<br />

The pressure cascade requires the following parameters:<br />

nciPressDZoneP dead zone is the area in actual<br />

pressure > setpoint pressure. In this<br />

area, no correction of the <strong>volume</strong><br />

fl ow is performed. The value is a positive<br />

offset to the pressure setpoint.<br />

nciPressDZoneM dead zone is the area in actual<br />

pressure < setpoint pressure. In this<br />

area, no correction of the <strong>volume</strong><br />

fl ow is performed. The value is<br />

a negative offset to the pressure<br />

setpoint.<br />

nciPressLimitP is the value carried out up to a<br />

correction of the <strong>volume</strong> fl ow is, if<br />

actual pressure > setpoint pressure.<br />

The value is a positive offset to the<br />

pressure setpoint.<br />

nciPressLimitM is the value carried out up to a<br />

correction of the <strong>volume</strong> fl ow is, if<br />

actual pressure < set point pressure.<br />

The value is a negative offset to<br />

the pressure setpoint.<br />

nciPressFlowStep is a limit to the maximum change of<br />

the fl ow rate per control step.<br />

nciPressPercentP is the maximum percentage by<br />

which the fl ow rate is increased if<br />

actual pressure > set point pressure.<br />

nciPressPercentM is the maximum percentage by<br />

which the fl ow rate is lowered if<br />

actual pressure < setpoint pressure.<br />

nciSensorPress<br />

nciPressNominal<br />

nciControlTime<br />

selects the type of the connected<br />

pressure sensor<br />

defines the pressure setpoint<br />

defines the control cycle<br />

If the pressure cascade control is activated the independent<br />

temperature control can not be used.<br />

Example of pressure cascade control:<br />

Given:<br />

Determined setpoint fl ow rate:<br />

1600 m³/h<br />

Setpoint pressure: nciPressNominal: -15 Pa Unterdruck<br />

Dead zone in the positive range: nciPressDZoneP: 5 Pa<br />

Dead zone in the negative range: nciPressDZoneM: 5 Pa<br />

Upper limit cascade: nciPressLimitP: 20 Pa<br />

Lower limit cascade: nciPressLimitM: 10 Pa<br />

Maximum change to the top: nciPressPercentP: 20%<br />

Maximum change to bottom: nciPressPercentM: 20%<br />

Case1: Actual value = -18 Pa No change since within the dead zone (nciPressNominal + nciPressDZoneP)<br />

Case2: Actual value = -11 Pa No change since within the dead zone (nciPressNominal - nciPressDZoneM)<br />

Case3: Actual value = -23 Pa Increase of the set fl ow rate to 1600 m³/h * 20% * min((23 – 15), 10) / 10 = 256 m³/h<br />

Case4: Actual value = -28 Pa Increase of the set fl ow rate to 1600 m³/h * 20% * min((28 – 15), 10) / 10 = 320 m³/h<br />

Case5: Actual value = -7 Pa Reduction of the nominal fl ow rate to 1600 m³/h * 20% * min((15 – 7), 20) / 20 = 128 m³/h<br />

Case6: Actual value = +11 Pa Reduction of the nominal fl ow rate to 1600 m³/h * 20% * min((15 + 11), 20) / 20 = 320 m³/h<br />

8 Technical Documentation <strong>VAV500</strong> • Date: 07/2011 • Subject to change without prior notice • www.schneider-elektronik.com

1. Node Object<br />

<strong>VAV500</strong><br />

<strong>Multi</strong>-<strong>functional</strong> <strong>variable</strong> <strong>air</strong> <strong>volume</strong> <strong>controller</strong>, <strong>analogue</strong>, LON, BACnet, Modbus<br />

LON-Network interface • Standard Variables (SNVTs)<br />

Below you find the table overview of the network interface. For a detailed description of the network interface<br />

request the detailled SNVT Description <strong>VAV500</strong>-L.<br />

The node object # 0 provides mechanisms to analyze and infl uence the node. It manages all other objects of the node<br />

and occurs only once. It has no application, but takes care only of the nodes. It handles for example network management<br />

functions and status reports.<br />

Node object network <strong>variable</strong>s:<br />

Mandatory Network Variables<br />

nviRequest SNVT Type: SNVT_obj_request Valid range: 0 s to 3600 s<br />

Function:<br />

Requesting various information and perform actions in the node.<br />

The following parameters can be processed:<br />

RQ_NORMAL:<br />

Initialize the node, reset the status<br />

RQ_DISABLED: Disable node<br />

RQ_UPDATE_STATUS: Query the status response via nvoStatus<br />

RQ_REPORT_MASK: Mask of all possible status bits<br />

RQ_SELF_TEST: Self-test of the node<br />

nvoStatus SNVT Type: SNVT_obj_status Valid range: 0 s to 3600 s<br />

Function:<br />

The output <strong>variable</strong> contains the answer to a question raised earlier about nviRequest<br />

with the required status:<br />

invalid_id:<br />

Incorrect object-ID requested or not available<br />

invalid_request: Wrong parameter requested or not available<br />

disabled:<br />

no function node (inactive)<br />

comm_failure:<br />

Communication failure<br />

fail_self_test:<br />

Self-test run error<br />

self_test_in_progress: Self-test activated<br />

nciMaxstsSendT SNVT Type: SNVT_elapsed_time Valid range: 0 s to 3600 s<br />

Function:<br />

Periodic transmission of nvoStatus. If the value = 0, then periodic transmission is disabled.<br />

2. Application object<br />

In the application objects the following types are distinguished:<br />

Open Loop Sensor<br />

Closed Loop Sensor<br />

Open Loop Actuator<br />

Closed Loop Actuator<br />

The described node is of type „Closed Loop Actuator“.<br />

nviExtFlow[16] SNVT Type: SNVT_fl ow Valid range: 0 l/s to 65534 l/s<br />

These 16 inputs are used for summation and for setpoint settings for <strong>variable</strong> fl ow rates. Via bindings to these 16 inputs,<br />

the <strong>volume</strong> fl ows of external devices or to a master-slave confi guration can be assigned via the LON network.<br />

nvoBoxFlow SNVT Type: SNVT_fl ow Valid range: 0 l/s to 65534 l/s<br />

This output shows the actual fl ow rate of fl ow <strong>controller</strong>, as measured through the <strong>analogue</strong> input of the pressure sensor.<br />

The <strong>variable</strong> is transmitted when the value has changed signifi cantly (adjusted with nciSendOnDltFlow) or if the heartbeat<br />

period has expired and its value has not changed in the meantime.<br />

nvoNomFlow SNVT Type: SNVT_fl ow Valid range: 0 l/s to 65534 l/s<br />

This value includes the set point of fl ow <strong>controller</strong>.<br />

nviFlowTempAddon SNVT Type: SNVT_fl ow Valid range: 0 l/s to 65534 l/s<br />

This <strong>variable</strong> increases the amount of <strong>air</strong> dynamically. The value of this <strong>variable</strong> will be added to the determined target<br />

value. Thus, for example an increase in the amount of <strong>air</strong> can be carried out for temperature control.<br />

Technical Documentation <strong>VAV500</strong> • Date: 07/2011 • Subject to change without prior notice • www.schneider-elektronik.com<br />

9

<strong>VAV500</strong><br />

<strong>Multi</strong>-<strong>functional</strong> <strong>variable</strong> <strong>air</strong> <strong>volume</strong> <strong>controller</strong>, <strong>analogue</strong>, LON, BACnet, Modbus<br />

LON-Network interface • Standard Variables (SNVTs)<br />

nvoPressure SNVT Type: SNVT_fl ow Valid range: -100 Pa bis +100 Pa<br />

This value contains the actual room pressure value, as measured through the <strong>analogue</strong> input of the room pressure<br />

sensor. The <strong>variable</strong> is transmitted when the value has changed signifi cantly (adjusted with nciSendOnDtPress) or if the<br />

heartbeat period has expired and its value has not changed in the meantime<br />

nvoTemperature SNVT Type: SNVT_temp_p Valid range: -273,17 °C to +327,66 °C<br />

This value contains the actual value of the temperature (only with connected temperature sensor).<br />

nviTemperature SNVT Type: SNVT_temp_p Valid range: -273,17 °C to +327,66 °C<br />

This value contains the setpoint value for the independent temperature control. If the value in nciTemperature > 0, then<br />

the value of nciTemperature is used as reference. With version 2 of the temperature control this <strong>variable</strong> contains the<br />

current actual temperature.<br />

nvoDigiIn1 SNVT Type: SNVT_switch Valid range: [(100,0 1), (0,0 0)]<br />

Status check of the digital input 1<br />

nvoDigiIn2 SNVT Type: SNVT_switch Valid range: [(100,0 1), (0,0 0)]<br />

Status check of the digital input 2<br />

nvoNormalRedu SNVT Type: SNVT_switch Valid range: [(100,0 1), (0,0 0)]<br />

State of the device, reduced operation (0,0 0), or normal operation (100.0 1)<br />

nviDDCNormaRedu SNVT Type: SNVT_switch Valid range: [(100,0 1), (0,0 0)]<br />

This <strong>variable</strong> is used to switch between reduced operation (0,0 0) and normal operation (100.0 1).<br />

nvoDDCNormaRedu SNVT Type: SNVT_switch Valid range: [(100,0 1), (0,0 0)]<br />

Image of nviDDCNormalRedu (100.0 1) = Normal operation, (0,0 0) = reduced operation.<br />

nvoOnOff SNVT Type: SNVT_switch Valid range: [(100,0 1), (0,0 0)]<br />

State of the device is switched on (100.0 1) or off (0,0 0).<br />

nviDDCOnOff SNVT Type: SNVT_switch Valid range: [(100,0 1), (0,0 0)]<br />

This <strong>variable</strong> is used to switch off and on operating, (100.0 1) = on, (0,0 0) = off.<br />

nvoDDCOnOff SNVT Type: SNVT_switch Valid range: [(100,0 1), (0,0 0)]<br />

Image of nviDDCOnOff (100.0 1) = on, (0,0 0) = off.<br />

nvoRoomAlarm SNVT Type: SNVT_switch Valid range: [(100,0 1), (0,0 0)]<br />

State of the room alarm (100.0 1) = alarm active, (0,0 0) = no alarm.<br />

nvoFlapPosition SNVT Type: SNVT_switch Valid range: 0 % bis 100 %<br />

Value contains the position of the damper in %.<br />

nvoVersion<strong>VAV500</strong> SNVT Typ: SNVT_str_asc Valid range: any string<br />

This <strong>variable</strong> contains the current software version of the device <strong>VAV500</strong>.<br />

10 Technical Documentation <strong>VAV500</strong> • Date: 07/2011 • Subject to change without prior notice • www.schneider-elektronik.com

<strong>VAV500</strong><br />

<strong>Multi</strong>-<strong>functional</strong> <strong>variable</strong> <strong>air</strong> <strong>volume</strong> <strong>controller</strong>, <strong>analogue</strong>, LON, BACnet, Modbus<br />

LON-Network interface • Standard Variables (SNVTs)<br />

3. Configuration parameter<br />

SNVT Type: SNVT_state<br />

nciHeartbeatnvo<br />

Valid range: any combination Default value: {1, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0}<br />

Returns the selection of the <strong>variable</strong>s sent during heartbeat. It allows multiple <strong>variable</strong>s are selected at a time:<br />

Bit 0 = 1: nvoRoomAlarm (Default)<br />

Bit 1 = 1: nvoOnOff<br />

Bit 2 = 1: nvoNormalRedu<br />

Bit 3 = 1: nvoBoxFlow<br />

Bit 4 = 1: nvoNomFlow<br />

Bit 5 = 1: nvoTemperature<br />

Bit 6 = 1: nvoPressure<br />

Bit 7 = 1: nvoFlapPosition<br />

SNVT Type: SNVT_state<br />

nciDeviceState<br />

Valid range: any combination Default value: {0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0}<br />

Bit 0 = 0: independent temperature control: Heating<br />

Bit 0 = 1: independent temperature control: cooling<br />

Bit 1 = 0: pressure cascade: supply <strong>air</strong><br />

Bit 1 = 1: pressure cascade: exhaust <strong>air</strong><br />

SNVT Type: SCPTdelayTime<br />

nciMinOutTm Valid range: 0,0 bis 6553,4 sec. At 0,0 function is Default value: 5,0<br />

turned off.<br />

This parameter determines the minimum transmission time distance for all output <strong>variable</strong>s.<br />

SNVT Type: SCPTmaxFlow<br />

nciFixFlowNorm<br />

Valid range: 0 l/s to 65534 l/s Default value: 0 l/s<br />

Value for consumers in the normal operation mode of the <strong>air</strong> fl ow <strong>controller</strong>.<br />

SNVT Type: SCPTminFlow<br />

nciFixFlowRedu<br />

Valid range: 0 l/s to 65534 l/s Default value: 0 l/s<br />

Value for consumers in the reduced operation mode of the <strong>air</strong> fl ow <strong>controller</strong>.<br />

SNVT Type: SCPTminFlow<br />

nciFlowRedu<br />

Valid range: 0 l/s to 65534 l/s Default value: 0 l/s<br />

Value of the minimum fl ow rate of the <strong>air</strong> fl ow <strong>controller</strong> for reduced mode. Flow <strong>controller</strong> is confi gured as constant fl ow<br />

<strong>controller</strong> (nciVAVType is 3 or 13).<br />

SNVT Type: SCPTmaxFlow<br />

nciFlowNorm<br />

Valid range: 0 l/s to 65534 l/s Default value: 0 l/s<br />

Value for the maximum fl ow rate of <strong>air</strong> fl ow <strong>controller</strong> for normal operation. Flow <strong>controller</strong> is confi gured as constant fl ow<br />

<strong>controller</strong> (nciVAVType is 3 or 13).<br />

SNVT Type: SNVT_count<br />

nciPercentFlow<br />

Valid range: 0 % to 200 % Default value: 100 %<br />

Value for percentage <strong>volume</strong> fl ow of the <strong>air</strong> fl ow <strong>controller</strong>.<br />

SNVT Type: SNVT_count<br />

nciVAVType<br />

Valid range: 0, 1, 2, 3, 11, 12, 13 Default value: 1<br />

Selects function of <strong>air</strong> fl ow <strong>controller</strong>.<br />

1 = summing, always on, summing selected channels and consumers<br />

11 = summing, on / off via LON, summing selected channels and consumers<br />

2 = room differential pressure sensor, always on, controls the difference between standard flow (operating) and<br />

FlowRedu (Reduced operation) and the sum of the selected channels and consumers<br />

12 = room differential pressure sensor, on / off via LON, controls the difference between standard flow (operating) and<br />

FlowRedu (Reduced operation) and the sum of the selected channels and consumers<br />

Technical Documentation <strong>VAV500</strong> • Date: 07/2011 • Subject to change without prior notice • www.schneider-elektronik.com<br />

11

<strong>VAV500</strong><br />

<strong>Multi</strong>-<strong>functional</strong> <strong>variable</strong> <strong>air</strong> <strong>volume</strong> <strong>controller</strong>, <strong>analogue</strong>, LON, BACnet, Modbus<br />

LON-Network interface • Standard Variables (SNVTs)<br />

3 = Constant <strong>volume</strong> fl ow <strong>controller</strong>, always on, controls FlowRedu or FlowNorm, depending on the condition<br />

13 = Constant <strong>volume</strong> fl ow <strong>controller</strong>, on / off via LON, controls FlowRedu or FlowNorm, depending on the condition<br />

0 = as 1: summing, always on, summarise selected channels and consumers<br />

SNVT Type: SCPTmaxFlow<br />

nciRoomAlarmFlow<br />

Valid range: 0 l/s to 65535 l/s Deafult value: 0 l/s<br />

Room alarm limit. The delay for the room alarm is fi xed at 5 minutes.<br />

SNVT Type: SNVT_count<br />

nciSensorPress<br />

Valid range: 1 Deafult value: 1<br />

Selection of the pressure sensor.<br />

1 = -50 Pa to +50 Pa<br />

SNVT Type: SNVT_press_p<br />

nciPressNominal<br />

Valid range: -100 Pa to +100 Pa Deafult value: +15 Pa<br />

Setpoint value of the room pressure in Pascal.<br />

SNVT Type: SNVT_press_p<br />

nciPressDZoneP<br />

Valid range: 0 Pa to 20 Pa Deafult value: 5 Pa<br />

Dead zone pressure control in the positive range in Pascal.<br />

SNVT Type: SNVT_press_p<br />

nciPressDZoneM<br />

Valid range: 0 Pa to 20 Pa Deafult value: 5 Pa<br />

Dead zone pressure control in the negative range in Pascal.<br />

SNVT Type: SNVT_press_p<br />

nciPressLimitP<br />

Valid range: -100 Pa to +100 Pa Deafult value: 0 Pa<br />

Pressure control limit as an offset to the setpoint value in the positive range in Pascal.<br />

If the value = 0, the pressure cascade in the positive range is disabled.<br />

SNVT Type: SNVT_press_p<br />

nciPressLimitM<br />

Valid range: -100 Pa to +100 Pa Deafult value: 0 Pa<br />

Pressure control limit as an offset to the setpoint value in the negative range in Pascal.<br />

If the value = 0, the pressure cascade in the negative range is disabled.<br />

SNVT Type: SNVT_count<br />

nciPressPercentP<br />

Valid range: 0 % to 100 % Deafult value: 20 %<br />

Maximum change value of the pressure cascade for <strong>air</strong> fl ow in % in the positive range.<br />

SNVT Type: SNVT_count<br />

nciPressPercentM<br />

Valid range: 0 % to 100 % Deafult value: 20 %<br />

Maximum change value of the pressure cascade for <strong>air</strong> fl ow in % in the negative range.<br />

SNVT Type: SCPTmaxFlow<br />

nciPressFlowStep<br />

Valid range: 0 l/s to 65535 l/s Deafult value: 10 l/s<br />

Limit value for the maximum change in fl ow rate under the pressure cascade control.<br />

SNVT Type: SCPTminFlow<br />

nciSendOnDltFlow<br />

Valid range: 0 l/s to 65535 l/s Deafult value: 6 l/s<br />

Value to the change in the value nvoBoxFlow required before a transmission takes place.<br />

SNVT Type: SNVT_switch<br />

nciTempActiv<br />

Valid range: [(100,0 1), (0,0 0)] Deafult value: (0,0 0)<br />

State of the independent temperature control, on (100,0 1) or off (0,0 0). The separate temperature <strong>controller</strong> regulates<br />

temperature from the predetermined value via an <strong>analogue</strong> control signal (range 0 V to 10 V) for a heating valve and a<br />

cooling valve.<br />

12 Technical Documentation <strong>VAV500</strong> • Date: 07/2011 • Subject to change without prior notice • www.schneider-elektronik.com

<strong>VAV500</strong><br />

<strong>Multi</strong>-<strong>functional</strong> <strong>variable</strong> <strong>air</strong> <strong>volume</strong> <strong>controller</strong>, <strong>analogue</strong>, LON, BACnet, Modbus<br />

LON-Network interface • Standard Variables (SNVTs)<br />

SNVT Type: SNVT_count<br />

nciSensorTemp<br />

Valid range: 0 to 1 Default value: 1<br />

Selects the type of sensor for temperature measurement.<br />

0 = temperature sensor on the internal temperature input<br />

1 = 0 V ... 10 V: 0 ° C ... 50 ° C<br />

SNVT Type: SNVT_temp_p<br />

nciTemperature<br />

Valid range: -273,17 °C to +327,66 °C Default value: --<br />

This value includes the static setpoint of temperature control. If a dynamic setpoint value is used via the <strong>variable</strong> nviTemperature,<br />

set nciTemperature has to be set to 0.<br />

SNVT Type: SCPTmaxFlow<br />

nciTempOffset<br />

Valid range: 0 l/s to 65535 l/s Default value: 0 l/s<br />

Offset value for temperature control.<br />

Depending on the difference (actual - setpoint value), an increase in the amount of <strong>air</strong> can be carried out. Contains this<br />

<strong>variable</strong> a value > 0, then for each 1 ° C difference the amount of <strong>air</strong> will be increased with this value.<br />

SNVT Type: SCPTdelayTime<br />

nciControlTime<br />

Valid range: 1,0 to 6553,4 sec Default value: 6,0<br />

This parameter determines the time interval of the control steps in the independent temperature control and in the pressure<br />

cascade.<br />

SNVT Type: SNVT_count<br />

nciControlFactor<br />

Valid range: 1 to 10 Default value: 4<br />

<strong>Multi</strong>plier for the independent temperature control or maximum value for the change per step in the pressure cascade.<br />

Technical Documentation <strong>VAV500</strong> • Date: 07/2011 • Subject to change without prior notice • www.schneider-elektronik.com<br />

13

p<br />

p<br />

p<br />

p<br />

p<br />

p<br />

<strong>VAV500</strong><br />

<strong>Multi</strong>-<strong>functional</strong> <strong>variable</strong> <strong>air</strong> <strong>volume</strong> <strong>controller</strong>, <strong>analogue</strong>, LON, BACnet, Modbus<br />

LON-<strong>volume</strong> fl ow <strong>controller</strong> operating modes<br />

LON network<br />

The LON network offers maximum fl exibility<br />

and safety. The building management<br />

system enables complete ventilation control<br />

and monitoring of all <strong>volume</strong> fl ow <strong>controller</strong>s<br />

as well as remote maintenance of<br />

the entire LabSystem product range. The<br />

building‘s central computer balances the<br />

ventilation requirements of the entire building<br />

and can also check all room pressure<br />

<strong>controller</strong>s for plausibility.<br />

Supply <strong>air</strong><br />

M<br />

<strong>VAV500</strong>-L<br />

Schematic diagram 1:<br />

Room balance via LON of up to 16 participants<br />

M<br />

Fume hood #1<br />

FC500<br />

LON<br />

M<br />

Fume hood #2<br />

FC500<br />

LON<br />

M<br />

#3 … #14 Fume hood #15 Exhaust #16<br />

LON-Network, FTT-10A<br />

FC500<br />

LON<br />

M<br />

Switchable<br />

exhaust<br />

<strong>VAV500</strong>-L<br />

CAV<br />

Floor exhaust<br />

Exhaust <strong>air</strong><br />

Room exhaust <strong>air</strong><br />

M<br />

<strong>VAV500</strong>-L<br />

Room balance in laboratories<br />

via LON<br />

Demand-related <strong>volume</strong> fl ows in laboratories<br />

change very quickly (< 3 sec) and<br />

high-speed regulation of room supply and exhaust <strong>air</strong> is<br />

essential. The required room negative or positive pressure<br />

in the laboratory must be maintained safely and and precisely<br />

at all times. Via the LON network, the SCHNEIDER<br />

VAV-L <strong>variable</strong> <strong>volume</strong> fl ow <strong>controller</strong> balances up to 16<br />

connected consumer loads with the appropriate exhaust <strong>air</strong><br />

<strong>volume</strong> fl ows and calculates the total and the difference to<br />

a specifi ed value (constant room <strong>air</strong> exchange rate). Thus<br />

this product is perfectly suited to room supply <strong>air</strong> (total) and<br />

exhaust <strong>air</strong> (difference) applications in laboratories.<br />

LON <strong>volume</strong> flow <strong>controller</strong> operating modes<br />

The <strong>VAV500</strong>-L <strong>variable</strong> <strong>volume</strong> fl ow <strong>controller</strong> with LON<br />

interface has various operating modes which can be confi -<br />

gured accordingly via the LON network. The following control<br />

types are implemented:<br />

• Variable <strong>volume</strong> flow <strong>controller</strong><br />

• 2 point constant <strong>volume</strong> flow <strong>controller</strong><br />

• Balancing <strong>volume</strong> flow <strong>controller</strong><br />

• Room <strong>volume</strong> flow differential <strong>controller</strong><br />

Lab room 1<br />

Variable <strong>volume</strong> flow <strong>controller</strong><br />

(operating mode 1)<br />

This description applies similary to the master and/or the<br />

slave.<br />

First the necessary confi guration properties are defi ned via<br />

the LON network.<br />

The setpoint setting of the <strong>volume</strong> fl ow that is to be regulated<br />

is done via the LON <strong>variable</strong> nviExtFlow[0]. Since summation<br />

of the different consumer loads (LON nodes) is not<br />

necessary here, this is the only setpoint setting. The <strong>volume</strong><br />

fl ow actual value is available via the LON <strong>variable</strong> nvo-<br />

BoxFlow and the <strong>volume</strong> fl ow setpoint via the LON <strong>variable</strong><br />

nvoNomFlow and may be used for testing or for master/<br />

slave sequential switching.<br />

Switching on/off via the DDC/BMS is possible with the LON<br />

<strong>variable</strong> nviDDCOnOff.<br />

For further explanations see the detailed SNVT description<br />

<strong>VAV500</strong>-L.<br />

Two independent control circuits with <strong>VAV500</strong>-L<br />

<strong>controller</strong><br />

Diagram 2 shows two control circuits independently operating<br />

(in terms of hardware and software) in a single<br />

<strong>VAV500</strong>-L <strong>controller</strong>, making it possible to implement two<br />

independent <strong>volume</strong> fl ow <strong>controller</strong>s. Operation is possible<br />

as Master 1 and Slave 1 or as Master 1 and Master 2. This<br />

can considerably reduce the total system costs, particularly<br />

for larger construction projects.<br />

Schematic diagram 2:<br />

Two independent control circuits master/master or<br />

master/slave<br />

Supply <strong>air</strong> Master 1 Master 2 or Slave 1<br />

M<br />

p<br />

<strong>VAV500</strong>-L<br />

M<br />

Exhaust <strong>air</strong><br />

p<br />

LON <strong>functional</strong>ity<br />

The LON functions of the VAV-L <strong>volume</strong> fl ow <strong>controller</strong> are<br />

implemented in accordance with the LonMark specifi cation<br />

8010 „VAV Controller (Variable Air Volume)“. See the SNVT<br />

list on pages 9 to 13.<br />

Laboratory / Cleanroom<br />

LON-Network, FTT-10A<br />

14 Technical Documentation <strong>VAV500</strong> • Date: 07/2011 • Subject to change without prior notice • www.schneider-elektronik.com

p<br />

p<br />

p<br />

p<br />

p<br />

<strong>VAV500</strong><br />

<strong>Multi</strong>-<strong>functional</strong> <strong>variable</strong> <strong>air</strong> <strong>volume</strong> <strong>controller</strong>, <strong>analogue</strong>, LON, BACnet, Modbus<br />

2 point constant <strong>volume</strong> flow <strong>controller</strong><br />

(operating mode 2)<br />

LON-<strong>volume</strong> fl ow <strong>controller</strong> operating modes<br />

Table 3: Forced control LON-operating mode 2<br />

This description applies similary to the master and / or the<br />

slave.<br />

First the required confi guration properties are defi ned via<br />

the LON network.<br />

Switching to 2-point operating mode is done via the LON<br />

<strong>variable</strong> nviDDCNormalRedu. The on/off function is also<br />

possible via the LON <strong>variable</strong> nviDDCOnOff. The standard<br />

values of the <strong>volume</strong> fl ows normal and reduced must<br />

already have been defi ned via the confi guration properties<br />

nciFlowNorm and nciFlowRedu.<br />

Switching can also be done via the digital inputs. The<br />

relationship is shown in table 3.<br />

Digital Inputs<br />

Function In 2 In 3 In4<br />

V MAX 0 0 0<br />

V MIN 1 0 0<br />

V MED 0 1 0<br />

V NOTFALL or<br />

damper = SHUT<br />

0 0 1<br />

Contact open = 0 (input not under current), contact closed<br />

= 1 (input under current).<br />

The digital input In1 has the highest priority and switches<br />

the fl ow <strong>controller</strong> <strong>VAV500</strong>-L ON or OFF.<br />

Balancing <strong>volume</strong> flow <strong>controller</strong><br />

(operating mode 3)<br />

This operating mode is particularly suitable for decentralized<br />

room control applications (e.g. laboratories with FC500<br />

LON fume hood <strong>controller</strong>s).<br />

In principle operating mode 1 applies<br />

here (<strong>variable</strong> <strong>volume</strong> fl ow <strong>controller</strong>).<br />

Schematic diagram 3:<br />

Room balance via LON of up to 16 participants<br />

Setpoint setting is achieved by automatic<br />

summation of up to 16 <strong>variable</strong> standard<br />

values via the LON network (e.g.<br />

exhaust <strong>air</strong> actual values of 16 fume<br />

hood <strong>controller</strong>s, such as FC500).<br />

The LON <strong>variable</strong>s nviExtFlow[0] to<br />

nviExtFlow[15] are designated for this<br />

purpose. Channel selection [0 to 15] is<br />

done via the LON <strong>variable</strong> nciChannels.<br />

Supply <strong>air</strong><br />

<strong>VAV500</strong>-L<br />

M<br />

M<br />

M<br />

FC500<br />

LON<br />

FC500<br />

LON<br />

M<br />

M<br />

FC500<br />

LON<br />

Switchable<br />

Exhaust<br />

Fume hood #1 Fume hood #2 #3 … #14 Fume hood #15 Exhaust #16<br />

LON-Network, FTT-10A<br />

Lab room 2<br />

<strong>VAV500</strong>-L<br />

CAV<br />

Floor exhaust<br />

Exhaust <strong>air</strong><br />

Constant loads, such as constant<br />

<strong>volume</strong> fl ow <strong>controller</strong>s (CAV) can be<br />

defi ned with the confi guration property<br />

nciFixFlowNorm (normal operation) and<br />

nciFixFlowRedu (reduced operation).<br />

Technical Documentation <strong>VAV500</strong> • Date: 07/2011 • Subject to change without prior notice • www.schneider-elektronik.com<br />

15

p<br />

p<br />

p<br />

p<br />

p<br />

<strong>VAV500</strong><br />

<strong>Multi</strong>-<strong>functional</strong> <strong>variable</strong> <strong>air</strong> <strong>volume</strong> <strong>controller</strong>, <strong>analogue</strong>, LON, BACnet, Modbus<br />

LON-<strong>volume</strong> fl ow <strong>controller</strong> operating modes<br />

Room <strong>volume</strong> flow difference <strong>controller</strong><br />

(operating mode 4)<br />

This operating mode is particularly<br />

suitable for room applications in which<br />

a constant room <strong>air</strong> exchange rate is<br />

required and the room exhaust <strong>air</strong> is<br />

generated by <strong>variable</strong> consumer loads.<br />

The required confi guration properties<br />

are fi rst defi ned via the LON network.<br />

In principle operating mode 3 applies<br />

here (balancing <strong>volume</strong> fl ow <strong>controller</strong>).<br />

The summated setpoint, consisting<br />

of the LON <strong>variable</strong>s nviExtFlow[0] to<br />

nviExtFlow[15] is now subtracted from<br />

a fixed value (room <strong>air</strong> exchange rate,<br />

LON <strong>variable</strong> nciMaxFlow). The result<br />

forms the new setpoint with which the<br />

room exhaust <strong>air</strong> <strong>controller</strong> is supplied.<br />

This ensures a constant room <strong>air</strong><br />

exchange rate, although the consumer<br />

loads change variably.<br />

Supply <strong>air</strong><br />

CAV<br />

Schematic diagram 4:<br />

Room <strong>volume</strong> flow difference <strong>controller</strong> and room balancing<br />

via LON of up to 16 participants<br />

M<br />

Fume hood #1<br />

FC500<br />

LON<br />

M<br />

Fume hood #2<br />

Lab room 3<br />

FC500<br />

LON<br />

M<br />

FC500<br />

LON<br />

#3 … #14 Fume hood #15 Exhaust #16<br />

LON-Network, FTT-10A<br />

M<br />

Switchable<br />

exhaust<br />

<strong>VAV500</strong>-L<br />

CAV<br />

Floor exhaust<br />

Exhaust <strong>air</strong><br />

Room exhaust <strong>air</strong><br />

M<br />

<strong>VAV500</strong>-L<br />

Diagram 5 shows the <strong>variable</strong> room<br />

exhaust <strong>air</strong> depending on the <strong>variable</strong><br />

consumer loads. The total exhaust<br />

<strong>air</strong> is the sum of the constant floor<br />