Clickable initiators, monomers and polymers in controlled radical ...

Clickable initiators, monomers and polymers in controlled radical ...

Clickable initiators, monomers and polymers in controlled radical ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

View Onl<strong>in</strong>e<br />

Downloaded on 09 November 2010<br />

Published on 20 September 2010 on http://pubs.rsc.org | doi:10.1039/C0PY00168F<br />

ence with propagat<strong>in</strong>g <strong>radical</strong>s lead<strong>in</strong>g to crossl<strong>in</strong>k<strong>in</strong>g. 77 high activation rates due to the suitable <strong>radical</strong>-stabilization<br />

Nevertheless, the TMS group was found to be <strong>in</strong>stable under the<br />

polymerization conditions us<strong>in</strong>g CuBr/PMDETA as catalyst that<br />

leads to a loss of protect<strong>in</strong>g group up to 70%. 78 The loss was<br />

ascribed to a nucleophilic attack to the TMS group by one of the<br />

nitrogen atoms of PMDETA. As a consequence, the less nucleophilic<br />

lig<strong>and</strong> bipyrid<strong>in</strong>e (bpy) was chosen to reduce the deprotection<br />

although it is not the optimum catalyst for ATRP reactions<br />

<strong>and</strong> does not avoid the decomposition completely. 78 Another<br />

strategy uses the more stable triisopropylsilyl group (TIPS) <strong>in</strong>stead<br />

of TMS reveal<strong>in</strong>g no loss dur<strong>in</strong>g the polymerization. 78 This might<br />

be due to the bulky character of the protect<strong>in</strong>g group that h<strong>in</strong>ders<br />

the nucleophilic attack of the metal/lig<strong>and</strong> complex. The alkynefunctionalized<br />

<strong><strong>in</strong>itiators</strong> bear<strong>in</strong>g either a chlor<strong>in</strong>e or a brom<strong>in</strong>e<br />

atom as an <strong>in</strong>itiat<strong>in</strong>g moiety were frequently reported for the<br />

polymerization of styrene, acrylates, methacrylates <strong>and</strong> N-isopropylacrylamide,<br />

whereby <strong>in</strong> some cases the term<strong>in</strong>al alkyne was<br />

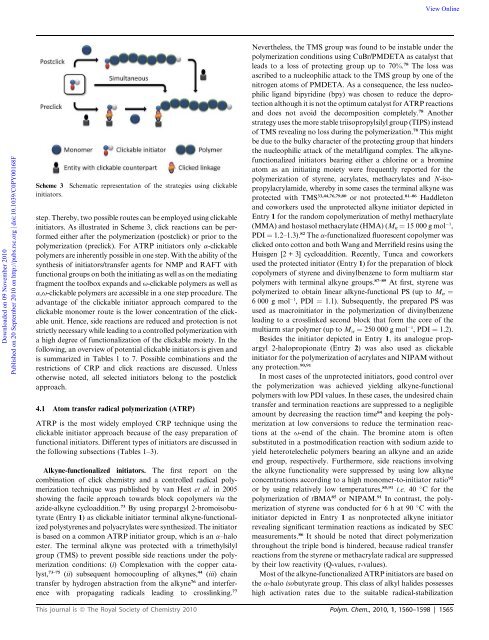

Scheme 3 Schematic representation of the strategies us<strong>in</strong>g clickable<br />

<strong><strong>in</strong>itiators</strong>.<br />

protected with TMS 33,44,76,79,80 or not protected. 81–86 Haddleton<br />

<strong>and</strong> coworkers used the unprotected alkyne <strong>in</strong>itiator depicted <strong>in</strong><br />

step. Thereby, two possible routes can be employed us<strong>in</strong>g clickable<br />

<strong><strong>in</strong>itiators</strong>. As illustrated <strong>in</strong> Scheme 3, click reactions can be performed<br />

either after the polymerization (postclick) or prior to the<br />

polymerization (preclick). For ATRP <strong><strong>in</strong>itiators</strong> only a-clickable<br />

<strong>polymers</strong> are <strong>in</strong>herently possible <strong>in</strong> one step. With the ability of the<br />

synthesis of <strong><strong>in</strong>itiators</strong>/transfer agents for NMP <strong>and</strong> RAFT with<br />

functional groups on both the <strong>in</strong>itiat<strong>in</strong>g as well as on the mediat<strong>in</strong>g<br />

fragment the toolbox exp<strong>and</strong>s <strong>and</strong> u-clickable <strong>polymers</strong> as well as<br />

a,u-clickable <strong>polymers</strong> are accessible <strong>in</strong> a one step procedure. The<br />

advantage of the clickable <strong>in</strong>itiator approach compared to the<br />

clickable monomer route is the lower concentration of the clickable<br />

unit. Hence, side reactions are reduced <strong>and</strong> protection is not<br />

strictly necessary while lead<strong>in</strong>g to a <strong>controlled</strong> polymerization with<br />

a high degree of functionalization of the clickable moiety. In the<br />

follow<strong>in</strong>g, an overview of potential clickable <strong><strong>in</strong>itiators</strong> is given <strong>and</strong><br />

is summarized <strong>in</strong> Tables 1 to 7. Possible comb<strong>in</strong>ations <strong>and</strong> the<br />

restrictions of CRP <strong>and</strong> click reactions are discussed. Unless<br />

otherwise noted, all selected <strong><strong>in</strong>itiators</strong> belong to the postclick<br />

approach.<br />

Entry 1 for the r<strong>and</strong>om copolymerization of methyl methacrylate<br />

(MMA) <strong>and</strong> hostasol methacrylate (HMA) (M n ¼ 15 000 g mol 1 ,<br />

PDI ¼ 1.2–1.3). 82 The a-functionalized fluorescent copolymer was<br />

clicked onto cotton <strong>and</strong> both Wang <strong>and</strong> Merrifield res<strong>in</strong>s us<strong>in</strong>g the<br />

Huisgen [2 + 3] cycloaddition. Recently, Tunca <strong>and</strong> coworkers<br />

used the protected <strong>in</strong>itiator (Entry 1) for the preparation of block<br />

co<strong>polymers</strong> of styrene <strong>and</strong> div<strong>in</strong>ylbenzene to form multiarm star<br />

<strong>polymers</strong> with term<strong>in</strong>al alkyne groups. 87–89 At first, styrene was<br />

polymerized to obta<strong>in</strong> l<strong>in</strong>ear alkyne-functional PS (up to M n ¼<br />

6 000 g mol 1 ,PDI¼ 1.1). Subsequently, the prepared PS was<br />

used as macro<strong>in</strong>itiator <strong>in</strong> the polymerization of div<strong>in</strong>ylbenzene<br />

lead<strong>in</strong>g to a crossl<strong>in</strong>ked second block that form the core of the<br />

multiarm star polymer (up to M w ¼ 250 000 g mol 1 ,PDI¼ 1.2).<br />

Besides the <strong>in</strong>itiator depicted <strong>in</strong> Entry 1, its analogue propargyl<br />

2-halopropionate (Entry 2) was also used as clickable<br />

<strong>in</strong>itiator for the polymerization of acrylates <strong>and</strong> NIPAM without<br />

any protection. 90,91<br />

In most cases of the unprotected <strong><strong>in</strong>itiators</strong>, good control over<br />

the polymerization was achieved yield<strong>in</strong>g alkyne-functional<br />

4.1 Atom transfer <strong>radical</strong> polymerization (ATRP)<br />

<strong>polymers</strong> with low PDI values. In these cases, the undesired cha<strong>in</strong><br />

transfer <strong>and</strong> term<strong>in</strong>ation reactions are suppressed to a negligible<br />

amount by decreas<strong>in</strong>g the reaction time 84 <strong>and</strong> keep<strong>in</strong>g the polymerization<br />

ATRP is the most widely employed CRP technique us<strong>in</strong>g the<br />

clickable <strong>in</strong>itiator approach because of the easy preparation of<br />

functional <strong><strong>in</strong>itiators</strong>. Different types of <strong><strong>in</strong>itiators</strong> are discussed <strong>in</strong><br />

the follow<strong>in</strong>g subsections (Tables 1–3).<br />

at low conversions to reduce the term<strong>in</strong>ation reac-<br />

tions at the u-end of the cha<strong>in</strong>. The brom<strong>in</strong>e atom is often<br />

substituted <strong>in</strong> a postmodification reaction with sodium azide to<br />

yield heterotelechelic <strong>polymers</strong> bear<strong>in</strong>g an alkyne <strong>and</strong> an azide<br />

Alkyne-functionalized <strong><strong>in</strong>itiators</strong>. The first report on the<br />

end group, respectively. Furthermore, side reactions <strong>in</strong>volv<strong>in</strong>g<br />

the alkyne functionality were suppressed by us<strong>in</strong>g low alkyne<br />

comb<strong>in</strong>ation of click chemistry <strong>and</strong> a <strong>controlled</strong> <strong>radical</strong> polymerization<br />

technique was published by van Hest et al. <strong>in</strong> 2005<br />

show<strong>in</strong>g the facile approach towards block co<strong>polymers</strong> via the<br />

azide-alkyne cycloaddition. 73 By us<strong>in</strong>g propargyl 2-bromoisobutyrate<br />

(Entry 1) as clickable <strong>in</strong>itiator term<strong>in</strong>al alkyne-functionalized<br />

polystyrenes <strong>and</strong> polyacrylates were synthesized. The <strong>in</strong>itiator<br />

is based on a common ATRP <strong>in</strong>itiator group, which is an a–halo<br />

ester. The term<strong>in</strong>al alkyne was protected with a trimethylsilyl<br />

group (TMS) to prevent possible side reactions under the polymerization<br />

conditions: (i) Complexation with the copper catalyst,<br />

concentrations accord<strong>in</strong>g to a high monomer-to-<strong>in</strong>itiator ratio 92<br />

or by us<strong>in</strong>g relatively low temperatures, 85,91 i.e. 40 C for the<br />

polymerization of tBMA 85 or NIPAM. 91 In contrast, the polymerization<br />

of styrene was conducted for 6 h at 90 C with the<br />

<strong>in</strong>itiator depicted <strong>in</strong> Entry 1 as nonprotected alkyne <strong>in</strong>itiator<br />

reveal<strong>in</strong>g significant term<strong>in</strong>ation reactions as <strong>in</strong>dicated by SEC<br />

measurements. 86 It should be noted that direct polymerization<br />

throughout the triple bond is h<strong>in</strong>dered, because <strong>radical</strong> transfer<br />

reactions from the styrene or methacrylate <strong>radical</strong> are suppressed<br />

by their low reactivity (Q-values, r-values).<br />

73–75 (ii) subsequent homocoupl<strong>in</strong>g of alkynes, 44 (iii) cha<strong>in</strong> Most of the alkyne-functionalized ATRP <strong><strong>in</strong>itiators</strong> are based on<br />

transfer by hydrogen abstraction from the alkyne 76 <strong>and</strong> <strong>in</strong>terfer-<br />

the a-halo isobutyrate group. This class of alkyl halides possesses<br />

This journal is ª The Royal Society of Chemistry 2010 Polym. Chem., 2010, 1, 1560–1598 | 1565