Documentation - SDMO

Documentation - SDMO

Documentation - SDMO

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

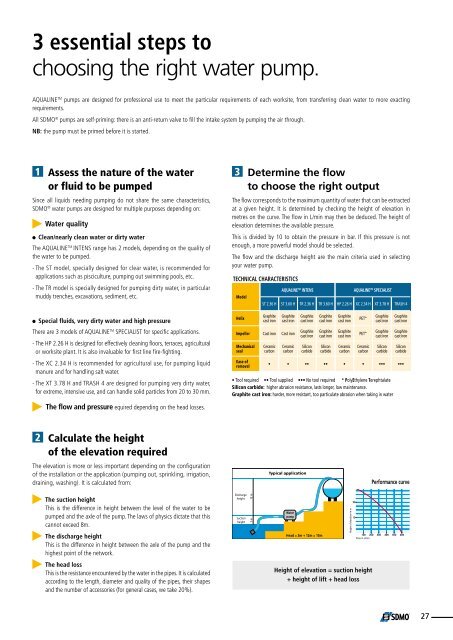

3 essential steps to<br />

choosing the right water pump.<br />

AQUALINE TM pumps are designed for professional use to meet the particular requirements of each worksite, from transferring clean water to more exacting<br />

requirements.<br />

All <strong>SDMO</strong> ® pumps are self-priming: there is an anti-return valve to fill the intake system by pumping the air through.<br />

NB: the pump must be primed before it is started.<br />

1 Assess the nature of the water 3 Determine the flow<br />

or fluid to be pumped<br />

to choose the right output<br />

Since all liquids needing pumping do not share the same characteristics,<br />

<strong>SDMO</strong> ® water pumps are designed for multiple purposes depending on:<br />

Water quality<br />

Clean/nearly clean water or dirty water<br />

The AQUALINE TM INTENS range has 2 models, depending on the quality of<br />

the water to be pumped.<br />

- The ST model, specially designed for clear water, is recommended for<br />

applications such as pisciculture, pumping out swimming pools, etc.<br />

- The TR model is specially designed for pumping dirty water, in particular<br />

muddy trenches, excavations, sediment, etc.<br />

The flow corresponds to the maximum quantity of water that can be extracted<br />

at a given height. It is determined by checking the height of elevation in<br />

metres on the curve. The flow in L/min may then be deduced. The height of<br />

elevation determines the available pressure.<br />

This is divided by 10 to obtain the pressure in bar. If this pressure is not<br />

enough, a more powerful model should be selected.<br />

The flow and the discharge height are the main criteria used in selecting<br />

your water pump.<br />

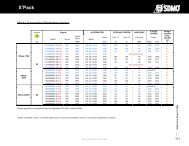

TECHNICAL CHARACTERISTICS<br />

Model<br />

AQUALINE TM INTENS<br />

AQUALINE TM SPECIALIST<br />

ST 2.36 H ST 3.60 H TR 2.36 H TR 3.60 H HP 2.26 H XC 2.34 H XT 3.78 H TRASH 4<br />

Special fluids, very dirty water and high pressure<br />

There are 3 models of AQUALINE TM SPECIALIST for specific applications.<br />

- The HP 2.26 H is designed for effectively cleaning floors, terraces, agricultural<br />

or worksite plant. It is also invaluable for first line fire-fighting.<br />

- The XC 2.34 H is recommended for agricultural use, for pumping liquid<br />

manure and for handling salt water.<br />

- The XT 3.78 H and TRASH 4 are designed for pumping very dirty water,<br />

for extreme, intensive use, and can handle solid particles from 20 to 30 mm.<br />

Helix<br />

Graphite<br />

cast iron<br />

Graphite<br />

cast iron<br />

Impeller Cast iron Cast iron<br />

Mechanical<br />

seal<br />

Ease of<br />

removal<br />

Ceramic<br />

carbon<br />

Ceramic<br />

carbon<br />

Graphite<br />

cast iron<br />

Graphite<br />

cast iron<br />

Silicon<br />

carbide<br />

Graphite<br />

cast iron<br />

Graphite<br />

cast iron<br />

Silicon<br />

carbide<br />

Graphite<br />

cast iron<br />

Graphite<br />

cast iron<br />

Ceramic<br />

carbon<br />

PET*<br />

PET*<br />

Ceramic<br />

carbon<br />

Graphite<br />

cast iron<br />

Graphite<br />

cast iron<br />

Silicon<br />

carbide<br />

Graphite<br />

cast iron<br />

Graphite<br />

cast iron<br />

Silicon<br />

carbide<br />

• • •• •• • • ••• •••<br />

• Tool required •• Tool supplied ••• No tool required * PolyEthylene Terephtalate<br />

Silicon carbide: higher abrasion resistance, lasts longer, low maintenance.<br />

Graphite cast iron: harder, more resistant, too particulate abrasion when taking in water<br />

The flow and pressure equired depending on the head losses.<br />

2 Calculate the height<br />

of the elevation required<br />

The elevation is more or less important depending on the configuration<br />

of the installation or the application (pumping out, sprinkling, irrigation,<br />

draining, washing). It is calculated from:<br />

Typical application<br />

Performance curve<br />

The suction height<br />

This is the difference in height between the level of the water to be<br />

pumped and the axle of the pump. The laws of physics dictate that this<br />

cannot exceed 8m.<br />

The discharge height<br />

This is the difference in height between the axle of the pump and the<br />

highest point of the network.<br />

The head loss<br />

This is the resistance encountered by the water in the pipes. It is calculated<br />

according to the length, diameter and quality of the pipes, their shapes<br />

and the number of accessories (for general cases, we take 20%).<br />

Discharge<br />

height<br />

Suction<br />

height<br />

12 m<br />

3 m<br />

Water<br />

pump<br />

Head = 3m + 12m = 15m<br />

Height of elevation in m<br />

Flow in L/min.<br />

Height of elevation = suction height<br />

+ height of lift + head loss<br />

27