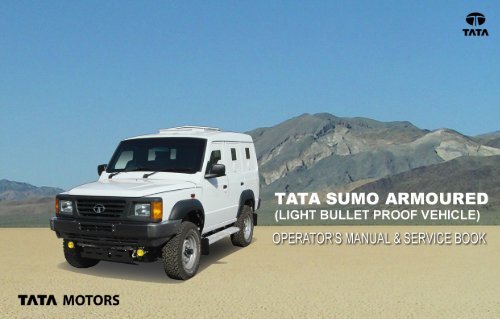

Sumo Armoured LBPV - Tata Motors Customer Care

Sumo Armoured LBPV - Tata Motors Customer Care

Sumo Armoured LBPV - Tata Motors Customer Care

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Owner’s Manual & Service Manual<br />

for<br />

TATA A SUMO<br />

LIGHT BULLET PROOF<br />

VEHICLE 4X4<br />

ISSUED BY<br />

PUNE

FOREWORD<br />

Thank you for selecting TATA LIGHT BULLET PROOF VEHICLE<br />

(4x4 ) of your choice.<br />

We welcome you to the world of advanced automotive engineering<br />

in a form especially suited to our operating conditions.<br />

This book gives you all the information necessary for making<br />

your ownership of the vehicle, a thoroughly satisfying experience.<br />

Should you need any special technical assistance, please<br />

contact us.<br />

Please note that by adhering to the correct operating procedures<br />

and scheduled maintenance, you can obtain the maximum<br />

performance from your vehicle.<br />

We request you to go through the book and derive many miles<br />

of motoring pleasure.<br />

We provide safe, high quality, high performance<br />

vehicles. In order to maintain the level of<br />

performance and reliability in the vehicle, it is<br />

important that only TATA MOTORS genuine<br />

accesories are to be fitted. Any accessory that is<br />

fitted or modification that is carried out can hamper<br />

the safety and performance of the vehicle besides<br />

depriving you of your warranty benefits.<br />

Use of genuine parts, designed and manufactured<br />

to our exacting standards, are the best way to<br />

maintain your vehicle in peak operating condition.<br />

Please do not use substitutes. They always prove<br />

costlier in the long run.<br />

Failure to use genuine parts can invalidate any<br />

future warranty claims.<br />

The information and specifications given in this<br />

book are valid as on the date of printing. TATA<br />

MOTORS LTD. reserves the right to make changes<br />

in design and specifications and/or to make<br />

additions to or improvements in this product without<br />

obligation to install them on products previously<br />

sold.<br />

(The contents given in this book are subject to change without notice, not binding and are for illustration purpose only.)<br />

iii

Contents<br />

Vehicle Identification .............. vi<br />

Vehicle details ............................ 1<br />

Warranty ..................................... 2<br />

Friendly notes<br />

Do's .............................................. 4<br />

Don’ts ........................................... 7<br />

Handling<br />

Location of aggregate<br />

serial numbers..............................8<br />

Keys.........................................................10<br />

Doors...........................................................10<br />

Rear view mirrors,Sunvisor .........11<br />

Seats.......................................................12<br />

First Aid Box & Fire<br />

Extinguisher..............................12<br />

Seat belt....................................13<br />

Vehicle tools and jack.................14<br />

Driving Controls..........................15<br />

iv<br />

Gear Shift Lever, Parking Brake,<br />

Spare Wheel.............................16<br />

Instruments Cluster/Instruments...17<br />

Steering lock cum<br />

ignition switch ....................... 20<br />

Combination switch.....................21<br />

Windsheild Wiper / Washer.........22<br />

Interior Lamps ...........................22<br />

Front Tow Hook.........................23<br />

Hazard Warning Switch,<br />

Tail Lamp. Registration Plate<br />

Lamp........................................24<br />

Front / Rear Fog lamps............. 25<br />

Head Lamp Levelling Switch, &<br />

High Mounted Stop Lamp.......... 26<br />

ECU,Towing Hook & Foot step.....27<br />

Roof Hatch & Observation<br />

Window ................................. 28<br />

Gun Port,Ventilator &<br />

Battery Isolator Switch.............. 29<br />

Engine compartment light,<br />

Bonnet opening and closing..,.... 30<br />

Turbocharger............................. 31<br />

Pre-silencer............................... 32<br />

Power steering ......................... 32<br />

Heating, Ventillation &<br />

Air Conditioning ....................... 35<br />

‘G’ Conscious pressure<br />

reducing valve........................... 37<br />

Preparing the vehicle for drive....38<br />

Driving, gear shifting ................ 41<br />

Driving Instructions, Braking ..... 42<br />

Stopping/starting the engine<br />

& Fuel economy........................ 43<br />

4x4 operation. ...........................44<br />

Vehicle maintenance<br />

Engine Compartment...................46<br />

Air Filter ................................... 47<br />

Engine Cooling system ............. 48

Contents<br />

Changing engine oil<br />

and oil filter ............................. 49<br />

Water Draining Procedure<br />

from Sedimenter........................50<br />

Fuel & Filter draining,<br />

Priming Pump / Pear Pump.........51<br />

Gear box Oil Checking/Changing..52<br />

Transfercase Oil Checking /<br />

Changing...........................................53<br />

Front / Rear Axle Oil Checking /<br />

Changing...........................................54<br />

Bleeding clutch system............... 55<br />

Brake system, Bleeding the<br />

brake system ........................... 56<br />

Brake adjustment....................... 58<br />

Adjustment of Parking brake....... 59<br />

Wheels and tyres....................... 60<br />

External Repair Kit ...................,.62<br />

Non-Skid Chains ........................63<br />

Tyre Rotation ......................... 63<br />

Battery...........................................64<br />

Head Lamp Adjustment................65<br />

Head lamp bulb replacement...... 67<br />

Bulb specifications..................... 68<br />

Fuses.......................................................69<br />

<strong>Care</strong> and cleaning of vehicle ... 70<br />

Preservation & De-preservation.. 73<br />

Special Operation Conditions .... 81<br />

Fuels, Lubricants, Coolants<br />

Fuels, Lubricants ...................... 82<br />

Coolants .................................. 83<br />

Recommended, oils & lubricant. 84<br />

Vehicle Data<br />

Technical Specifications............. 85<br />

Preliminary Trouble Shooting ..88<br />

Lubrication and Maintenance<br />

schedule<br />

Lubrication points ..................... 96<br />

Special instructions ................... 98<br />

Lubrication & Maintenance<br />

schedule.................................................99<br />

Vehicle record<br />

Service performed................... 102<br />

Repairs carried out.................. 104<br />

Abbreviations ......................... 106<br />

v

Vehicle identification<br />

Photographs<br />

TATA LIGHT BULLET PROOF VEHICLE 4 X 4 - DIFFERENT VIEWS<br />

vi

Vehicle details<br />

VERSION<br />

DESCRIPTION<br />

TATA LIGHT BULLET<br />

PROOF VEHICLE 4X4<br />

WITH 115PS 4SP DICOR<br />

ENGINE<br />

TATA <strong>LBPV</strong> 4X4 WITH 4SP DICOR ENGINE, 115PS, POWER STEERING,<br />

BUCKET SEAT, 6 SEATER, BHARAT STAGE III<br />

1

Warranty<br />

Terms and condition<br />

We WARRANT the TATA <strong>LBPV</strong><br />

4X4 vehicles and parts thereof<br />

manufactured by us to be free from<br />

defect in material and workmanship,<br />

subject to the following terms and<br />

conditions :<br />

1. This warranty shall be for 24<br />

months or 20,000 kms<br />

whichever expires first from the<br />

date of delivery of the vehicle.<br />

2. Our obligation under this<br />

warranty shall be limited to<br />

repairing or replacing, free of<br />

charge, such parts of the<br />

vehicle which, in our opinion,<br />

are defective, on the vehicle<br />

being brought to us or to our<br />

dealers within the warranty<br />

period. The parts so repaired<br />

or replaced shall also be<br />

warranted for quality and<br />

workmanship but such warranty<br />

shall be warranted for quality<br />

and workmanship but such<br />

warranty shall be co-terminus<br />

with this original warranty.<br />

3. Any part which is found to be<br />

defective and is replaced by<br />

us under the warranty shall be<br />

our property.<br />

4. As for such parts as tyres,<br />

batteries, transfer case, rubber<br />

parts, electrical equipment,<br />

power steering equipment, A.C.<br />

equipment not manufactured by<br />

us but supplied by other<br />

parties, this warranty shall not<br />

apply, but buyers of the vehicle<br />

shall be entitled to, so far as<br />

permissible by law, all such<br />

rights as we may have against<br />

such parties under their<br />

warranties in respect of such<br />

parts.<br />

5. This warranty shall not apply if<br />

the vehicle or any part thereof<br />

is repaired or altered otherwise<br />

than in accordance with our<br />

standard repair procedure, or<br />

by any person other than our<br />

sales or service establishments,<br />

our authorised dealers, subdealers<br />

or service centres in<br />

WARRANTY<br />

any way so as , in our<br />

judgement which shall be final<br />

and binding, to effect its<br />

reliability, nor shall it apply if,<br />

in our opinion which shall be<br />

final and binding the vehicle is<br />

subjected to misuse,<br />

negligence, improper or<br />

inadequate maintenance or<br />

accident or loading in excess<br />

of such carrying capacity as<br />

certified by us, or such<br />

services as prescribed in our<br />

Owner’s Manual and Service<br />

Book are not carried out by<br />

the buyer through our sales or<br />

service establishments, our<br />

authorised dealers or their<br />

sub-dealers or service centres.<br />

6. This warranty shall not cover<br />

normal wear and tear or any<br />

inherent normal deterioration of<br />

the vehicle or any of its parts<br />

arising from the actual use of<br />

the vehicle or any damage due<br />

to negligent or improper<br />

operation or storage of the<br />

vehicle. This warranty shall not<br />

2

Warranty<br />

Terms and condition<br />

apply to normal maintenance<br />

services viz. oils & fluid<br />

changes, head lamps<br />

focussing, fastener<br />

retightening, wheel balancing,<br />

tyre rotation, adjustment of<br />

valve clearance, fuel timing,<br />

ignition timing and<br />

consumables like bulbs, fuel<br />

filters and oil filters etc. This<br />

warranty shall not apply to any<br />

damage or deterioration caused<br />

by environmental pollution or<br />

bird droppings. This warranty<br />

shall not apply to V-belts, hoses<br />

and gas leaks in case of air<br />

conditioned vehicle. Slight<br />

irregularities not recognised as<br />

affecting the function or quality<br />

of the vehicle or parts, such<br />

as slight noise or vibration,<br />

defects appearing only under<br />

particular or irregular<br />

operations are item considered<br />

characteristic of the vehicle.<br />

7. This warranty shall be null and<br />

void if the vehicle is subjected<br />

to abnormal use such as<br />

rallying, racing or participation<br />

in any other competitive sports.<br />

This warranty shall not apply<br />

to any repairs or replacements<br />

as a result of accident or<br />

collision.<br />

8. This warranty is expressly in<br />

lieu of all warranties, whether<br />

by law or otherwise, expressed<br />

or implied, and all other<br />

obligations or liabilities on our<br />

part and we neither assume nor<br />

authorise any person to<br />

assume on our behalf, any<br />

other liability arising from the<br />

sale of the vehicle or any<br />

agreement in relation thereto.<br />

9. The buyer shall have no other<br />

rights except those set out<br />

above and have, in particular,<br />

no right to repudiate the sale,<br />

or any agreement or to claim<br />

any reduction in the purchase<br />

price of the vehicle, or to<br />

demand any damages or<br />

compensation for losses,<br />

incidental or indirect, or<br />

inconvenience or consequential<br />

WARRANTY<br />

damages, loss of vehicle, or<br />

loss of time, or otherwise,<br />

incurred or accrued.<br />

10. Any claim arising from this<br />

warranty shall be recognised<br />

only if it is notified in writing<br />

to us or to our concerned<br />

dealer without any delay soon<br />

after such defect as covered<br />

any ascertained under this<br />

warranty.<br />

11. This warranty shall stand<br />

terminated if the vehicle is<br />

taransferred or otherwise<br />

alienated by the buyer without<br />

our prior written consent.<br />

12. We reserve our rights to make<br />

any change or modification in<br />

the design of the vehicle or its<br />

parts or to introduce any<br />

improvement therein or to<br />

incorporate in the vehicle any<br />

additional part or accessory at<br />

any time without incurring any<br />

obligation to incorporate the<br />

same in the vehicles previously<br />

sold.<br />

3

Friendly notes<br />

4<br />

Do's<br />

1. Use recommended oils and<br />

lubricants only.<br />

2. Change oil in engine, gear box,<br />

transfer case, steering system,<br />

front live axle and rear axle at<br />

prescribed intervals.<br />

3. Use only genuine oil filter and<br />

fuel filter elements. Replace<br />

them at regular intervals as<br />

prescribed.<br />

4. Clean air filter element<br />

regularly. Replace filter<br />

element when service indicator<br />

shows red band even after<br />

cleaning the filter element.<br />

5. Ensure periodic servicing as<br />

per maintenance schedule.<br />

6. Insist on use of genuine cobranded<br />

spare parts.<br />

7. Ensure that caps of auxiliary<br />

tank and radiator are firmly<br />

fitted to keep the cooling<br />

system pressurised and to<br />

Do’s<br />

maintain coolant level. Always<br />

use radiator cap only of 1.0<br />

kg/cm2 (14 PSI), for<br />

replacement.<br />

8. check tyres for damage from<br />

time to time and remove any<br />

foreign bodies embedded in<br />

treads.<br />

When replacing tyres, have the<br />

wheels balanced. Keep grease,<br />

oil and fuel away from the<br />

tyres. In case of uneven tyre<br />

wear get the vehicle attended<br />

to by any of our authorised<br />

service set-ups.<br />

9. Maintain correct tyre<br />

pressure<br />

10. Check battery every week and<br />

top up electrolyte level. Keep<br />

battery terminals clean and<br />

cable joints tight. Apply<br />

vaseline/petroleum jelly on<br />

terminals. Use distilled water<br />

only for topping up.

Friendly notes<br />

Do's<br />

11. Observe correct polarity when<br />

connecting battery terminals.<br />

12. Disconnect alternator/battery<br />

terminals, ECU connections<br />

while carrying out any<br />

welding on the vehicle.<br />

13. Avoid panic braking. Use<br />

lower gears while descending<br />

gradients.<br />

14. Start moving the vehicle always<br />

in the 1st gear to avoid premature<br />

clutch wear.<br />

15. Keep both brake pedal and<br />

parking brake properly<br />

adjusted.<br />

16. Before engaging reverse<br />

gear, ensure that the vehicle<br />

has come to a stop, declutch,<br />

wait for a few seconds and then<br />

shift into reverse gear.<br />

17. When parking on slopes, use<br />

wheel chocks, apply parking<br />

brake and keep vehicle in low<br />

gear.<br />

Do’s<br />

18. In case of emergency parking<br />

or breakdown on road, pull<br />

the hazard warning switch to<br />

flash all the blinker lights to<br />

warn other road users.<br />

19. Release parking brake before<br />

driving off.<br />

20. Release the ignition key as<br />

soon as engine starts.<br />

21. Retighten wheel mounting nuts<br />

after 100 km of every wheel<br />

change.<br />

Tightening Torque : 12-15 mkg.<br />

22. Use only recommended FUSES<br />

and always keep spare fuses<br />

in the box.<br />

23. Inspect the engine belts<br />

replace, if found torn, cracked,<br />

worn or soaked in oil.<br />

5

Friendly notes<br />

Do's<br />

24. Ensure doors are properly<br />

closed.<br />

25. Insulation in the cab room<br />

should be kept-up in good<br />

condition.<br />

27. Vehicle has a turbocharged<br />

engine, keep engine in idlling<br />

speed for atleast a minute<br />

after starting and also before<br />

stopping it, to protect the<br />

turbo charger against damage<br />

due to oil starvation.<br />

Air conditioning system :<br />

1. Whenever vehicle is parked in<br />

the sun, drive with ventilator<br />

open for a few minutes to blowoff<br />

for hot air before switching<br />

on A.C.<br />

2. Keep all gun port, ventilator,<br />

roof hatch closed, when AC<br />

system is working.<br />

Do’s<br />

3. During stop and go city<br />

driving use lower gears to<br />

obtain efficient cooling.<br />

4. If you feel irritation in the eyes<br />

due to smoke or during long<br />

drive, stop AC and ventilate for<br />

half a minute by opening<br />

ventilator.<br />

5. Before stopping the engine first<br />

switch-off AC and then the<br />

blower.<br />

6. During off-season operate the<br />

air conditioner a few times<br />

every month to lubricate<br />

components.<br />

6

Friendly notes<br />

Dont's<br />

1. Do not use Clutch Pedal as<br />

Foot Rest. This will reduce<br />

clutch life. Avoid clutch riding.<br />

2. Do not Coast vehicle in<br />

Neutral and engine switchedoff<br />

position. This is a safety<br />

hazard.<br />

3. Do not run engine without<br />

Radiator Cap. Use genuine<br />

Cap only, to keep system<br />

pressurised.<br />

4. Do not overtighten engine oil<br />

filter.<br />

5. Vehicle has a turbocharged<br />

engine, do not stop the<br />

engine at once, allow it to run<br />

at idling speed for atleast 1<br />

minute. Also do not accelerate<br />

engine till the engine oil<br />

pressure has built up.<br />

6. Do not open HP system under<br />

any condition. It should be<br />

handled by trained professional<br />

only. (i.e. HP Pump, Rail,<br />

Injector, HP lines)<br />

7. Do not clean Engine<br />

Compartment with high<br />

pressure water jet. It can cause<br />

Malfunctioning of electronic<br />

components. Cleaning can be<br />

done with high pressure air.<br />

8. Do not clean air filter cartidge<br />

with high pressure air.<br />

Air conditioning system :<br />

Dont's<br />

1. Do not cause heating of AC<br />

pipe (where fitted), while<br />

welding / brazing in its<br />

vicinity.<br />

2. Do not open any hose / pipe<br />

points of AC system, where<br />

fitted.<br />

3. Do not put your hand inside<br />

the condenser fan when the<br />

grille is removed. Disconnect<br />

power supply to fan and switch<br />

off engine before any<br />

maintenance work, where<br />

applicable.<br />

7

Handling<br />

Location of aggregate serial mumbers<br />

Chassis number on frame Engine Number Gear box number ( G-76)<br />

XXXXXXX<br />

Transfer case number (4x4)<br />

Rear axle number (Spicer)<br />

Front live axle number (4x4)<br />

8

Handling<br />

Location of aggregate serial mumbers<br />

Body shell number plate (under<br />

bonnet)<br />

9

Handling<br />

Doors<br />

1<br />

Key (Two Nos.)<br />

Two identical keys have been provided<br />

for operation of steering lock cum<br />

ignition switch, for locking and<br />

unlocking of driver’s and co-driver’s<br />

side door, glove box, fuel tank flap and<br />

rear door.<br />

10<br />

Locking and Unlocking of Doors<br />

From outside : To unlock the door<br />

turn key anticlockwise and swing<br />

handle (1) upwards. To lock the door<br />

turn key clockwise.<br />

From inside : Lift knob (2) and then<br />

only pull handle (3) in the door panel<br />

to unlock the door. To lock the door<br />

press knob (2).<br />

In case knob (2) is pressed with<br />

door open, it will get released<br />

automatically when door is closed.<br />

The co-driver’s side door and rear<br />

door can be opened from outside as<br />

well as inside but locking is from<br />

inside by pressing knob 2. The rear<br />

door can be opened and locked from<br />

inside.

Handling<br />

Rear view mirrors, Sunvisors<br />

Sun visors<br />

Rear view mirror<br />

Rear view mirrors - outside<br />

Rear view mirrors<br />

Rear view mirrors are fitted on driver’s<br />

side door and co-driver’s side door.<br />

They can be adjusted to the desired<br />

positions by hand. The mirror can be<br />

folded backwards for convenience<br />

when the vehicle is to be driven<br />

through narrow passages.<br />

An additional adjustable rear view<br />

mirror is fitted inside the cab. Mirrors<br />

can be adjusted with the lever provided<br />

inside the cab on the doors.<br />

Rear view mirror in cabin<br />

Sunvisors<br />

Two adjustable sun visors are provided<br />

inside the cab to prevent sun glare.<br />

11

Handling<br />

Seats<br />

1. Seat Reclining Adjustment Lever<br />

2. Seat Adjustment (Forward/Backward) Lever<br />

Driver and Co-driver Seat :<br />

Adjustable type driver’s seat is<br />

provided. To Achieve correct position<br />

for proper driving, lift handle (2) to slide<br />

the seat either forward or backward.<br />

Once the desired position is achieved,<br />

push down the handle to lock the seat.<br />

Adjust the backrest to desired position<br />

using the lever(1) on right handside<br />

of backrest. Release the lever to lock<br />

it.<br />

12<br />

Seats for Rear Passengers<br />

Seats for rear passengers :<br />

Two seats are provided on both side<br />

for two persons to seat. Storage space<br />

is available below seat squabs.

Handling<br />

Seat belts<br />

1. Anchor 2. Webbing 3. Tongue 4. Buckle 5. Release button<br />

Seat Belt :<br />

The vehicle has been fitted with three<br />

point belt for extra safety for driver .<br />

Fastening the belt<br />

Insert belt tongue into buckle, a<br />

positive locking ‘click’ indicates correct<br />

and safe assembly.<br />

Releasing the belt<br />

Press the release button, the tongue<br />

will be ejected clear of the looking<br />

mechanism within the buckle.<br />

Belt adjustment<br />

When the vehicle is at rest, adjust the<br />

length of belt to suit convenience.<br />

Insert belt tongue in buckle. A positive<br />

click indicates correct assembly.<br />

Adjust length of the belt to suit you<br />

and fasten. The lap section should be<br />

comfortably tight, the diagonal sections<br />

should be adjusted so that a flat hand<br />

will just pass between the chest and<br />

the strap.<br />

13

Handling<br />

Seat belts, Tools<br />

To tighten (shorten) the belt<br />

Pull free end of webbing through<br />

adjuster until required adjustment is<br />

achieved.<br />

To loosen (lengthen) the belt<br />

Tilt the adjuster by means of the grip<br />

and slide it along the strap until suitably<br />

adjusted.<br />

CAUTION<br />

The belt is designed for use of<br />

only one person.<br />

The belt should at all times be<br />

adjusted and used in accordance<br />

with the instructions and no<br />

excessive slackness in the belt<br />

should be evident<br />

Avoid twisting the straps during<br />

use.<br />

Webbing must not be allowed to<br />

chafe against sharp edges on<br />

seat or bodywork.<br />

Do not make any alterations or<br />

additions to the belt. If in doubt,<br />

consult the authorised dealer.<br />

Belt that have been cut, frayed,<br />

damaged or have been stressed<br />

through impact, should be<br />

replaced.<br />

To clean, an occasional wipe with<br />

warm soapy water will maintain the<br />

webbing in a clean condition. Do<br />

not use bleach or dye under any<br />

circumstances.<br />

Periodic inspection of the<br />

installation will ensure safe and<br />

reliable service of the seat belt.<br />

Vehicle Jack & Tools<br />

Tool bag with tools, jack and handle<br />

are kept below the drivers seat.<br />

14

Handling<br />

Driving Controls<br />

Driving Control - TATA LIGHT BULLET PROOF VEHICLE 4x4<br />

1. Steering Wheel<br />

2. Instrument Cluster<br />

3. Combi-switch<br />

4. Ignition cum steering lockswitch<br />

5. Bonnet opening lever<br />

6. Accelerator pedal<br />

7. Brake pedal<br />

8. Clutch pedal<br />

9. Parking Brake<br />

10. Jack<br />

11. Gear shifting lever<br />

15

Handling<br />

Gear Shifting Lever, Parking Brake & Spare wheel<br />

2<br />

1<br />

Gear shift lever knob<br />

Gear Shift Lever :<br />

The different gear positions are<br />

markedon the knob. The 5th gear (an<br />

overdrive) has been provided to obtain<br />

better fuel economy while driving on<br />

highways.<br />

16<br />

1. Parking brake released<br />

2. Parkeing brake applied<br />

Parking Brake (Floor mounted) :<br />

The Parking brake is mounted on floor<br />

between RH door and driver’s seat.<br />

To apply the parking brake, pull lever<br />

full up. To release it, pull the lever up<br />

slightly, press the release button and<br />

push the lever down.<br />

Ensure parking brake is released<br />

before driving the vehicle. Indication<br />

is given on instrument cluster.<br />

Spare wheel<br />

Spare Wheel<br />

Spare wheel is located behind driver<br />

and co-driver seat.<br />

To remove the spare wheel, loosen<br />

spare wheel strap by operating<br />

ratchet. After loosening strap, remove<br />

hook and take out the spare wheel.

Handling<br />

Instrument cluster<br />

5 6 7 8 9 10<br />

11<br />

4<br />

3<br />

12<br />

2<br />

1<br />

13<br />

15<br />

14<br />

Instrument cluster<br />

17

Handling<br />

1. Fuel gauge<br />

18<br />

It indicate the apporximate level of<br />

fuel in tank.<br />

Fill up the tank with recommended<br />

diesel fuel well in advance, before<br />

the needle touches ‘E’ mark on the<br />

gauge.<br />

2. CHECK ENGINE<br />

Indicator<br />

This lamp indicates engine<br />

condition, when a malfunctioning<br />

occurs in engine OR EMS, this<br />

lamp indicates as below :<br />

i. Come ‘ON’ when key is in ‘IGN’<br />

position and goes ‘OFF’ after<br />

starting engine.<br />

ii. Remains ‘ON’ in engine<br />

running if malfuctioning occurs.<br />

3. Glow plug indicator<br />

light (Amber)<br />

CHECK<br />

ENGINE<br />

In the ‘ON’ position, the glow plug<br />

controller switches on the glow plugs<br />

and glow plug indicator comes ‘ON’.<br />

After a few seconds depending on<br />

the ambient temperature, the<br />

indicator light only goes ‘OFF’<br />

indicating that the engine can be<br />

started.<br />

If the glow plug indicator does not<br />

go ‘OFF’ automatically, get the<br />

electrical system of your vehicle<br />

checked.<br />

4. High beam indicator<br />

(Blue)<br />

5. Battery charging<br />

indicator light. (Red)<br />

It comes on when ignition key is<br />

turned to position ‘ON’ and must<br />

go ‘OFF’ when the engine starts<br />

running. if continues to glow, then<br />

it has to be checked at authorised<br />

dealer.<br />

6. Turn signal indicator<br />

(Left) (Green)<br />

7. Speedometer<br />

It indicate vehicle speed in km/h<br />

8. Odometer registers total distance<br />

covered by the vehicle in km.<br />

9. Turn signal indicator<br />

(Right) (Green)<br />

10. Oil pressure<br />

indicator light (Red)<br />

Instruments<br />

It comes on when ignition key is<br />

turned to position ‘ON’ and goes<br />

off as soon as the required oil<br />

pressure has developed after the<br />

engine has started. If the light<br />

continues to glow when the<br />

engine is running, it indicated low<br />

oil level in engine oil sump, or a<br />

fault in the lubrication or electrical<br />

system.<br />

Continued running of the engine<br />

when the oil pressure indicator<br />

light is on, may damage the<br />

engine.

Handling<br />

Instruments<br />

11. Brake fluid level /<br />

parking brake<br />

indicator: (Red)<br />

This indicator light is used for both<br />

the functions. When ignition is ON<br />

position the lamp will glow. Thus<br />

it shows bulb is OK.<br />

After the engine has started,<br />

light will go Off automatically. The<br />

light will remain ON, if the break<br />

fluid level is low or the parking<br />

brake is applied.<br />

12. Water in Fuel<br />

Sedimenter Indicator<br />

Whenever water in fuel sedimenter<br />

indicator glows in instrument<br />

cluster, the water need to be<br />

drained from fuel sedimenter.<br />

(Refer Page 50)<br />

13.Coolant temperature gauge<br />

( 0 C) Red band of this gauge<br />

indicates engine overheating.<br />

P<br />

14. Four wheel drive high<br />

indicator light (4x4)<br />

(Green)<br />

4WDH<br />

It comes on when ignition key is<br />

turned to position’ON’ and goes<br />

‘OFF’ after a few seconds. The<br />

light glows continuously<br />

when four wheel drive high mode<br />

is selected for vehicle driving.<br />

17. Four wheel drive low<br />

indicator light (4x4)<br />

(Green)<br />

4WDL<br />

It comes on when ignition key is<br />

turned to position ‘ON’ and goes<br />

off after a few seconds. The light<br />

glows continuously when four<br />

wheel drive low mode is selected<br />

for vehicle driving.<br />

19

Handling<br />

Steering lock cum ignition switch<br />

Steering lock cum ignition Switch<br />

Steering lock ignition switch<br />

Steering is provided with steering lock<br />

cum ignition switch<br />

<br />

<br />

<br />

20<br />

To lock steering while parking the<br />

vehicle as safety against theft.<br />

To start and stop the engine.<br />

To switch on and off the electrical<br />

system other than listed below.<br />

Steering lock cum ignition switch key<br />

positions<br />

Horn, parking lamps, engine<br />

inspection lamp, hazard warning<br />

switch, headlamp, map reading<br />

lamp, black out head lamp/ stop<br />

lamp / parking lamp and roof light<br />

convoy lamp,tail lamp,side<br />

indicator, Blinker stop light.<br />

<br />

To switch on and off accessories<br />

only.<br />

The switch is located on the steering<br />

column support and has the following<br />

key positions :<br />

LOCK<br />

Key can be inserted or taken out only<br />

in this position. Steering gets locked<br />

only after the key is withdrawn from<br />

the switch. After withdrawing the key<br />

from the switch ensure that steering<br />

is locked by turning steering wheel<br />

clockwise and anticlockwise.<br />

To unlock the steering, insert the key<br />

into the switch and turn it clockwise.<br />

If any difficulty arises in unlocking turn<br />

the steering wheel a little clockwise or<br />

anticlockwise while turning the key.<br />

ACC<br />

By turning the key to ‘ACC’ position<br />

power supply to accessories is<br />

switched on.

Handling<br />

ON<br />

By turning the key to this position all<br />

remaining electrical systems become<br />

operative and fuel guage, temperature<br />

gauge, battery charging indicator, low oil<br />

pressure indicator, parking brake/low<br />

brake fluid indicators, Check Engine,<br />

Water Seperator will come `ON’.<br />

In case of 4x4 vehicle in addition to<br />

above 4WDH & 4WDL lamps will come<br />

on and goes off after a few seconds.<br />

In ‘ON’ position, glow plug indicator<br />

lights up. After a few seconds, depeding<br />

on the ambient temperature, the<br />

indicator light only goes off indicating<br />

that the engine can be started.<br />

START<br />

Turn the key further clockwise to start<br />

position (spring loaded) to operate<br />

starter motor. As soon as the engine<br />

starts release the ignition key, so that key<br />

can come back to ‘ON’ position and<br />

starter motor disengages. Vehicle is<br />

driven in this position. By turning the<br />

ignition key from ‘ON’ position to ‘ACC’<br />

32 3<br />

4 1<br />

Combination switch - Turn signals, High/Low<br />

beam and High Flash<br />

or ‘LOCK’ position engine can be<br />

stopped.<br />

Combination switch<br />

The combination switch is mounted on<br />

steering column. It’s right side lever<br />

operates turn signals,<br />

Turn Signals<br />

Moving the combination switch lever in<br />

sideways direction operates the turn<br />

signals :<br />

Position ‘3’<br />

Position ‘4’<br />

- Turn signal left<br />

- Turn signal right<br />

The lever returns to neutral position<br />

automatically when the steering<br />

wheel is returned to straight ahead<br />

position.<br />

The combination switch lever can be<br />

operated up and down to select the<br />

headlight beam as follows :<br />

Position 1<br />

Position 2<br />

Combination switch<br />

- High beam<br />

- High beam flash<br />

High Beam Flash (No.2 position)<br />

High beam flash will be ‘ON’ as long<br />

as lever is held in position `2’ . This is<br />

spring loaded position and can be<br />

used in day time also for giving signal<br />

to the on coming traffic.<br />

21

Handling<br />

Windshield Wiper / Washer & Interior Lamp<br />

POSITION FOR<br />

WASH-ON<br />

Windshield wiper/washer operating lever<br />

Winshield wiper / washer<br />

The combination switch lever mounted<br />

on the left side operates the windshield<br />

wipers and washer :<br />

Position :<br />

‘OFF’- Wiper motor switched ‘OFF’<br />

‘INT’ - Wiper sweeps intermittently<br />

‘LO’ - Low speed of wiper motor<br />

‘HI’<br />

- High speed of wiper motor To<br />

operate windshield washer, lift<br />

the lever. The winshield washer<br />

will remain in operation as long<br />

as the lever is held in this<br />

position.<br />

Interior Lamp Location<br />

Interior Lamps :<br />

A interior lamp is fitted near inside<br />

rear view mirror for illunination. The<br />

individual ‘ON / OFF’ switch is provided<br />

on the lamp itself.<br />

This lamp is controlled by a door<br />

switch. This lamp comes ‘ON’ if any<br />

one door is open. Door switches are<br />

fitted on RHS/LHS door and tailgate.<br />

22

Handling<br />

Interior Lamps & Front Tow Hook<br />

Door Control Switch<br />

Interior Lamp<br />

Interior Lamp Door Control Switch- Tailgate<br />

FrontTowing Hook<br />

Door Control Switch<br />

Front Towing Hook :<br />

Front tow hook is below front bumper<br />

for vehicle towing.<br />

Towing Procedure :<br />

Make sure that, the vehicle is in neutral<br />

condition and in 4X2 mode while<br />

towing. Maximum driving speed 40<br />

kmph.<br />

Interior Lamp Door Control Switch<br />

23

Handling<br />

Hazard warning switch,Tail Lamp & Registration Plate Lamp<br />

Hazard warning switch<br />

Hazard warning switch<br />

This can be operated without ignition<br />

‘ON’. Pull the hazard warning switch<br />

(red knob) on the nacelle behind the<br />

steering wheel, all side indicator lights<br />

will flash simultaneously to warn the<br />

other road users about any hazardous<br />

condition of the vehicle. Depress<br />

the knob again to switch ‘OFF’ the<br />

hazard function.<br />

Rear Tail Lamp<br />

Tail Lamp :<br />

The tail lamp assembly incorporates<br />

the following :<br />

1. Rear Stop Lamp<br />

2. Rear Direction Indicator<br />

3. Reverse Light<br />

4. Rear Parking Lamp<br />

Registration Plate Lamp<br />

Registration Plate Lamp :<br />

Two concealed lamp are provided for<br />

illumination of the rear registration plate.<br />

24

Handling<br />

Front & Rear Fog Lamps<br />

2<br />

1<br />

Front Fog Lamp<br />

Front and Rear Fog Lamps :<br />

The front fog lamps are provided on<br />

the front chassis frame to improve<br />

thevisibility in foggy weather. The front<br />

fog lamp can be switched ‘ON’ by<br />

pushing the switch once with the<br />

headlamp ‘ON’ till the parking brake is<br />

switched ‘OFF;. The rear fog lamp<br />

willswitch ‘OFF’ if parking lamps are<br />

switched ‘OFF’ and will not come ‘ON’<br />

Rear Fog Lamp<br />

again with parking lamp ‘ON’ until<br />

deliberately switched ‘ON’ again.<br />

The switch for front fog lamp is an<br />

‘ON / OFF’ type switch. The rear fog<br />

lamp has the in-built tell tale indicating<br />

lamps for indicating the fog lamp<br />

operation.<br />

1. Switch for Rear Fog Lamp<br />

2. Switch for Front Fog Lamp<br />

25

Handling<br />

Head Lamp Levelling Switch & High Mounted Stop Lamp<br />

Headlamp Leveling Switch<br />

Head Lamp Leveling Switch (if fitted):<br />

A headlamp leveling switch is provided<br />

at the LH side of the steering column<br />

on dash board.<br />

As and when required headlamp leveling<br />

setting is done by rotating the<br />

knob to select one of the level marked<br />

in the switch depending upon the loading<br />

of vehicle.<br />

Switch<br />

Position<br />

O<br />

Loading Condition<br />

Unladen + Driver/Driver<br />

+ Co-driver<br />

1 Driver + Co-driver + All<br />

seats occupied<br />

2 Laden + All seats<br />

occupied<br />

3 Laden + All seats<br />

occupied + permissible<br />

luggage load<br />

High Mounted Stop Lamp<br />

High Mounted Stop Lamp:<br />

High mounted stop lamp is located on<br />

tail gate and it glows whenever service<br />

brake is applied in additional to<br />

two stop lamps.<br />

26

Handling<br />

ECU, Rear Towing Hook & Rear Foot Step<br />

ECU<br />

ECU :<br />

DICOR engine common rail system<br />

consist of ECU, sensors and<br />

actuators. The ECU receives input<br />

from various sensors located on the<br />

engine and the vehicle to decide the<br />

injected quantity and injection timing<br />

best suited for the engine to work with<br />

maximum efficiency and safety ECU<br />

is fitted inside the engine compartment<br />

Rear Central Towing Hook<br />

Rear Central Towing Hook :<br />

Rear central towing hook with locking<br />

arrangement has been provided for<br />

towing the trailor.<br />

Rear Foot Step<br />

Rear Foot Steps :<br />

Rear foot steps on RHS/LHS has been<br />

provided for ease of entering in or<br />

alighting from rear compartment.<br />

27

Handling<br />

Roof Hatch, Oservation Window and Gun Port<br />

1<br />

Roof Hatch (Optional Fitment)<br />

Roof Hatch :<br />

The roof hatch is provided for<br />

observation and firing front & rear.<br />

Roof Hatch Lock<br />

1. Handles<br />

Roof Hatch Lock:<br />

To open the roof hatch, first unlock the<br />

the latch knob by using key. Rotate the<br />

latch knob and push the hatch doors<br />

upwards.<br />

For closing the hatch doors, pull the<br />

handle swhich are provied on the doors<br />

from inside.<br />

1. Obeservation Window<br />

2. Gun port on rear door<br />

Observation Window With Gun<br />

Ports:<br />

Observation window (1) with gun port (2)<br />

is provided on tail gate door.<br />

28

Handling<br />

Gun Port, Ventilator & Battery Isolator Switch<br />

Gun port<br />

Gun Port :<br />

Gun ports are provided on the front<br />

left door, middle both doors, tail gate<br />

and LH & RH side windows at rear.<br />

Opening the gun port, press the knob<br />

and rotate in either direction.<br />

Gun ports are used to place gun for<br />

firing.<br />

Ventilator<br />

Ventilator :<br />

Battery Isolator Switch<br />

Battery Isolator Switch :<br />

Ventilator is located on the roof above<br />

driver & co-driver.<br />

Ventilator is provided for fresh air<br />

intake, when HVAC is not working.<br />

Battery Isolator Switch:<br />

This switch is provided near the gear<br />

shift lever to isolate the battery from<br />

electrical system when required. Battery<br />

Battery is connected to the starter and<br />

other circuitry through isolator switch.<br />

This is to be switched OFF while<br />

carrying out any work on the vehicle<br />

and also when the vehicle is parked<br />

for long duration to avoid battery<br />

drainage. This will also prevent any<br />

inadvertent short circuits during<br />

repairs.<br />

29

Handling<br />

Engine compartment light, Bonnet Opening / Closing<br />

1. Engine compartment light<br />

2. Engine compartment light switch<br />

Engine compartment light :<br />

To operate engine compartment light<br />

pull switch (2)<br />

Bonnet opening and closing :<br />

To open bonnet pull lever (1) This will<br />

release the bonnet lock. To open fully,<br />

lift the additional lock lever located on<br />

the bonnet centre with the help of<br />

finger. Use the bonnet stay rod to keep<br />

the bonnet open.<br />

30<br />

Bonnet Opening lever<br />

For closing the bonnet, disengage the<br />

stay rod, clamp it properly and press<br />

down the bonnet till it is fully shut.<br />

Ensure that the bonnet is fully<br />

locked driving off.<br />

In case of failure of cable attached to<br />

lever (1) bonnet lock can be opened by<br />

inserting a screw driver from the top<br />

centre position of grille through a slot<br />

provided behind it on the sheet metal<br />

Additional lock lever<br />

and by pressing the lock plate toward<br />

your left. Push upward the additional<br />

lock lever at your right and lift the bonnet<br />

while the lock plate is kept pressed with<br />

the help of a screw driver.

Handling<br />

Fresh<br />

Air in<br />

Turbocharger<br />

Compressor<br />

Wheel<br />

Turbocharger is an efficient<br />

supercharging device used in our<br />

engine. It makes use of thermal energyof<br />

engine exhaust gases to run a turbine<br />

which in turn drives a compressor to<br />

force air uner pressure into the inlet<br />

manifold.<br />

Pressure oil<br />

from engine<br />

Oil drain to engine<br />

Exhaust<br />

gas out<br />

Turbine Wheel<br />

Assembly<br />

Lubrication of Turbocharger :<br />

The rotor assembly of the<br />

turbocharger is supported by two<br />

floating lead bronze sleeve bearings<br />

in the bearing housing. These bearings<br />

are lubricated with the finest filtered<br />

and cooled oil from the lubrication<br />

Turbocharger<br />

system of the engine. There is a heat<br />

shield arrangement. provided between<br />

the gas chamber of the turbine nd the<br />

bearing housing to avoid heating of<br />

the bearings.<br />

Maintenance of Variable Geometry<br />

Turbocharger<br />

1. Tighten the following fasteners at<br />

PDI and thereafter at specified<br />

intervals.<br />

Turbocharger mounting<br />

Intercooler mounting<br />

Turbocharger hose connections<br />

& its mountings<br />

Intercooler hose connections<br />

and its mountings<br />

2. Check intercooler fins for any dust<br />

accumulations and clean by<br />

compressed air at at specified<br />

intervals.<br />

3. Check end play of turbocharger<br />

shaft and radial clearance between<br />

turbine wheel and housing at<br />

specified intervals.<br />

31

Handling<br />

Pre-silencer & Power steering<br />

1. RESERVOIR<br />

2. PUMP<br />

3. POWER STG.GEAR BOX<br />

4. FREE PLAY ADJUSTER<br />

5. LOCK NUT<br />

Pre-silencer:<br />

The construction of Presilencer consists<br />

of a cylindrical outer jacket, inside to<br />

which cylindrical perforated pipe & baffle<br />

are welded to it. As Exhaust gases<br />

passes through it expansion of gases<br />

occurs. At the both ends of presilencer<br />

triangular flanges are provided for the<br />

fitment of front & middle pipe assemblies.<br />

32<br />

Power steering - schematic circuit<br />

POWER STEERING<br />

Power steering is fitted for lighter<br />

steering effort and easy<br />

manoeuvrability. The system consists<br />

of steering gear box, hydraulic pump<br />

and hydraulic reservoir suitably<br />

mounted and connected by piping.<br />

Pump drive is through ‘V’ belt from<br />

engine. Power assistance is available<br />

during normal functioning of the<br />

power steering system.<br />

In case of any failure in hydraulic<br />

system, the steering can be<br />

operated mechanically with<br />

increased steering effort for<br />

bringing the vehicle to a repair<br />

station.

Handling<br />

Power steering hydraulic reservoir<br />

Procedure for oil filling and<br />

bleeding the power steering<br />

system.<br />

(Ensure that the reservoir is totally<br />

cleaned before starting the work.)<br />

1. Fill the reservoir nearly full.<br />

Crank the engine for 10 seconds<br />

without, if possible, allowing it<br />

to start. If the engine does start,<br />

shut off immediately.<br />

Check and refill the reservoir. Repeat<br />

at least three times, each time<br />

checking and refilling the reservoir.<br />

2. Check for any leakage in the<br />

system and if noticed take<br />

corrective action.<br />

3. Start the engine and steer the<br />

vehicle from full left to full right<br />

turn 3-4 times. Add fluid, if<br />

necessary to maintain the level up<br />

to the filter top.<br />

4. With the engine at steady speed,<br />

check for bubble / foaming in the<br />

fluid. If present it indicates that<br />

air is geting sucked into the<br />

system. Check the suction line /<br />

fittings and correct if necessary.<br />

5. Once the system is bled properly<br />

and free from foaming, there<br />

should not be appreciable change<br />

in fluid level in the reservoir, when<br />

the engine is started / stopped<br />

repeatedly. Top up or remove<br />

excess fluid so that the final level<br />

is at ‘H’ mark on dipstick.<br />

Power steering<br />

6. Now the system is ready for<br />

driving.<br />

CAUTION<br />

Do not allow the fluid level to drop<br />

significantly or run out of the<br />

reservoir during the above<br />

operation. This may induce air into<br />

the system.<br />

Do not start the engine without fluid<br />

in the power steering system. This<br />

will result in serious damage to the<br />

pump.<br />

NOTICE<br />

Always use recommended brand<br />

of fluid from closed container. Any<br />

dirty fluid poured in the system will<br />

result in damage to pump / gear.<br />

33

Handling<br />

Power Steering Belt tension<br />

Free play adjustment<br />

Ensure that vehicle is in straight ahead<br />

position. Remove tie rod ball joint on<br />

pitman arm. Hold sector shaft adjuster<br />

screw with 6 mm hexagonal key and<br />

loosen lock nut. Hold pitman arm and<br />

turn sector shaft adjuster screw<br />

clockwise till there is just no play of<br />

pitman arm. Tighten lock nut of<br />

adjuster screw without distrubing its<br />

position by holding with hex key. Turn<br />

steering wheel through its full<br />

movement and ensure that sector<br />

shaft movement is smooth throughout<br />

its range. Refit the tie rod ball joint to<br />

pitman arm. For any other complaints,<br />

get the system checked and rectified<br />

at our authorised workshops.<br />

For adjusting the power steering belt<br />

tension please refer page no.51.<br />

34<br />

Power steering pump belt tension<br />

Check :<br />

Check the conditions of belts on the<br />

engine. Examine the edge of the belt<br />

for cracks or fraying.<br />

Check the tension of the belt by<br />

pushing on it with your thumb<br />

Alternator/Power Steering belt as<br />

shown in Figure.<br />

The belts should have deflection of 8<br />

to 10 mm. (X).<br />

If the belt tension is not proper, get it<br />

attended at the nearest TATA<br />

Authorised Workshop.

Handling<br />

Heating,Ventilation & Air Conditioning<br />

C. Air Direction Control Knob :<br />

The air flow can be changed by turning<br />

the switch (C) to the desired direction.<br />

A<br />

D<br />

B<br />

E<br />

C<br />

Towards face<br />

Towards face and feet<br />

Towards feet<br />

HEATING, VENTILATION & AIR<br />

CONDITIONING : (if installed)<br />

A. Temperature Control Knob :<br />

The air temperature in the vehicle can<br />

be controlled by operating the<br />

temperature control knob (A) at the left<br />

hand side of the control panel. The<br />

temperature can be increased by<br />

rotating the knob towards the red<br />

segment and decreased by rotating it<br />

towards the blue segment.<br />

B. Blower Speed Regulation Knob<br />

:<br />

The ventilation system has a four<br />

speed blower. The blower speeds can<br />

be regulated to any one of the following<br />

speeds by operating the knob (B) at<br />

the centre of the control panel.<br />

1. LOW 2. MEDIUM 3. HIGH VERY<br />

HIGH<br />

Towards feet and windshield<br />

(Recommended for clearing<br />

fogging on windshield)<br />

Air demist / defrost windshield<br />

(Recommended for clearing<br />

heavy fog and snow)<br />

D. A.C. ON/OFF Switch :<br />

The A.C. can be switched 'ON' by<br />

pressing the switch (D) on the A.C.<br />

control panel provided the blower is<br />

`ON' and the engine is running. The<br />

indicator lamp will show that the A.C.<br />

is `ON'.<br />

35

Handling<br />

Heating,Ventilation & Air Conditioning<br />

E. Air Circulation Switch :<br />

In HVAC version to put air circulation<br />

mode in recirculation, press switch<br />

'E'. The indicator lamp will show air<br />

circulation is in recirculation.<br />

To put vehicle in Fresh mode release<br />

switch 'E'. Indicator lamp will be<br />

'OFF'.<br />

In recirculation mode, air inside the<br />

vehicle is circulated again and again.<br />

In Fresh mode, air is taken from<br />

atmosphere and circulated in the<br />

vehicle. Recirculation mode can be<br />

used<br />

While driving in dusty condition<br />

To avoid traffic pollution<br />

To get quick cooling/heating as<br />

required.<br />

Whenever discomfort is felt switch air<br />

circulation mode to fresh.<br />

NOTICE<br />

1. The A.C. can be switched `ON' only<br />

if the blower is 'ON' and engine is<br />

running. When A.C. is switched 'ON'<br />

engine idling RPM increases<br />

marginally, to adjust to the A.C.<br />

compressor load. When desired<br />

temperature is achieved A.C. trips<br />

'OFF' automatically.<br />

2. The A.C. compressor gets<br />

switched 'OFF' automatically when<br />

engine gets overheated. The A.C. is<br />

automatically switched 'ON' when the<br />

engine cools down.<br />

Normal Cooling :<br />

A.C.<br />

Knob 'B'<br />

Knob 'C'<br />

- ON<br />

- Desired speed position<br />

- Towards face<br />

Switch 'E' - Suitably as explained<br />

Quick Cooling :<br />

If your car is left in the sun with window<br />

closed, inside temperature increases.<br />

To achieve quick cooling effect, open the<br />

windows briefly while you operate the air<br />

conditioner, with air circulation switch is<br />

in Fresh mode, fan at higher speed and<br />

air direction towards 'FACE'. All vents to<br />

be opened completely.<br />

Once temperature inside has come<br />

down sufficiently, close the windows and<br />

change air circulation suitably to fresh/<br />

recirculation.<br />

36

Handling<br />

“G” Conscious pressure reducing valve for brakes<br />

“G” Conscious pressure<br />

reducing valve for brakes<br />

This valve consists of a barrel with<br />

one inlet and one outlet. A steel<br />

ball is kept rolling free in the barrel.<br />

When the brakes are applied the<br />

brake fluid going to rear wheel<br />

cylinders passes through this valve<br />

around the steel ball and goes out<br />

from other end to rear wheel<br />

cylinders. As the brakes are applied<br />

and vehicle decelerates, the free<br />

rolling ball moves forward due to<br />

its momentum and closes the port<br />

stopping the further supply of brake<br />

fluid to rear wheel cylinders. This<br />

ensures that cylinder pressure is<br />

limited to a value which avoids<br />

wheel locking.<br />

To achieve the specific cutout point<br />

the valve body is mounted on<br />

vehicle at 26 0 angle so that the ball<br />

has to climb some slope before<br />

closing the outlet port.<br />

37

Handling<br />

Preparing the vehicle for the drive<br />

Fuel tank fillerneck<br />

Check the following regularly,<br />

particularly before starting on a<br />

long journey.<br />

1. Fuel level in tank<br />

38<br />

Top up if required with correct<br />

diesel fuel, secure cap and lock<br />

the flap.<br />

1.Engine oil filler Cap<br />

2. Engine oil level<br />

2. Dip Stick<br />

Check engine oil level before<br />

starting the engine or at least 20<br />

minutes after stopping the engine.<br />

Top up if oil level is less than<br />

midway between upper and lower<br />

marks on the dipstick.<br />

The oil level should not exceed the<br />

'MAX’ mark. USE ONLY THE<br />

GENUINE CO- BRANDED OILS.<br />

Coolant Tank<br />

3. Coolant level<br />

With the engine cool, check the<br />

coolant in the no loss tank. The level<br />

should be between the 'FULL' and<br />

'MIN' marks. if the level is<br />

below the 'MIN' mark, top up with the<br />

genuine co-branded coolant. Bring<br />

the level upto the 'FULL' mark. The<br />

level must not exceed the 'FULL'<br />

mark. If the coolant level drops with<br />

in a short time after replenishing,<br />

there may be a leak in the system.

Handling<br />

Preparing the vehicle for the drive<br />

Rectify the leakage and top up<br />

radiator also. Use recommended<br />

coolant.<br />

If no leak can be found inspection<br />

should be carried out at a Authorised<br />

service outlet.<br />

NOTICE<br />

Always use radiator cap only of 1.0<br />

kg/cm 2 (14 psi), ifrequired to be<br />

replaced.<br />

4. Ensure battery electrolyte level is<br />

10-12 mm above top of battery<br />

plates. Top up with distilled water if<br />

required (NOT ACID).<br />

Keep battery terminals clean and<br />

tight. Apply petroleum jelly / vaseline<br />

on terminals for protection against<br />

corrosion. Secure cover provided<br />

over positive terminal.<br />

5. Check all lights, horn,<br />

gauges,switches and wiper for<br />

proper functioning.<br />

6. Check condition and tension of<br />

belts. ADJUST tension if necessary.<br />

Checking belts tension<br />

7. Check leakages of coolant, fuel<br />

and oil at all joints of hoses and<br />

pipes and rectify, if any. If coolant<br />

leakage is noticed, rectify the<br />

leakages and top up radiator also<br />

with recommended coolant.<br />

8. Check level of brake fluid in<br />

plastic container. Top up if<br />

necessary. Do not overfill. Use<br />

only GENUINE CO-BRANDED<br />

brake fluid.<br />

1. Brake fluid Container<br />

2. Clutch fluid Container<br />

9. Check level of clutch fluid in<br />

plastic container. Top up if<br />

necessary. Do not overfill as this<br />

would result in spillage during clutch<br />

operation. Use only GENUIN<br />

CO-BRANDED clutch fluid.<br />

10. Check level of water in Windshield<br />

washer reservoir, located in the<br />

engine compartment near the fuse<br />

box. Top up with clean water if<br />

required.<br />

39

Handling<br />

Preparing the vehicle for the drive<br />

B<br />

Gear box oil filler plug (G-76) Rear axle oil filler plug Transfer case<br />

A. Drain plug B. Oil level plug<br />

40<br />

Do not use soap solution.<br />

11. Level of gear box oil<br />

Periodically check gear box oil<br />

level.<br />

12.Level of front live axle oil (4x4)<br />

Periodically check front live axle oil<br />

level.<br />

13.Level of rear axle oil<br />

Periodically check rear axle oil<br />

level.<br />

14.Check condition of wiper<br />

blades, replace if rubber profile<br />

is damaged.<br />

15.Check level of oil in steering<br />

gear box.<br />

16.Check oil level in power steering<br />

hydraulic tank, where applicable.<br />

17.Check and correct tyre inflation<br />

pressure (with cold tyres).<br />

18.Level of transfer case oil (4x4)<br />

Periodically check oil level<br />

A<br />

CAUTION<br />

Do not use impact wrench to<br />

remove or install level / filling plug<br />

or drain plug since this will damage<br />

threads in the transfer case cover.<br />

19. Clean transfer case breather<br />

regularly for 4x4 vehicle.

Driving<br />

Before Driving<br />

Check<br />

<br />

<br />

<br />

<br />

<br />

Adjust<br />

<br />

<br />

Ensure<br />

<br />

<br />

<br />

<br />

Coolant level<br />

Engine oil level<br />

Tyre pressure<br />

Brake and clutch fluid level<br />

Doors are firmly closed<br />

Driver seat<br />

Rear view mirrors<br />

Gear shift lever is in neutral<br />

position.<br />

All switches and lamps are<br />

working.<br />

Brake fail indicator is 'OFF'<br />

Fuel level indicated in fuel<br />

gauge is above reserve<br />

mark.<br />

Gear lever knob (G-76 gear box)<br />

Start the engine and observe that :<br />

(Where turbocharged engine is fitted,<br />

run engine in low idle speed for<br />

atleast 1 minute and do not<br />

accelerate the engine till the engine<br />

oil pressure is built up.)<br />

Low oil pressure indicator light goes<br />

'OFF'<br />

Battery charging indicator light goes<br />

'OFF'<br />

Driving & Gear Shifting<br />

4 WDH and 4 WDL indicator lights<br />

go off in 2H mode in case of 4x4<br />

vehicle.<br />

VEHICLE IS NOW READY FOR A<br />

DRIVE<br />

DO NOT ALLOW VEHICLE TO ROLL<br />

BACK ON GRADIENTS.<br />

During Running-in period<br />

i.e. first 2,000 km. of operation :<br />

Do not exceed the following vehicle<br />

speeds :<br />

For 4x4 vehicles<br />

Gear<br />

Speed in km/hr.<br />

4x2 4x4 (low)<br />

1st to 2nd 20 10<br />

2nd to 3rd 35 14<br />

3rd to 4th 50 -<br />

4th to 5th 75 -<br />

41

Driving Instructions<br />

Driving , Gear Shifting, Braking<br />

<br />

<br />

<br />

42<br />

Avoid rapid acceleration and<br />

prolonged high speed runnings of<br />

the engine.<br />

Avoid sudden braking.<br />

Retighten wheel nuts to 12-15 mkg<br />

torque after first 100 km of running<br />

of a new vehicle and after every<br />

wheel change.<br />

Driving instructions<br />

<br />

<br />

<br />

<br />

DRIVE SAFELY AND JUDICIOUSLY<br />

REMEMBER SAFETY FIRST.<br />

Depress clutch pedal fully before<br />

shifting gears. This will ensure<br />

longer synchro cone life.<br />

For smooth starting of vehicle<br />

without jerks, synchronise<br />

release of clutch pedal with<br />

pressing of accelerator pedal.<br />

Start the vehicle in first gear only.<br />

Change gears at appropriate<br />

speeds and do not lug the engine<br />

by too early shifting to higher<br />

gear at low speeds.<br />

Recommended speeds for gear<br />

changes ( For 4x4 vehicles)<br />

<br />

<br />

<br />

Gear<br />

Speed in km/hr.<br />

4x2 4x4 (low)<br />

1st 22 10<br />

2nd 40 15<br />

3rd 60 -<br />

4th 70 -<br />

5th 85 -<br />

Engage reverse gear, only when<br />

vehicle is stationary.<br />

To engage reverse gear, move<br />

ear shift lever to extreme left and<br />

push it forward.<br />

Depress clutch pedal fully before<br />

engaging the reverse gear. Wait<br />

for a few seconds then engage<br />

the gear. If the gear shifting does<br />

not occur, then release the clutch<br />

pedal, once again press the<br />

clutch pedal and engage the<br />

reverse gear.<br />

Braking<br />

<br />

<br />

<br />

<br />

<br />

While braking on turns apply<br />

brakes gently.<br />

Before driving down a long steep<br />

gradient, reduce vehicle speed<br />

by changing to lower gear.<br />

Do not ride the brakes as they<br />

may overheat and their<br />

performance may be impaired.<br />

Do not use half engaged clutch<br />

to hold the vehicle on up<br />

gradient as this will result in<br />

premature clutch failure.<br />

After driving through pockets of<br />

water, apply the brake a few<br />

times at low speed to get rid of<br />

moisture inside the brake drums.<br />

When it begins to rain, reduce<br />

vehicle speed and avoid sudden<br />

braking.

Driving Instructions<br />

Engine Starting & Stopping and Fuel Economy<br />

Starting the engine :<br />

Before starting<br />

1. Apply parking brake.<br />

b. Ensure gear lever in neutral.<br />

3. Insert the key in steering cum<br />

ignition lock and turn it to ‘ON’<br />

position.<br />

4. Press the clutch pedal fully.<br />

5. Now crank the engine.<br />

6. If the engine does not start turn<br />

the key to ‘OFF’ position and<br />

try after 30 seconds.<br />

NOTICE<br />

After starting run the engine in<br />

low idle speed for at least 30 sec.<br />

Do not press accelerator pedal<br />

while starting the engine to avoid<br />

damage to turbocharger.<br />

Stopping the engine :<br />

Before switching ‘OFF’ the engine, run<br />

the engine idle for atleast 30 seconds<br />

and then switch ‘OFF’. This will allow<br />

the engine oil to lubricate the turbo-<br />

charger, till its speed is fully reduced<br />

and also allow the unit to cool down.<br />

Above precautions will ensure<br />

satisfactory life and performance from<br />

the turbocharger.<br />

Fuel Economy :<br />

a. Drive smoothly, accelerate<br />

gradually and anticipate stops.<br />

b. Best fuel consumption is obtained<br />

at low engine speeds in the<br />

highest possible gear without<br />

labouring the engine.<br />

c. Driving with accelerator pedal fully<br />

depressed means using<br />

excessive fuel.<br />

d. Do not allow the engine to labour<br />

by too early high gear changes.<br />

Change to lower gear when<br />

engine no longer runs smoothly<br />

e. If possible do not idle the engine<br />

for more than 5 minutes. Switch<br />

‘OFF’ the engine.<br />

f. Do not ride clutch. Do not use<br />

clutch pedal as foot rest.<br />

g. When changing from 4H/4L to 2H<br />

of transfer case, 2H free wheeling<br />

should be done . If 2H free<br />

wheeling is not done the hub locks<br />

of front hub are remain locked<br />

causing unnecessary rotation of<br />

front drive components and this<br />

consumes more fuel.<br />

H. Depending on traffic conditions<br />

a constant speed should be<br />

maintained<br />

The vehicle uses more fuel,<br />

every time you speed up or slow<br />

down.<br />

I. Avoid hard braking, abrupt<br />

cornering and rapid acceleration.<br />

43

Driving Instructions<br />

Location of 4x4 Selector switch<br />

Transfer Case and Transfer Case<br />

nselector Electric Switch :<br />

On four wheel drive vehicles<br />

transfer case is fitted after the gear<br />

box for driving front live axle along<br />

with rear axle.<br />

The following 3 positions are<br />

provided on selector switch :<br />

2H Only rear wheels are driven and<br />

transfer case operates at 1:1<br />

ratio.<br />

44<br />

Automatic Hub Lock<br />

4H All four wheels are driven and<br />

transfer case operates at 1:1<br />

ratio.<br />

4L<br />

All four wheels are driven and<br />

transfer case operates at 2.48:1<br />

speed reduction ratio.<br />

Automatic hub locks (4x4)<br />

While driving in 2H mode this<br />

mechanism on the front axle hub<br />

allows the hub to free wheel. This<br />

4x4 Operations<br />

avoids the unnecessary spinning of<br />

front axle drive components and<br />

results in fuel saving, reduced noise<br />

and longer component life.<br />

As soon as 4H or 4L mode is<br />

selected the hub gets automatically<br />

connected to front drive line to<br />

increase the traction.<br />

Instructions for 4x4 operation<br />

1. With ignition ‘ON’ 4WDH &<br />

4WDL indicator lights on panel<br />

should glow for a few seconds<br />

onlyd then go off.<br />

CAUTION<br />

While in 2H mode, continuous<br />

illumination of 4WDL & 4WDH<br />

lights indicate electrical fault like<br />

short or open circuit. Do not<br />

march the vehicle in this case.<br />

2. Shifting from 2H to 4H : Turn<br />

the selector knob from 2H to 4H<br />

position. 4WDH indicator on<br />

instrument panel will light up.

Driving Instructions<br />

Changing from 2H to 4H can be<br />

done at any speed upto 65 km/h.<br />

No pressing of clutch pedal is<br />

required<br />

3. Shifting from 4H to 2H : Turn<br />

the selector knob from 4H to 2H<br />

position. 4WDH indicator on<br />

instrument panel will go off.<br />

Changing from 4H to 2H can be<br />

done at any speed upto 65<br />

km/h. No pressing of clutch pedal<br />

is required.<br />

Free wheeling of front hub : After<br />

shifting from 4H to 2H, for effecting<br />

free wheeling of front wheels,<br />

direction of vehicle motion needs<br />

to be changed. If in4H mode the<br />

vehicle was moving forward then<br />

stop it, wait and then engage<br />

reverse gear of main gear box. If it<br />

was moving reverse in 4H mode<br />

then stop it, wait and then engage<br />

forward gear of main gear box.<br />

(After stopping and changing the<br />

gear the vehicle must travel in<br />

opposite direction for a minimum<br />

of three meters, before free<br />

wheeling takes place.)<br />

4. Shifting from 4H to 4L<br />

Stop the vehicle. Press clutch<br />

pedal. Turn the selector knob from<br />

4H to 4L position. 4WDL indicator<br />

light on instrument panel will blink<br />

a few times and remain on.<br />

5. Shifting from 4L to 4H<br />

Stop the vehicle. Press clutch<br />

pedal. Turn the selector knob from<br />

4L to 4H position. 4WDH indicator<br />

light on instrument panel will blink<br />

a few times and remain on.<br />

CAUTION<br />

In case of malfunctioning in<br />

shifting from 4H to 4L or 4L to<br />

4H, respectively 4L or 4H<br />

indicator light will flash<br />

continuously, Do not march the<br />

vehicle in such a case.<br />

4x4 Operations<br />

Do not use 4H or 4L modes<br />

continuously on dry and hard<br />

surfaced road except for<br />

checking operations.<br />

Limited Slip Differential :<br />

A standard differential delivers torque<br />

equally to each wheel. In case one<br />

wheel loses traction and begins to<br />

spin, the differential distributes the<br />

rotary speed unequally but with same<br />

torque. This can cause the wheel with<br />

good traction to slow down or stop<br />

while the wheel which lost traction<br />

rotates with increased speed. Such a<br />

situation can prevent the vehicle from<br />

moving. The limited slip differential<br />

provided in the rear axle takes care<br />

of such situations. The clutch lock<br />

arrangement provided internally,<br />

ensures that in case one wheel loses<br />

traction and begins to slip, a locking<br />

action takes place which prevents<br />

differential action and both wheels turn<br />

at the same speed.<br />

45

Vehicle Maintenance<br />

Engine Compartment<br />

ENGINE COMPARTMENT<br />

1. Fuse Box<br />

2. Power Steering Fluid Container<br />

3. Brake Fluid Container<br />

4. Clutch Fluid Container<br />

5. Engine Oil Filler Cap<br />

6. Dip Stick<br />

7. Air Filter<br />

8. Air Pre-cleaner<br />

9. Radiator Cap<br />

10. Engine Coolant Tank<br />

11. Windshield Washer Fluid Container<br />

46

Vehicle Maintenance<br />

Air Filter<br />

Air Filter :<br />

The air filter element should be<br />

periodically cleaned.Replace the air<br />

filter element with a new one when the<br />

service indicator shows red band<br />

even after cleaning.<br />

Always use genuine air filter element.<br />

Air filter for SUMO <strong>Armoured</strong> DICOR<br />

diesel engine is located at LH side of<br />

engine compartment.<br />

Replacement of Air Filter Element :<br />