Water booklet single pages.qxd - City of St. George

Water booklet single pages.qxd - City of St. George

Water booklet single pages.qxd - City of St. George

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

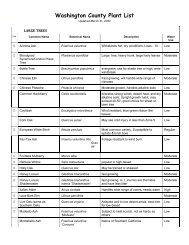

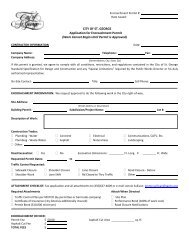

2 0 0 5 A N N U A L W A T E R R E P O R T<br />

QUAIL CREEK WATER TREATMENT PLANT<br />

MILLION GALLONS<br />

500<br />

450<br />

400<br />

350<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

0<br />

2004 / 2005<br />

PRODUCTION TOTAL<br />

77.4<br />

109.5<br />

219.7<br />

60<br />

247.2<br />

277.9<br />

351.9<br />

435.6<br />

428.6<br />

488<br />

433<br />

0 0 0 0 0<br />

0 00<br />

JAN FEB MAR APR MAY JUN JUL AUG SEP OCT NOV<br />

422<br />

321<br />

294.5<br />

259<br />

180<br />

50<br />

DEC<br />

2004<br />

2005<br />

The QCWTP is the first culinary water treatment plant built by the <strong>City</strong> <strong>of</strong> <strong>St</strong>. <strong>George</strong>. The Virgin<br />

River is the water source for the plant. The plant began operating in 1988 with a production capacity<br />

<strong>of</strong> ten million gallons a day (MGD). The plant was expanded in the year 1995 to a capacity <strong>of</strong> 20<br />

MGD. In the fall <strong>of</strong> the year 2004, construction began to expand plant production capacity to 40<br />

MGD. Treated water from the QCWTP will be fed into the regional pipeline as a resource for the <strong>City</strong><br />

<strong>of</strong> <strong>St</strong>. <strong>George</strong> as well as Ivins, Washington and Santa Clara cities. The current expansion project includes<br />

several components.<br />

DISSOLVED AIR FLOTATION SYSTEM (DAF)<br />

The construction <strong>of</strong> a DAF system with the capacity to treat 40 MGD makes the QCWTP the largest<br />

DAF plant in the western United <strong>St</strong>ates. The DAF system super saturates water with air at 90 pounds per<br />

square inch (PSI) <strong>of</strong> pressure. The water is then injected into the water supply and allowed to return to<br />

atmospheric pressure. In this process the dissolved air comes out <strong>of</strong> the solution and floats the particles in<br />

the water. The floating particles are called sludge and are skimmed <strong>of</strong>f <strong>of</strong> the water into a collection system<br />

for drying and disposal. Because this system does not use filters, no backwashing is required, reducing<br />

the amount <strong>of</strong> water that goes to "waste" in the treatment process.<br />

NEW 9.5 MILLION GALLON STORAGE<br />

Construction <strong>of</strong> a new 9.5 million gallon water storage tank combined with the existing five million gallon<br />

storage provides the storage needed to supply water to the regional pipeline.<br />

OTHER ASPECTS OF THE EXPANSION<br />

Construction <strong>of</strong> a new pretreatment basin, flow control building, four new filters, four new sludge<br />

lagoons and a new reclamation building. The computer program that monitors the levels in the<br />

two water storage tanks as well as the treatment process is also being upgraded.<br />

1 8