British American Tobacco P21.pdf - Corby Borough Council

British American Tobacco P21.pdf - Corby Borough Council

British American Tobacco P21.pdf - Corby Borough Council

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

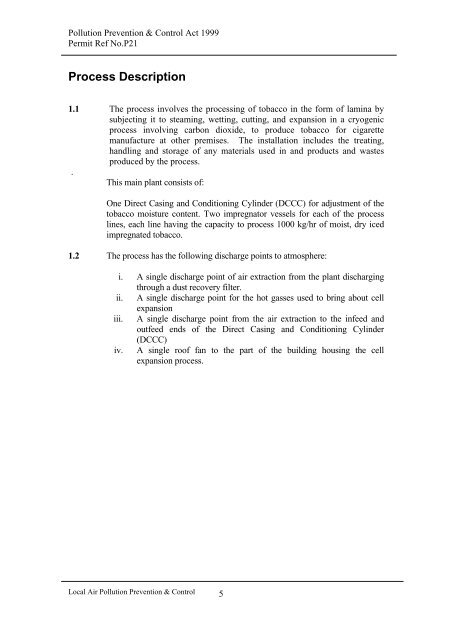

Pollution Prevention & Control Act 1999<br />

Permit Ref No.P21<br />

Process Description<br />

1.1 The process involves the processing of tobacco in the form of lamina by<br />

subjecting it to steaming, wetting, cutting, and expansion in a cryogenic<br />

process involving carbon dioxide, to produce tobacco for cigarette<br />

manufacture at other premises. The installation includes the treating,<br />

handling and storage of any materials used in and products and wastes<br />

produced by the process.<br />

.<br />

This main plant consists of:<br />

One Direct Casing and Conditioning Cylinder (DCCC) for adjustment of the<br />

tobacco moisture content. Two impregnator vessels for each of the process<br />

lines, each line having the capacity to process 1000 kg/hr of moist, dry iced<br />

impregnated tobacco.<br />

1.2 The process has the following discharge points to atmosphere:<br />

i. A single discharge point of air extraction from the plant discharging<br />

through a dust recovery filter.<br />

ii. A single discharge point for the hot gasses used to bring about cell<br />

expansion<br />

iii. A single discharge point from the air extraction to the infeed and<br />

outfeed ends of the Direct Casing and Conditioning Cylinder<br />

(DCCC)<br />

iv. A single roof fan to the part of the building housing the cell<br />

expansion process.<br />

Local Air Pollution Prevention & Control 5