TDS-BSR 900 - Soltex

TDS-BSR 900 - Soltex

TDS-BSR 900 - Soltex

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

3707 FM 1960 West, Suite 560<br />

Houston, TX 77068<br />

Phone: 281-587-0<strong>900</strong><br />

Fax: 281-587-1998<br />

www.soltexinc.com<br />

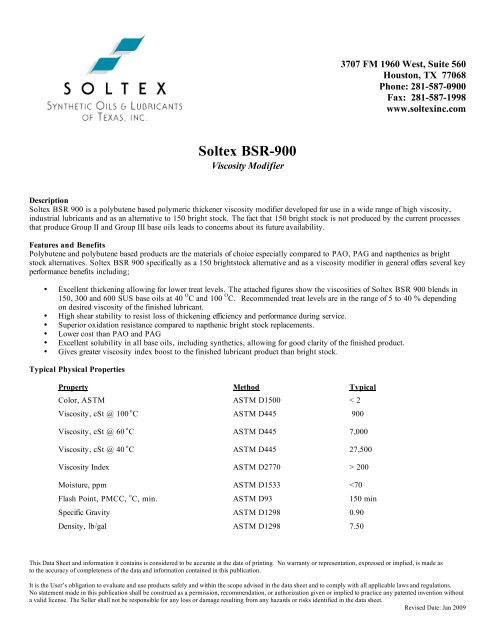

<strong>Soltex</strong> <strong>BSR</strong>-<strong>900</strong><br />

Viscosity Modifier<br />

Description<br />

<strong>Soltex</strong> <strong>BSR</strong> <strong>900</strong> is a polybutene based polymeric thickener viscosity modifier developed for use in a wide range of high viscosity,<br />

industrial lubricants and as an alternative to 150 bright stock. The fact that 150 bright stock is not produced by the current processes<br />

that produce Group II and Group III base oils leads to concerns about its future availability.<br />

Features and Benefits<br />

Polybutene and polybutene based products are the materials of choice especially compared to PAO, PAG and napthenics as bright<br />

stock alternatives. <strong>Soltex</strong> <strong>BSR</strong> <strong>900</strong> specifically as a 150 brightstock alternative and as a viscosity modifier in general offers several key<br />

performance benefits including;<br />

• Excellent thickening allowing for lower treat levels. The attached figures show the viscosities of <strong>Soltex</strong> <strong>BSR</strong> <strong>900</strong> blends in<br />

150, 300 and 600 SUS base oils at 40 O C and 100 O C. Recommended treat levels are in the range of 5 to 40 % depending<br />

on desired viscosity of the finished lubricant.<br />

• High shear stability to resist loss of thickening efficiency and performance during service.<br />

• Superior oxidation resistance compared to napthenic bright stock replacements.<br />

• Lower cost than PAO and PAG<br />

• Excellent solubility in all base oils, including synthetics, allowing for good clarity of the finished product.<br />

• Gives greater viscosity index boost to the finished lubricant product than bright stock.<br />

Typical Physical Properties<br />

Property Method Typical<br />

Color, ASTM ASTM D1500 < 2<br />

Viscosity, cSt @ 100 o C ASTM D445 <strong>900</strong><br />

Viscosity, cSt @ 60 o C ASTM D445 7,000<br />

Viscosity, cSt @ 40 o C ASTM D445 27,500<br />

Viscosity Index ASTM D2770 > 200<br />

Moisture, ppm ASTM D1533

<strong>Soltex</strong> <strong>BSR</strong> <strong>900</strong> Blend Viscosity at 40 deg C<br />

600<br />

500<br />

KV 40, cSt<br />

400<br />

300<br />

200<br />

600 sus base oil<br />

300 sus base oil<br />

100<br />

150 sus base oil<br />

0<br />

0 5 10 15 20 25 30 35 40 45<br />

<strong>Soltex</strong> <strong>BSR</strong> <strong>900</strong> Wt %<br />

<strong>Soltex</strong> <strong>BSR</strong> <strong>900</strong> Blend Viscosity at 100 deg C<br />

40<br />

35<br />

600 sus base oil<br />

30<br />

KV 100, cSt<br />

25<br />

20<br />

15<br />

300 sus base oil<br />

150 sus base oil<br />

10<br />

5<br />

0<br />

0 5 10 15 20 25 30 35 40 45<br />

<strong>Soltex</strong> <strong>BSR</strong> <strong>900</strong> Wt %<br />

This Data Sheet and information it contains is considered to be accurate at the date of printing. No warranty or representation, expressed or implied, is made as<br />

to the accuracy of completeness of the data and information contained in this publication.<br />

It is the User’s obligation to evaluate and use products safely and within the scope advised in the data sheet and to comply with all applicable laws and regulations.<br />

No statement made in this publication shall be construed as a permission, recommendation, or authorization given or implied to practice any patented invention without<br />

a valid license. The Seller shall not be responsible for any loss or damage resulting from any hazards or risks identified in the data sheet.<br />

Revised Date: Jan 2009