General machine brochure - Spiro International SA

General machine brochure - Spiro International SA

General machine brochure - Spiro International SA

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

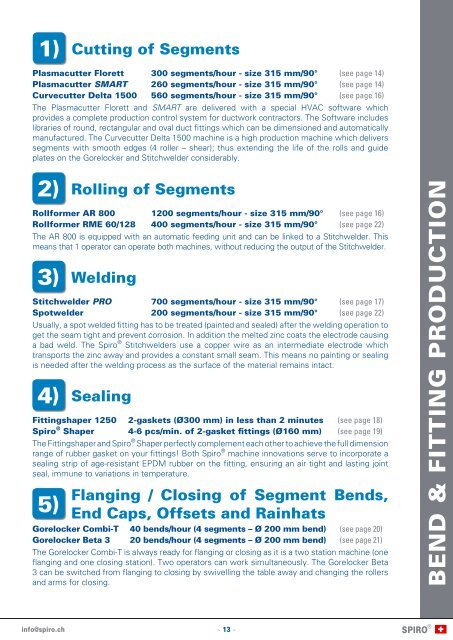

1)<br />

Cutting of Segments<br />

Plasmacutter Florett 300 segments/hour - size 315 mm/90° (see page 14)<br />

Plasmacutter SMART 260 segments/hour - size 315 mm/90° (see page 14)<br />

Curvecutter Delta 1500 560 segments/hour - size 315 mm/90° (see page 16)<br />

The Plasmacutter Florett and SMART are delivered with a special HVAC software which<br />

provides a complete production control system for ductwork contractors. The Software includes<br />

libraries of round, rectangular and oval duct fittings which can be dimensioned and automatically<br />

manufactured. The Curvecutter Delta 1500 <strong>machine</strong> is a high production <strong>machine</strong> which delivers<br />

segments with smooth edges (4 roller – shear); thus extending the life of the rolls and guide<br />

plates on the Gorelocker and Stitchwelder considerably.<br />

2) Rolling of Segments<br />

Rollformer AR 800 1200 segments/hour - size 315 mm/90° (see page 16)<br />

Rollformer RME 60/128 400 segments/hour - size 315 mm/90° (see page 22)<br />

The AR 800 is equipped with an automatic feeding unit and can be linked to a Stitchwelder. This<br />

means that 1 operator can operate both <strong>machine</strong>s, without reducing the output of the Stitchwelder.<br />

3) Welding<br />

Stitchwelder PRO 700 segments/hour - size 315 mm/90° (see page 17)<br />

Spotwelder 200 segments/hour - size 315 mm/90° (see page 22)<br />

Usually, a spot welded fitting has to be treated (painted and sealed) after the welding operation to<br />

get the seam tight and prevent corrosion. In addition the melted zinc coats the electrode causing<br />

a bad weld. The <strong>Spiro</strong> ® Stitchwelders use a copper wire as an intermediate electrode which<br />

transports the zinc away and provides a constant small seam. This means no painting or sealing<br />

is needed after the welding process as the surface of the material remains intact.<br />

4) Sealing<br />

Fittingshaper 1250 2-gaskets (Ø300 mm) in less than 2 minutes (see page 18)<br />

<strong>Spiro</strong> ® Shaper 4-6 pcs/min. of 2-gasket fittings (Ø160 mm) (see page 19)<br />

The Fittingshaper and <strong>Spiro</strong> ® Shaper perfectly complement each other to achieve the full dimension<br />

range of rubber gasket on your fittings! Both <strong>Spiro</strong> ® <strong>machine</strong> innovations serve to incorporate a<br />

sealing strip of age-resistant EPDM rubber on the fitting, ensuring an air tight and lasting joint<br />

seal, immune to variations in temperature.<br />

5)<br />

Flanging / Closing of Segment Bends,<br />

End Caps, Offsets and Rainhats<br />

Gorelocker Combi-T 40 bends/hour (4 segments – Ø 200 mm bend) (see page 20)<br />

Gorelocker Beta 3 20 bends/hour (4 segments – Ø 200 mm bend) (see page 21)<br />

The Gorelocker Combi-T is always ready for flanging or closing as it is a two station <strong>machine</strong> (one<br />

flanging and one closing station). Two operators can work simultaneously. The Gorelocker Beta<br />

3 can be switched from flanging to closing by swivelling the table away and changing the rollers<br />

and arms for closing.<br />

BEND & FITTING PRODUCTION<br />

info@spiro.ch<br />

~ 13 ~ SPIRO ®