Complex Equipment Supplier Guide - Spring

Complex Equipment Supplier Guide - Spring

Complex Equipment Supplier Guide - Spring

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

System Integrators Sheet Metal Fabricators Precision Machining Secondary Processes<br />

and Supporting Industries<br />

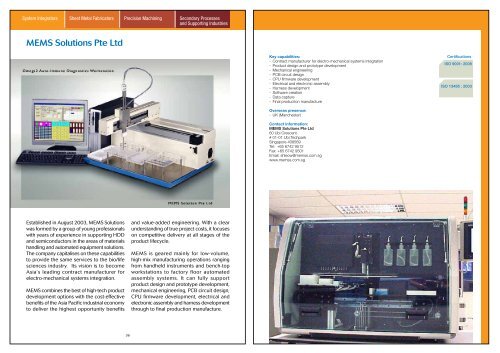

MEMS Solutions Pte Ltd<br />

Key capabilities:<br />

- Contract manufacturer for electro-mechanical systems integration<br />

- Product design and prototype development<br />

- Mechanical engineering<br />

- PCB circuit design<br />

- CPU firmware development<br />

- Electrical and electronic assembly<br />

- Harness development<br />

- Software creation<br />

- Data capture<br />

- Final production manufacture<br />

Certifications<br />

ISO 9001: 2008<br />

ISO 13485 : 2003<br />

Overseas presence:<br />

- UK (Manchester)<br />

Contact information:<br />

MEMS Solutions Pte Ltd<br />

60 Ubi Crescent<br />

# 01-01 Ubi Techpark<br />

Singapore 408569<br />

Tel: +65 6742 9512<br />

Fax: +65 6742 9501<br />

Email: shleow@memss.com.sg<br />

www.memss.com.sg<br />

Established in August 2003, MEMS Solutions<br />

was formed by a group of young professionals<br />

with years of experience in supporting HDD<br />

and semiconductors in the areas of materials<br />

handling and automated equipment solutions.<br />

The company capitalises on these capabilities<br />

to provide the same services to the bio/life<br />

sciences industry. Its vision is to become<br />

Asia’s leading contract manufacturer for<br />

electro-mechanical systems integration.<br />

MEMS combines the best of high-tech product<br />

development options with the cost-effective<br />

benefits of the Asia Pacific industrial economy<br />

to deliver the highest opportunity benefits<br />

and value-added engineering. With a clear<br />

understanding of true project costs, it focuses<br />

on competitive delivery at all stages of the<br />

product lifecycle.<br />

MEMS is geared mainly for low-volume,<br />

high-mix manufacturing operations ranging<br />

from handheld instruments and bench-top<br />

workstations to factory floor automated<br />

assembly systems. It can fully support<br />

product design and prototype development,<br />

mechanical engineering, PCB circuit design,<br />

CPU firmware development, electrical and<br />

electronic assembly and harness development<br />

through to final production manufacture.<br />

36<br />

37