spg mitteilungen communications de la ssp - Schweizerische ...

spg mitteilungen communications de la ssp - Schweizerische ...

spg mitteilungen communications de la ssp - Schweizerische ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SPG Mitteilungen Nr. 40<br />

Structural MEMS Testing<br />

Alex Dommann and Antonia Neels*<br />

EMPA, Lerchenfeldstrasse 5, 9014 St. Gallen, alex.dommann@empa.ch<br />

*CSEM, Microsystems Technology Division, 2002 Neuchâtel<br />

In single crystal silicon (SCSi) based <strong>de</strong>vices, stress and<br />

loading in operation introduces <strong>de</strong>fects during the Micro-<br />

ElectroMechanical Systems (MEMS) life time and increases<br />

the risk of failure. Reliability studies on potential<br />

failure sources have an impact on MEMS <strong>de</strong>sign and are<br />

essential to assure the long term functioning of the <strong>de</strong>vice.<br />

Defects introduced by Deep Reactive-Ion Etching (DRIE),<br />

thermal annealing, dicing and bonding and also the <strong>de</strong>vice<br />

environment (radiations, temperature) influence the crystalline<br />

perfection and have a direct impact on the mechanical<br />

properties of MEMS and their aging behavior. Defects and<br />

<strong>de</strong>formations are analyzed using High Resolution X-ray Diffraction<br />

Methods (HRXRD) such as Reciprocal Space Maps<br />

(RSM). Micro systems technology can be highly reliable,<br />

but can be different from those of solid-state electronics.<br />

Therefore testing techniques must be <strong>de</strong>veloped to accelerate<br />

MEMS-specific failures [1 - 4].<br />

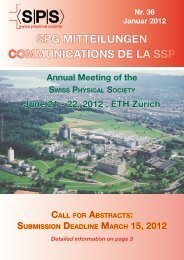

which is <strong>de</strong>tected via the broa<strong>de</strong>ning of the X-ray peak<br />

in a "rocking-curve" (RC) measurement. Analysis is performed<br />

with high resolution X-ray diffraction. The set-up is<br />

composed by curved multi<strong>la</strong>yer x-ray mirrors named after<br />

Herbert Göbel (Göbel mirror) in front of the X-ray tube, followed<br />

by a monochromator for monochromatization and<br />

collimation of X-ray beams by using a 4-Crystal monochromator<br />

with two channel-cut Ge [220] called Bartels monochromator<br />

(Fig. 2). Two configurations are possible for the<br />

diffracted beam si<strong>de</strong>, <strong>de</strong>pending on the methods applied:<br />

Rocking curve (RC) or Reciprocal space map (RSM). Both<br />

methods allow measuring strain and <strong>de</strong>fects concentration<br />

in a crystal. The instrument used for HRXRD is shown (Figure<br />

1).<br />

New MEMS fabrication processes and packaging concepts<br />

find applications in areas where a high reliability is nee<strong>de</strong>d<br />

such as in aerospace, automotive or watch industry. This<br />

creates a strong <strong>de</strong>mand in quality control and failure analysis<br />

and also brings new challenges, particu<strong>la</strong>rly in the fields<br />

of testing and qualification. Non-<strong>de</strong>structive HRXRD methods<br />

are applied to monitor the mobility of <strong>de</strong>fects and strain<br />

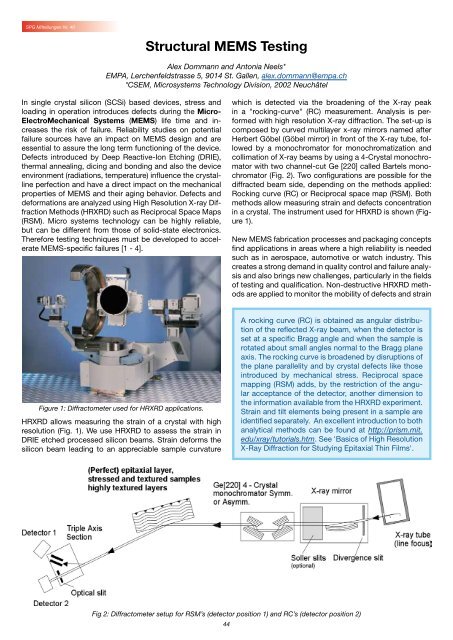

Figure 1: Diffractometer used for HRXRD applications.<br />

HRXRD allows measuring the strain of a crystal with high<br />

resolution (Fig. 1). We use HRXRD to assess the strain in<br />

DRIE etched processed silicon beams. Strain <strong>de</strong>forms the<br />

silicon beam leading to an appreciable sample curvature<br />

A rocking curve (RC) is obtained as angu<strong>la</strong>r distribution<br />

of the reflected X-ray beam, when the <strong>de</strong>tector is<br />

set at a specific Bragg angle and when the sample is<br />

rotated about small angles normal to the Bragg p<strong>la</strong>ne<br />

axis. The rocking curve is broa<strong>de</strong>ned by disruptions of<br />

the p<strong>la</strong>ne parallelity and by crystal <strong>de</strong>fects like those<br />

introduced by mechanical stress. Reciprocal space<br />

mapping (RSM) adds, by the restriction of the angu<strong>la</strong>r<br />

acceptance of the <strong>de</strong>tector, another dimension to<br />

the information avai<strong>la</strong>ble from the HRXRD experiment.<br />

Strain and tilt elements being present in a sample are<br />

i<strong>de</strong>ntified separately. An excellent introduction to both<br />

analytical methods can be found at http://prism.mit.<br />

edu/xray/tutorials.htm. See 'Basics of High Resolution<br />

X-Ray Diffraction for Studying Epitaxial Thin Films'.<br />

Fig 2: Diffractometer setup for RSM’s (<strong>de</strong>tector position 1) and RC’s (<strong>de</strong>tector position 2)<br />

44