You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>SBCR</strong>01<br />

Mono-beam safety control unit (category 2)<br />

for accident prevention in dangerous areas<br />

● System composed of a control unit and a pair of optic<br />

sensors – M18 (SK) or M30 (TK)<br />

● Control unit mountable on DIN rail:<br />

The same control unit can use 5 different pairs of sensors<br />

M18 and M30 for increased money and space saving: optic<br />

protection (4 models) or surface protection with STP<br />

accessory (1 model)<br />

● Control circuit with intrinsic safety system<br />

● The <strong>SBCR</strong>01 safety system is certified as a category 2<br />

protection device and complies with the pr EN50100<br />

standard<br />

● 2 safety relays in the output circuit<br />

● Free/engaged area LED indicator<br />

● Response time 35ms (typical), 140 ms (max.)<br />

Ordering system<br />

serie<br />

S B C R 0 1 - A<br />

operating voltage<br />

control unit for single through beam<br />

<strong>SBCR</strong>01<br />

A<br />

24VAC<br />

D<br />

48VAC<br />

H<br />

115VAC<br />

Z<br />

230VAC<br />

S<br />

24VDC<br />

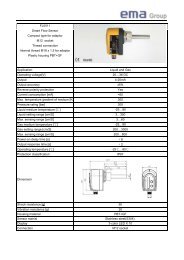

Dimensions<br />

21 2<br />

3<br />

20 19 18 17 16 15 14 13 12 11<br />

1. emitter wiring connections<br />

70<br />

0V<br />

+9V<br />

Check +<br />

EMITTER<br />

Check -<br />

TEST<br />

<strong>SBCR</strong>01<br />

ENGAGED<br />

AREA<br />

+9V<br />

0V<br />

RECEIVER<br />

FREE<br />

AREA<br />

OUT<br />

4<br />

5<br />

2. TEST contact for checking external actuators<br />

9<br />

SUPPLY<br />

N (-) L1 (+)<br />

F<br />

MM<br />

CHECK OUTPUT<br />

OPER. OUTPUT<br />

1 2 3 4 5 6 7 8 9 10<br />

3. receiver wiring connections<br />

8<br />

7 6<br />

100<br />

4. red LED (engaged area indicator)<br />

5. green LED (clear area indicator)<br />

6. OPERATING OUTPUT<br />

7. CHECK OUTPUT<br />

110<br />

8. power supply (24-48-110-220VAC; 24VDC)<br />

10<br />

10<br />

18<br />

9. power supply fuse (inside)<br />

10. fastening holes 85x60mm

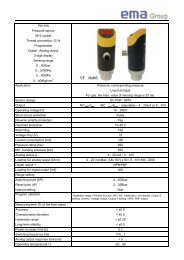

<strong>SBCR</strong>01<br />

Specifications<br />

Model <strong>SBCR</strong>O1-A <strong>SBCR</strong>O1-D <strong>SBCR</strong>O1-H <strong>SBCR</strong>O1-Z <strong>SBCR</strong>O1-S<br />

Type AC AC AC AC DC<br />

Operating voltage 24VAC 48VAC 115VAC 230VAC 24VDC<br />

Tolerance<br />

Line frequency<br />

Max. absorption<br />

Available functions<br />

Safety output<br />

Max. switching voltage<br />

Max. switching current<br />

Contact isolation<br />

Contact life<br />

Response time<br />

LED indicators<br />

Inputs<br />

Protection degree<br />

Temperature range<br />

Storage temperature<br />

Ambient humidity<br />

Housing material<br />

Weight (approx.)<br />

+ 10% - 15%<br />

50 - 60 Hz<br />

6VA<br />

Start/Restart, EDM (to be realized with external contactors)<br />

forced contact relay: 1 contact NO, 1 contact NC<br />

250VAC<br />

6A (in use), 20A (switching)<br />

250VAC<br />

1x10 5 (electrical), 1x10 7 (mechanical)<br />

35ms (typical), 140ms (max.)<br />

green (free area), red (engaged area)<br />

Test<br />

IEC IP20<br />

0…+50°C<br />

-25°…+75°C<br />

35…95%<br />

ABS<br />

440g<br />

±15%<br />

-<br />

250mA<br />

Wiring diagrams<br />

L (+)<br />

emitter<br />

receiver<br />

Emergency<br />

BL/3<br />

BN/1<br />

BK/4<br />

WH/2<br />

BK/4<br />

BN/1<br />

BL/3<br />

20 19 17 18 11 13 12 8 6<br />

Start<br />

Test<br />

09Vcheck<br />

out 9V 0<br />

2<br />

1<br />

L (+)<br />

N (-)<br />

Power supply<br />

+<br />

-<br />

Relay<br />

C<br />

operating<br />

output<br />

check<br />

output<br />

3<br />

MM<br />

D<br />

k1<br />

test<br />

input<br />

10 4 15<br />

16<br />

k3<br />

k1<br />

k3<br />

k2<br />

k1<br />

k3<br />

k2<br />

C<br />

K1<br />

k2<br />

K2 K3<br />

R<br />

N (-)<br />

K1, K2, K3:<br />

External<br />

contactors<br />

R, C:<br />

Arc suppression<br />

unit<br />

To the line<br />

K2<br />

K2<br />

K2<br />

K3<br />

K3<br />

K3<br />

K1<br />

K1<br />

K1<br />

To the motor which starts-up<br />

the dangerous movement<br />

19

<strong>SBCR</strong>01<br />

The following sensors can be connected to the <strong>SBCR</strong>01 safety control unit:<br />

SK serie: SK1 models M18 through-beam optical protection guard up to 4m<br />

SK serie: SK2 models M18 through-beam optical protection guard up to 8m<br />

SK serie: SK4 models M18 through-beam optical protection guard up to 4m (visible light)<br />

SK serie: SK3 models M18 through-beam with STP accessories surface protection guard up to 3m<br />

TK serie: TK1 model M30 through-beam optical protection guard up to 50m<br />

Description<br />

The <strong>SBCR</strong>01 safety system’s purpose is to protect the access area<br />

of machines with dangerous moving parts, which are ever more<br />

frequently used in productive processes.<br />

The <strong>SBCR</strong>01 safety system is made up of a control unit and a pair<br />

of cylindrical sensors, emitter and receiver, which can be those in<br />

the SK (M18) or in the TK (M30) range.<br />

The safety sensors emit a beam of red or infrared light which<br />

locks out the dangerous movement the moment it is interrupted<br />

by an opaque object.<br />

The <strong>SBCR</strong>01 system represents an inescapable and therefore<br />

extremely safe system with an extremely quick response time.<br />

The protection capacity in terms of the size of the protected<br />

zone, target to be detected and safety distance, depends on the<br />

intrinsic characteristics of the safety light curtain, in accordance<br />

with the pr EN50100-1 and pr EN50100-2 regulations, and on the<br />

application conditions in accordance with the regulation EN294<br />

and EN999.<br />

The <strong>SBCR</strong>01 system is capable of detecting an individual failure<br />

by carrying out a periodic test cycle, which can be activated<br />

through the relative test input.<br />

If a failure is detected, the system activates the safety conditions<br />

by locking the dangerous movement.<br />

The <strong>SBCR</strong>01 control unit is equipped with two forced contact<br />

relay outputs: an operating output and a check output. The operating<br />

output is used to control the dangerous movement (NO<br />

contact), while the check output is used to activate a supplementary<br />

control for the operating output (NC contact).<br />

The availability of two supplementary outputs allows an “alternate<br />

control” to be carried out, which prevents systematic failures.<br />

SK3 through-beam<br />

(with sensitivity<br />

adjustment)<br />

Aluminium support<br />

STP accessory<br />

Soft compressible<br />

rubber<br />

The receiver is equipped with a sensitivity adjuster which can be<br />

used to determine the level of the pressure which sets-off the<br />

activation; the adjustment allows the activation threshold to be<br />

set from a few millimetres up to a maximum of 13mm, which correspond<br />

to the inside diameter of the STP accessory.<br />

It is preferable for the operator to have an activation threshold<br />

of a few millimetres, as this reduces the possibility of eventual<br />

panic situations.<br />

However, maintaining this threshold cannot be guaranteed in the<br />

event of a failure. As a consequence, the system must be designed<br />

so that it is safe (the operator shall not get hurt) even if<br />

the activation threshold, for whatever reason, reaches the maximum<br />

level.<br />

dangerous<br />

machine<br />

Besides optical protections through sensors SK1, SK2, SK3 and<br />

TK1, the <strong>SBCR</strong>01 control unit can also perform pressure protections<br />

on a length of up to 3m, using SK3 sensors and the STP<br />

accessory.<br />

Fitting the system as indicated in the figure, the safety light curtain<br />

beam is directed towards the inside of the soft, compressible<br />

rubber accessory; pressure on the rubber part will interrupt<br />

the inside beam and cause the system to switch to the safety<br />

mode.<br />

surface<br />

pressure<br />

protection<br />

beam not interrupted<br />

by the processed material<br />

material being processed<br />

which does not interfere<br />

with the beam<br />

beam interrupted<br />

(pressure on the rubber guide)<br />

free guarded area<br />

normal operation<br />

engaged guarded area<br />

locked operation<br />

20

<strong>SBCR</strong>01<br />

The STP accessory end parts, into which the sensors are<br />

fitted, cannot be part of the sensitive field – this must be kept<br />

in mind at the beginning of the project.<br />

If it is necessary to obtain an area which is more sensitive to<br />

pressure, there is a STOK accessory which has an adjustable<br />

mechanical shutter.<br />

Applications<br />

The optical-electronic <strong>SBCR</strong>01 safety system can be<br />

specifically used as a safety component in the following application<br />

fields:<br />

Perimeter protections<br />

these are required to protect the operator from voluntary or accidental<br />

intrusion into a danger area where there are fixed or mobile<br />

manufacturing machines.<br />

Some examples can be:<br />

Packaging machinery in general;<br />

Conveyor and assembly lines;<br />

Automatic warehouses<br />

Robotized areas;<br />

Palletizers and unloaders;<br />

Wrapping machines;<br />

Machines for the ceramic industry.<br />

Elimination of possible interference<br />

between fixed machines and movable machinery or units inside<br />

the equipped production facilities, in compliance with the rules<br />

for the realisation of anti-collision systems or “give-way” systems<br />

for material handling.<br />

Some examples can be:<br />

material handling areas;<br />

hoisting machines;<br />

work places with overhead travelling cranes or lifting cranes.<br />

Surface protection<br />

this is required to protect the operator from getting his hands<br />

crushed or when it is necessary to work in close contact with the<br />

machine.<br />

Some examples can be:<br />

rollers;<br />

machines for hide processing;<br />

sacking and packaging machines;<br />

automatic gates and doors.<br />

21