added value - Statkraft

added value - Statkraft

added value - Statkraft

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

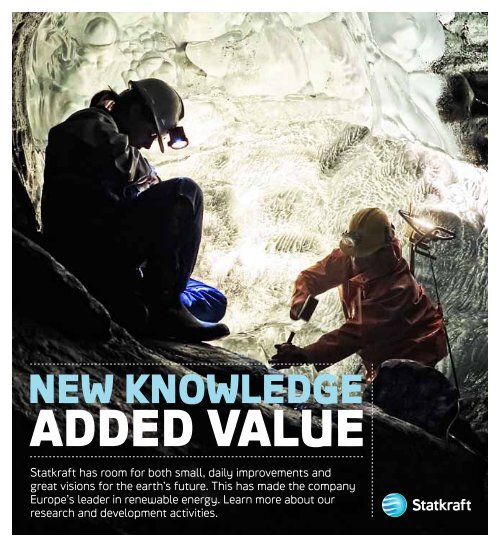

New knowledge<br />

<strong>added</strong> <strong>value</strong><br />

<strong>Statkraft</strong> has room for both small, daily improvements and<br />

great visions for the earth’s future. This has made the company<br />

Europe’s leader in renewable energy. Learn more about our<br />

research and development activities.

Three perspectives on R&D in <strong>Statkraft</strong><br />

Vision and reality<br />

Climate change is the most serious<br />

threat facing mankind. But despite the bleak<br />

outlook, climate change also offers opportunities<br />

for companies with tradition, resources<br />

and expertise within renewable energy. The<br />

development of renewable energy will be<br />

one of the most important tasks in the world<br />

in the time ahead, and it will be demanding,<br />

both in terms of technology and finance.<br />

<strong>Statkraft</strong> takes these challenges seriously,<br />

and therefore focuses on research and<br />

development, both in the long and short<br />

term, to meet the world’s future needs for<br />

renewable energy. Challenges regarding<br />

the environment and sustainability must be<br />

solved when new energy facilities are built.<br />

Innovation and new approaches are vital in<br />

order to find sustainable solutions.<br />

<strong>Statkraft</strong> and research communities we<br />

cooperate with, have significant knowledge<br />

about these issues. In order to solve the<br />

climate challenges, we believe in cooperation<br />

between business, industry and research<br />

institutions.<br />

Innovation is one of <strong>Statkraft</strong>’s three core<br />

<strong>value</strong>s. We want to further develop existing<br />

solutions and to implement new technologies.<br />

<strong>Statkraft</strong>’s innovation activities will<br />

contribute to increase the Group’s future<br />

competitiveness, and create results and<br />

<strong>added</strong> <strong>value</strong> for the company and society<br />

in general. There is room for both daily<br />

improvements as well as grand visions about<br />

the earth’s future in <strong>Statkraft</strong>. This has made<br />

us the largest producer of renewable energy<br />

in Europe. Here we would like to offer some<br />

examples of what we do.<br />

Christian Rynning-Tønnesen<br />

president and CEO, <strong>Statkraft</strong><br />

Without research and<br />

development <strong>Statkraft</strong> would<br />

not be Europe’s leader in<br />

renewable energy.<br />

maturity<br />

exploration<br />

Corporate<br />

R&D programs<br />

improvement<br />

<strong>Statkraft</strong>’s innovation strategy is closely aligned to our business<br />

strategy as we believe this is the key to turning R&D results and<br />

knowledge into actual innovation. We also seek to develop a balanced<br />

R&D portfolio with regards to levels of technological maturity<br />

and development lead time.<br />

Improvement projects are aimed towards continuous improvement of<br />

current operations. The purpose is to increase efficiency and further<br />

develop sustainable and environmentally friendly solutions in ongoing<br />

operations. Through the improvement projects we solve our short<br />

term challenges in existing business.<br />

Three R&D programs are established to meet the medium term need<br />

for development within specific business areas; hydropower, wind<br />

power and district heating. Through these R&D programs we develop<br />

competitive advantages and new business models to enhance future<br />

efficiency and quality in our operations. Finding environmentally<br />

friendly solutions and implementing actions to prevent unnecessary<br />

negative consequences to nature and wildlife counts for a significant<br />

part of the programs. The projects are performed in close collaboration<br />

with national and international R&D communities.<br />

Finally, our exploration activities are focused on technologies that<br />

may become important in the longer term. Promising opportunities<br />

may lead us to engage in long term development efforts and bring<br />

new sustainable solutions to the energy market.<br />

Read and learn more about:<br />

time<br />

Weather is money. Providing hydrologists with a more precise<br />

“crystal ball”.<br />

Save the salmon! Researchers look for the optimum balance<br />

between salmon and power generation.<br />

Wind energy turbines with suction. New technologies driving<br />

down costs of offshore wind farms.<br />

What will our rubbish cost? The answer will be of <strong>value</strong> to<br />

<strong>Statkraft</strong>’s district heating ventures.<br />

World leader in osmotic power. Developing the perfect membrane<br />

remains one of the key challenges.

maturity<br />

exploration<br />

Corporate<br />

R&D programs<br />

improvement<br />

time<br />

Continuous improvement of<br />

current operations, solving<br />

short term challenges in<br />

existing business<br />

Learning from your<br />

own errors is an important<br />

source of knowledge.<br />

The R&D work in <strong>Statkraft</strong> under the “Improvement”<br />

label addresses everyday issues<br />

and give quick results. In these projects we<br />

look at existing facilities, investigate faults<br />

and renovate or improve elements in the day<br />

to day operations.<br />

“Our motivation is to learn as much as possible<br />

about what is going on and to get the<br />

most out of our resources, such as increasing<br />

the effect from turbines, or to sensibly renovate<br />

a dam. It is about learning from previous<br />

errors, and introducing measures that are as<br />

inexpensive as possible, while at the same<br />

time complying with all regulatory requirements,”<br />

says Anne Marit Ruud, section head<br />

Construction.<br />

Input to Improvement projects can come<br />

from our own business areas, from research<br />

institutions, consultancy firms or from the<br />

industry organization Energy Norway.<br />

The R&D work also has an important recruitment<br />

function. “Some of our R&D funds<br />

are for example spent on professors and<br />

students at the Department of Hydraulic and<br />

Environmental Engineering and the Hydropower<br />

and water research labs at the Norwegian<br />

University of Science and Technology<br />

(NTNU. We have seen a significant increase in<br />

Master’s degree students specializing within<br />

hydropower related topics. The latter is<br />

particularly important to us, as it contributes<br />

to the recruitment of necessary expertise for<br />

the future” Ruud stresses.<br />

3D erosion estimates<br />

Some of <strong>Statkraft</strong>’s rockfill dams have<br />

had short period leaks through the core. To<br />

increase employees’ expertise for estimating<br />

the strength of the dam and the water flow<br />

force it can handle, there is an R&D project<br />

under way to develop a 3D estimate model.<br />

The model is capable of estimating both the<br />

quantity of water and the direction of the<br />

water flow through the dam. Other issues<br />

under consideration include the direction of<br />

the plastering rock in the dam. A Master’s<br />

student has been hired to carry out the R&D<br />

project, and she is using <strong>Statkraft</strong>’s Jukla<br />

dam as a case study.<br />

Hydrologists get a new<br />

“crystal ball”<br />

In order for <strong>Statkraft</strong> to optimize power<br />

production, prognoses for influx to power<br />

plants and reservoirs are an important aspect<br />

of the decision-making basis. Today hydrological<br />

models deliver influx prognoses up to ten<br />

days ahead, but carry with them a degree of<br />

uncertainty. When using hydrological models,<br />

one must take some uncertainties into consideration.<br />

One type of uncertainty relates to the<br />

observations of precipitation and temperature.<br />

Other uncertainties originate from conditions<br />

in the hydrological model, such as snow and<br />

groundwater reservoirs.<br />

Together with SINTEF, project personnel<br />

from <strong>Statkraft</strong> aim to<br />

establish a framework to<br />

describe the various<br />

sources of uncertainty<br />

and finally determine<br />

their net effect.<br />

This means that the<br />

influx prognoses can<br />

be based on probability<br />

rather than<br />

expected <strong>value</strong>s, which<br />

means they will be<br />

far more informative<br />

when projecting the<br />

power generation.<br />

Can chemistry undercover<br />

transformer faults?<br />

In order to identify the fault that caused the transformer at the<br />

Svartisen Power Station to fail in 2011, <strong>Statkraft</strong> has initiated<br />

an R&D project for chemical analyses. This incident was very<br />

costly for <strong>Statkraft</strong>, and a thorough analysis of the mechanisms<br />

that took place may therefore be very useful in the long term,<br />

both to strengthen the expertise in the company and to prevent<br />

future disruptions and similar failures. Samples are collected<br />

from the crash location in the transformer, and to identify various<br />

causal connections, the analyses are reviewed together with electric<br />

measurements from before the breakdown. The results will be<br />

used for updating requirement specifications and operational<br />

routines in order to improve future reliability in operations.<br />

51.5<br />

TWh<br />

In 2011, <strong>Statkraft</strong><br />

produced a total of<br />

51.5 TWh of energy<br />

(51.5 billion kilowatt<br />

hours). This is<br />

enough to supply<br />

more than two<br />

million homes with<br />

energy (measured<br />

by Norwegian consumption,<br />

which is<br />

the world’s highest).<br />

Of this production,<br />

91 per cent<br />

came from renewable<br />

sources, while<br />

natural gas power<br />

(mainly in Germany)<br />

contributed 8.9 per<br />

cent.<br />

Did you know ...<br />

… that <strong>Statkraft</strong> is<br />

Europe’s largest<br />

producer of renewable<br />

energy?<br />

<strong>Statkraft</strong> has a total<br />

of 3400 employees<br />

in 20 countries<br />

around the world.

hydropower<br />

maturity<br />

exploration<br />

Corporate<br />

R&D programs<br />

improvement<br />

time<br />

Three R&D programmes aim<br />

to meet the medium term<br />

needs for development within<br />

three core business areas.<br />

Did you know ...<br />

… that in 2011,<br />

<strong>Statkraft</strong> produced<br />

46 TWh of energy<br />

from its hydropower<br />

plants, equivalent<br />

to the consumption<br />

of more than 1.7<br />

million Norwegian<br />

homes?<br />

100<br />

million<br />

For the period<br />

from 2011 to 2014,<br />

<strong>Statkraft</strong> has<br />

allocated a total of<br />

NOK 100 million to<br />

its hydropower R&D<br />

programme.<br />

Best possible flow<br />

The project «Flow Control Technology» is<br />

another example of a successful partnership<br />

with suppliers. The goal for this project was<br />

to apply new technology and knowledge to<br />

minimize the negative effect of flows in the<br />

lead blades on Francis turbines. Both when<br />

the water is entering and exiting the turbine,<br />

there is a risk of wear, strain and loss of<br />

energy efficiency due to flow phenomena. In<br />

short, it is about creating the best possible<br />

flow in production.<br />

The project found solutions for some of<br />

these challenges which can be applied to<br />

both hydro and wind power.<br />

A turbine revolution<br />

Norwegian water is usually very clean, but outside of Norway, power<br />

producers often face major challenges in connection with sediment<br />

and silt in the water flow. As a result of the intense water pressure,<br />

these particles may cause severe damage in the turbines, leading to<br />

rapid wear. To cope with this problem, SN Power (where <strong>Statkraft</strong> is the<br />

majority owner) has entered a partnership with the supplier Dynavec<br />

to develop a new Pelton turbine design. In conventional turbine<br />

designs, the turbine is in one piece, making it difficult to achieve the<br />

optimum coating or surface treatment. This new design is revolutionary<br />

as it is module based, i.e. in individual sections. The advantage<br />

is that each section can be thoroughly coated before the turbine is<br />

assembled. This decreases wear and increases its life span.<br />

Another advantage of the new design is that the individual parts<br />

can be replaced without having to move the entire wheel. Thus, the<br />

facility does not have to be shut down for longer periods of time during<br />

maintenance, and downtime is greatly reduced. This is the very<br />

first solution of this kind, and a fine example of explicit technology<br />

development carried out with a supplier.<br />

Optimum conditions for salmon<br />

<strong>Statkraft</strong> is also engaged in more long term research, for example<br />

through the research centre CEDREN, one of a total of 11 research<br />

centres for environmentally friendly energy (FME) established by the<br />

Research Council of Norway. CEDREN addresses issues concerning<br />

environmental design. A basic theme is how future facilities and river<br />

systems can be designed to even further preserve the environment<br />

while maintaining power production.<br />

One example is the EnviDORR project, which has developed a new<br />

model for hydropower facilities, which optimizes the relationship between<br />

power generation and salmon, both in the current and future<br />

climate. The model becomes a tool for regulating water flow and<br />

production in a river system, so that conditions are optimal, both for<br />

the salmon and for <strong>Statkraft</strong>.<br />

We develop clean energy for the<br />

future, in interaction with the<br />

environment and society in general.<br />

How should <strong>Statkraft</strong> relate to a changing European<br />

energy market? How can the company<br />

utilise and further develop its strong hydropower<br />

position?<br />

These are just some of the questions we seek<br />

to answer through the Hydropower programme<br />

which will secure access to relevant technology,<br />

contribute to sustainable solutions, and<br />

ensure recruitment and expertise building in<br />

<strong>Statkraft</strong>.<br />

“The program has a strategy function that<br />

involves looking further and higher ahead to<br />

develop hydropower as a renewable source of<br />

energy for the future” says programme head<br />

Uta Gjertsen. One of the challenges high on the<br />

agenda are ageing hydropower facilities. Many<br />

of the facilities and components are now nearing<br />

the end of their design life time, and require<br />

rejuvenation and upgrades.<br />

“We also have many projects abroad. This is<br />

demanding for us as the developer, in terms of<br />

both technical and environmental requirements.<br />

There are other geological and topological conditions,<br />

other climate and social conditions we<br />

must take into consideration,” Uta says.<br />

Another important issue is related to the<br />

changing European energy system, with more<br />

renewable and inflexible power generation (solar<br />

and wind). “As the share of inflexible energy<br />

increases, it will impact us who produce flexible<br />

hydropower. This so-called regulating power issue<br />

is an important area of knowledge in terms<br />

of <strong>Statkraft</strong>’s future opportunities,” Uta argues.<br />

All the projects in the Hydropower programme<br />

are externally operated, meaning that<br />

they are executed in partnership with other<br />

research institutions and suppliers.

wind power<br />

maturity<br />

improvement<br />

Corporate<br />

R&D programs<br />

exploration<br />

time<br />

Three R&D programmes aim<br />

to meet the medium term<br />

needs for development within<br />

three core business areas.<br />

The development of<br />

offshore wind power requires<br />

massive research<br />

and development efforts.<br />

In order to compete in the rapidly<br />

growing offshore wind market,<br />

<strong>Statkraft</strong> has to limit the financial risk<br />

associated with investments. Cost<br />

reductions are therefore one of the<br />

main objectives in the R&D programme<br />

for competitive wind power.<br />

“Compromising on safety and the<br />

environment simultaneously is unacceptable”<br />

says Jørgen Krokstad, who<br />

heads the programme.<br />

There are greater challenges connected<br />

with establishing and operating<br />

wind farms in deep waters than<br />

onshore. Therefore around 70 per cent<br />

of the programme’s funds have been<br />

allocated to offshore wind and 30 per<br />

cent to onshore wind. In addition the<br />

programme’s diverse activities involve<br />

wind turbine technology development,<br />

operation and maintenance of wind<br />

farms, health, safety and consequences<br />

for the environment.<br />

One important ambition is to<br />

promote development of internal<br />

expertise through the R&D activities.<br />

“This is critical in order to succeed in<br />

the offshore wind market in the long<br />

term. In-house expertise is the most<br />

important aspect in terms of reducing<br />

risk associated with major investments,”<br />

Krokstad argues.<br />

Mobile wind farm control<br />

It is important for wind power producers to receive updated and<br />

exact operating data, and to be independent of the turbine suppliers.<br />

<strong>Statkraft</strong>’s wind farm programme has therefore developed a system<br />

for improved monitoring of the wind farms, called “Wind Power Management<br />

System”. The system will function as an independent basis<br />

for analysis of the wind farm and is an important element for achieving<br />

increased control of the farms. The system is currently delivered<br />

as a web application, however, a mobile app is planned for the future.<br />

Offshore wind turbines<br />

sucked in to the seabed<br />

One of the main challenges for <strong>Statkraft</strong>’s ambitions within offshore<br />

wind energy is to cut costs related to turbine installations far<br />

out to sea. Additionally, these installation efforts must take place<br />

in a way that does not harm the environment. Important progress is<br />

achieved on both fronts, in the form of a new concept for the foundations<br />

for offshore wind energy turbines.<br />

The current technology, which is being used at the Sheringham<br />

Shoal wind farm outside the UK, is based on so-called mono pillars,<br />

which are driven into the seabed. This technique generates a lot of<br />

noise, and it requires installation vessels and good weather.<br />

The new concept is being developed by Universal Foundation,<br />

where the Fred. Olsen Group is the main owner. It involves the application<br />

of the suction anchor principle, a Norwegian patent originally<br />

developed for the petroleum industry. In short, this means that the<br />

foundations are sucked in to the seabed using negative pressure.<br />

The technique does not require costly installation vessels, unlike the<br />

current solution. It is also gentler on the marine environment as it<br />

generates less noise.<br />

Doctor of offshore<br />

wind energy<br />

<strong>Statkraft</strong> is also an active participant in<br />

the two major national FME programmes<br />

Nowitech and Norcowe, in cooperation with<br />

both national and international industrial<br />

players. These programmes produce knowledge<br />

within the most important disciplines<br />

for offshore wind energy, including several<br />

PhDs. New theoretical models are being developed,<br />

as well as simulation programmes<br />

for wind generation and wind turbine construction,<br />

measuring techniques and testing<br />

stations. The aim is to raise Norwegian R&D<br />

knowledge on offshore wind energy to a top<br />

international level.<br />

Did you know ...<br />

… that <strong>Statkraft</strong>’s<br />

wind power<br />

production in 2011<br />

increased by 24 per<br />

cent to 0.8 TWh?<br />

This is enough to<br />

supply more than<br />

31 000 Norwegian<br />

homes. <strong>Statkraft</strong><br />

develops and operates<br />

wind farms in<br />

the UK, Norway and<br />

Sweden.<br />

80<br />

<strong>Statkraft</strong> has allocated<br />

NOK 80 million to its<br />

wind power R&D programme<br />

for the period<br />

from 2011 to 2014.

iomass<br />

maturity<br />

exploration<br />

Corporate<br />

R&D programs<br />

improvement<br />

time<br />

Three R&D programmes aim<br />

to meet the medium term<br />

needs for development within<br />

three core business areas.<br />

What will biomass<br />

cost in the future?<br />

<strong>Statkraft</strong>’s district heating facility is<br />

fuelled by various forms of bioenergy, including<br />

waste. Fluctuations in the demand for biomass<br />

impact prices and availability. Forecasts<br />

on how access, price and selection of various<br />

types of biofuels will develop in both long<br />

and short term are critical in order to develop<br />

competitive business models for the future.<br />

Biomass is an environmentally<br />

friendly and renewable energy<br />

source that is a natural part of<br />

<strong>Statkraft</strong>’s area of interest.<br />

440 GWh<br />

Did you know …<br />

… that in 2011,<br />

<strong>Statkraft</strong> produced<br />

440 GWh of energy<br />

based on bio fuels?<br />

This figure includes<br />

Norwegian and<br />

Swedish bio fuel<br />

facilities, and is<br />

enough to heat<br />

around 28 000<br />

houses.<br />

More environmentally friendly<br />

bio heat at Marienborg<br />

In the spring of 2011, <strong>Statkraft</strong> Varme decided that<br />

there was a need to rebuild the biofuel facility at Marienborg<br />

in Trondheim. The original goal was to reduce<br />

the risk of fire and explosions, but extensive changes<br />

were also made to increase the level of automation and<br />

to increase the facility’s flexibility to use various types<br />

of fuel. Furthermore, we wanted to ensure that the<br />

facility is efficient and does not have larger emissions<br />

when being partially run than when at full capacity. The<br />

project was carried out in cooperation with the Swedish<br />

boiler supplier KMW Energi AB. The facility has been in a<br />

test phase since 2011, and the results are excellent. Stable<br />

operations, lower emissions, high level of flexibility<br />

and good profitability are among the important milestones<br />

reached. In all, the project has provided <strong>Statkraft</strong><br />

Varme with a safer and more robust facility.<br />

Office building<br />

School<br />

hot water ∏<br />

cooled water π<br />

A lot of biomass research<br />

Heat Production Plant<br />

Residence<br />

CenBio is a multidiscipline research centre for environmentally<br />

friendly energy (FME) which looks at the entire<br />

bioenergy <strong>value</strong> chain from raw material to the traded<br />

product.<br />

One of the objectives for the centre is to develop a<br />

sustainable utilisation of biomass for the generation of<br />

electricity and heat. <strong>Statkraft</strong> is taking part in CenBio<br />

to participate in concentrated, focused and long-term<br />

research efforts at a high international level.<br />

Biomass is a renewable resource that could replace<br />

fossil fuels within heating and power generation, and<br />

in the long-term, perhaps even the transport sector.<br />

As a leading national player within development and<br />

operation of renewable heating, <strong>Statkraft</strong> is engaged<br />

in finding the best possible utilisation of biomass in the<br />

energy system, both today and in the longer term. What<br />

can be done to strengthen already established activities?<br />

How can the company make use of its specialist<br />

expertise in terms of developing new business opportunities?<br />

These are key questions in the bioenergy R&D<br />

programme.<br />

“The bioenergy programme is closely connected to<br />

our district heating activities. Our ambition is to reduce<br />

risk and increase profitability, while strengthening our<br />

ability to realize new bio-related business opportunities,”<br />

says programme head Monica Havskjold.<br />

Biomass is a commodity that can be traded both locally<br />

and globally, and to ensure the optimum access to fuel, a<br />

good understanding of the market is required, particularly<br />

in a long term perspective. The Bioenergy Programme<br />

in <strong>Statkraft</strong> will help us establish this expertise.<br />

Cost efficiency is a key term in the R&D programme.<br />

Development of new system solutions and technologies<br />

for energy conversion are prioritized areas. Projects that<br />

help improving existing equipment and solutions are often<br />

completed through a joint effort between <strong>Statkraft</strong><br />

and the supplier.<br />

“An important milestone for the programme is to contribute<br />

to reduce the ecological footprint. This involves,<br />

among other things, replacing fossil fuels with biomass<br />

as well as utilizing the fuel in an efficient manner,”<br />

Monica emphasizes.

maturity<br />

exploration<br />

Corporate<br />

R&D programs<br />

improvement<br />

Intense research is<br />

underway on new<br />

resources and<br />

new technology in<br />

a number of energy<br />

areas. <strong>Statkraft</strong><br />

is focused on<br />

solutions that will<br />

have long-term<br />

significance, and<br />

is already a world<br />

leader in osmotic<br />

power. But the<br />

company also<br />

sees opportunities<br />

in geothermal<br />

energy, new forms<br />

of energy storage<br />

and so-called smart<br />

energy technologies.<br />

time<br />

Activities focused on technologies<br />

that may become<br />

dominant in the long term.<br />

Osmotic power:<br />

Selecting<br />

the perfect<br />

membrane<br />

<strong>Statkraft</strong> is spearheading work in osmotic<br />

power, and is currently investing considerable<br />

resources in developing the right technology.<br />

Facts<br />

osmotic power<br />

<strong>Statkraft</strong> is now a world<br />

leader within the development<br />

of osmotic power – a<br />

clean and renewable energy<br />

form with a global potential of<br />

between 1600 and 1700 TWh.<br />

When freshwater meets<br />

saltwater, for instance, when<br />

a river runs into the ocean,<br />

vast amounts of energy are<br />

liberated. This energy can be<br />

utilised for power generation<br />

through osmosis.<br />

“We don’t know if we will succeed, but<br />

osmotic power is a very exciting opportunity.<br />

We really need to explore whether<br />

osmotic power can be a part of the future,”<br />

says Stein Erik Skilhagen, who heads the<br />

osmotic power department in <strong>Statkraft</strong>.<br />

He points out that the ambitions for<br />

renewable energy requires a steady flow<br />

of new, clean energy sources.<br />

“Today we see strong growth in new<br />

technologies, such as solar power and<br />

offshore wind. We still need more renewable<br />

energy, and osmotic power may play<br />

a vital role here,” Skilhagen argues.<br />

The idea of utilising the naturally occurring<br />

phenomena of osmosis first started in the 1970s, but it was not<br />

until the end of the 1990s that the idea was taken further through a<br />

partnership between SINTEF and <strong>Statkraft</strong>. In 2009, <strong>Statkraft</strong> opened<br />

the world’s first osmotic power prototype at Tofte outside Oslo, a<br />

technology testing facility. One of the main challenges is to develop a<br />

membrane with the necessary properties.<br />

“The membrane is the heart of an osmotic power plant. The other<br />

technology is mostly already available, while the membranes are now<br />

the main focus for innovation and research,” says Geir Brekke, Head of<br />

Technology in <strong>Statkraft</strong>’s osmotic power department.<br />

“The function of the membrane is to separate freshwater and<br />

saltwater in such a way that enables water molecules to travel from<br />

the freshwater to the saltwater, without salt molecules going the opposite<br />

way. This creates pressure on the saltwater side, which can be<br />

utilised to operate a turbine”, Brekke explains.<br />

Developing a membrane with the right properties requires patience and a<br />

lot of experimentation, but researchers at <strong>Statkraft</strong> and SINTEF are making<br />

steady progress. Perhaps the osmotic era is just around the corner?<br />

The membrane is the<br />

heart of an osmotic<br />

power plant. The<br />

other technology<br />

is mostly already<br />

available, while the<br />

membranes are<br />

now the main focus<br />

for innovation and<br />

research,” Geir<br />

Brekke and Stein Erik<br />

Skilhagen explain.<br />

Geothermal energy:<br />

A globe of power<br />

The earth’s interior hides<br />

vast amounts of renewable<br />

energy. The challenge is to<br />

bring it to the surface.<br />

A large proportion of Iceland’s energy<br />

needs is covered by utilising heated<br />

groundwater for both electricity generation<br />

and, not least, through district heating.<br />

In Norway, and most other countries,<br />

a similar access to the same heating<br />

resource would entail a far greater drilling<br />

depth. Thus far, this resource is far<br />

too costly for commercial use unless the<br />

natural conditions are in place.<br />

In order to generate electricity of the<br />

heat from the earth’s interior, the temperature<br />

needs to be at least 120-125 degrees<br />

centigrade, and the higher the temperature,<br />

the higher the efficiency. One thing<br />

is that the drilling operation itself is quite<br />

expensive, another challenge is that<br />

there are no methods to<br />

specify what sort<br />

of geology and<br />

heating potential<br />

there is at<br />

great depths<br />

without drilling<br />

first. A lot<br />

of the current<br />

research is<br />

therefore focused<br />

on achieving<br />

improved estimates<br />

and developing efficient drilling<br />

methods to lower costs and increase<br />

drilling speeds.<br />

<strong>Statkraft</strong> recognises that geothermal<br />

energy may become increasingly<br />

important. The company is therefore<br />

considering building a 1.5 MW deep geothermal<br />

demonstration plant for heating<br />

purposes in Norway.

maturity<br />

exploration<br />

Corporate<br />

R&D programs<br />

improvement<br />

time<br />

Activities focused on technologies<br />

that may become<br />

important in the longer term.<br />

Smart Energy Technologies:<br />

New balance<br />

An electricity system must always balance<br />

production and consumption. An increased development<br />

of inflexible sources such as solar<br />

and wind, and a lack of storage opportunities<br />

to cope with this, contribute to challenging<br />

this balance. Intense work is therefore underway<br />

to increase the flexibility of the system.<br />

The current electricity system is designed<br />

for a one-way flow of electricity. However,<br />

in the future, the system must handle electricity<br />

going both ways.<br />

One reason for this is that end users are<br />

becoming “prosumers”; they both cosume<br />

and produce energy. Productions can occur<br />

by roof-mounted solar panels, wind turbines<br />

etc. To enable and optimize all energy<br />

resources in an efficient manner, and regardless<br />

of their localisation, “smart grids” and<br />

“smart technologies” should be applied.<br />

There is a strong international focus on<br />

technologies. All links in the chain, from<br />

generation to consumption, must be adapted<br />

to a more flexible future, and the result<br />

will be a “smarter” connection across the<br />

<strong>value</strong> chain. It is challenging to say anything<br />

for certain as to how existing profitability<br />

will be affected and what new opportunities<br />

may arise for innovative companies.<br />

The driving force for this development is<br />

stronger in areas with a great need for renewable<br />

energy, however, Norway will<br />

not be unaffected. The consequences<br />

may be significant for<br />

<strong>Statkraft</strong>, particularly in Europe,<br />

but this development also creates<br />

growth opportunities. Hence,<br />

<strong>Statkraft</strong> is performing<br />

analysis to evaluate<br />

drivers and<br />

barriers as well<br />

as cost, volume<br />

and market<br />

access for<br />

smart energy<br />

technologies.<br />

Norwegian reservoirs are often dubbed Europe’s future batteries as they can store water.<br />

Energy Storage:<br />

Airy storage plans<br />

When the wind does not blow, the sun<br />

does not shine and the reservoirs are at<br />

their lowest, we need backup energy. Both<br />

pumped storage power, air below ground<br />

and recently developed batteries can be the<br />

solution.<br />

Norwegian reservoirs are often referred<br />

to as “Europe’s future batteries”. The reason<br />

is that we can save our water when for<br />

instance German and British wind farms<br />

have sufficient generation and are<br />

able to transmit power to us.<br />

When there is no wind, we may<br />

use the reservoirs and send<br />

power in the opposite<br />

direction.<br />

Did you know ...<br />

… that we already<br />

have battery packages<br />

with great<br />

capacity? There<br />

is for instance a<br />

facility in the US<br />

with a capacity of<br />

a whopping 32 MW<br />

(8 MWh).<br />

From<br />

This is not yet the reality, as these plans<br />

require major transmission cables to the UK<br />

and Germany.<br />

Pumped storage is one way of storing<br />

energy. Water is run through turbines when<br />

there is a need for electricity and pumped<br />

back into the reservoirs at other times of the<br />

day, when electricity is cheaper.<br />

Through its Exploration programme of<br />

energy storage, <strong>Statkraft</strong> is monitoring development<br />

and performing analyses regarding<br />

technologies that might compete with<br />

pumped storage and hydro power reservoirs,<br />

such as compressed air below ground<br />

and new battery technology. The automotive<br />

industry’s focus on lithium-ion batteries<br />

has indicated that this storage method may<br />

develop substantially in coming years.<br />

The emerging storage technologies may in<br />

near future contribute within several regulation<br />

processes to maintain proper and economic<br />

viable operation of the grid, such as<br />

load shift, peak shaving, spinning reserves,<br />

as well as firming intermittent wind and<br />

solar power before it enters the grid.<br />

R&D to innovation<br />

– striving for excellence.<br />

Innovation is essential to secure future competitiveness and market position in the energy<br />

sector. Equally important is finding innovative solutions to provide the world’s future need<br />

for renewable energy in order to reduce climate changes. <strong>Statkraft</strong> is conscious about the<br />

responsibility we carry with regard to future generations.<br />

Research and development are key tools for<br />

promoting innovation. The main objective of<br />

our R&D activities is to develop technology<br />

and knowledge in order to continuously improve<br />

our existing business and operations,<br />

finding new ways to produce pure energy or<br />

smarter ways to operate in the market.<br />

In order to turn R&D investments into<br />

actual innovation we pay special attention to<br />

the following 3 criteria:<br />

1<br />

Relevance to business strategy is<br />

a key criterion for successful innovation<br />

in <strong>Statkraft</strong>. We strive for close<br />

alignment between the business<br />

strategy and the R&D activities we<br />

idea generation<br />

initiate. Value-creation and market orientation<br />

are drivers for R&D-investments. Close cooperation<br />

between the business areas and R&Ddepartment<br />

is essential to realize this ambition.<br />

2Building competence and knowledge<br />

for the future is a long<br />

term investment, and must rely on<br />

a shared effort amongst several<br />

stakeholders, both nationally and<br />

internationally. <strong>Statkraft</strong> plays an active role<br />

in this matter, focusing on development of<br />

strategic long-term collaboration with external<br />

partners, to promote knowledge sharing and<br />

common understanding of future threats and<br />

opportunities.<br />

selection<br />

execution<br />

3The innovation <strong>value</strong> chain<br />

(see figure below) illustrates the<br />

importance of being great at all<br />

stages of the <strong>value</strong> chain in order<br />

to turn R&D investments into<br />

innovation and <strong>added</strong> <strong>value</strong>. We strive to continuously<br />

develop our ability to identify great<br />

ideas and to select the most promising projects<br />

to invest in. Furthermore, we follow up<br />

execution to secure high quality and relevant<br />

solutions, and we emphasize the implementation<br />

of new knowledge and new solutions<br />

in our daily operations and business models.<br />

In this way we seek to create <strong>value</strong> both in<br />

our business and towards society at large.<br />

implementation<br />

We know we must maintain the same high quality in all stages of the innovation chain if we are to be successful with innovation. (Hansen and Birkinshaw, 2007, HBR)

www.statkraft.com<br />

Developed in cooperation with REDINK. Design: REDINK