Polaris-12 Spec Sheet - Sterner Lighting

Polaris-12 Spec Sheet - Sterner Lighting

Polaris-12 Spec Sheet - Sterner Lighting

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

I N F R A N O R<br />

P O L A R I S - <strong>12</strong><br />

Job Name:_____________________________________<br />

Fixture Type:<br />

t<br />

_ __________________________________<br />

Job Number: ob u ___________________________________<br />

Distributor: ____________________________________<br />

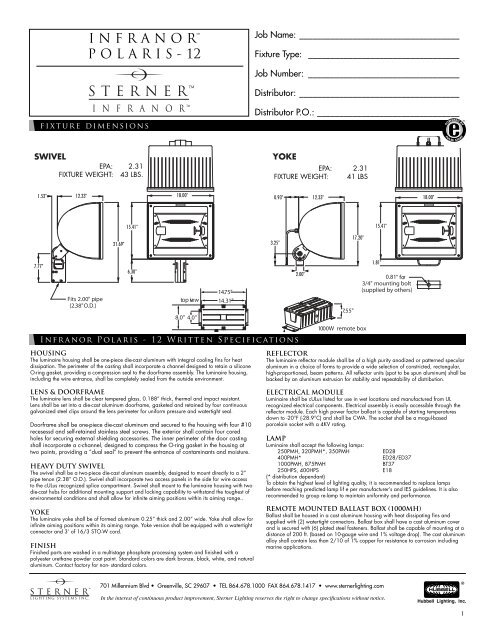

fixture F I X T dimensions<br />

R E D M E<br />

Distributor D P.O.: to ________________________________<br />

SWIVEL<br />

EPA: 2.31<br />

FIXTURE WEIGHT: 43 LBS.<br />

YOKE<br />

EPA: 2.31<br />

FIXTURE WEIGHT: 41 LBS<br />

1.52"<br />

<strong>12</strong>.33"<br />

18.00"<br />

0.93"<br />

<strong>12</strong>.33"<br />

18.00"<br />

15.41"<br />

15.41"<br />

21.69"<br />

3.25"<br />

17.20"<br />

7.77"<br />

Fits 2.00" pipe<br />

(2.38" O.D.)<br />

6.30"<br />

8.0" 4.0"<br />

14.75"<br />

14.31"<br />

4 8<br />

top view<br />

in 3" l s)<br />

2) (<br />

4)<br />

(<br />

6) (7 8)<br />

( )<br />

1<br />

Infranor <strong>Polaris</strong> - <strong>12</strong> Written <strong>Spec</strong>ifications<br />

2) suppl ed (4) cl<br />

Housing<br />

The luminaire housing shall be one-piece die-cast aluminum with integral cooling fins for heat<br />

dissipation. The perimeter of the casting shall incorporate a channel designed to retain a silicone<br />

O-ring gasket, providing a compression seal to the doorframe assembly. The luminaire housing,<br />

including the wire entrance, shall be completely sealed from the outside environment.<br />

g<br />

2.00"<br />

7.55"<br />

1000W POLE remote box<br />

1.81"<br />

0.81" for<br />

3/4" mounting bolt<br />

(supplied by others)<br />

REFLECTOR<br />

The luminaire reflector module shall be of a high purity anodized or patterned specular<br />

aluminum in a choice of forms to provide a wide selection of constricted, rectangular,<br />

high-proportioned, beam patterns. All reflector units (spot to be spun aluminum) shall be<br />

backed by an aluminum extrusion for stability and repeatability of distribution.<br />

LENS & DOORFRAME<br />

The luminaire lens shall be clear tempered glass, 0.188” thick, thermal and impact resistant.<br />

Lens shall be set into a die-cast aluminum doorframe, gasketed and retained by four continuous<br />

galvanized steel clips around the lens perimeter for uniform pressure and watertight seal.<br />

Doorframe shall be one-piece die-cast aluminum and secured to the housing with four #10<br />

recesessd and self-retained stainless steel screws. The exterior shall contain four cored<br />

holes for securing external shielding accessories. The inner perimeter of the door casting<br />

shall incorporate a c-channel, designed to compress the O-ring gasket in the housing at<br />

two points, providing a “dual seal” to prevent the entrance of contaminants and moisture.<br />

HEAVY DUTY SWIVEL<br />

The swivel shall be a two-piece die-cast aluminum assembly, designed to mount directly to a 2”<br />

pipe tenon (2.38” O.D.). Swivel shall incorporate two access panels in the side for wire access<br />

to the cULus recognized splice compartment. Swivel shall mount to the luminaire housing with two<br />

die-cast hubs for additional mounting support and locking capability to withstand the toughest of<br />

environmental conditions and shall allow for infinite aiming positions within its aiming range..<br />

YOKE<br />

The luminaire yoke shall be of formed aluminum 0.25” thick and 2.00” wide. Yoke shall allow for<br />

infinite aiming positions within its aiming range. Yoke version shall be equipped with a watertight<br />

connector and 3’ of 16/3 STO-W cord.<br />

FINISH<br />

Finished parts are washed in a multistage phosphate processing system and finished with a<br />

polyester urethane powder coat paint. Standard colors are dark bronze, black, white, and natural<br />

aluminum. Contact factory for non- standard colors.<br />

ELECTRICAL MODULE<br />

Luminaire shall be cULus listed for use in wet locations and manufactured from UL<br />

recognized electrical components. Electrical assembly is easily accessible through the<br />

reflector module. Each high power factor ballast is capable of starting temperatures<br />

down to -20°F (-28.9°C) and shall be CWA. The socket shall be a mogul-based<br />

porcelain socket with a 4KV rating.<br />

LAMP<br />

Luminaire shall accept the following lamps:<br />

250PMH, 320PMH*, 350PMH<br />

ED28<br />

400PMH*<br />

ED28/ED37<br />

1000PMH, 875PMH<br />

BT37<br />

250HPS, 400HPS<br />

E18<br />

(* distribution dependant)<br />

To obtain the highest level of lighting quality, it is recommended to replace lamps<br />

before reaching predicted lamp lif e per manufacturer’s and IES guidelines. It is also<br />

recommended to group re-lamp to maintain uniformity and performance.<br />

REMOTE MOUNTED BALLAST BOX (1000MH)<br />

Ballast shall be housed in a cast aluminum housing with heat dissipating fins and<br />

supplied with (2) watertight connectors. Ballast box shall have a cast aluminum cover<br />

and is secured with (6) plated steel fasteners. Ballast shall be capable of mounting at a<br />

distance of 200 ft. (based on 10-gauge wire and 1% voltage drop). The cast aluminum<br />

alloy shall contain less than 2/10 of 1% copper for resistance to corrosion including<br />

marine applications.<br />

n su p ied i h o<br />

t701 ht Millennium connector Blvd and • 3 Greenville, of 16/3 S SC 29607 • TEL 864.678.1000 FAX 864.678.1417 • www.sternerlighting.com<br />

E<br />

O W c<br />

d ith l t<br />

8 X<br />

In the 2/09 interest wwwof ste continuous nerlighting com product improvement, <strong>Sterner</strong> <strong>Lighting</strong> reserves capable the right o mounting to change specifications at a distanc without of 00 notice. ft. (<br />

Hub ell Li hting Inc.<br />

1

<strong>Polaris</strong> - <strong>12</strong><br />

Ordering ORDER NG N SEQUENCE<br />

Sequence ENCE<br />

O IN U C<br />

Item Sequence:<br />

ORD<br />

O<br />

1<br />

2<br />

em<br />

Item ORDER tem<br />

Seque<br />

t m SSeque<br />

Sequ<br />

I em Seq nc<br />

NUN<br />

M ER:<br />

ORDER<br />

R<br />

HOUSING<br />

HOUSING<br />

PL<strong>12</strong><br />

3<br />

4 5<br />

LAMP BEAM VOLTAGE<br />

BALLAST<br />

WATTAGE<br />

PATTERN<br />

BE<br />

250PMH<br />

320PMH<br />

350PMH<br />

400PMH 1,2,3<br />

875PMH<br />

1000PMH 4,5,6,7<br />

250HPS<br />

400HPS<br />

SP 1,2 HPM 3,5<br />

RN 5 HPM1 1,2<br />

RM 5 HPW 3,5<br />

RW 5<br />

Notes:<br />

6<br />

MODEL<br />

STYLE<br />

<strong>12</strong>0 277 C<br />

SW<br />

208 347<br />

YK<br />

240 480 7<br />

HPW1 1,2<br />

1) ‘400PMH’ only available with ‘SP’, ‘BI’, ‘HPM1’ & ‘HPW1’ distributions.<br />

2) ‘SP’, ‘BI’, ‘HPM1’, ‘HPW1’ requires ED28 lamps in ‘400MH’.<br />

3) ‘400PMH’ & ‘HPM’, ‘HPW’ distributions require ED37 lamps.<br />

4) ‘1000PMH‘ uses remote ballast box.<br />

5) ‘1000PMH’ only available with ’RN’, ‘RM’, ‘RW’, ‘HPM’ & ‘HPW’ distributions.<br />

7<br />

MOUNTING<br />

OPTIONS<br />

PD<br />

ST<br />

WM<br />

DP 5<br />

(swivel only)<br />

N<br />

PL<br />

WB<br />

SF<br />

(yoke only)<br />

8<br />

SHIELD<br />

OPTIONS<br />

TS<br />

EC 9<br />

4S<br />

BD<br />

SG 6,9<br />

N<br />

9<br />

GENERAL<br />

OPTIONS<br />

FL<br />

SC<br />

PCL 7<br />

N<br />

100<br />

FINISH<br />

BK<br />

BZ<br />

WH<br />

AL<br />

NS 10<br />

6) ‘1000PMH’ not available with ‘SG’, ‘FL, ‘PCL’ options.<br />

7) ‘PCL’ Eye Dot Photocell not available in ‘1000PMH’ or ‘480V’.<br />

8) ‘DP’ option automatically doubles the fixture quantity unless otherwise specified.<br />

9) ‘SG’ not available with ‘EC’.<br />

10) Please supply metal color chip or supply RAL# for any ‘NS’ finish.<br />

6.00” 6 a<br />

5) 5) ‘1000 0<br />

1. Housing . HOU 5<br />

0 MH MH 1 SIN 00PMH only l a v<br />

N 2. th ‘R R<br />

2 L M H Amp MP RW M & PW M P<br />

WATT & H s<br />

Attage<br />

W<br />

ibu b d ion . ibut 1<br />

AGG<br />

ons 0 y<br />

3. 3 r R fo fo BEA Beam y RAL an an fo NS S<br />

M any fii<br />

PPattern<br />

PATT S n TTERN<br />

h<br />

HO SI<br />

2. L TTA<br />

H A 2 L I D L A E AAG AGE O D I U M<br />

HALIDE &SODIUM<br />

TTEGE<br />

33. BE BBEA 3<br />

A M B P T<br />

q (PL<strong>12</strong>)<br />

q (250PMH) ED28 q (250HPS) E18 q (SP)* q (RN) q (RM) q (RW)<br />

ED28 q (400HPS) E18<br />

<strong>12</strong>0)<br />

4. Voltage<br />

4 OLTO GE TA<br />

20)<br />

)<br />

q (<strong>12</strong>0)<br />

q (208)<br />

q (240)<br />

(*480V not o avano b e vw a h<br />

Ey<br />

Eye le with<br />

‘ ye PCL<br />

D<br />

Do<br />

‘ Eye PPhot Photocell<br />

otoce cell<br />

Dot Photocell l pt pt<br />

op ion.<br />

347)<br />

onn )<br />

option.)<br />

5 C)<br />

ALo r & Co<br />

W<br />

2 T 43 : 3L<br />

SS<br />

Ballast<br />

A Lo<br />

T<br />

S<br />

6 M EL<br />

Model DEL S STY LE<br />

* Co e & Coil W) Sw vel Style<br />

0<br />

C *<br />

l<br />

1<br />

WT<br />

EPA W 3<br />

43<br />

2.31<br />

L<br />

S<br />

BS<br />

6. 4<br />

q (C)* Core & Coil q (SW) Swivel<br />

1 .00<br />

(<br />

(*’SP’, ‘HPM1’ & ‘HPW1’ ddistributions b require ED28 l lamps in ‘ ‘400PMH’.)<br />

)<br />

(**‘HPM’ & ‘HPW’ distributions require ED37 lamps in ’400PMH’.)<br />

(’1000PMH’ only available with ‘RN’, ‘RM’, ‘RW’, ‘HPM’ & ‘HPW’ distributions.)<br />

(SP=spot , R=rectangular,HP=high-point, N=narrow, M=medium, W=wide.)<br />

Fi s 2.00 pipe (2 38 O.D.)<br />

7. 7<br />

. Swivel DSW 7<br />

W Ba e WI V VE<br />

PPad<br />

Mounting E MMoUNTIN o<br />

MoU I<br />

NG Options OP O<br />

(S TIONS T ) PTI SStanch<br />

O S ( nDP’ NS (’ (<br />

option P oop ’DP’ automatical on<br />

op a tomati<br />

ion a (D ica y<br />

al<br />

Domat oub y ) ddoub e cD l h e a es<br />

do fix tth e or fix tixtur Top re an qquan f Mo antin<br />

ty y<br />

quan ss unless o<br />

l<br />

h<br />

ss<br />

t rwotherwise o h<br />

unWM<br />

e e<br />

ss othe ) fie<br />

sp pW<br />

w<br />

)<br />

c<br />

) B se Pa<br />

q (PD) Base Pad<br />

(Anchors supplied p<br />

i d by by 4) others.)<br />

”<br />

56”<br />

2.06 2.06<br />

0.56” 0 I<br />

(4<br />

I.D. I D<br />

0” 4)<br />

6.0 6 00<br />

bol ” di d<br />

cir<br />

bolt circ le<br />

6.25”<br />

238”<br />

O<br />

O.D. O D<br />

All wem mp<br />

ded one n<br />

constructi<br />

t t e l<br />

welded ded construction c n<br />

(2.00” st sch s<br />

el<br />

h<br />

p pe<br />

40 0<br />

steel l pipe)<br />

0.25” 0 7. Yoke P7 YOKE B<br />

O<br />

a<br />

eY P aMounting eKE MMoUN o<br />

MoUN U<br />

N ING I<br />

Options<br />

G OOP G W<br />

Tl<br />

BBr<br />

PT<br />

O<br />

) B se Pl e<br />

WB<br />

a l Br a<br />

k<br />

q (WB) Wall Bracket q (SF) Slip Fitter<br />

q (PL) Base Plate<br />

(Anchors<br />

(Ancho<br />

suppl<br />

s s pp<br />

ed<br />

ed<br />

by<br />

by<br />

others.)<br />

o he<br />

(<br />

0 56<br />

0656<br />

00 (<br />

b(4lt<br />

.0 d<br />

6.00 dia.<br />

b t ir<br />

bo t circle<br />

6.0<br />

6.00<br />

3/4" mounting u<br />

hardw e<br />

hardware<br />

3 0<br />

3.00”<br />

.3<br />

1.38”<br />

C s du l 0 38<br />

Cast du t le iron 0.38<br />

su face ba<br />

surface base<br />

SHIEL LD<br />

8 SHI OPTION O I N<br />

D PTI<br />

4.50” 4 2.00” IPS tenon t n n<br />

n s<br />

4 50 50 ste<br />

truct<br />

All Ao<br />

p<br />

l c mmponen ents p t<br />

welded cons tructi st s ee e<br />

we weld<br />

(For d d concrete<br />

onstr<br />

cttion<br />

pou n<br />

(For (For concrete n r t pour)<br />

r<br />

21.75” 2 1.52<br />

7.77"<br />

8 ( Shie Top h e d Options<br />

(EC<br />

E<br />

q (EC)* Egg Crate q (4S) Four Sided q (BD) Barn Door q (N) Not Required<br />

q (TS) Top Shield<br />

17.67" 79 25 4.25"<br />

<strong>12</strong> 14.68"<br />

q (277)<br />

q (347)<br />

q (480)<br />

q (320PMH)<br />

q (350PMH) ED28<br />

q (400PMH)* ED28/ED37<br />

q (875PMH) ED37<br />

q (1000PMH)**BT17<br />

(*‘400PMH’ ED28 only available with ‘SP’, ‘BI’, ‘HPM1’ & ‘HPW1’ distributions.)<br />

(**’1000PMH’ uses remote ballast box.)<br />

(**’1000PMH’ only available with ‘RN’, ‘RM’,‘ RW’, ‘HPM’ & ‘HPW’ distributions.)<br />

(**’1000PMH’not available with ‘SG’ & ‘PCL’ options.)<br />

7 Sw e<br />

277 7<br />

S<br />

<strong>12</strong> 15.07"<br />

(* Core & coil ballast is high-power factor<br />

and rated for -20°F (-28.9°C).)<br />

(*’1000PMH’ uses remote ballast box.)<br />

<strong>12</strong>.33<br />

p<br />

All welded om ompone n<br />

cons<br />

n<br />

ructi<br />

s e l<br />

welded d construction c n<br />

21.69" (2<br />

2.00<br />

2 00<br />

IPS 24 IP<br />

tenon 00n n<br />

(<br />

2<br />

28)<br />

28 28<strong>12</strong>”<br />

1<br />

4 00”<br />

24.00”<br />

15.41"<br />

6.30"<br />

ica ( . ly doubles t<br />

Fits Fits 2.00” 2 IPS IPS<br />

WT:43 LBS<br />

18.00"<br />

3.00”<br />

4.00 4 00<br />

11.00”<br />

4.00” 4 0.93"<br />

3.25"<br />

2.00<br />

<strong>12</strong> 33"<br />

(WM) Wa<br />

q (WM) Wall Mount<br />

(Anchors rs supplied s ed by b others.)<br />

)<br />

14 38”<br />

IP<br />

2.00” 2 IPS IPS tenon<br />

n<br />

14.38”<br />

4.00”<br />

0.44” 0 (4)<br />

1 n .00 t uc<br />

mpon t<br />

All All<br />

welded m one onen<br />

constructi t e<br />

we weld ded d construction<br />

tion<br />

8.00”<br />

600”<br />

”<br />

(Anchors<br />

(Ancho<br />

suppl<br />

s s pp<br />

ed<br />

ed<br />

by<br />

by16 others<br />

o he 3/8” )<br />

s<br />

3.4<br />

3.44<br />

.8<br />

1 1 ” b<br />

To fi 2.00 2.3<br />

1.81 1.16” /8 o<br />

a u t<br />

pipe To fit tenon 2 00 (2 38 O(mi<br />

D )<br />

3/8” locking<br />

Can U-bolts moun (U-bolt y<br />

pipe ten<br />

to 2.00 pipe (max) with<br />

(m x n<br />

n.)<br />

4 x 00 4 00 long o<br />

bolt<br />

to 2.0 pip (max) w<br />

bo t<br />

3 1<br />

(min )<br />

v<br />

U b l s (U b lt by th<br />

U-bolts (U-bolts by others).<br />

3.13”<br />

Removable<br />

pipe plug<br />

pipe<br />

installin<br />

plug for<br />

instal ing<br />

1.50<br />

3/4" 3/<br />

hardware<br />

mounting u<br />

water t<br />

water-tite<br />

1<br />

hardware<br />

conne<br />

t / p<br />

connect r<br />

5/8 piv t<br />

(supplie<br />

are<br />

3 5<br />

b lt<br />

(supp ied)<br />

bolt<br />

3/4 mount ng hardw<br />

3 5<br />

3/4 mounting hardware<br />

3 50”<br />

6<br />

5.63” o a<br />

splice Removable<br />

splice<br />

1.50”<br />

0.56"<br />

co inspection inspe ti<br />

er<br />

1.5<br />

0. Water-tite<br />

3.50” 3.5 (<br />

s n alloy ov r<br />

Connect<br />

(4)<br />

er<br />

Connector Re<br />

4.5<br />

h<br />

8.0<br />

4.50”<br />

C s z<br />

as du<br />

8 00<br />

Cast tenza loy<br />

1/2<br />

Cast ducti e on<br />

5 50”<br />

fitter<br />

5.50”<br />

fitter<br />

hole em hole<br />

set<br />

p vable va<br />

horizo<br />

s rews<br />

plug<br />

wall bra ket a<br />

g for<br />

wa l bracket and<br />

1/2 sideyok<br />

1/2" et sideyok<br />

horizonta se t<br />

horizontal sector<br />

scr mounti<br />

screws mounting<br />

17.67" 79 25 4.25"<br />

S ) St nc i<br />

q (ST) Stanchion<br />

<strong>12</strong> 15.07"<br />

17.67" 79 25 4.25"<br />

(D ) Dual Post Top Mount<br />

q (DP) Dual Post-Top Mount<br />

15.07" 2<br />

17.67" 79 56.56"<br />

(*’C’ safety cable is only available<br />

with ‘YK’ yoke option.)<br />

q (YK) Yoke*<br />

1.94"<br />

6.00”<br />

1<br />

EPA: WT 2.31 41 L<br />

S<br />

WT:41 6 34" LBS 18 0<br />

" 17mou<br />

20"<br />

15.41"<br />

1<br />

W<br />

m un<br />

81<br />

lied by o he g<br />

4<br />

bs)<br />

mounting<br />

t<br />

d by bo t<br />

others)<br />

the )<br />

supplied by others)<br />

8.00” 8 q (SG)* Polycarbonate Stone Guard<br />

q (HPW)**q (HPW1)*<br />

q (HPM)** q (HPM1)*<br />

18.00"<br />

q (N)<br />

Not Required<br />

q (N)<br />

Not Required<br />

q (<br />

9 General GENERA ENERA<br />

Options L OPT<br />

PPT<br />

O<br />

IO<br />

10 FINI Finish<br />

1 INI<br />

ISH H<br />

q (FL) Fuse Luminaire q (SC) Safety Cable q (PCL)* Eye Dot Photocell q (BK) Black q (BZ) Dark Bronze<br />

(* ‘PCL’ not available in ‘250MH’.)<br />

q (N) Not Required<br />

q (AL) Natural Aluminum q (NS)*Non-Standard<br />

(*’SG’ not available with ‘EC’.)<br />

q (WH) White<br />

(*Please supply metal color chip or<br />

supply RAL# for any ‘NS’ finish.)<br />

:<br />

l<br />

STERNER R E M A R LIGHTING K S : • 701 Millennium Blvd • Greenville, SC 29607 • TEL 864.678.1000 FAX 864.678.1417 • www.sternerlighting.com 5/10 2<br />

R E A S