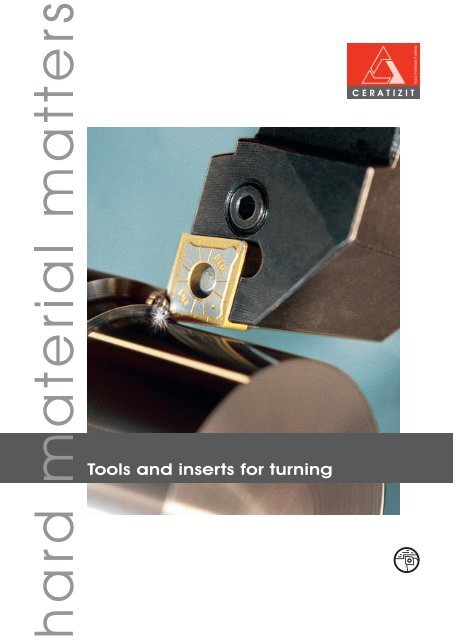

Tools and inserts for turning - Sanimex

Tools and inserts for turning - Sanimex

Tools and inserts for turning - Sanimex

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Tools</strong> <strong>and</strong> <strong>inserts</strong> <strong>for</strong> <strong>turning</strong>

CERATIZIT - the parent companies<br />

Headquarters <strong>and</strong> parent company in MAMER / Luxemburg<br />

Parent company in REUTTE / Austria<br />

Direct sales <strong>and</strong> distribution partners<br />

A2

Our facilities <strong>and</strong> production<br />

methods represent<br />

state-of-the-art technology<br />

We rely on more than 80 years of<br />

know-how in the field of<br />

powder metallurgy<br />

Engineering know-how <strong>and</strong><br />

on site application advice<br />

We promote intensive<br />

dialogue with our business<br />

partners<br />

Our quality management systems meet<br />

the highest st<strong>and</strong>ards<br />

A3

CERATIZIT WinTool<br />

The electronic tooling catalogue<br />

CERATIZIT WinTool is a modern tooling in<strong>for</strong>mation system<br />

which provides additional support <strong>for</strong> you when choosing <strong>and</strong> applying tools <strong>for</strong> machining.<br />

arguments in favour of WinTool:<br />

Electronic “Catalogue“<br />

Up-to-date <strong>and</strong> complete data,<br />

possibility to add personal comments,<br />

structured data usable in various applications,<br />

export of drawing data as DXF-<strong>for</strong>mat.<br />

Continuous 1:1 graphic support<br />

Simple recognition of tool components,<br />

true-to-scale representation of complete<br />

tools.<br />

Easy to use PC software<br />

Easy installation, minimal training<br />

requirements, structured user-friendly search<br />

<strong>for</strong> tool data.<br />

Extendable<br />

Integration of customer-specific data <strong>and</strong><br />

other manufacturers‘ data is possible<br />

without problems.<br />

“Compact“ - “Professional“ version<br />

“Compact“:<br />

Free of charge, complete catalogue with<br />

basic functions<br />

Additional functions of “Professional“:<br />

Import of individual component data,<br />

assembly of more than 20 complete tools,<br />

creation of individual tool lists, data export.<br />

A4

www.ceratizit.com<br />

News<br />

Applications<br />

One mouse-click will provide you with:<br />

Materials<br />

• News from the world of powder metallurgy<br />

• Extensive in<strong>for</strong>mation about the<br />

CERATIZIT product range<br />

• St<strong>and</strong>ard <strong>and</strong> special solutions in the field<br />

of metal working<br />

• Clear explanations concerning application<br />

<strong>and</strong> materials<br />

• Retrievable product <strong>and</strong> tooling catalogues<br />

• Possibility of direct contact via e-mail worldwide<br />

• Tips <strong>for</strong> application <strong>and</strong> in<strong>for</strong>mation about<br />

training courses<br />

Service<br />

Contact<br />

A5

Contents<br />

Introduction<br />

Application<br />

Inserts<br />

<strong>Tools</strong><br />

Technical<br />

in<strong>for</strong>mation<br />

Page A8-A9<br />

Page B2-B5<br />

Page C2-C30<br />

Page D2-D72<br />

PageE2-E7<br />

Page A10-A15<br />

Page B6-B7<br />

Page C32-C54<br />

Page D74-D101<br />

Page E8-E17<br />

V C<br />

Page A16-A39<br />

Page B8-B9<br />

Page C56-C57<br />

Page D103-D112<br />

Page E18-E23<br />

SVVCN<br />

PSBNL<br />

SCACL<br />

CC..<br />

Page A40-A51<br />

Page B10-B13<br />

Page C59-C68<br />

Page E24-E26<br />

Page A54-A55<br />

Page B14-B15<br />

Page C70-C73<br />

Branch<br />

solutions<br />

Page A56-A60<br />

Page B16-B17<br />

Page C75-C77<br />

Page B18-B19<br />

Page B20-B21<br />

A7

Introduction<br />

Easy<br />

Choice<br />

Page<br />

A8-A9<br />

“Easy Choice“<br />

Selection has never been so easy!<br />

The <strong>turning</strong> catalogue has been divided into 5 chapters.<br />

The different colours of the navigation bars on the right-h<strong>and</strong><br />

side of the catalogue make a first quick selection guide to<br />

the various chapters.<br />

(See illustration on right-h<strong>and</strong> side)<br />

Tool selection via the chapter “Application“<br />

2<br />

1<br />

3<br />

1<br />

Look <strong>for</strong> the machining method of your choice using the right navigation bar.<br />

2<br />

Here you can choose the applicable clamping system <strong>for</strong> the <strong>inserts</strong>.<br />

3<br />

In horizontal direction you will find the available tools listed according to the insert <strong>for</strong>ms <strong>and</strong> the<br />

approach angle <strong>for</strong> the chosen application <strong>and</strong> the requested clamping system.<br />

The shank diameters <strong>and</strong> a cross-reference to the page containing detailed tool data complete<br />

the in<strong>for</strong>mation.<br />

A8

“Easy Choice“<br />

Selection has never been so easy!<br />

Introduction<br />

Chapter “<strong>Tools</strong>“<br />

1<br />

Page A8-A9<br />

Page A10-A15<br />

Page A16-A39<br />

2<br />

1<br />

In<strong>for</strong>mation about the application possibilities<br />

of the tools <strong>and</strong> <strong>inserts</strong>.<br />

Page A40-A51<br />

2<br />

Reference to the appropriate <strong>inserts</strong> <strong>and</strong><br />

tools.<br />

Page A54-A55<br />

Chapter “Inserts“<br />

Chapter “Technical in<strong>for</strong>mation“<br />

1<br />

Page A56-A60<br />

2<br />

A9

Introduction<br />

ISO designation system<br />

Tool holders<br />

ISO<br />

tool<br />

holders<br />

Page<br />

A10-A11<br />

ISO<br />

boring<br />

bars<br />

90° 75°<br />

90° 45° 60°<br />

Page<br />

A12-A13<br />

ISO<br />

<strong>inserts</strong><br />

Retained via centre<br />

screw<br />

Retained from<br />

above <strong>and</strong> via bore<br />

A B C D E<br />

90°<br />

90° 107,5° 93°<br />

F G H J K<br />

75°<br />

95°<br />

50° 63° 117,5°<br />

75°<br />

Page<br />

A14-A15<br />

Retained via the<br />

bore<br />

Retained from<br />

above<br />

L<br />

M N P R<br />

45° 60° 93° 72,5° 60°<br />

Special version<br />

S T U V W<br />

Clamping method Style Cutting<br />

direction<br />

Y<br />

85°<br />

S C L C R<br />

1<br />

2<br />

3<br />

4<br />

5<br />

Insert shape<br />

Clearance angle<br />

Included angle<br />

Included angle<br />

Other shapes<br />

Clearance angles not<br />

included within the<br />

st<strong>and</strong>ard <strong>for</strong> which<br />

particular in<strong>for</strong>mation<br />

is necessary<br />

A10

ISO designation system<br />

Tool holders<br />

Introduction<br />

Page A8-A9<br />

Page A10-A15<br />

Page A16-A39<br />

Shank width<br />

Cutting edge length<br />

Page A40-A51<br />

25 25 M 12<br />

6<br />

7<br />

8<br />

9<br />

Page A54-A55<br />

Shank height Cartridge Tool length<br />

Special<br />

tolerances<br />

Page A56-A60<br />

Tool holder<br />

h 1<br />

h 2<br />

h 2<br />

h 1<br />

Cartridge<br />

Round shank<br />

1 st position:<br />

C = cartridge<br />

2 nd position:<br />

A = ISO 5611<br />

l 1<br />

mm<br />

l 1<br />

mm<br />

Special<br />

length X<br />

l 1<br />

Qualified<br />

high-precision tools<br />

f 1 f 1<br />

f 2 f b<br />

2<br />

l 1 l 1 l 1<br />

A11

Introduction<br />

ISO designation system<br />

Boring bars<br />

ISO<br />

tool<br />

holders<br />

Page<br />

A10-A11<br />

ISO<br />

boring<br />

bars<br />

Steel shank<br />

As C<br />

with coolant hole<br />

Page<br />

A12-A13<br />

ISO<br />

<strong>inserts</strong><br />

Steel shank<br />

with coolant hole<br />

Steel shank<br />

with antivibration system<br />

As C with<br />

antivibration system<br />

As C with coolant hole <strong>and</strong><br />

antivibration system<br />

Retained via centre<br />

screw<br />

Retained from<br />

above <strong>and</strong> via bore<br />

Page<br />

A14-A15<br />

Steel shank with coolant hole<br />

<strong>and</strong> antivibration system<br />

Heavy metal<br />

Carbide shank<br />

with steel head<br />

Heavy metal<br />

with coolant hole<br />

Retained via the<br />

bore<br />

Special version<br />

Retained from<br />

above<br />

Shank version<br />

Clamping method<br />

S 32 U S S<br />

1<br />

2<br />

3<br />

4<br />

5<br />

Shank Ø Tool length Insert shape<br />

d 1<br />

mm<br />

l 1<br />

mm<br />

Included angle<br />

l 1<br />

Included angle<br />

d 1<br />

Special<br />

Other shapes<br />

A12

ISO designation system<br />

Boring bars<br />

Introduction<br />

Page A8-A9<br />

Page A10-A15<br />

Page A16-A39<br />

*) Factory st<strong>and</strong>ard CERATIZIT<br />

Style<br />

Cutting<br />

direction<br />

Cutting edge length<br />

Page A40-A51<br />

K C R 12<br />

6<br />

7<br />

8<br />

9<br />

Page A54-A55<br />

Clearance angle<br />

Page A56-A60<br />

Clearance angles not<br />

included within the<br />

st<strong>and</strong>ard <strong>for</strong> which<br />

particular in<strong>for</strong>mation<br />

is necessary<br />

A13

Introduction<br />

ISO designation system<br />

Inserts<br />

ISO<br />

tool<br />

holders<br />

Page<br />

A10-A11<br />

ISO<br />

boring<br />

bars<br />

Included<br />

angle<br />

Page<br />

A12-A13<br />

ISO<br />

<strong>inserts</strong><br />

Included<br />

angle<br />

Page<br />

A14-A15<br />

Other shapes<br />

Clearance angles not<br />

included within the<br />

st<strong>and</strong>ard <strong>for</strong> which<br />

particular in<strong>for</strong>mation<br />

is necessary<br />

Special version<br />

Insert shape<br />

Clearance<br />

angle<br />

Tolerances<br />

Form of top<br />

surface<br />

T P U N<br />

1 2<br />

3<br />

4<br />

Tolerance in inches<br />

ASA <strong>and</strong> BHMA deviation with regard to ISO<br />

X = Special version not according to ISO<br />

* Depends on insert size<br />

Form of top<br />

surface<br />

Symbols as above<br />

Changes at inscribed<br />

circle IK < 1/4“<br />

IK ≥ 1/4“<br />

N / R / F<br />

A / M / G<br />

X<br />

IK < 1/4“<br />

E<br />

D<br />

X<br />

A14

ISO designation system<br />

Inserts<br />

Introduction<br />

Page A8-A9<br />

7.1 Inserts with corner radii<br />

Sharp<br />

etc.<br />

mm<br />

06<br />

09<br />

11<br />

16<br />

22<br />

27<br />

33<br />

44<br />

Inches<br />

5/32<br />

7/32<br />

1/4<br />

3/8<br />

1/2<br />

5/8<br />

3/4<br />

1<br />

mm<br />

3,96<br />

5,56<br />

6,35<br />

9,52<br />

12,7<br />

15,8<br />

19,0<br />

25,4<br />

mm<br />

03<br />

05<br />

06<br />

09<br />

12<br />

15<br />

19<br />

25<br />

Inches<br />

1/16<br />

3/32<br />

1/8<br />

5/32<br />

3/16<br />

7/32<br />

1/4<br />

5/16<br />

3/8<br />

mm<br />

1,59<br />

2,38<br />

3,18<br />

3,97<br />

4,76<br />

5,56<br />

6,35<br />

7,94<br />

9,52<br />

Index<br />

01<br />

02<br />

03<br />

T3<br />

04<br />

05<br />

06<br />

07<br />

09<br />

7.2 Inserts with secondary<br />

cutting edge<br />

7.2.1 Angle of main cutting<br />

edge to secondary<br />

cutting edge<br />

45° A 85° F<br />

60° D 90° P<br />

75° E<br />

7.2.2 Clearance angle of<br />

secondary cutting<br />

edge according to<br />

position 2<br />

7.3 Special version ZZ<br />

Honed<br />

Chamfered<br />

Chamfered <strong>and</strong><br />

honed<br />

Doublechamfered<br />

Double-chamfered<br />

& honed<br />

Page A10-A15<br />

Page A16-A39<br />

Cutting edge<br />

length<br />

Insert<br />

thickness<br />

Corner radius<br />

Cutting<br />

edge<br />

Cutting<br />

direction<br />

Page A40-A51<br />

22 04 12<br />

5 1 8 9<br />

4 3 3<br />

6 1<br />

5 2 10<br />

6 2<br />

7 1<br />

7 2<br />

Page A54-A55<br />

Page A56-A60<br />

Cutting edge<br />

length<br />

Code<br />

2<br />

3<br />

4<br />

5<br />

6<br />

8<br />

Inches<br />

1/4<br />

3/8<br />

1/2<br />

5/8<br />

3/4<br />

1<br />

Insert thickness<br />

Code Inches<br />

1 1/16<br />

2<br />

1/8<br />

3 3/16<br />

4<br />

1/4<br />

5 5/16<br />

6<br />

3/8<br />

Corner radius<br />

Code<br />

0<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

X<br />

Corner radius inches<br />

max. 0,004<br />

1/64<br />

1/32<br />

3/64<br />

1/16<br />

5/64<br />

3/32<br />

7/64<br />

1/8<br />

-<br />

For special <strong>for</strong>ms of the<br />

chip groove in the 10 th<br />

position manufacturer<br />

specific chip grooves <strong>and</strong><br />

designations can be<br />

indicated.<br />

A15

Introduction<br />

MasterGuide<br />

Master<br />

Guide<br />

Material<br />

Page<br />

A16-A17<br />

Grade<br />

overview<br />

Page<br />

A18-A21<br />

Main grades<br />

<strong>for</strong><br />

Based on VDI 3323 CERATIZIT ‘s MasterGuide divides<br />

materials into six main groups.<br />

Each is given a colour, according to the system partly<br />

adopted in ISO 513.<br />

Page<br />

A22-A39<br />

Blue: steel<br />

machining, cementation,<br />

tempered <strong>and</strong> constructional<br />

steels<br />

Yellow: stainless steel<br />

ferritic Cr-steels,<br />

austenitic CrNi-steels,<br />

martensitic Cr-steels,<br />

duplex steels<br />

Red: cast iron<br />

grey cast iron,<br />

tempered iron,<br />

spheroidal cast iron,<br />

sintered iron<br />

Green: non ferrous metals <strong>and</strong><br />

non metals<br />

Al wrought <strong>and</strong> Al cast alloys,<br />

copper, copper alloys,<br />

non metal materials<br />

Orange: heat resistant alloys<br />

Ni-/Co-base-alloys,<br />

Ti-alloys<br />

White: hard materials<br />

hardened steels (≥45 HRC),<br />

chilled castings,<br />

hard cast irons<br />

Machining application type<br />

Each coloured segment is divided into three<br />

sections, <strong>and</strong> each section indicates the relevant<br />

machining application type:<br />

R = Rough machining M = Medium machining F = Fine machining<br />

A16

MasterGuide<br />

Introduction<br />

Application<br />

Page A8-A9<br />

The ideal application area <strong>for</strong> each insert is indicated by a black<br />

circle. Extended applications are indicated by an open circle.<br />

The CERATIZIT MasterGuide provides you with an easily<br />

underst<strong>and</strong>able structure <strong>for</strong> choosing a product <strong>and</strong> enables you<br />

to reduce grade <strong>and</strong> geometry stocks.<br />

Page A10-A15<br />

Main application Extended application<br />

Page A16-A39<br />

Page A40-A51<br />

The right indexable insert at one glance.<br />

Page A54-A55<br />

Page A56-A60<br />

Main application:<br />

Fine <strong>and</strong> medium machining of aluminium. Fine<br />

machining of cast iron <strong>and</strong> heat resistant alloys.<br />

Extended application:<br />

Fine machining of stainless steel.<br />

A17

Introduction<br />

Master<br />

Guide<br />

Carbide (HW + HC)<br />

Grade overview<br />

Page<br />

A16-A17<br />

Grade<br />

overview<br />

Grade<br />

designation<br />

St<strong>and</strong>ard<br />

designation<br />

Application range<br />

05 15 25 35 45<br />

01 10 20 30 40 50<br />

Steel<br />

A R F N S H<br />

Stainless<br />

Material group<br />

Cast iron<br />

Non ferrous<br />

metals<br />

Heat<br />

resistant<br />

Hard<br />

materials<br />

Page<br />

A18-A21<br />

Main grades<br />

<strong>for</strong><br />

H210T<br />

H216T/<br />

H10T<br />

HW-M10<br />

HW-K10<br />

HW-K15<br />

Page<br />

A22-A39<br />

CTW7120<br />

S40T<br />

HW-M20<br />

HW-K20<br />

HW-P40<br />

HW-M40<br />

HC-P10<br />

GM507<br />

HC-M10<br />

HC-K15<br />

HC-P15<br />

GM517<br />

HC-M15<br />

HC-K15<br />

CTP2120<br />

HC-M20<br />

HC-K20<br />

HC-P25<br />

CTC1125<br />

HC-M25<br />

HC-K20<br />

GM527<br />

HC-P25<br />

HC-M20<br />

CTC1135<br />

HC-P35<br />

HC-M35<br />

CTC2135<br />

HC-M35<br />

GM537<br />

HC-P35<br />

HC-M25<br />

GM40<br />

HC-P35<br />

HC-M30<br />

GM540<br />

HC-P35<br />

HC-M30<br />

01 10 20 30 40 50<br />

05 15 25 35 45<br />

Main application<br />

Extended application<br />

A18

Grade overview<br />

Introduction<br />

Carbide (HW + HC)<br />

Grade<br />

designation<br />

St<strong>and</strong>ard<br />

designation<br />

Application range<br />

05 15 25 35 45<br />

01 10 20 30 40 50<br />

Steel<br />

A R F N S H<br />

Stainless<br />

Material group<br />

Cast iron<br />

Non ferrous<br />

metals<br />

Heat<br />

resistant<br />

Hard<br />

materials<br />

Page A8-A9<br />

AMZ<br />

HC-K10<br />

SR17<br />

HC-P15<br />

HC-K15<br />

Page A10-A15<br />

HC-P25<br />

SR127<br />

HC-M20<br />

HC-K20<br />

Page A16-A39<br />

SR226<br />

HC-P25<br />

HC-K20<br />

CM40<br />

HC-P40<br />

HC-M35<br />

Page A40-A51<br />

01 10 20 30 40 50<br />

05 15 25 35 45<br />

Main application<br />

Extended application<br />

Cermet (HT+HC)<br />

Page A54-A55<br />

Grade<br />

designation<br />

St<strong>and</strong>ard<br />

designation<br />

Application range<br />

Material group<br />

A R F N S H<br />

01<br />

05 15 25 35 45<br />

10 20 30 40 50<br />

Steel<br />

Stainless<br />

Cast iron<br />

Non ferrous<br />

metals<br />

Heat<br />

resistant<br />

Hard<br />

materials<br />

Page A56-A60<br />

HT-P10<br />

TCM407<br />

HT-M05<br />

HT-K05<br />

HT-P15<br />

TCM10<br />

HT-M10<br />

HT-K10<br />

HC-P10<br />

TCC410<br />

HC-M10<br />

HC-K05<br />

01 10 20 30 40 50<br />

05 15 25 35 45<br />

Main application<br />

Extended application<br />

A19

Introduction<br />

Master<br />

Guide<br />

Grade overview<br />

Carbide (HW+HC) EcoCut-Mini (solid hardmetal)<br />

Page<br />

A16-A17<br />

Grade<br />

designation<br />

St<strong>and</strong>ard<br />

designation<br />

Application range<br />

Material group<br />

A R F N S H<br />

Grade<br />

overview<br />

01<br />

05 15 25 35 45<br />

10 20 30 40 50<br />

Steel<br />

Stainless<br />

Cast iron<br />

Non ferrous<br />

metals<br />

Heat<br />

resistant<br />

Hard<br />

materials<br />

TSM33<br />

HW-K30<br />

Page<br />

A18-A21<br />

Main grades<br />

<strong>for</strong><br />

CM45<br />

HC-P45<br />

HC-M40<br />

01 10 20 30 40 50<br />

05 15 25 35 45<br />

Main application<br />

Extended application<br />

Page<br />

A22-A39<br />

A20

Grade overview<br />

Introduction<br />

CBN (BN)<br />

Grade<br />

designation<br />

St<strong>and</strong>ard<br />

designation<br />

01<br />

Application range<br />

05 15 25 35 45<br />

10 20 30 40 50<br />

A R F N S H<br />

Steel<br />

Stainless<br />

Material group<br />

Cast iron<br />

Non ferrous<br />

metals<br />

Heat<br />

resistant<br />

Hard<br />

materials<br />

Page A8-A9<br />

TA120<br />

BN-K05<br />

TA201<br />

BN-K10<br />

Page A10-A15<br />

01 10 20 30 40 50<br />

05 15 25 35 45<br />

Main application<br />

Extended application<br />

PCD (DP)<br />

Page A16-A39<br />

Grade<br />

designation<br />

St<strong>and</strong>ard<br />

designation<br />

Application range<br />

Material group<br />

A R F N S H<br />

S010<br />

DP-K01<br />

01<br />

05 15 25 35 45<br />

10 20 30 40 50<br />

Steel<br />

Stainless<br />

Cast iron<br />

Non ferrous<br />

metals<br />

Heat<br />

resistant<br />

Hard<br />

materials<br />

Page A40-A51<br />

S025<br />

DP-K05<br />

01 10 20 30 40 50<br />

05 15 25 35 45<br />

Main application<br />

Extended application<br />

Page A54-A55<br />

HSS<br />

Grade<br />

designation<br />

St<strong>and</strong>ard<br />

designation<br />

Application range<br />

Material group<br />

A R F N S H<br />

Page A56-A60<br />

01<br />

05 15 25 35 45<br />

10 20 30 40 50<br />

Steel<br />

Stainless<br />

Cast iron<br />

Non ferrous<br />

metals<br />

Heat<br />

resistant<br />

Hard<br />

materials<br />

SM80<br />

PM-HSS<br />

01 10 20 30 40 50<br />

05 15 25 35 45<br />

Main application<br />

Extended application<br />

Silicon nitride (Si 3<br />

N 4<br />

)<br />

Grade<br />

designation<br />

St<strong>and</strong>ard<br />

designation<br />

Application range<br />

Material group<br />

A R F N S H<br />

05 15 25 35 45<br />

01 10 20 30 40 50<br />

CTN3110 K15<br />

Steel<br />

Stainless<br />

Cast iron<br />

Non ferrous<br />

metals<br />

Heat<br />

resistant<br />

Hard<br />

materials<br />

CTM3110 K15<br />

01 10 20 30 40 50<br />

05 15 25 35 45<br />

Main application<br />

Extended application<br />

A21

Introduction<br />

Master<br />

Guide<br />

Page<br />

A16-A17<br />

Grade<br />

overview<br />

S40T<br />

(P40, M40)<br />

Main grades <strong>for</strong><br />

Steel<br />

Composition:<br />

Co 11.0%; composite carbides 12.0%;<br />

WC rest<br />

Grain size: 1 - 2 µm<br />

Hardness: HV 1420<br />

Page<br />

A18-A21<br />

Main grades<br />

<strong>for</strong><br />

Toughness<br />

0 2 4 6 8 10<br />

Page<br />

A22-A39<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

SR127<br />

(P25, M20, K20)<br />

Toughness:<br />

0 2 4 6 8 10<br />

Composition:<br />

Co 6.0%; composite carbides 0.6%;<br />

WC rest<br />

Grain size: 1 - 2 µm<br />

Hardness: HV 1450<br />

Coating specification:<br />

CVD<br />

TiC + Ti (C,N) + TiN + Al 2<br />

O 3;<br />

12 µm<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

SR226<br />

(P25, K20)<br />

Toughness:<br />

0 2 4 6 8 10<br />

Composition:<br />

Co 9.0%; composite carbides 4.0%;<br />

WC rest<br />

Grain size: 1 - 1.5 µm<br />

Hardness: HV 1510<br />

Coating specification:<br />

CVD<br />

AI 2<br />

O 3<br />

+ TiN + Ti(C,N); 5,5 µm<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

For EcoCut applications only<br />

A22

Main grades <strong>for</strong><br />

Steel<br />

Introduction<br />

GM507<br />

(P10, M10, K15)<br />

Toughness:<br />

0 2 4 6 8 10<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

Composition:<br />

Co 5.8%; composite carbides 6.5%;<br />

WC rest;<br />

Grain size: 1 - 2 µm<br />

Hardness: HV 1550<br />

Coating specification:<br />

CVD<br />

Ti (C,N) + Ti (C,N) + Ti (N,B) + Al 2<br />

O 3<br />

+ D.S.<br />

18 µm<br />

Properties/application:<br />

> Excellent heat resistance<br />

For high-per<strong>for</strong>mance <strong>turning</strong><br />

Page A8-A9<br />

Page A10-A15<br />

Page A16-A39<br />

GM517<br />

(P15, M15, K15)<br />

Toughness:<br />

0 2 4 6 8 10<br />

Composition:<br />

Co 5.8%; composite carbides 6.4%;<br />

WC rest<br />

Grain size: 1 - 2 µm<br />

Hardness: HV 1480<br />

Coating specification:<br />

CVD<br />

Ti (C,N) + Ti (C,N) + Ti (N,B) + Al 2<br />

O 3<br />

+ D.S.<br />

18 µm<br />

Page A40-A51<br />

Page A54-A55<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

Page A56-A60<br />

CTC1125<br />

(P25, M20)<br />

Toughness:<br />

0 2 4 6 8 10<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

Composition:<br />

Co 7,0%; composite carbides 8,0%;<br />

WC rest<br />

Grain size: 1 - 2 µm<br />

Hardness: HV 1450<br />

Coating specification:<br />

CVD<br />

Ti (C,N) + Ti (C,N) + Ti (N,B) + Al 2<br />

O 3<br />

+ D.S.<br />

18 µm<br />

Properties/application:<br />

> grade with peripheral zone<br />

A23

Introduction<br />

Main grades <strong>for</strong><br />

Steel<br />

Master<br />

Guide<br />

Page<br />

A16-A17<br />

Grade<br />

overview<br />

Page<br />

A18-A21<br />

Main grades<br />

<strong>for</strong><br />

Page<br />

A22-A39<br />

GM527<br />

(P25, M20)<br />

Toughness:<br />

0 2 4 6 8 10<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

Composition:<br />

Co 6.0%; composite carbides 0.6%;<br />

WC rest<br />

Grain size: 1 - 2 µm<br />

Hardness: HV 1450<br />

Layer system:<br />

CVD<br />

Ti (C,N) + Ti (C,N) + TiN + Ti (N,B) +<br />

Ti (C,N) + TiN; 12 µm<br />

Properties/application:<br />

> Low tendency to stick<br />

A24

Introduction<br />

Page A8-A9<br />

Page A10-A15<br />

Page A16-A39<br />

Page A40-A51<br />

Page A54-A55<br />

Page A56-A60<br />

A25

Introduction<br />

Main grades <strong>for</strong><br />

Steel<br />

Master<br />

Guide<br />

Page<br />

A16-A17<br />

Grade<br />

overview<br />

Page<br />

A18-A21<br />

Grade<br />

description<br />

CTC1135<br />

(P35)<br />

Toughness:<br />

0 2 4 6 8 10<br />

Composition:<br />

Co 9,5%; Mischkarbide 6,5%; WC Rest<br />

Grain size: 1 - 2 µm<br />

Hardness: HV 1400<br />

Coating specification:<br />

CVD<br />

Ti (C,N) + Ti (C,N) + TiN + Ti (N,B) +<br />

Ti (C,N) + TiN; 12 µm<br />

Properties/application:<br />

> grade with peripheral zone<br />

Page<br />

A22-A39<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

GM537<br />

(P35, M25)<br />

Composition:<br />

Co 8.0%; composite carbides 4.2%; WC<br />

rest<br />

Grain size: 1 - 2 µm<br />

Hardness: HV 1330<br />

Toughness:<br />

0 2 4 6 8 10<br />

Coating specification:<br />

CVD<br />

Ti (C,N) + Ti (C,N) + TiN + Ti (N,B) +<br />

Ti (C,N) + TiN; 12 µm<br />

Properties/application:<br />

> Low tendency to stick<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

GM40<br />

(P35, M30)<br />

Composition:<br />

Co 11.0%; composite carbides 12.0%;<br />

WC rest<br />

Grain size: 1 - 2 µm<br />

Hardness: HV 1420<br />

Coating specification:<br />

CVD<br />

TiC + Ti (C,N) + TiN; 5,5 µm<br />

Toughness:<br />

0 2 4 6 8 10<br />

Properties/application:<br />

> Universally applicable grade<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

A26

TCC410<br />

(P10, M10, K05)<br />

Main grades <strong>for</strong><br />

Steel<br />

Composition: cermet<br />

Co/Ni 12.2%; WC 15.0%; TaNbC 10.0%;<br />

TiCN rest<br />

Hardness: HV 1620<br />

Coating specification:<br />

CVD<br />

TiN + Ti(C,N) + Ti(C,N) + Al 2<br />

O 3<br />

+ Ti(C,N,B);<br />

6 µm<br />

Introduction<br />

Page A8-A9<br />

Toughness:<br />

0 2 4 6 8 10<br />

Properties/application:<br />

> Excellent resistance to oxidation<br />

Page A10-A15<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

Page A16-A30<br />

TCM407<br />

(P10, M05, K05)<br />

Composition: cermet<br />

Co/Ni 8.0%; WC 16.0%; TaNbC 10.0%;<br />

TiCN rest<br />

Hardness: HV 1780<br />

Properties/application:<br />

> For very high cutting speeds<br />

> Optimally suitable <strong>for</strong> finishing<br />

Page A40-A51<br />

Page A54-A55<br />

Toughness:<br />

0 2 4 6 8 10<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

Page A56-A60<br />

TCM10<br />

(P15, M10, K10)<br />

Composition: cermet<br />

Co/Ni 12.2%; WC 15.0%; TaNbC 10.0%<br />

TiCN rest<br />

Hardness: HV 1620<br />

Toughness:<br />

0 2 4 6 8 10<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

A27

Introduction<br />

Master<br />

Guide<br />

Page<br />

A16-A17<br />

Grade<br />

overview<br />

S40T<br />

(P40, M40)<br />

Main grades <strong>for</strong><br />

Stainless steel<br />

Composition:<br />

Co 11.0%; composite carbides 12.0%;<br />

WC rest<br />

Grain size: 1 - 2 µm<br />

Hardness: HV 1420<br />

Page<br />

A18-A21<br />

Grade<br />

description<br />

Toughness:<br />

0 2 4 6 8 10<br />

Page<br />

A22-A39<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

CM40<br />

(P40, M35)<br />

Composition:<br />

Co 11.0%; composite carbides 12.0%;<br />

WC rest<br />

Grain size: 1 - 2 µm<br />

Hardness: HV 1420<br />

Toughness:<br />

0 2 4 6 8 10<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

Coating specification:<br />

PVD<br />

TiAlN; 2 - 4 µm<br />

Properties/application:<br />

> Excellent resistance to edge<br />

chipping<br />

For EcoCut application only<br />

CM45<br />

(P45, M40)<br />

Composition:<br />

Co 10,0%; WC rest<br />

Grain size: 0.7 µm (fine grain grade)<br />

Hardness: 1600<br />

Coating specification:<br />

PVD,<br />

TiAlN; 2 - 4 µm<br />

Toughness:<br />

0 2 4 6 8 10<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

For EcoCut application only<br />

A28

CTP2120<br />

(M20)<br />

Main grades <strong>for</strong><br />

Stainless steel<br />

Composition:<br />

Co 10,0%; composite carbides 2,0%;<br />

WC rest<br />

Grain size: 1 µm<br />

Hardness: HV 1560<br />

Introduction<br />

Page A8-A9<br />

Toughness:<br />

0 2 4 6 8 10<br />

Coating specification:<br />

PVD<br />

TiAIN; 2 - 5 µm<br />

Page A10-A15<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

Page A16-A39<br />

CTC2135<br />

(M35)<br />

Composition:<br />

Co 9,5%; composite carbides 6,5%;<br />

WC rest<br />

Grain size: 1 - 2 µm<br />

Hardness: HV 1400<br />

Page A40-A51<br />

Toughness:<br />

0 2 4 6 8 10<br />

Coating specification:<br />

CVD<br />

Ti (C,N) + Ti (C,N) + TiN + Ti (N,B) +<br />

Ti (C,N) + TiN; 6 µm<br />

Page A54-A55<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

Page A56-A60<br />

GM40<br />

(P35, M30)<br />

Composition:<br />

Co 11.0%; composite carbides 12.0%;<br />

WC rest<br />

Grain size: 1 - 2 µm<br />

Hardness: HV 1420<br />

Coating specification:<br />

CVD<br />

TiC + Ti (C,N) + TiN; 5,5 µm<br />

Toughness:<br />

0 2 4 6 8 10<br />

Properties/application:<br />

> Universally applicable grade<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

A29

Introduction<br />

Main grades <strong>for</strong><br />

Stainless steel<br />

Master<br />

Guide<br />

Page<br />

A16-A17<br />

Grade<br />

overview<br />

Page<br />

A18-A21<br />

Grade<br />

description<br />

GM540<br />

(P35, M30)<br />

Toughness:<br />

0 2 4 6 8 10<br />

Composition:<br />

Co 8.0%; composite carbides 4.2%;<br />

WC rest<br />

Grain size: 1 - 2 µm<br />

Hardness: HV 1330<br />

Coating specification:<br />

CVD<br />

Ti (C,N) + Ti (C,N) + TiN + Ti (N,B) +<br />

Ti (C,N) + TiN; 6 µm<br />

Page<br />

A22-A39<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

For difficult to machine stainless steels<br />

A30

H216T/<br />

H10T<br />

(K15)<br />

Main grades <strong>for</strong><br />

Cast iron<br />

Composition:<br />

Co 6.0%; WC rest<br />

Grain size: 1 µm<br />

Hardness: HV 1630<br />

Introduction<br />

Page A8-A9<br />

Toughness:<br />

0 2 4 6 8 10<br />

Page A10-A15<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

Page A16-A39<br />

SR17<br />

(P15, K15)<br />

Composition:<br />

Co 6.0%; WC rest<br />

Grain size: 1 µm<br />

Hardness: HV 1630<br />

Coating specification:<br />

CVD<br />

Ti (C,N) + Ti (C,N) + Al 2<br />

O 3<br />

; 12 µm<br />

Page A40-A51<br />

Page A54-A55<br />

Toughness:<br />

0 2 4 6 8 10<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

Page A56-A60<br />

SR127<br />

(P25, M20, K20)<br />

Toughness:<br />

0 2 4 6 8 10<br />

Composition:<br />

Co 6.0%; composite carbides 0.6%;<br />

WC rest<br />

Grain size: 1 - 2 µm<br />

Hardness: HV 1450<br />

Coating specification:<br />

CVD<br />

Ti (C,N) + Ti (C,N) + TiN + Al 2<br />

O 3<br />

; 12 µm<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

A31

Introduction<br />

Main grades <strong>for</strong><br />

Cast iron<br />

Master<br />

Guide<br />

Page<br />

A16-A17<br />

Grade<br />

overview<br />

Page<br />

A18-A21<br />

Grade<br />

description<br />

SR226<br />

(P25, K20)<br />

Toughness:<br />

0 2 4 6 8 10<br />

Composition:<br />

Co 9.0%; composite carbides 4.0%;<br />

WC rest<br />

Grain size: 1 - 1.5 µm<br />

Hardness: HV 1510<br />

Coating specification:<br />

CVD<br />

AI 2<br />

O 3<br />

+ TiN + Ti(C,N); 5,5 µm<br />

Page<br />

A22-A39<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

For EcoCut applications only<br />

GM507<br />

(P10, M10, K15)<br />

Toughness:<br />

0 2 4 6 8 10<br />

Composition:<br />

Co 5.8%; composite carbides 6.4%;<br />

WC rest; grade with peripheral zone<br />

Grain size: 1 - 2 µm<br />

Hardness: HV 1550<br />

Coating specification:<br />

CVD<br />

Ti (C,N) + Ti (C,N) + Ti (N,B) + Al 2<br />

O 3<br />

+ D.S.<br />

18 µm<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

GM517<br />

(P15, M15, K15)<br />

Toughness:<br />

0 2 4 6 8 10<br />

Composition:<br />

Co 5.8%; composite carbides 6.4%;<br />

WC rest<br />

Grain size: 1 - 2 µm<br />

Hardness: HV 1480<br />

Coating specification:<br />

CVD<br />

Ti (C,N) + Ti (C,N) + Ti (N,B) + Al 2<br />

O 3<br />

+ D.S.<br />

18 µm<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

A32

TCC410<br />

(P10, M10, K05)<br />

Main grades <strong>for</strong><br />

Cast iron<br />

Composition: cermet<br />

Co/Ni 12.2%; WC 15.0%; TaNbC 10.0%<br />

TiCN rest<br />

Hardness: HV1620<br />

Coating specification:<br />

CVD<br />

TiN + Ti(C,N) + Ti(C,N) + Al 2<br />

O 3<br />

+ Ti(C,N,B);<br />

6 µm<br />

Introduction<br />

Page A8-A9<br />

Toughness:<br />

0 2 4 6 8 10<br />

Page A10-A15<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

Page A16-A39<br />

CTN3110<br />

(K10)<br />

Composition:<br />

Si 3<br />

N 4<br />

; > 2 µm<br />

Hardness: HV1550<br />

Properties/application:<br />

> For rough <strong>turning</strong><br />

Page A40-A51<br />

Page A54-A55<br />

Toughness:<br />

0 2 4 6 8 10<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

Page A56-A60<br />

CTM3110<br />

(K10)<br />

Composition:<br />

Si 3<br />

N 4<br />

; > 2 µm<br />

Hardness: HV 1550<br />

Coating specification:<br />

CVD<br />

AI 2<br />

O 3<br />

+ Ti(C,N) + TiN; >2 µm<br />

Toughness:<br />

0 2 4 6 8 10<br />

Properties/application:<br />

> For chromium cast alloys<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

A33

Introduction<br />

Main grades <strong>for</strong><br />

Non ferrous metals <strong>and</strong> non metals<br />

Master<br />

Guide<br />

Page<br />

A16-A17<br />

Grade<br />

overview<br />

Page<br />

A18-A21<br />

Grade<br />

description<br />

H210T<br />

(K10)<br />

Toughness:<br />

0 2 4 6 8 10<br />

Composition:<br />

Co 6.0%; WC rest<br />

Grain size: Fine grain grade 0.8 µm<br />

Hardness: HV 1850<br />

Properties/application:<br />

> Optimally suitable <strong>for</strong> super alloys,<br />

titanium, refractory metals (W, Mo),<br />

aluminium, glass & carbon fibre<br />

rein<strong>for</strong>ced plastics<br />

> Low tendency to stick<br />

Page<br />

A22-A39<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

H216T/<br />

H10T<br />

(K15)<br />

Composition:<br />

Co 6.0%; WC rest<br />

Grain size: 1 µm<br />

Hardness: HV 1630<br />

Properties/application:<br />

> Optimally suitable <strong>for</strong> aluminium<br />

> Low tendency to stick<br />

Toughness:<br />

0 2 4 6 8 10<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

AMZ<br />

(K10)<br />

Composition:<br />

Co 6.0%; WC rest<br />

Grain size: 1 µm<br />

Hardness: HV 1630<br />

Coating specification:<br />

PVD<br />

TiAlN; 2 - 4 µm<br />

Toughness:<br />

0 2 4 6 8 10<br />

Properties/application:<br />

> Optimally suitable <strong>for</strong> aluminium,<br />

cast iron<br />

> Low tendency to stick<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

A34

Main grades <strong>for</strong><br />

Non ferrous metals <strong>and</strong> non metals<br />

Introduction<br />

TSM33<br />

(K20)<br />

Composition:<br />

Co 10,0%; WC rest<br />

Grain size: 0.7 µm (fine grain grade)<br />

Hardness: HV 1550<br />

Page A8-A9<br />

Toughness:<br />

0 2 4 6 8 10<br />

Page A10-A15<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

For EcoCut applications only<br />

Page A16-A39<br />

CTW7120<br />

(K20)<br />

Composition:<br />

Co 10,0%; WC rest<br />

Grain size: 0.7 µm (fine grain grade)<br />

Hardness: HV 1550<br />

Properties/application:<br />

> Ideal <strong>for</strong> non ferrous metals<br />

> Subsstrate <strong>for</strong> PVD coatings<br />

Page A40-A51<br />

Page A54-A55<br />

Toughness:<br />

0 2 4 6 8 10<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

Page A56-A60<br />

A35

Introduction<br />

Master<br />

Guide<br />

Page<br />

A16-A17<br />

Grade<br />

overview<br />

Page<br />

A18-A21<br />

Grade<br />

description<br />

S010<br />

(DP-K01)<br />

Main grades <strong>for</strong><br />

Non ferrous metals <strong>and</strong> non metals<br />

Toughness:<br />

0 2 4 6 8 10<br />

Composition:<br />

Polycrystalline diamond (PCD)<br />

Grain size: ~ 5 µm<br />

Properties:<br />

> Maximum wear resistance <strong>and</strong><br />

hardness<br />

> Low toughness<br />

Page<br />

A22-A39<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

For abrasive non ferrous metals, plastic, graphite<br />

S025<br />

(DP-K05)<br />

Composition:<br />

Polycrystalline diamond (PCD)<br />

Grain size: ~ 25 µm<br />

Properties:<br />

> High wear resistance<br />

> Good toughness<br />

> Suitable <strong>for</strong> interrupted cuts<br />

Toughness:<br />

0 2 4 6 8 10<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

For non ferrous metals, plastic<br />

A36

Main grades <strong>for</strong><br />

Heat resistant alloys / titanium<br />

Introduction<br />

H210T<br />

(K10)<br />

Composition:<br />

Co 6.0%; WC rest<br />

Grain size:<br />

Fine grain grade 0.8 µm<br />

Hardness: HV 1850<br />

Page A8-A9<br />

Toughness:<br />

0 2 4 6 8 10<br />

Properties/application:<br />

> Optimally suitable <strong>for</strong> super alloys,<br />

titanium, refractory metals (W, Mo)<br />

Page A10-A15<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

Page A16-A39<br />

CM40<br />

(P40, M35)<br />

Composition:<br />

Co 11.0%; composite carbides 12.0%;<br />

WC rest<br />

Grain size: 1 - 2 µm<br />

Hardness: HV 1420<br />

Coating specification:<br />

PVD<br />

TiAlN; 2 - 4 µm<br />

Page A40-A51<br />

Page A54-A55<br />

Toughness:<br />

0 2 4 6 8 10<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

Properties/application:<br />

> Excellent resistance to edge<br />

chipping<br />

For EcoCut application only<br />

Page A56-A60<br />

CTP2120<br />

(M20)<br />

Composition:<br />

Co 10,0%; composite carbides 2,0%;<br />

WC rest<br />

Grain size: 1 µm<br />

Hardness: HV 1560<br />

Coating specification:<br />

PVD<br />

TiAIN; 2 - 5 µm<br />

Toughness:<br />

0 2 4 6 8 10<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

A37

Introduction<br />

Main grades <strong>for</strong><br />

Heat resistant alloys / titanium<br />

Master<br />

Guide<br />

Page<br />

A16-A17<br />

Grade<br />

overview<br />

Page<br />

A18-A21<br />

Grade<br />

description<br />

CM45<br />

(P45, M40)<br />

Toughness:<br />

0 2 4 6 8 10<br />

Composition:<br />

Co 10,0%; WC rest<br />

Grain size: 0.7 µm (fine grain grade)<br />

Hardness: HV 1600<br />

Coating specification:<br />

PVD,<br />

TiAlN; 2 - 4 µm<br />

Page<br />

A22-A39<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

For EcoCut application only<br />

CTC2135<br />

(M35)<br />

Composition:<br />

Co 9,5%; composite carbides 6,5%;<br />

WC rest<br />

Grain size: 1 - 2 µm<br />

Hardness: HV 1400<br />

Toughness:<br />

0 2 4 6 8 10<br />

Coating specification:<br />

CVD<br />

Ti (C,N) + Ti (C,N) + TiN + Ti (N,B) +<br />

Ti (C,N) + TiN; 6 µm<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

A38

Main grades <strong>for</strong><br />

Hard materials<br />

Introduction<br />

TA120<br />

(BN-K05)<br />

Composition:<br />

Cubic boron nitride (CBN), 80 % by vol.<br />

+ binder (ceramic)<br />

Grain size: ~ 15 µm<br />

Page A8-A9<br />

Insert <strong>for</strong>m: Solid<br />

Toughness:<br />

0 2 4 6 8 10<br />

Properties/application:<br />

> Very well-suited <strong>for</strong> dry machining<br />

Page A10-A15<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

Particularly suitable <strong>for</strong> chilled castings<br />

Page A16-A39<br />

TA201<br />

(BN-K10)<br />

Composition:<br />

Cubic boron nitride (CBN), 65 % by vol.<br />

+ binder (TiN)<br />

Grain size: ~ 2 µm<br />

Insert <strong>for</strong>m: Brazed segment<br />

Page A40-A51<br />

Toughness:<br />

0 2 4 6 8 10<br />

Properties/application:<br />

> Very well-suited <strong>for</strong> dry machining<br />

> For finishing<br />

Page A54-A55<br />

Wear resistance:<br />

0 2 4 6 8 10<br />

Particularly suitable <strong>for</strong> tempered steels<br />

Page A56-A60<br />

A39

Introduction<br />

The easy way to success<br />

Inserts <strong>for</strong> the Maxilock N system<br />

The easy<br />

way to<br />

success<br />

Page<br />

A40-A43<br />

Chip<br />

grooves<br />

Page<br />

A44-A51<br />

Hard<br />

Heat<br />

resistant<br />

alloys<br />

materials<br />

-CF<br />

Steel<br />

Non ferrous<br />

metals<br />

Chip groove<br />

Stainless<br />

steels<br />

Cast iron<br />

Machining type<br />

Material<br />

Consistent<br />

cutting depth<br />

TCC410<br />

TCM10<br />

TCC410<br />

-<br />

-<br />

Inconsistent<br />

cutting depth<br />

-<br />

-<br />

-<br />

-<br />

-<br />

Interrupted<br />

cutting depth<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-F32<br />

-<br />

CTP2120<br />

CTP2120<br />

CTP2120<br />

CTP2120<br />

-<br />

CTP2120<br />

-<br />

CTP2120<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-TF<br />

(-F40)<br />

GM517<br />

GM527/CTC1125<br />

GM517<br />

-<br />

GM527/CTC1125<br />

GM527/CTC1125<br />

GM537<br />

SR127<br />

-<br />

GM537<br />

GM537<br />

GM537<br />

SR127<br />

-<br />

-<br />

-TFQ<br />

TCC410<br />

TCC410<br />

TCC410<br />

-<br />

-<br />

GM507<br />

GM507<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-TMF<br />

GM517/GM507<br />

GM527<br />

-<br />

-<br />

GM537<br />

GM527<br />

GM537<br />

-<br />

-<br />

-<br />

GM537<br />

GM537<br />

-<br />

-<br />

-<br />

-TMM<br />

GM507<br />

-<br />

-<br />

-<br />

-<br />

GM507<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-M42<br />

-<br />

CTP2120<br />

-<br />

-<br />

-<br />

-<br />

CTP2135<br />

-<br />

-<br />

-<br />

-<br />

CTP2135<br />

-<br />

-<br />

-<br />

-TM<br />

(-M40)<br />

GM517/GM507<br />

GM527/CTC1125<br />

SR127/CTC1125<br />

-<br />

GM540<br />

GM527/CTC1125<br />

GM537/GM40<br />

SR127<br />

-<br />

GM540<br />

GM537/GM40<br />

GM540<br />

-<br />

-<br />

-<br />

-M52<br />

-<br />

CTP2120<br />

CTP2120<br />

-<br />

CTP2120<br />

-<br />

CTP2120<br />

CTP2120<br />

-<br />

-<br />

-<br />

-<br />

CTP2120<br />

-<br />

-<br />

A40

The easy way to success<br />

Inserts <strong>for</strong> the Maxilock N system<br />

Introduction<br />

Hard<br />

Heat<br />

resistant<br />

alloys<br />

materials<br />

Steel<br />

Non ferrous<br />

metals<br />

Stainless<br />

steels<br />

Cast iron<br />

Consistent<br />

cutting depth<br />

Inconsistent<br />

cutting depth<br />

Interrupted<br />

cutting depth<br />

Page A8-A9<br />

Chip groove<br />

-TRM<br />

Machining type<br />

Material<br />

GM527/GM507<br />

GM527<br />

-<br />

-<br />

GM527<br />

GM527<br />

GM537<br />

-<br />

-<br />

GM537<br />

GM537<br />

GM537<br />

-<br />

-<br />

-<br />

Page A10-A15<br />

-TMR<br />

GM517/GM507<br />

GM527<br />

SR17/GM507<br />

-<br />

GM527<br />

GM527<br />

GM540<br />

SR127<br />

-<br />

GM540<br />

GM537/GM40<br />

GM540<br />

-<br />

-<br />

-<br />

Page A16-A30<br />

-TRR<br />

GM527/GM507<br />

GM527<br />

-<br />

-<br />

GM527<br />

GM537<br />

GM537<br />

-<br />

-<br />

GM537<br />

GM537<br />

GM537<br />

-<br />

-<br />

-<br />

Page A40-A51<br />

-TR<br />

GM527/GM507<br />

GM527<br />

SR127/GM507<br />

-<br />

GM537<br />

GM537<br />

GM537<br />

SR127<br />

-<br />

GM540<br />

GM537<br />

GM540<br />

-<br />

-<br />

-<br />

Page A54-A55<br />

Q-RM<br />

Double Edge<br />

GM517<br />

GM517<br />

GM517<br />

-<br />

GM517<br />

GM517/GM527<br />

GM517/GM527<br />

GM517/GM527<br />

-<br />

GM517/GM527<br />

GM527<br />

GM527<br />

GM527<br />

-<br />

GM527<br />

Page A56-A60<br />

A41

Introduction<br />

The easy way to success<br />

Inserts <strong>for</strong> the Maxilock S system<br />

The easy<br />

way to<br />

success<br />

Page<br />

A40-A43<br />

Chip<br />

grooves<br />

Hard<br />

Heat<br />

resistant<br />

alloys<br />

materials<br />

Steel<br />

Non ferrous<br />

metals<br />

Stainless<br />

steels<br />

Cast iron<br />

Consistent<br />

cutting depth<br />

Inconsistent<br />

cutting depth<br />

Interrupted<br />

cutting depth<br />

Page<br />

A44-A51<br />

Chip groove<br />

-FN<br />

Machining type<br />

Material<br />

SM80<br />

SM80<br />

-<br />

SM80<br />

SM80<br />

SM80<br />

-<br />

SM80<br />

SM80<br />

SM80<br />

-<br />

SM80<br />

-F23<br />

-<br />

CTP2120<br />

CTP2120<br />

CTP2120<br />

CTP2120<br />

-<br />

CTP2120<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-SF<br />

TCM407<br />

GM527<br />

TCM410<br />

GM527<br />

TCM10<br />

GM540<br />

SR127<br />

GM540<br />

GM537/GM40<br />

GM540<br />

SR127<br />

-<br />

-SMF<br />

TCC410/GM507<br />

GM527<br />

TCC410/GM507<br />

GM527<br />

GM537<br />

GM537<br />

-<br />

-<br />

GM537<br />

GM537<br />

-<br />

-<br />

-F43<br />

-<br />

CTC2135<br />

-<br />

-<br />

-<br />

-<br />

CTC2135<br />

-<br />

-<br />

-<br />

-<br />

CTC2135<br />

-<br />

-<br />

-<br />

-SM<br />

GM527<br />

GM527<br />

SR127<br />

GM527<br />

GM537/GM40<br />

GM540<br />

SR127<br />

GM540<br />

GM537/GM40<br />

GM540<br />

SR127<br />

-<br />

A42

The easy way to success<br />

Inserts <strong>for</strong> the Maxilock S system<br />

Introduction<br />

Hard<br />

Heat<br />

resistant<br />

alloys<br />

materials<br />

Steel<br />

Non ferrous<br />

metals<br />

Stainless<br />

steels<br />

Cast iron<br />

Consistent<br />

cutting depth<br />

Inconsistent<br />

cutting depth<br />

Interrupted<br />

cutting depth<br />

Page A8-A9<br />

Chip groove<br />

-23P<br />

Machining type<br />

Material<br />

-<br />

-<br />

-<br />

H216T<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

Page A10-A15<br />

-25Q<br />

-<br />

H210T<br />

H210T<br />

H210T<br />

H210T<br />

-<br />

H210T<br />

H210T<br />

H210T<br />

H210T<br />

-<br />

-<br />

-<br />

H210T<br />

-<br />

Page A16-A30<br />

-25P<br />

AMZ<br />

AMZ<br />

AMZ<br />

H210T<br />

AMZ<br />

AMZ<br />

AMZ<br />

AMZ<br />

H210T<br />

AMZ<br />

-<br />

-<br />

-<br />

H210T<br />

-<br />

Page A40-A51<br />

-27<br />

AMZ<br />

AMZ<br />

AMZ<br />

H10T<br />

-<br />

AMZ<br />

AMZ<br />

AMZ<br />

H10T<br />

-<br />

-<br />

-<br />

H10T<br />

H10T<br />

-<br />

Page A54-A55<br />

Page A56-A60<br />

A43

Introduction<br />

The easy<br />

way to<br />

success<br />

Page<br />

A40-A43<br />

Chip<br />

grooves<br />

Chip grooves<br />

-CF / -F32 / -TF / -TFQ<br />

Application range:<br />

CNMG 1204..EN-CF<br />

a p<br />

: 0,05 - 2,0 mm<br />

f: 0,05 - 0,2 mm<br />

> Steel in general<br />

> Stainless steels<br />

> Spheroidal cast iron<br />

Page<br />

A44-A51<br />

For cermets only<br />

Application range:<br />

CNGP 120408FN-F32<br />

ap: 0,10 - 4,00 mm<br />

f: 0,10 - 0,25 mm<br />

> Super alloys<br />

> Titanium<br />

> Spheroidal cast iron<br />

> Non ferrous metals<br />

Application range:<br />

CNMG 1204..EN-TF<br />

a p<br />

: 0,2 - 2,5 mm<br />

f: 0,08 - 0,3 mm<br />

> Steel in general<br />

> Cementation steels<br />

> Stainless steels<br />

> Grey cast iron <strong>and</strong><br />

spheroidal cast iron<br />

Application range:<br />

CNMG 120408EN-TFQ<br />

a p<br />

: 0,5 - 4,0 mm<br />

f: 0,1 - 0,4 mm<br />

> Steel in general<br />

> Stainless steels<br />

> Grey cast iron<br />

CNMG 120412EN-TFQ<br />

a p<br />

: 0,5 - 5,0 mm<br />

f: 0,1 - 0,6 mm<br />

More detailed in<strong>for</strong>mation<br />

about MASTERFINISH<br />

see page E9.<br />

For particularly high<br />

surface quality<br />

A44

Chip grooves<br />

-TMF / -TMM / -M42 / -TM<br />

Introduction<br />

Application range:<br />

CNMG 1204..EN-TMF<br />

a p<br />

: 0,5 - 5,0 mm<br />

f: 0,12 - 0,4 mm<br />

> Cementation steels<br />

> Stainless steels<br />

> Carbon steels<br />

> Steels with low to<br />

medium strength<br />

(up to approx. 700 N/mm 2 )<br />

Page A8-A9<br />

For cementation steels<br />

Page A10-A15<br />

Application range:<br />

Page A16-A30<br />

CNMG 1204..EN-TMM<br />

a p<br />

: 1,0 - 4,0 mm<br />

f: 0,15 - 0,5 mm<br />

> Steel in general<br />

> Low alloyed steels up<br />

to 900 N/mm 2<br />

Page A40-A51<br />

For profile machining<br />

Page A54-A55<br />

Application range:<br />

CNMG 120408EN-M42<br />

ap: 1,0 - 4,0 mm<br />

f: 0,2 - 0,4 mm<br />

> Stainless steels<br />

> Steel in general<br />

Page A56-A60<br />

Steel in general<br />

Application range:<br />

CNMG 120408EN-TM<br />

a p<br />

: 1,0 - 3,5 mm<br />

f: 0,15 - 0,35 mm<br />

CNMG 190616EN-TM<br />

a p<br />

: 2,0 - 8,0 mm<br />

f: 0,25 - 0,6 mm<br />

> Steel in general<br />

> Stainless steels<br />

A45

Introduction<br />

The easy<br />

way to<br />

success<br />

Page<br />

A40-A43<br />

Chip<br />

grooves<br />

Chip grooves<br />

-M52 / -TRM / -TMR<br />

Application range:<br />

DNMG 150408EN-M52<br />

ap: 1,5 - 4,00 mm<br />

f: 0,2 - 0,38 mm<br />

> Stainless steels<br />

> Steel in general<br />

> Super alloys<br />

> Non ferrous metals<br />

Page<br />

A44-A51<br />

Application range:<br />

CNMG 120408EN-TRM<br />

a p<br />

: 0,5 - 3,0 mm<br />

f: 0,2 - 0,4 mm<br />

CNMG 160616EN-TRM<br />

a p<br />

: 1,0 - 6,0 mm<br />

f: 0,25 - 0,8 mm<br />

> Steel in general<br />

> Roller bearing steel<br />

> Stainless steels<br />

For roller bearing steels<br />

Application range:<br />

CNMG 120408EN-TMR<br />

a p<br />

: 1,5 - 5,0 mm<br />

f: 0,3 - 0,5 mm<br />

CNMG 160616EN-TMR<br />

a p<br />

: 2,5 - 10,0 mm<br />

f: 0,4 - 0,8 mm<br />

> Steel in general<br />

> Roller bearing steel<br />

> Stainless steels<br />

> Cast iron<br />

For steel <strong>and</strong> cast iron<br />

A46

Chip grooves<br />

-TRR / -TR / Q-RM<br />

Introduction<br />

Application range:<br />

CNMM 120412SN-TRR<br />

a p<br />

: 1,0 - 6,0 mm<br />

f: 0,3 - 0,6 mm<br />

CNMM 190616SN-TRR<br />

a p<br />

: 3,0 - 12,0 mm<br />

f: 0,4 - 0,8 mm<br />

> Stainless steels<br />

> Roller bearing steel<br />

> Steels of low to<br />

medium strength<br />

300-800 N/mm 2<br />

Page A8-A9<br />

For <strong>for</strong>ged parts<br />

Page A10-A15<br />

Application range:<br />

CNMM 120412EN-TR<br />

a p<br />

: 2,5 - 6,0 mm<br />

f: 0,4 - 0,6 mm<br />

CNMM 190616EN-TR<br />

a p<br />

: 4,0 - 12,0 mm<br />

f: 0,5 - 1,0 mm<br />

> Steel in general<br />

> Spheroidal cast iron<br />

> Stainless steels<br />

Page A16-A30<br />

Page A40-A51<br />

Page A54-A55<br />

Application range:<br />

DE-TNMG 160408Q-RM<br />

a p<br />

: 1,0 - 4,0 mm<br />

f: 0,4 - 0,7 mm<br />

DE-TNMG 220412Q-RM<br />

a p<br />

: 1,0 - 5,0 mm<br />

f: 0,6 - 1,0 mm<br />

DE-TNMG 270616Q-RM<br />

a p<br />

: 1,0 - 6,0 mm<br />

f: 0,8 - 1,4 mm<br />

> Steel in general<br />

> Stainless steels<br />

> Grey cast <strong>and</strong><br />

spheroidal cast iron<br />

Page A56-A60<br />

A47

Introduction<br />

The easy<br />

way to<br />

success<br />

Page<br />

A40-A43<br />

Chip<br />

grooves<br />

Chip grooves<br />

-FN / F23 / -SF / -SMF<br />

Application range:<br />

CCGT 1204..FN<br />

a p<br />

: 0,05 - 2,0 mm<br />

f: 0,03 - 0,2 mm<br />

> Steels with low<br />

strength<br />

> Non ferrous metals<br />

> Super alloys<br />

Page<br />

A44-A51<br />

Sintered HSS<br />

<strong>for</strong> low cutting speeds<br />

Application range:<br />

CCGT 09T3..FN-F23<br />

ap: 0,10 - 2,00 mm<br />

f: 0,06 - 0,13 mm<br />

> Steel in general<br />

> Spheroidal cast iron<br />

> Stainless steels<br />

> Super alloys<br />

Application range:<br />

CCMT 1204..EN-SF<br />

a p<br />

: 0,05 - 2,5 mm<br />

f: 0,05 - 0,25 mm<br />

> Steel in general<br />

> Spheroidal cast iron<br />

> Stainless steels<br />

Application range:<br />

CCMT 1204..EN-SMF<br />

a p<br />

: 0,1 - 2,5 mm<br />

f: 0,08 - 0,3 mm<br />

> Steel in general<br />

> Stainless steels<br />

A48

Chip grooves<br />

F43 / -SM<br />

Introduction<br />

Application range:<br />

VNMG 160404EN-F40<br />

ap: 0,50 - 2,00 mm<br />

f: 0,05 - 0,15 mm<br />

VNMG 160408EN-F40<br />

ap: 0,65 - 2,5 mm<br />

f: 0,10 - 0,25 mm<br />

> Steel in general<br />

> Stainless steels<br />

Page A8-A9<br />

Page A10-A15<br />

Application range:<br />

Page A16-A30<br />

CCMT 060204EN-SM<br />

a p<br />

: 0,05 - 2,0 mm<br />

f: 0,15 - 0,25 mm<br />

CCMT 120412EN-SM<br />

a p<br />

: 1,5 - 5,0 mm<br />

f: 0,15 - 0,45 mm<br />

> Steel in general<br />

> Spheroidal cast iron<br />

> Stainless steels<br />

Page A40-A51<br />

Page A54-A55<br />

Page A56-A60<br />

A49

Introduction<br />

The easy<br />

way to<br />

success<br />

Page<br />

A40-A43<br />

Chip<br />

grooves<br />

Chip grooves<br />

-23P / -25Q / -25P / -27<br />

Application range:<br />

CCGT 09T308FN-23P<br />

a p<br />

: 0,5 - 4,5 mm<br />

f: 0,05 - 0,3 mm<br />

> Soft aluminium<br />

wrought alloys<br />

(Al Mn / Al Mg)<br />

Page<br />

A44-A51<br />

Particularly suitable <strong>for</strong> extrusion<br />

molded work pieces<br />

Application range:<br />

CCGT 120408FN-25Q<br />

a p<br />

: 1,0 - 6,5 mm<br />

f: 0,05 - 0,6 mm<br />

More detailed in<strong>for</strong>mation<br />

about MASTERFINISH<br />

see page E9.<br />

For particularly high surface quality<br />

> Aluminium cast <strong>and</strong><br />

wrought alloys, also<br />

with low Si-content<br />

(G-AlSi2, AlMgSi)<br />

> Fine finishing of<br />

stainless steel <strong>and</strong><br />

super alloys<br />

Application range:<br />

CCGT 120408FN-25P<br />

a p<br />

: 0,5 - 8,0 mm<br />

f: 0,05 - 0,6 mm<br />

Well-suited <strong>for</strong><br />

profile boring<br />

> Aluminium cast <strong>and</strong><br />

wrought alloys, also<br />

with low Si-content<br />

(G-AlSi2, AlMgSi)<br />

> Fine finishing of<br />

stainless steel <strong>and</strong><br />

super alloys<br />

> Carbon <strong>and</strong> glass fibre<br />

rein<strong>for</strong>ced plastic<br />

> Copper alloys<br />

Application range:<br />

CCGT 1204..FN-27<br />

a p<br />

: 1,0 - 10,0 mm<br />

f: 0,1 - 0,75 mm<br />

> Aluminium cast <strong>and</strong><br />

wrought alloys in<br />

general<br />

> Non ferrous metals<br />

> Cast irons<br />

For universal application<br />

A50

Additional chip grooves<br />

Introduction<br />

-11<br />

Application range:<br />

> Profile <strong>turning</strong><br />

> Small feed rates<br />

Page A8-A9<br />

-12<br />

Application range:<br />

> Profile <strong>turning</strong><br />

> Medium feed rates<br />

Page A10-A15<br />

-42<br />

Application range:<br />

> Super alloys<br />

> Titanium<br />

> Aluminium<br />

> Stainless steels<br />

Page A16-A30<br />

Page A40-A51<br />

-57<br />

Application range:<br />

> Steel <strong>and</strong> cast iron<br />

in general<br />

Page A54-A55<br />

-ER/-EL<br />

Application range:<br />

> Steel<br />

> Stainless steels<br />

Page A56-A60<br />

-EN<br />

Application range:<br />

> Steel in general<br />

A51

Our tool solutions have never been so close to you.<br />

• SPEED • INFORMATION • SERVICES • BUSINESS - JUST CLICK<br />

• Topical product catalogue including all CERATIZIT products of the cutting<br />

• tool sector<br />

• Tool configurator, accessories <strong>and</strong> alternative tools<br />

• On-line ordering<br />

• Personal order templates <strong>and</strong> checklists<br />

• On-line availability check<br />

• Direct link to your personal CERATIZIT contact person<br />

• CERATIZIT optimisation tips through our E-TECHADVISER<br />

• On-line checking of all your transactions (invoices, deliveries, payments)<br />

• Shipment tracking (Track&Trace)<br />

PLANSEE E-SOLUTIONS Centre, Tel: +43 (5672) 600-2071<br />

E-mail: esolutions@plansee.com<br />

A52

CERATIZIT Maxidrill<br />

<strong>Tools</strong> <strong>and</strong> <strong>inserts</strong> <strong>for</strong> drilling into solid material<br />

• Flexible drilling from<br />

dia. 14-53 mm<br />

• Drilling depths:<br />

1.5D up to 3xD<br />

• <strong>Tools</strong> with helical chip<br />

pockets<br />

• Insert program <strong>for</strong> all<br />

materials<br />

Program see special catalogue<br />

"<strong>Tools</strong> <strong>and</strong> <strong>inserts</strong> <strong>for</strong> drilling<br />

into solid material"<br />

No. 149<br />

A53

Introduction<br />

Clamping systems<br />

Clamping<br />

systems<br />

Maxilock N<br />

Page A54<br />

Correct<br />

clamping<br />

system<br />

Page A55<br />

This clamping system is suitable <strong>for</strong> all<br />

<strong>inserts</strong> with hole. The actuation screw<br />

can easily be reached from the upper<br />

<strong>and</strong> the lower side of the holder. In the<br />

unlocked position constituent parts<br />

remain intact.<br />

Clamping screw<br />

Insert<br />

Shim<br />

Shim pin<br />

Lever<br />

Maxilock S<br />

The <strong>for</strong>m-lock screw guarantees a safe<br />

connection of the insert <strong>and</strong> the tool<br />

holder. Chip evacuation is not hindered<br />

by obstructive clamping elements. Due to<br />

the neutral insert position the effective<br />

rake angle is identical to that of the insert<br />

<strong>for</strong>m <strong>and</strong> geometry.<br />

Clamping screw<br />

Insert<br />

Shim<br />

Threaded shim screw<br />

Maxilock P<br />

The insert with a clearance angle of 7°<br />

<strong>and</strong> a cylindrical bore is fixed with a<br />

wedge <strong>and</strong> claw lock against a fix pin.<br />

Up to 3 cutting edges can be used<br />

(1 support face).<br />

Clamping element<br />

Insert<br />

Shim<br />

Wedge<br />

Pad pin<br />

Simplex N / P<br />

The tried <strong>and</strong> tested CERATIZIT Simplex<br />

clamping systems are characterised by<br />

their simplicity. The insert is clamped by<br />

means of a claw.<br />

Not suitable <strong>for</strong> drawing cuts.<br />

Clamping screw<br />

<strong>and</strong> clamping claw<br />

Insert<br />

Shim<br />

Shim pin<br />

A54

Choice of the correct clamping system<br />

Introduction<br />

Clamping system<br />

Cutting depth / feed rate<br />

(mm)<br />

a p<br />

f a p<br />

f a p<br />

f<br />

Insert<br />

shape<br />

Insert<br />

- <strong>for</strong>m of top surface<br />

0,3 - 2,0<br />

0,08 - 0,25<br />

2,0 - 6,0<br />

0,2 - 0,6<br />

5,0 - 15,0<br />

0,5 - 1,5<br />

Page A8-A9<br />

Maxilock N<br />

Page A10-A15<br />

Page A16-A30<br />

Maxilock S<br />

Page A40-A51<br />

Page A54-A55<br />

Maxilock P<br />

Page A56-A60<br />

Simplex N<br />

KNUX<br />

KNUX<br />

Simplex P<br />

A55

Branch solutions<br />

Offering component specific system solutions is indispensable.<br />

In this field CERATIZIT provides the following<br />

services <strong>for</strong> selected customer segments:<br />

• Complete tool solutions<br />

• Optimised cutting materials <strong>and</strong> geometries<br />

• Engineering know-how <strong>and</strong> application support direct to end-user<br />

• Training courses <strong>and</strong> seminars<br />

• Extensive support with O.E.M. project capability<br />

• Construction <strong>and</strong> manufacture of special tools<br />

• Coordination of project teams<br />

Aluminium wheel machining<br />

Program<br />

see special brochure<br />

“<strong>Tools</strong> <strong>and</strong> <strong>inserts</strong> <strong>for</strong><br />

aluminium wheel machining“<br />

No. 129/ 1<br />

A56

Branch solutions<br />

Machining of roller bearing rings<br />

Bar peeling<br />

Program<br />

see special catalogue<br />

“<strong>Tools</strong> <strong>and</strong> indexable <strong>inserts</strong> <strong>for</strong> bar<br />

peeling“<br />

No. 174<br />

A57

Branch solutions<br />

Tube machining<br />

Aerospace<br />

A58

Branch solutions<br />

Railway wheel machining<br />

Program<br />

see special catalogue<br />

“Wheel set machining“<br />

No. 152<br />

A59

A60

External machining<br />

CERATIZIT Maxilock<br />

& Simplex<br />

Page<br />

B2-B5<br />

Page<br />

B6-B7<br />

Page<br />

B8-B9<br />

Page<br />

B10-B13<br />

Internal machining<br />

CERATIZIT Maxilock<br />

& Simplex<br />

Page<br />

B14-B15<br />

Page<br />

B16-B17<br />

Page<br />

B18-B19<br />

Drilling, external <strong>and</strong><br />

internal machining<br />

CERATIZIT EcoCut<br />

Page<br />

B20-B21<br />

B1

System<br />

External machining<br />

Longitudinal <strong>turning</strong><br />

PCBNR/L<br />

PSBNR/L<br />

PSDNN<br />

= 25 - 32 mm<br />

Page D2<br />

= 20 - 40 mm<br />

Page D10-D11<br />

= 16 - 40 mm<br />

Page D12<br />

SCACR/L<br />

SCDCL<br />

SCMCN<br />

= 08 - 20 mm<br />

Page D20-D21<br />

= 08 - 14 mm<br />

Page D22<br />

= 16 - 32 mm<br />

Page D26<br />

CSBNR/L<br />

CSDNN<br />

CTANR/L<br />

= 20 - 25 mm<br />

Page D61 = 20 - 32 mm<br />

Page D62 = 20 - 25 mm<br />

Page D64<br />

CSBPR/L CTAPR/L CTGPR/L<br />

= 20 - 25 mm Page D68 = 20 - 25 mm<br />

Page D69 = 10 - 12 mm<br />

Page D71<br />

B2

External machining<br />

Longitudinal <strong>turning</strong><br />

Application<br />

PTGNR/L<br />

PTTNR/L<br />

Page B2-B5<br />

= 16 - 32 mm<br />

Page D16<br />

= 20 - 25 mm<br />

Page D18<br />

Page B6-B7<br />

SCRCR/L<br />

SSBCR/L<br />

SSDCN<br />

Page B8-B9<br />

= 08 - 10 mm<br />

Page D27<br />

= 16 - 25 mm<br />

Page D36<br />

= 12 - 25 mm<br />

Page D37<br />

Page B10-B13<br />

Page B14-B15<br />

CTGNR/L<br />

CTRNR<br />

Page B16-B17<br />

Page B18-B19<br />

= 10 - 12 mm<br />