Download the November/December 2003 Issue in PDF format

Download the November/December 2003 Issue in PDF format

Download the November/December 2003 Issue in PDF format

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

s<strong>in</strong>ce part of <strong>the</strong> distribution falls outside <strong>the</strong><br />

USL. With <strong>the</strong> mean of <strong>the</strong> distribution located<br />

where it is, some percentage of parts will fall outside<br />

<strong>the</strong> USL.<br />

Double-Sided and S<strong>in</strong>gle-Sided Tolerances<br />

Double-sided tolerances or bilateral tolerances<br />

are those which def<strong>in</strong>e a nom<strong>in</strong>al dimension<br />

along with a plus or m<strong>in</strong>us tolerance. Bilateral<br />

tolerances tend to generate distributions that are<br />

normal. Typically a gear size over p<strong>in</strong>s, wires or<br />

balls would be bilateral.<br />

S<strong>in</strong>gle-sided or unilateral tolerances have a<br />

s<strong>in</strong>gle limit tolerance. A zero-based dimension<br />

unilateral tolerance has zero as <strong>the</strong> <strong>in</strong>herent target<br />

value. Typically gear runout, pitch variation, etc.<br />

are unilateral tolerances. Unilateral tolerances by<br />

nature tend to generate distributions that have a<br />

visible amount of skewness or non-normality.<br />

S<strong>in</strong>gle-sided tolerances are calculated us<strong>in</strong>g <strong>the</strong><br />

Cpk or Ppk <strong>in</strong>dices as described above.<br />

Some customers use different methods <strong>in</strong> handl<strong>in</strong>g<br />

<strong>the</strong> data to calculate <strong>the</strong> capability <strong>in</strong>dex for<br />

unilateral tolerances. One example is demonstrated<br />

<strong>in</strong> <strong>the</strong> Delphi specification SD-002 (Ref. 3). A<br />

mirror image trans<strong>format</strong>ion is used to “normalize”<br />

<strong>the</strong> data set. The data is ordered from <strong>the</strong><br />

smallest values to <strong>the</strong> largest values. When <strong>the</strong>re<br />

is an odd number of data po<strong>in</strong>ts, <strong>the</strong> median is <strong>the</strong><br />

middle value of <strong>the</strong> ordered data. When <strong>the</strong>re is<br />

an even number of data po<strong>in</strong>ts, <strong>the</strong> median is <strong>the</strong><br />

average of <strong>the</strong> two middle values of <strong>the</strong> ordered<br />

data set. The trans<strong>format</strong>ion is made by first<br />

remov<strong>in</strong>g all <strong>the</strong> data po<strong>in</strong>ts that fall above <strong>the</strong><br />

median for a m<strong>in</strong>imum specification and below<br />

<strong>the</strong> median for a maximum specification. For<br />

each rema<strong>in</strong><strong>in</strong>g data value, a correspond<strong>in</strong>g value<br />

is created equally distant from <strong>the</strong> median on <strong>the</strong><br />

median’s opposite side. Standard techniques are<br />

<strong>the</strong>n used to calculate a “trial” standard deviation<br />

from <strong>the</strong> mirrored data set.<br />

Us<strong>in</strong>g σ trial , all values that exceed <strong>the</strong> (median<br />

— ^<br />

Reference value<br />

Gage Bias<br />

Figure 15—Gage bias.<br />

Observed average<br />

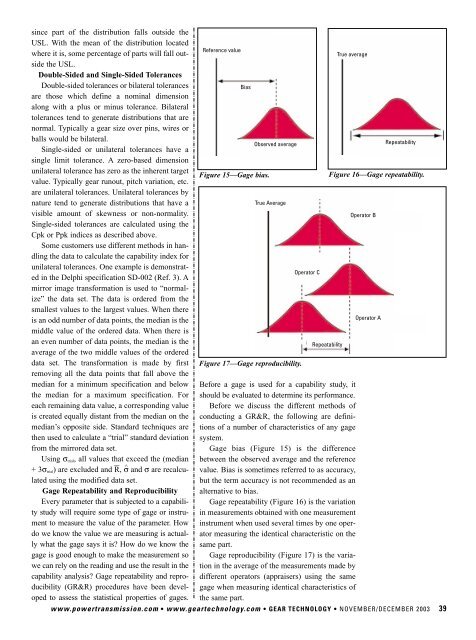

Figure 17—Gage reproducibility.<br />

Before a gage is used for a capability study, it<br />

should be evaluated to determ<strong>in</strong>e its performance.<br />

Before we discuss <strong>the</strong> different methods of<br />

conduct<strong>in</strong>g a GR&R, <strong>the</strong> follow<strong>in</strong>g are def<strong>in</strong>itions<br />

of a number of characteristics of any gage<br />

system.<br />

Gage bias (Figure 15) is <strong>the</strong> difference<br />

between <strong>the</strong> observed average and <strong>the</strong> reference<br />

value. Bias is sometimes referred to as accuracy,<br />

but <strong>the</strong> term accuracy is not recommended as an<br />

alternative to bias.<br />

Gage repeatability (Figure 16) is <strong>the</strong> variation<br />

<strong>in</strong> measurements obta<strong>in</strong>ed with one measurement<br />

<strong>in</strong>strument when used several times by one operator<br />

measur<strong>in</strong>g <strong>the</strong> identical characteristic on <strong>the</strong><br />

same part.<br />

Gage reproducibility (Figure 17) is <strong>the</strong> variation<br />

<strong>in</strong> <strong>the</strong> average of <strong>the</strong> measurements made by<br />

different operators (appraisers) us<strong>in</strong>g <strong>the</strong> same<br />

gage when measur<strong>in</strong>g identical characteristics of<br />

Figure 16—Gage repeatability.<br />

+ 3σ trial ) are excluded and R, σ and σ are recalculated<br />

us<strong>in</strong>g <strong>the</strong> modified data set.<br />

Gage Repeatability and Reproducibility<br />

Every parameter that is subjected to a capability<br />

study will require some type of gage or <strong>in</strong>strument<br />

to measure <strong>the</strong> value of <strong>the</strong> parameter. How<br />

do we know <strong>the</strong> value we are measur<strong>in</strong>g is actually<br />

what <strong>the</strong> gage says it is? How do we know <strong>the</strong><br />

gage is good enough to make <strong>the</strong> measurement so<br />

we can rely on <strong>the</strong> read<strong>in</strong>g and use <strong>the</strong> result <strong>in</strong> <strong>the</strong><br />

capability analysis? Gage repeatability and reproducibility<br />

(GR&R) procedures have been developed<br />

to assess <strong>the</strong> statistical properties of gages. <strong>the</strong> same part.<br />

www.powertransmission.com • www.geartechnology.com • GEAR TECHNOLOGY • NOVEMBER/DECEMBER <strong>2003</strong> 39<br />

Bias<br />

True Average<br />

Gage Repeatability<br />

Operator C<br />

Repeatability<br />

True average<br />

Operator B<br />

Gage Repeatability<br />

Operator A<br />

Repeatability