PDF Download - Glidewell Dental Labs

PDF Download - Glidewell Dental Labs

PDF Download - Glidewell Dental Labs

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

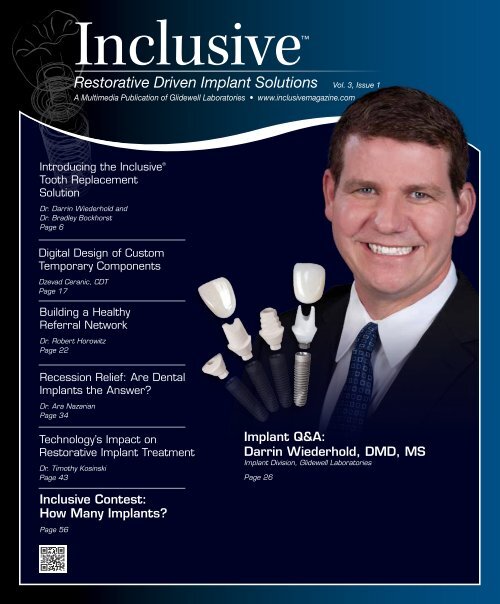

Inclusive<br />

Restorative Driven Implant Solutions Vol. 3, Issue 1<br />

A Multimedia Publication of <strong>Glidewell</strong> Laboratories • www.inclusivemagazine.com<br />

Introducing the Inclusive ®<br />

Tooth Replacement<br />

Solution<br />

Dr. Darrin Wiederhold and<br />

Dr. Bradley Bockhorst<br />

Page 6<br />

Digital Design of Custom<br />

Temporary Components<br />

Dzevad Ceranic, CDT<br />

Page 17<br />

Building a Healthy<br />

Referral Network<br />

Dr. Robert Horowitz<br />

Page 22<br />

Recession Relief: Are <strong>Dental</strong><br />

Implants the Answer?<br />

Dr. Ara Nazarian<br />

Page 34<br />

Technology’s Impact on<br />

Restorative Implant Treatment<br />

Dr. Timothy Kosinski<br />

Page 43<br />

Implant Q&A:<br />

Darrin Wiederhold, DMD, MS<br />

Implant Division, <strong>Glidewell</strong> Laboratories<br />

Page 26<br />

Inclusive Contest:<br />

How Many Implants?<br />

Page 56

On the Web<br />

Here’s a sneak peek at additional<br />

Inclusive magazine content available online<br />

ONLINE Video Presentations<br />

• Dr. Darrin Wiederhold introduces the Inclusive ® Tooth Replacement<br />

Solution, a comprehensive package for predictably placing<br />

and restoring dental implants.<br />

• The <strong>Glidewell</strong> Laboratories Implant Department staff outlines<br />

the lab’s process of designing and milling custom temporary<br />

components.<br />

• Dr. Wiederhold discusses his experience with the Inclusive Tooth<br />

Replacement Solution and shares his vision for upcoming educational<br />

courses at the <strong>Glidewell</strong> International Technology Center.<br />

• Dr. Timothy Kosinski explores the role of new technologies in<br />

simplifying and improving implant treatment services.<br />

• Dr. Bradley Bockhorst discusses specific guidelines when working<br />

with the Inclusive Tooth Replacement Solution, including<br />

proper implant orientation and seating of custom components.<br />

Check out the latest issue of Inclusive<br />

magazine online or via your smartphone at<br />

www.inclusivemagazine.com<br />

gIDE LECTURE-ON-DEMAND PREVIEW<br />

• Dr. Stefan Paul discusses a vital component for long-term implant<br />

success in this gIDE video lecture, “Restorative Excellence —<br />

Occlusion on Implant-Retained Restorations.”<br />

ONLINE CE credit<br />

• Get free CE credit for the material in this issue with each test you<br />

complete and pass. To get started, visit our website and look for<br />

the articles marked with “CE.”<br />

Look for these icons on the pages that follow<br />

for additional content available online

Contents<br />

ALSO IN THIS ISSUE<br />

14 Clinical Tip: Implant Orientation for<br />

Inclusive Tooth Replacement Solution<br />

Components<br />

17 Lab Sense: Virtual Design of<br />

Inclusive Custom Temporary<br />

Components<br />

40 Clinical Tip: Placing Custom<br />

Healing Abutments<br />

52 Restorative Driven Implant<br />

Treatment: From Immediate<br />

Temporization to Final Restoration<br />

56 Inclusive Contest:<br />

How Many Implants?<br />

6<br />

22<br />

26<br />

34<br />

43<br />

Benefits of the Inclusive ® Tooth Replacement Solution<br />

Complex treatment modalities can make it difficult to treat implant<br />

patients efficiently while still maintaining quality of care. With<br />

their in-depth look at the Inclusive ® Tooth Replacement Solution,<br />

Drs. Darrin Wiederhold and Bradley Bockhorst address this<br />

challenge by utilizing predesigned custom temporary components<br />

to provide patient-specific temporization and contoured healing.<br />

Building a Restorative Driven Referral Network<br />

A thriving surgical practice is largely dependent on the success of<br />

the restorative dentists, laboratory technicians and other co-treating<br />

professionals who help carry an implant case to completion. Experienced<br />

periodontist Dr. Robert Horowitz identifies some of the most<br />

common areas of miscommunication in the treatment progression<br />

and looks at how implant specialists might help to maximize<br />

patient satisfaction and profitability for their referring doctors.<br />

Implant Q&A: An Interview with Dr. Darrin Wiederhold<br />

For some clinicians, venturing into the realm of dental implants is<br />

a daunting prospect. In his first published interview as a member<br />

of the <strong>Glidewell</strong> Laboratories clinical team, accomplished dentist<br />

Dr. Darrin Wiederhold outlines some of the practical steps a clinician<br />

can take to gain the knowledge, confidence and experience required<br />

to successfully join the ranks of implant professionals.<br />

Incorporating Implants into Your Daily Practice<br />

A dentist feeling the pinch in a difficult economy is apt to seek<br />

more efficient ways to provide services, or to take on new services<br />

typically referred to another provider. Dr. Ara Nazarian addresses<br />

the difficulties of traditional implant treatment and explains how a<br />

restorative-driven approach simplifies the process, making it more<br />

convenient and affordable for both the dentist and the patient.<br />

Implant Solutions Utilizing the Latest Technology<br />

Dentists today stand to benefit from technological innovations that<br />

make procedures more predictable and less invasive. Dr. Timothy<br />

Kosinski showcases the use of digital treatment planning to promote<br />

safe and simple guided implant delivery, followed by the placement<br />

of prefabricated custom temporary components that allow<br />

for unprecedented versatility at the time of surgery.<br />

– Contents – 1

Letter from the Editor<br />

Clinicians are faced with many challenges when restoring dental implants. One of these is<br />

sculpting the soft tissue into the optimal contours, and then transferring those contours to<br />

the master cast to allow for fabrication of the final restoration. In the past, various attempts<br />

to achieve this goal ranged from modifying healing abutments to adding composite to stock<br />

impression copings. These procedures were often cumbersome and did not offer a simple,<br />

complete solution. With advances in virtual design and CAD/CAM technologies, an array of<br />

prosthetic components can now be custom made — pre- or post-surgically — to address<br />

these issues.<br />

<strong>Glidewell</strong> Laboratories receives more than 200 implant cases a day, and we routinely see<br />

impressions where a narrow impression coping was utilized. The challenge in these cases<br />

is to create a restoration that has a natural emergence profile. This problem, coupled with<br />

our experience designing and milling custom abutments, led to the development of the<br />

Inclusive ® Tooth Replacement Solution.<br />

At the core of the Inclusive Tooth Replacement Solution is an anatomically shaped transgingival<br />

section that is virtually designed over the proposed implant site. This base design<br />

is then used to create a custom healing abutment or a custom temporary abutment and a<br />

provisional crown. A matching custom impression coping allows for the soft tissue contours<br />

to be transferred to the master cast, resulting in a superior final restoration.<br />

The solution offers flexibility in that the case can be immediately temporized, if appropriate,<br />

or the alternate custom healing abutment can be delivered. The components can easily be<br />

adjusted or modified as needed.<br />

The goal of the Inclusive Tooth Replacement Solution is to provide the clinician with a<br />

complete, restorative-driven solution for a missing tooth, from treatment planning to final<br />

prosthesis, with all of the necessary components and tools, including the implant. This issue<br />

of Inclusive magazine was conceived to introduce you to our laboratory’s new conventionaldiameter<br />

implant system and tooth replacement solution. Eager for your feedback, we<br />

invite you to read the articles and check out the multimedia content available online at<br />

www.inclusivemagazine.com.<br />

Dr. Bradley C. Bockhorst<br />

Editor-in-Chief, Clinical Editor<br />

inclusivemagazine@glidewelldental.com<br />

– Letter from the Editor – 3

Publisher<br />

Jim <strong>Glidewell</strong>, CDT<br />

Editor-in-Chief and clinical editor<br />

Bradley C. Bockhorst, DMD<br />

Managing Editors<br />

Jim Shuck; Mike Cash, CDT<br />

Creative Director<br />

Rachel Pacillas<br />

Contributing editors<br />

Greg Minzenmayer; Dzevad Ceranic, CDT;<br />

David Casper; Tim Torbenson<br />

copy editors<br />

Eldon Thompson, Barbara Young,<br />

Megan Affleck, David Frickman, Jennifer Holstein<br />

digital marketing manager<br />

Kevin Keithley<br />

Graphic Designers/Web Designers<br />

Jamie Austin, Deb Evans, Joel Guerra,<br />

Audrey Kame, Lindsey Lauria, Phil Nguyen,<br />

Kelley Pelton, Melanie Solis, Ty Tran, Makara You<br />

Photographers/Clinical Videographers<br />

Sharon Dowd, Mariela Lopez<br />

James Kwasniewski, Marc Repaire, Sterling Wright<br />

Illustrator<br />

Phil Nguyen<br />

coordinatorS/AD Representatives<br />

Teri Arthur, Vivian Tsang<br />

If you have questions, comments or suggestions, e-mail us at<br />

inclusivemagazine@glidewelldental.com. Your comments may<br />

be featured in an upcoming issue or on our website.<br />

© 2012 <strong>Glidewell</strong> Laboratories<br />

Neither Inclusive magazine nor any employees involved in its publication<br />

(“publisher”) makes any warranty, express or implied, or assumes<br />

any liability or responsibility for the accuracy, completeness, or usefulness<br />

of any information, apparatus, product, or process disclosed, or<br />

represents that its use would not infringe proprietary rights. Reference<br />

herein to any specific commercial products, process, or services by<br />

trade name, trademark, manufacturer or otherwise does not necessarily<br />

constitute or imply its endorsement, recommendation, or favoring<br />

by the publisher. The views and opinions of authors expressed<br />

herein do not necessarily state or reflect those of the publisher and<br />

shall not be used for advertising or product endorsement purposes.<br />

CAUTION: When viewing the techniques, procedures, theories and<br />

materials that are presented, you must make your own decisions<br />

about specific treatment for patients and exercise personal professional<br />

judgment regarding the need for further clinical testing or education<br />

and your own clinical expertise before trying to implement new<br />

procedures.<br />

Inclusive is a registered trademark of Inclusive <strong>Dental</strong> Solutions.<br />

Contributors<br />

■ Bradley C. Bockhorst, DMD<br />

After receiving his dental degree from Washington<br />

University School of <strong>Dental</strong> Medicine,<br />

Dr. Bradley Bockhorst served as a Navy <strong>Dental</strong><br />

Officer. Dr. Bockhorst is director of clinical<br />

technologies at <strong>Glidewell</strong> Laboratories, where he<br />

oversees Inclusive ® Digital Implant Treatment<br />

Planning services and is editor-in-chief and<br />

clinical editor of Inclusive magazine. A member of the CDA,<br />

ADA, AO, ICOI and the AAID, Dr. Bockhorst lectures internationally<br />

on an array of dental implant topics. Contact him at<br />

800-521-0576 or inclusivemagazine@glidewelldental.com.<br />

■ DZEVAD CERANIC, CDT<br />

Dzevad Ceranic began his career at <strong>Glidewell</strong><br />

Laboratories while attending Pasadena<br />

City College’s dental laboratory technology<br />

program. In 1999, Dzevad began working<br />

at <strong>Glidewell</strong> as a waxer and metal finisher,<br />

then as a ceramist. After being promoted to<br />

general manager of the Full-Cast department,<br />

he assisted in facilitating the lab’s transition to CAD/CAM.<br />

In June 2008, Dzevad took on the company’s rapidly growing<br />

Implant department, and in 2009 completed an eight-month<br />

implants course at UCLA School of Dentistry. Today, Dzevad<br />

leads a team of 220 people at the lab and continues to implement<br />

cutting-edge technology throughout his department. Contact him<br />

at inclusivemagazine@glidewelldental.com.<br />

■ ROBERT A. HOROWITZ, DDS<br />

Dr. Robert Horowitz graduated from Columbia<br />

University School of <strong>Dental</strong> and Oral Surgery<br />

in 1982. After a one-year general practice<br />

residency, he finished a two-year specialty<br />

training program in periodontics at New York<br />

University and the Manhattan VA Hospital.<br />

In 1996, Dr. Horowitz completed a two-year<br />

fellowship program in Implant Surgery at NYU, focusing on<br />

bone grafting procedures. He is a clinical assistant professor<br />

in the department of periodontology and implant dentistry at<br />

NYU College of Dentistry, where he teaches and conducts<br />

research in bone grafting. He is also on faculty and conducts<br />

research in the departments of oral surgery, biomaterials<br />

and biomimetics, and oral diagnosis. Dr. Horowitz has<br />

lectured nationally and internationally and published more<br />

than 40 scientific articles and case studies. Contact him at<br />

inclusivemagazine@glidewelldental.com.<br />

4<br />

– www.inclusivemagazine.com –

■ TIMOTHY F. KOSINSKI, DDS, MAGD<br />

Dr. Timothy Kosinski graduated from the<br />

University of Detroit Mercy School of Dentistry<br />

and received a Master of Science degree in<br />

biochemistry from Wayne State University School<br />

of Medicine. An adjunct assistant professor at<br />

UDM School of Dentistry, he serves on the editorial<br />

review board of numerous dental journals and is<br />

a Diplomate of the ABOI/ID, ICOI and AO. Dr. Kosinski is a Fellow<br />

of the AAID and received his Mastership in the AGD, from which<br />

he received the 2009 Lifelong Learning and Service Recognition<br />

award. Contact him at 248-646-8651, drkosin@aol.com or www.<br />

smilecreator.net.<br />

■ Darrin M. Wiederhold, DMD, MS<br />

Dr. Darrin Wiederhold received his DMD in<br />

1997 from Temple University School of Dentistry<br />

and a master’s degree in oral biology in 2006<br />

from the Medical University of Ohio at Toledo.<br />

Before joining <strong>Glidewell</strong> in August 2011, he<br />

worked in several private practices and as a<br />

staff dentist for the U.S. Navy. As staff dentist<br />

in <strong>Glidewell</strong>’s Implant division, he performs implant and<br />

conventional restorative procedures at the lab’s on-site training<br />

facility, and helps support the lab’s digital treatment planning<br />

and guided surgery services. An integral part of the lab’s Implant<br />

Research & Development group, he is also involved in training<br />

and education on implant surgery and prosthetics. Contact him<br />

at inclusivemagazine@glidewelldental.com.<br />

■ ARA NAZARIAN, DDS, DICOI<br />

Dr. Ara Nazarian maintains a private practice in<br />

Troy, Mich., with an emphasis on comprehensive<br />

and restorative care. He is the director of the<br />

Reconstructive Dentistry Institute, a Diplomate<br />

of the ICOI, and has conducted lectures and<br />

hands-on workshops on esthetic materials and<br />

dental implants throughout the U.S., Europe,<br />

New Zealand and Australia. Dr. Nazarian is also the creator of<br />

the DemoDent patient education model system. His articles have<br />

been published in many of today’s popular dental publications.<br />

Contact him at 248-457-0500 or www.aranazariandds.com.<br />

■ PAresh B. Patel, DDS<br />

Dr. Patel is a graduate of the University of North<br />

Carolina at Chapel Hill School of Dentistry<br />

and the Medical College of Georgia/AAID<br />

MaxiCourse. He is cofounder of the American<br />

Academy of Small Diameter Implants and<br />

a clinical instructor at the Reconstructive<br />

Dentistry Institute. Dr. Patel has placed more<br />

than 2,500 small-diameter implants and has worked as a lecturer<br />

and clinical consultant on mini implants for various companies.<br />

He belongs to numerous dental organizations, including the<br />

ADA, North Carolina <strong>Dental</strong> Society and AACD. Dr. Patel is also<br />

a member and president of the Iredell County <strong>Dental</strong> Society in<br />

Mooresville, N.C. Contact him at pareshpateldds2@gmail.com or<br />

www.dentalminiimplant.com.<br />

– Contributors – 5

Clinical Benefits of the<br />

Inclusive ® Tooth Replacement Solution<br />

Go online for<br />

in-depth content<br />

by Darrin W. Wiederhold, DMD, MS and Bradley C. Bockhorst, DMD<br />

We live in a society of 60-second fast-food drive-thrus, global news<br />

delivered instantly on our smartphones and bundled cable packages.<br />

We demand ever-faster results and increasingly streamlined efficiency. Even dentists are<br />

powerless against the current of progress and the need to accomplish more in less time.<br />

A hallmark of the most successful modern clinicians is the ability to strike a balance<br />

between a daily load of 12 to 16 patients and maintaining the same high standard of<br />

care. No easy task, to be sure — particularly when it comes to treatment involving<br />

dental implants.<br />

Current protocols for implant patients are compartmentalized. The implant manufacturer<br />

is responsible for the components, and the dental laboratory is responsible for<br />

the restoration — after the clinical situation has been determined. From the restorative<br />

perspective, this is equivalent to erecting a house upon an existing foundation, limiting<br />

the builder to what is already there. Developing proper esthetics in an implant case<br />

involves soft tissue contouring that begins at a foundational level, the moment the<br />

implant is placed. Stock components do not allow for this, which means the doctor must<br />

spend valuable chairtime developing custom components or forgo their use altogether,<br />

forcing a choice between quantity of cases or quality of individual patient care.<br />

With the advent of the Inclusive ® Tooth Replacement Solution from <strong>Glidewell</strong> Laboratories,<br />

practitioners no longer have to choose one or the other. Specially designed custom<br />

temporary components allow for immediate provisionalization specific to the needs of<br />

each patient, and a matching custom impression coping communicates the final gingival<br />

architecture to the dental laboratory. Add to this the implant, surgical drills, a prosthetic<br />

guide, final custom abutment and final BruxZir ® Solid Zirconia restoration (<strong>Glidewell</strong><br />

Laboratories), and the clinician receives, in a single box, all the components needed to<br />

place, provisionalize and restore the implant up front. In addition to providing the physical<br />

components (Figs. 1a, 1b), the Inclusive Tooth Replacement Solution supports an easyto-follow<br />

workflow that helps ensure predictability and long-term success, streamlining<br />

the entire process for maximum efficiency. Armed with a clear sense of the endgame and<br />

the tools and road map to get there, experienced and novice clinicians alike can place and<br />

restore dental implants with greater confidence and ease.<br />

6<br />

– www.inclusivemagazine.com –

Inclusive Tooth Replacement Solution<br />

Conventional Procedure – Single Tooth<br />

Step-by-Step<br />

Clinician<br />

<strong>Glidewell</strong> Laboratories<br />

Appointment<br />

1<br />

Consultation Data Collection<br />

• Complete Inclusive Tooth Replacement Solution Rx<br />

indicating desired implant size, drill preference, tooth #,<br />

required shade for BioTemps provisional crown and any<br />

special design instructions.<br />

• Take PVS impressions.<br />

• Take bite registration.<br />

• Take photos.<br />

• Send Rx to <strong>Glidewell</strong> with impressions, bite registration<br />

and photos.<br />

Design and fabricate Inclusive Tooth<br />

Replacement Solution components<br />

(7 days in lab):<br />

• Prosthetic guide<br />

• Custom healing abutment<br />

• Custom impression coping<br />

• Custom temporary abutment and<br />

BioTemps crown<br />

• Inclusive implant<br />

• Disposable surgical drills<br />

Appointment<br />

2<br />

Surgery<br />

• Try in prosthetic guide.<br />

• Place implant.<br />

• Deliver custom healing abutment or custom temporary<br />

abutment and BioTemps provisional crown.<br />

• Set post-op recall schedule.<br />

• Keep custom impression coping in patient’s chart or<br />

forward to restorative dentist.<br />

Appointment<br />

3<br />

Final Impressions<br />

• Remove custom temporary components and seat custom<br />

impression coping. Tighten coping screw. Take a PA film to<br />

verify seating, if necessary.<br />

• Take a full-arch impression, opposing impression and bite<br />

registration, as well as a shade.<br />

• Replace the impression coping with the temporary<br />

restoration or healing abutment.<br />

• Complete Inclusive Tooth Replacement Solution Rx,<br />

indicating choice of Inclusive Custom Abutment (titanium<br />

or zirconia) and final shade.<br />

• Send Rx to <strong>Glidewell</strong> with the impressions and bite<br />

registration.<br />

Design and mill final restorative<br />

components (13 days in lab):<br />

• Inclusive Custom Abutment<br />

(titanium or zirconia)<br />

• BruxZir Solid Zirconia or IPS e.max<br />

crown<br />

Appointment Final<br />

4<br />

Delivery<br />

• Remove custom temporary components for the implant<br />

and irrigate thoroughly.<br />

• Seat final abutment and tighten abutment screw to<br />

35 Ncm. Take a PA to verify seating, if necessary.<br />

• Try in crown. Adjust interproximal and occlusal contacts<br />

as needed.<br />

• Cement crown. Ensure all excess cement is removed.<br />

• Set recall schedule.<br />

– Clinical Benefits of the Inclusive Tooth Replacement Solution – 7

Inclusive Tooth Replacement<br />

Solution Implant Treatment<br />

Workflow<br />

1. Implant Consultation and<br />

Data Collection<br />

2. Day of Surgery Protocol<br />

3. Healing Phase<br />

4. Restorative Phase:<br />

Final Impressions<br />

5. Delivery of Final Prosthesis<br />

Implant Consultation<br />

and Data Collection<br />

As with any larger, more complex<br />

dental case, the taking of preoperative<br />

records and thorough treatment<br />

planning are of paramount importance<br />

when implants are prescribed —<br />

whether it be a single-tooth replacement<br />

or full-mouth rehabilitation. A<br />

truly comprehensive treatment plan<br />

consists of the following:<br />

1. Full-arch upper and lower impressions<br />

(preferably PVS) for the<br />

fabrication of study models<br />

2. An accurate bite registration<br />

3. Full-mouth radiographs, including<br />

a panoramic and CBCT scan (as<br />

needed)<br />

NOTE: If you do not have a CBCT scanner<br />

in your office, the patient can be referred<br />

to an imaging center.<br />

4. Shade match of the existing dentition<br />

5. Preoperative patient photos<br />

While obtaining the aforementioned<br />

records will minimize risk and optimize<br />

the chances of success, the issue<br />

of cost can be a limiting factor, particularly<br />

when dealing with a CBCT scan.<br />

If necessary, explain to the patient the<br />

rationale for the expense of the CBCT<br />

scan by detailing the advantages of<br />

this technology over conventional radiography.<br />

In instances where the cost<br />

is prohibitive, single-tooth implant<br />

cases can still be undertaken with<br />

a high degree of predictability using<br />

conventional radiography alone. Success<br />

in such cases is largely dependent<br />

on the experience level of the clinician,<br />

so an honest assessment of your own<br />

comfort level and abilities will be invaluable<br />

in avoiding potential pitfalls.<br />

Once you have collected the various<br />

data mentioned above and selected<br />

a diameter and length of implant,<br />

forward the appropriate diagnostic<br />

materials (i.e., impressions, models,<br />

bite registration, shade selection and<br />

implant size) to <strong>Glidewell</strong> Laboratories<br />

for fabrication of the Inclusive Tooth<br />

Replacement Solution components.<br />

Upon receipt, the laboratory will pour<br />

and articulate the models, then assemble<br />

the following components:<br />

1. Prosthetic guide (Fig. 1a)<br />

2.Custom temporary abutment<br />

(Fig. 1a)<br />

3.BioTemps ® provisional crown<br />

(<strong>Glidewell</strong> Laboratories) (Fig. 1a)<br />

4. Custom healing abutment<br />

(Fig. 1a)<br />

5. Custom impression coping<br />

(Fig. 1a)<br />

6. Surgical drills (Fig. 1b)<br />

7. Inclusive ® Tapered Implant<br />

(<strong>Glidewell</strong> Laboratories) (Fig. 1b)<br />

The complete set of necessary items<br />

will be delivered to you in one convenient,<br />

all-inclusive box (Fig. 2).<br />

<br />

Figure 1a: Prosthetic guide, custom temporary abutment,<br />

BioTemps provisional crown, custom healing<br />

abutment, custom impression coping<br />

Figure 1b: Inclusive Tapered Implant and disposable<br />

surgical drills<br />

Figure 2: Inclusive Tooth Replacement Solution<br />

Developing proper esthetics in an implant<br />

case involves soft tissue contouring<br />

that begins at a foundational level,<br />

the moment the implant is placed.<br />

<br />

8<br />

– www.inclusivemagazine.com –

Day of Surgery Protocol<br />

On the day of the implant surgery,<br />

remove the contents of the box and<br />

place them alongside your usual surgical<br />

armamentarium. Confirm the fit<br />

of the prosthetic guide prior to beginning<br />

the procedure (Fig. 3). Make<br />

sure the guide fits snugly around the<br />

teeth, and that there is no rocking or<br />

displacement. Be sure also to visually<br />

confirm that the proposed location of<br />

the implant osteotomy correlates with<br />

your planned location.<br />

Once the implant has been placed<br />

(Figs. 4–11), the decision is made —<br />

based on the level of primary stability<br />

— to place either the custom healing<br />

abutment or the custom temporary<br />

abutment and accompanying Bio-<br />

Temps crown. Either option affords<br />

the opportunity to begin sculpting<br />

the soft tissue architecture around the<br />

implant and developing the future<br />

emergence profile.<br />

To ensure the optimal soft tissue<br />

response and facilitate complete seating<br />

of either the custom healing abutment<br />

or custom temporary abutment and<br />

BioTemps crown, it is recommended<br />

that a tissue punch, or other surgical<br />

means, be utilized to remove the<br />

soft tissue over the osteotomy site.<br />

Note also that the margin of the<br />

custom temporary abutment is set<br />

at approximately 2 mm. Depending<br />

on the thickness of the patient’s soft<br />

tissue, the abutment can be adjusted<br />

and the BioTemps crown relined as<br />

needed. It is critical that the custom<br />

healing abutment or BioTemps crown<br />

be 1–1.5 mm out of occlusion to avoid<br />

any occlusal stresses on the implant as<br />

it osseointegrates (Figs. 12–14).<br />

Once the appropriate custom abutment<br />

has been placed, the implant is<br />

allowed to osseointegrate as normal.<br />

The custom impression coping should<br />

be stored with the patient’s chart to<br />

be used when the implant is ready<br />

to be restored.<br />

Figure 3: Prosthetic guide try-in<br />

Figure 4: 2.3/2.0 mm pilot drill through prosthetic<br />

guide<br />

Figure 6: 2.3/2.0 mm pilot drill to depth<br />

Figure 8: Implant on carrier<br />

Figure 5: Periapical radiograph to verify position<br />

Figure 7: Completed osteotomy following use of the<br />

2.8/2.3 mm surgical drill<br />

Figure 9: Final seating of implant with torque wrench<br />

– Clinical Benefits of the Inclusive Tooth Replacement Solution – 9

Healing Phase<br />

As with any implant treatment protocol,<br />

it is generally advisable that the<br />

patient return for monthly follow-up<br />

appointments to ensure osseointegration<br />

is proceeding well and to adjust<br />

the provisional restoration as needed.<br />

Figure 10: Flat oriented toward the facial<br />

Figure 12: Custom temporary abutment seated<br />

Figure 14: BioTemps crown temporarily cemented<br />

Figure 11: Periapical radiograph to verify implant<br />

position<br />

Figure 13: Abutment screw tightened to 15 Ncm,<br />

with access opening sealed and flap sutured back<br />

into place<br />

Figure 15: Custom impression coping and screw<br />

access opening sealed with soft wax<br />

Restorative Phase:<br />

Final Impressions<br />

When an adequate amount of time has<br />

elapsed and successful osseointegration<br />

of the implant has been confirmed,<br />

the restorative phase begins. Fortunately,<br />

because the contours of the custom<br />

impression coping match those of the<br />

custom healing abutment or custom<br />

temporary abutment, it is simple to<br />

remove the custom abutment, seat the<br />

custom impression coping (Fig. 15)<br />

and take an accurate final impression<br />

(Fig. 16). Either a closed-tray or opentray<br />

technique may be used, but it<br />

should be a full-arch impression. A<br />

full-arch opposing impression and<br />

bite registration are also required.<br />

You then complete a simple prescription<br />

form included with the original<br />

solution components, selecting<br />

your choice of final custom abutment<br />

(titanium or zirconia) and indicating<br />

the final shade for your BruxZir<br />

or IPS e.max ® (Ivoclar Vivadent; Amherst,<br />

N.Y.) restoration. There are no<br />

additional laboratory fees at this point<br />

because the cost of these final restorative<br />

components is included in the<br />

price of the solution. Simply forward<br />

the final impressions and bite registration<br />

along with the completed prescription<br />

to <strong>Glidewell</strong> Laboratories for<br />

fabrication of the definitive restoration.<br />

Figure 16: Final impression<br />

10<br />

– www.inclusivemagazine.com –

Delivery of Final Prosthesis<br />

The final step in the process is delivery<br />

of the final prosthesis (Figs. 17–23). On<br />

the day of delivery, the custom temporary<br />

abutment is once again removed<br />

and all debris cleaned from inside and<br />

around the implant. The final Inclusive<br />

® Custom Abutment (<strong>Glidewell</strong> Laboratories)<br />

and BruxZir crown are tried in,<br />

and the contours, contacts and occlusion<br />

checked and adjusted as needed.<br />

Final occlusion should be light on the<br />

implant-retained crown, with forces<br />

directed as much as possible along the<br />

long axis, minimizing lateral forces.<br />

The abutment screw is tightened to<br />

35 Ncm, the head of the abutment screw<br />

is covered and the crown cemented. It<br />

is imperative to meticulously remove<br />

all excess cement. Home care instructions<br />

are given to the patient, and a<br />

recall schedule is set.<br />

<br />

Because the<br />

contours of the<br />

custom impression<br />

coping match those<br />

of the custom healing<br />

abutment or custom<br />

temporary abutment,<br />

it is simple to<br />

remove the custom<br />

abutment, seat the<br />

custom impression<br />

coping and take<br />

an accurate<br />

final impression.<br />

<br />

Figure 17: Delivery of Inclusive Zirconia Custom Abutment<br />

Figure 18: Abutment screw tightened to 35 Ncm Figure 19: Access opening sealed<br />

Figure 20: Interproximal and occlusal contacts checked<br />

– Clinical Benefits of the Inclusive Tooth Replacement Solution – 11

Figure 21: BruxZir crown cemented in place and all excess cement removed<br />

Figure 22: Final restoration (buccal view)<br />

Figure 23: Final restoration (occlusal view)<br />

<br />

Conclusion<br />

Implants can be a rewarding, profitable<br />

addition to any practice. As our<br />

patient population becomes more<br />

dental savvy, the demand for clinicians<br />

who are adept at placing and<br />

restoring dental implants continues<br />

to grow exponentially. <strong>Dental</strong> implant<br />

treatment is very much the future of<br />

dentistry as a solution to partial or<br />

total edentulism, and it should be part<br />

of any discussion with patients regarding<br />

the restoration of missing teeth.<br />

A key challenge lies in treating a maximum<br />

number of patients in a minimum<br />

amount of time — without sacrificing<br />

the quality of treatment. An excellent<br />

way to address this is by providing<br />

patient-specific temporization and<br />

contoured healing through the use of<br />

predesigned custom temporary components.<br />

Temporization sets the tone<br />

for the final esthetic outcome, the parameters<br />

for which are unique to each<br />

patient. So why treat them all with the<br />

same stock temporary components?<br />

As the demand for implants grows,<br />

so does the need for cost- and timeeffective<br />

ways to provide this service.<br />

The Inclusive Tooth Replacement<br />

Solution provides a highly efficient,<br />

predictable and affordable method<br />

of both placing and restoring dental<br />

implants. In conjunction with the<br />

clinician’s experience and skill, it is<br />

designed to equip dentists with the<br />

tools to provide this service in a single,<br />

comprehensive package. IM<br />

A key challenge lies in treating a maximum number of patients<br />

in a minimum amount of time — without sacrificing the quality<br />

of treatment. An excellent way to address this is by providing<br />

patient-specific temporization and contoured healing through<br />

the use of predesigned custom temporary components.<br />

<br />

12<br />

– www.inclusivemagazine.com –

Clinical Tip:<br />

Go online for<br />

in-depth content<br />

Implant Orientation for Inclusive® Tooth<br />

Replacement Solution Components<br />

by Bradley C. Bockhorst, DMD and<br />

Darrin M. Wiederhold, DMD, MS<br />

The Inclusive ® Tooth Replacement<br />

Solution from <strong>Glidewell</strong> Laboratories<br />

features custom temporary components<br />

designed to guide soft tissue<br />

contours during the healing phase.<br />

Whether you utilize the custom temporary<br />

abutment or custom healing<br />

abutment, the following guidelines<br />

can help to ensure a smooth delivery<br />

at the time of surgery.<br />

Aligning the Abutment Connection<br />

The custom temporary components<br />

of the Inclusive Tooth Replacement<br />

Solution are designed, presurgically,<br />

with one flat of the internal<br />

hex positioned toward the<br />

facial. During surgery, the final<br />

position of the implant should match<br />

this orientation. This is accomplished<br />

by aligning one of the flats on the implant<br />

driver to the facial (Figs. 1–3). If<br />

the seated abutment is rotated slightly,<br />

it can be removed and minor adjustments<br />

made to the rotational position<br />

of the implant.<br />

Seating the Custom Abutment<br />

Assuming there is adequate attached<br />

gingiva and no grafting is planned,<br />

flapless surgery can minimize postoperative<br />

discomfort and swelling,<br />

leading to higher patient satisfaction.<br />

Also, because the periosteum is not reflected,<br />

the blood supply to the bone<br />

is not disrupted, reducing potential resorption.<br />

With the growing popularity<br />

of minimally invasive surgery, the use<br />

of a tissue punch (or other tools, such<br />

as a laser) can make it much simpler<br />

to seat anatomically contoured abutments<br />

during a flapless procedure<br />

(Figs. 4–9). Once adequate tissue has<br />

been removed, the custom temporary<br />

abutment is seated and the abutment<br />

screw tightened to 15 Ncm. A periapical<br />

film should be taken, if necessary,<br />

to verify complete seating. The screw<br />

opening is sealed and the BioTemps ®<br />

provisional crown (<strong>Glidewell</strong> Laboratories)<br />

is seated with provisional<br />

cement. It is absolutely critical that all<br />

excess cement be removed and the<br />

temporary taken out of occlusion.<br />

In flapped cases, the abutment can be<br />

delivered and the complete seating<br />

visualized directly. The soft tissue can<br />

then be reapproximated and sutured<br />

around the abutment (Figs. 10–12). IM<br />

Figure 1: Flat to facial in flapped case<br />

Figure 2: Flat to facial in flapless case<br />

Figure 3: Final implant position<br />

14<br />

– www.inclusivemagazine.com –

Case 1: Tissue Punch<br />

Figure 4: Tissue punch Figure 5: Custom temporary abutment seated Figure 6: BioTemps crown cemented into place<br />

Case 2: Laser (Case courtesy of Dr. Dean Saiki, Oceanside, Calif.)<br />

Figure 7: Laser-assisted gingivoplasty Figure 8: Custom temporary abutment seated Figure 9: BioTemps crown cemented into place<br />

Case 3: Flapped<br />

Figure 10: Custom temporary abutment seated<br />

Figure 11: Flap sutured around abutment<br />

Figure 12: BioTemps crown cemented into place<br />

– Clinical Tip: Implant Orientation for Inclusive Tooth Replacement Solution Components – 15

Lab Sense:<br />

Virtual Design of Inclusive®<br />

Custom Temporary Components<br />

Go online for<br />

in-depth content<br />

by Dzevad Ceranic, CDT<br />

In processing restorations for more than 160,000 implant cases, the Implant<br />

Department at <strong>Glidewell</strong> Laboratories has accumulated a unique understanding<br />

of the industry as a whole, observing everything from shifting trends to emerging techniques<br />

to common difficulties experienced by practicing clinicians. In this column, we endeavor to<br />

share some of the insights we have obtained, in hopes of improving the quality and efficiency<br />

of cases everywhere.<br />

The esthetic result of any crown & bridge restoration is greatly dependent on the gingival<br />

contours from which that restoration emerges. Implant restorations pose greater difficulty<br />

given the collapse of soft tissue that typically occurs in the edentulous site, and stock abutments<br />

employed during the healing phase may not provide suitable tissue support to achieve the<br />

desired gingival anatomy. A custom temporary abutment and provisional restoration give<br />

the clinician greater control over papillae development and gingival contours, but even if<br />

the desired anatomy is developed intraorally, how does one accurately convey the final soft<br />

tissue architecture to the laboratory using a traditional impression post? To better assist the<br />

technician in designing the most natural emergence profile, a custom impression coping<br />

is required to properly replicate the soft tissue anatomy during the impression procedure.<br />

Yet, the majority of cases received here at <strong>Glidewell</strong> Laboratories suggest that methods for<br />

developing a custom impression coping chairside are either too tedious or time-consuming<br />

for most clinicians to trouble with, outside of the most demanding anterior situations.<br />

Drawing on our experience with CAD/CAM technology, however, it is now possible to provide<br />

a complete custom temporary solution consisting of a custom BioTemps ® provisional crown<br />

(<strong>Glidewell</strong> Laboratories) over a custom temporary abutment, an optional custom healing<br />

abutment (for cases in which immediate loading may be contraindicated) and a matching<br />

custom impression coping. Use of these components allows the restorative clinician to<br />

shape and support the soft tissue as desired during the healing phase, and maintain and<br />

capture that carefully contoured gingival anatomy during the impression procedure. Given<br />

this information, the laboratory technician has an accurate understanding of the gingival<br />

architecture from which to design a natural emergence profile for the most predictable and<br />

pleasing esthetic result.<br />

17

Digital Manufacturing Process<br />

The process by which <strong>Glidewell</strong> Laboratories<br />

designs and mills its custom temporary components<br />

is much the same as that it uses to produce<br />

its Inclusive ® Custom Implant Abutments. Using<br />

this proven CAD/CAM technology, our laboratory<br />

has successfully manufactured more than 160,000<br />

custom abutments.<br />

•Step 1: Model Scan<br />

For conventional cases, the process begins with<br />

articulated, presurgical study models, in which the<br />

proposed implant location is indexed with the aid<br />

of the prosthetic guide. A scanning abutment is then<br />

placed in the proposed implant site. The purpose of<br />

the scanning abutment is to capture the implant’s<br />

angulation, its location relative to the adjacent dentition,<br />

and the abutment connection orientation,<br />

all of which is translated to the design software<br />

when the model undergoes three-dimensional optical<br />

scanning (Fig. 1).<br />

•Step 2: Design of Custom Components<br />

Once a virtual model is created (Fig. 2), complete<br />

with a virtual analog demonstrating the proposed<br />

implant location (Fig. 3), the custom temporary<br />

abutment, custom BioTemps crown, custom healing<br />

abutment and custom impression coping are<br />

Figure 1: Model placed into optical scanner<br />

Figure 2: Scanned model with opposing<br />

Figure 3: Virtual analog placement<br />

18<br />

– www.inclusivemagazine.com –

designed using a proprietary add-on software module<br />

developed for the <strong>Dental</strong>Designer system from<br />

3Shape (New Providence, N.J.). The computer software<br />

allows the digital technician to manipulate the<br />

size and shape of the component using precise measurements<br />

(Figs. 4–7).<br />

Such precision is critical in implant cases, where<br />

contacts and occlusion help to determine the<br />

functional load to be placed on the implant. To allow<br />

for discrepancies in implant placement following<br />

surgery, the BioTemps provisional is designed with<br />

extra relief space within the cement space (Fig. 8),<br />

providing an internal offset in the area between the<br />

temporary crown and custom temporary abutment.<br />

Figure 4: Custom healing abutment designed<br />

Figure 5: Custom impression coping designed<br />

Figure 6: Custom temporary abutment designed<br />

Figure 7: BioTemps crown designed<br />

Figure 8: BioTemps crown designed with internal relief space<br />

– Lab Sense: Virtual Design of Inclusive Custom Temporary Components – 19

•Step 3: Milling of Custom Components<br />

Once the digital design of each component<br />

has been finalized, the files are transferred to a<br />

state-of-the-art computer-aided milling station. The<br />

custom impression coping, custom temporary<br />

abutment and custom healing abutment are all<br />

milled from polyether ether ketone (PEEK), an<br />

organic polymer thermoplastic (Figs. 9, 10).<br />

The BioTemps provisional crown is milled from<br />

poly(methyl methacrylate) (PMMA), a transparent<br />

thermoplastic sometimes referred to as acrylic glass<br />

(Figs. 11, 12). After seating is confirmed, the custom<br />

temporary crown is stained according to the shade<br />

prescribed by the clinician, then glazed before a<br />

final quality inspection is performed.<br />

Figure 9: PEEK abutment blank ready for milling<br />

Figure 10: Milled PEEK abutment<br />

Figure 11: Close-up of PMMA milling<br />

Figure 12: PMMA block after milling<br />

20<br />

– www.inclusivemagazine.com –

Figure 12: PMMA block after milling<br />

Figure 12: PMMA block after milling<br />

Inclusive ® Tooth Replacement Solution<br />

The finished custom temporary components<br />

(Fig. 13), along with the physical models and<br />

prosthetic guide, are sent to the clinician as part of<br />

the newly launched Inclusive ® Tooth Replacement<br />

Solution. One of the goals of this solution, which<br />

also includes an Inclusive ® Tapered Implant and<br />

the appropriate surgical drills (Fig. 14), is to provide<br />

clinicians with everything they need to provisionalize<br />

the case at the time of implant placement. This way,<br />

the patient can leave the office with an esthetic<br />

restoration in place. These custom temporary<br />

components not only serve to manage and maintain<br />

the desired gingival contours critical to a natural<br />

emergence profile, but also give the clinician and<br />

patient a chance to preview the ultimate result —<br />

providing valuable preliminary information and<br />

increasing the likelihood of acceptance upon<br />

delivery of the final restorative components<br />

(Inclusive Custom Abutment and BruxZir ® Solid<br />

Zirconia crown [<strong>Glidewell</strong> Laboratories]) that<br />

complete the Inclusive Tooth Replacement Solution.<br />

Summary<br />

Without proper communication of the desired<br />

gingival architecture, a laboratory technician must<br />

rely on model manipulation and guesswork when<br />

designing a patient’s final implant restoration.<br />

Such techniques tend to be less predictable and<br />

may compromise the esthetic outcome. Custom<br />

temporary components designed and milled using<br />

proven CAD/CAM techniques enable clinicians to<br />

guide soft tissue contours during the healing phase,<br />

and a matching custom impression coping serves<br />

to accurately preserve and capture these contours<br />

during the impression procedure. The overall<br />

result of this custom temporary solution is a clear<br />

translation of the desired gingival anatomy to the<br />

lab technician for use in designing the optimal<br />

emergence profile, greatly increasing the esthetic<br />

predictability of the final restorative result. IM<br />

Custom temporary components ... enable clinicians to guide soft tissue contours<br />

during the healing phase, and a matching custom impression coping serves to<br />

accurately preserve and capture these contours during the impression procedure.<br />

Figure 13: Inclusive Tooth Replacement Solution custom temporary components<br />

Figure 14: Inclusive Tapered Implant with surgical drills<br />

– Lab Sense: Virtual Design of Inclusive Custom Temporary Components – 21

Building a Referral Network Through<br />

Restorative Driven Implant Concepts<br />

by Robert A. Horowitz, DDS<br />

Introduction<br />

One might argue that the outcome of any implant case<br />

begins with a successful surgery. Most patients are less<br />

concerned with root-form placement, however, than<br />

they are with the esthetics and functionality of the final<br />

restoration. The success of any surgical practice is therefore<br />

highly dependent on the success of its referral network —<br />

the restorative dentists, laboratory technicians and other<br />

co-treating professionals who help to carry an implant case<br />

to completion.<br />

that have been known to complicate implant cases between<br />

the surgical and restorative phases. Intended to promote<br />

an effective, streamlined process resulting in a predictable<br />

outcome, this all-in-one, restorative-based solution (Fig. 1)<br />

offers a number of advantages for the team of providers<br />

working together to ensure each patient receives the best<br />

possible care.<br />

Fortunately, the factors that drive growth for a specialist<br />

practice are the same as those that drive growth for a<br />

general practice or laboratory, chiefly patient satisfaction<br />

and profitability — factors that derive from proper planning,<br />

efficient treatment and minimal complications. Treatment<br />

planning each case to include restorative considerations<br />

from the outset and ensuring proper collaboration and<br />

communication among all members of the team will greatly<br />

enhance the likelihood of a successful outcome and the<br />

efficiency with which it is achieved.<br />

The Inclusive ® Tooth Replacement Solution from <strong>Glidewell</strong><br />

Laboratories represents an intriguing new tool in the effort<br />

to address planning, communication and component issues<br />

Figure 1: Temporary, impression and final phases of the patient-specific Inclusive<br />

Tooth Replacement Solution<br />

22<br />

– www.inclusivemagazine.com –

Restorative Treatment Planning<br />

To obtain an ideal surgical outcome, a full diagnosis must<br />

be completed before the initiation of treatment. The final<br />

prosthetic design should also be considered. The more<br />

comprehensive the diagnosis, the better the final restoration<br />

will be. Clinical photographs and radiographs, periodontal<br />

evaluation, esthetic evaluation, diagnostic casts on an<br />

adjustable articulator with a wax-up of the teeth (present<br />

and missing) in ideal functional and esthetic locations, and<br />

a cone beam volumetric tomogram taken with a radioopaque<br />

stent are all helpful tools for accomplishing this.<br />

The laboratory technician is forced to approximate the<br />

design of the restorative components. In many cases, this<br />

results in an abutment or crown that does not quite fit<br />

properly, causes tissue blanching or looks less than natural<br />

where it emerges from the gingiva. Adjustments or even a<br />

remake may be required, costing the clinician and patient<br />

valuable chairtime.<br />

It is tempting for some surgical specialists to take prosthetic<br />

diagnosis and soft tissue sculpting for granted. They might<br />

think these are concerns chiefly for the restorative dentist.<br />

Why should a specialist take time to do general work? The<br />

truth is, these are foundational components that help lay<br />

the groundwork for the definitive restoration. Extra time<br />

spent in the planning stages can be rewarded tenfold in<br />

terms of time saved addressing complications that may<br />

otherwise result later in the case. Making the restorative<br />

clinician’s job easier is pleasing to both the clinician and the<br />

patient, fostering goodwill and leading to a greater number<br />

of future referrals.<br />

The Inclusive Tooth Replacement Solution places a great<br />

degree of emphasis on the preplanning of each case from<br />

a restorative perspective. Implant and case-specific surgical<br />

drills are provided according to the surgeon’s prescription,<br />

along with a prosthetic guide — fabricated from an initial<br />

impression — to help ensure proper implant placement<br />

(Fig. 2). Laboratory technicians then utilize digital technology<br />

to design and mill a custom temporary abutment and<br />

provisional restoration (Fig. 3), making them available at<br />

the time of surgery. For clinical flexibility, a custom healing<br />

abutment is also provided (Fig. 3). The purpose of these<br />

custom temporary components is to begin sculpting the<br />

gingiva on the day the implant is inserted. Rather than<br />

ignoring the soft tissue contours or leaving them to chance,<br />

they are guided during the healing phase to prepare for<br />

an ideal emergence profile of the final restoration. And<br />

because the components are pre-milled, the chairside<br />

time that might otherwise be spent crafting a provisional<br />

restoration is eliminated.<br />

Figure 2: The Inclusive Tooth Replacement Solution includes a prosthetic guide<br />

to help ensure proper implant placement.<br />

Restorative Communication<br />

Upon completion of the healing phase, the patient<br />

returns to the referring restorative clinician, who takes<br />

the impression for the lab. The typical challenge with<br />

implant cases is that a stock, cylindrical impression<br />

coping cannot properly capture the gingival architecture.<br />

Figure 3: The Inclusive Tooth Replacement Solution also includes a custom temporary<br />

abutment, a provisional restoration, and a custom healing abutment.<br />

– Building a Referral Network Through Restorative Driven Implant Concepts – 23

Figure 4: A custom impression coping (right) is designed to match the gingival<br />

architecture sculpted by the custom temporary abutment (center) and custom<br />

healing abutment (left). The custom impression coping would be forwarded to the<br />

restorative dentist.<br />

The Inclusive Tooth Replacement Solution addresses this<br />

issue from the outset with a custom impression coping<br />

(Fig. 4) designed to match the gingival architecture sculpted<br />

by the custom temporary abutment. When the patient<br />

returns to the referring doctor, the doctor simply removes<br />

the temporary, places the custom impression coping, takes<br />

the impression and sends it to the lab. The full gingival<br />

architecture is precisely captured for lab use, without the<br />

need to create a custom impression coping chairside.<br />

Restorative Outcome<br />

When utilizing the Inclusive Tooth Replacement Solution,<br />

restorative dentists get the benefit of a laboratory that<br />

has restored more than 160,000 implant cases. They can<br />

therefore expect precise, quality restorations without<br />

any unnecessary complications. A custom abutment and<br />

monolithic crown are milled to precisely match the digital<br />

design files used in the creation of the custom temporary<br />

components. Because of this, the abutment and crown<br />

should seat easily with a precise fit. Any adjustments should<br />

be minimal, allowing the patient to leave the office with a<br />

natural-looking definitive restoration requiring no further<br />

corrective appointments.<br />

Laboratory Support<br />

To maximize the number of successful referrals, an implant<br />

specialist needs to offer support to less-experienced<br />

restorative providers. An important ancillary benefit to<br />

<strong>Glidewell</strong>’s Inclusive Tooth Replacement Solution is that<br />

each case incorporates patient-specific custom components,<br />

simplifying treatment steps for less-experienced restorative<br />

clinicians. Further, the solution includes the customer<br />

support of a highly experienced team of technical advisors<br />

who can assist the restorative doctor with any questions or<br />

concerns that arise. This frees up the specialist staff to focus<br />

on specialized procedures, while still providing the referring<br />

doctor with answers to any questions or concerns. Users<br />

of the Inclusive Tooth Replacement Solution also benefit<br />

from a significant cost savings over the price of individual<br />

components. As the laboratory manufactures the implants<br />

and all other components on site at its state-of-the-art<br />

U.S. facility, vendor markups are reduced. A single price<br />

covers the entire cost of the solution, eliminating the<br />

guesswork often associated with determining treatment fees<br />

for the placement and restoration of implants.<br />

Summary<br />

The success of those who specialize in the placement of<br />

dental implants is determined in no small measure by<br />

the success of their restorative teams. A specialist who<br />

demonstrates an appreciation for the concerns of his cotreating<br />

professionals stands a better chance of achieving<br />

a positive outcome for the patient in the most efficient,<br />

predictable manner possible. With the Inclusive Tooth<br />

Replacement Solution, many of the communication gaps<br />

that traditionally interrupt the treatment chain are avoided.<br />

Soft tissue architecture is carefully managed from the outset<br />

and communicated effectively to the restorative team.<br />

Parts produced with CAD/CAM technology demonstrate<br />

precise fit and proper occlusion. The restorative process is<br />

simplified, encouraging referrals from clinicians who might<br />

otherwise be reluctant to prescribe implants, considering<br />

them too complex or time-consuming. By maximizing the<br />

patient satisfaction and profitability of referring doctors, the<br />

specialist practice will ultimately benefit. IM<br />

24<br />

– www.inclusivemagazine.com –

Implant Q&A:<br />

An Interview with<br />

Dr. Darrin Wiederhold<br />

Go online for<br />

in-depth content<br />

Interview of Darrin M. Wiederhold, DMD, MS<br />

by Bradley C. Bockhorst, DMD<br />

Dr. Darrin Wiederhold is an accomplished dentist and a<br />

new member of the <strong>Glidewell</strong> Laboratories clinical team. In this<br />

exclusive interview, he outlines the preparatory steps a clinician<br />

can take to successfully incorporate implant dentistry<br />

into their practice. He also discusses his experience<br />

with the new Inclusive ® Tapered Implant System and<br />

Inclusive ® Tooth Replacement Solution, and shares<br />

his vision for upcoming educational courses at the<br />

<strong>Glidewell</strong> International Technology Center.<br />

Dr. Bradley Bockhorst: Today we will spend some time talking with the<br />

newest member of the <strong>Glidewell</strong> clinical team, Dr. Darrin Wiederhold, about<br />

some of the projects and technologies we’ve been working on here at the laboratory.<br />

Darrin, can you tell the Inclusive audience a little bit about yourself?<br />

Dr. Darrin Wiederhold: Sure, I’d be happy to. I’m originally from the East Coast;<br />

a Pennsylvania boy. My dad worked for the CIA, so I had an opportunity to<br />

travel throughout my childhood and live in or visit six of the seven continents.<br />

I haven’t made it to Antarctica yet, but being a lover of the sun, I don’t see<br />

myself heading that way anytime soon. When I graduated from high school in<br />

Indonesia, I came back to Pennsylvania, went to college up in University Park<br />

and then to Temple University School of Dentistry down in Philadelphia.<br />

When I finished dental school, I had already started to get some experience<br />

with implants. I became interested in surgery during dental school, so I<br />

started to take some courses to prepare for possibly placing implants<br />

as a restorative dentist or, ultimately, as an oral surgeon. I was about<br />

99 percent sure I wanted to do oral surgery when I got out, but I wanted<br />

to be 100 percent sure before I made that commitment, so I enrolled in a<br />

GPR program up in Buffalo, New York, that had an extensive oral surgery<br />

component. I got a chance to do a lot of trauma cases and even got some<br />

26<br />

– www.inclusivemagazine.com –

early exposure to implants there. I decided that it was absolutely what I wanted<br />

to do. So, I applied and was admitted into an oral surgery residency program at<br />

the University of Kentucky at Lexington. I was there a year and had just finished<br />

my intern year when, for personal reasons, I had to withdraw from the program<br />

and take some time off. Two years later, I came back and did a second year of<br />

GPR down in Kentucky as their chief resident. So I had an opportunity to do<br />

about three years of additional training after dental school.<br />

BB: That brings up an interesting question. There’s a lot of interest among general<br />

dentists in starting to place implants. I think just like doing any other kind of<br />

procedure, whether it is wisdom teeth extractions, root canals or ortho, you have<br />

to make sure you’re well trained, confident and competent before you start doing<br />

it. Now, they don’t necessarily have to go through two GPRs and an oral surgery<br />

residency, but what are your thoughts as far as what general dentists should do in<br />

preparation for starting to place implants?<br />

DW: I don’t know that they need all of that additional training, but you do<br />

want more than just a weekend course. You really want to take a comprehensive<br />

course that’s going to expose you to bone physiology, make sure you’re familiar<br />

with all the terminology, allow you to do some live surgeries and develop your<br />

treatment planning skills. You want to become proficient in those aspects and<br />

work as much as you can.<br />

You really<br />

want to take a<br />

comprehensive<br />

course that’s<br />

going to ... allow<br />

you to do some<br />

live surgeries<br />

and develop<br />

your treatment<br />

planning skills.<br />

– Implant Q&A: An Interview with Dr. Darrin Wiederhold – 27

BB: There are some excellent implant courses out there, such as those at the Misch<br />

International Implant Institute and the AAID MaxiCourses ® . The Implants A-to-Z<br />

course at UCLA with Drs. Sascha Jovanovic and George Perri is also a great course.<br />

DW: Absolutely. If you have the opportunity and can invest in one of the yearlong<br />

courses, do it. Essentially, you can’t get enough education. That’s the takeaway<br />

here. Gaining understanding of the fundamentals is crucial. You really want to<br />

be proficient beyond just having a good sense of your surgical skills, the bone<br />

morphology and the anatomy in that area.<br />

Beyond that, though, I would say, managing cases postoperatively is imperative.<br />

You hope every case you do is going to be flawless, but complications can arise,<br />

and the more cases you do, it’s inevitable that you are going to encounter some<br />

challenges and difficulties. It’s important to work at becoming increasingly<br />

proficient and minimizing those complications, so when they do arise, you’ll<br />

have a good sense of how you’re going to handle the situation and can keep<br />

levelheaded during the surgery if you do encounter a problem. If you have a<br />

solid foundation to draw from and something unexpected comes up, you’ll have<br />

fewer sleepless nights.<br />

BB: So the key is knowing how to manage complications. Or, even better, how to<br />

avoid them by recognizing them ahead of time. Another recommendation might be<br />

to have a mentor.<br />

DW: Sure, if you have the opportunity to shadow someone — an oral surgeon,<br />

a periodontist or a general dentist who has extensive experience placing<br />

implants — you can shadow them in their office, watch them, and have them<br />

with you while you’re doing several of your cases.<br />

Additionally, I would say the number one thing would be case selection. You<br />

want to make sure that the first few cases you do are what you would consider<br />

“the ideal.” These cases are going to be the most straightforward, and will,<br />

hopefully, present you with the least challenges so that you can develop your<br />

skills, confidence and competence. Having that safety net in place, with a mentor<br />

or someone you can shadow, makes the process a lot easier.<br />

The number one<br />

thing would be<br />

case selection.<br />

You want to<br />

make sure that<br />

the first few<br />

cases you do<br />

are what you<br />

would consider<br />

“the ideal.”<br />

BB: OK, so we’ve got the correct amount of education. We’ve found a mentor<br />

and those ideal cases. Now what? What’s the ideal first case a clinician should be<br />

looking for?<br />

DW: I would say a maxillary first premolar. It affords all the surgical challenges<br />

that come with the maxilla, whether it be the sinus or avoiding the adjacent<br />

teeth. It allows you to work in the less dense bone, so it’s less forgiving and<br />

you have to be more proficient with it, but it gives you easy access without the<br />

esthetic challenges of an anterior tooth. So, if you can round up a good number<br />

of maxillary premolar cases out of the gate, really get your hands wet, then<br />

repetition is the key. If it seems like they’re getting too easy — that’s a good sign.<br />

It means you’re developing your skills and comfort level. Once you get that true<br />

sense of confidence in yourself and your cases are going well, then it might be<br />

time to branch out to an anterior tooth or a molar. You really can’t put a number<br />

on it, but the more “straightforward” cases you can do will really go a long way<br />

toward increasing your chances for success.<br />

BB: I think that goes back to a key point: having a mentor who can provide surgical<br />

backup. It’s about knowing what cases you’re comfortable with and what you should<br />

refer out. That way, if you run into a problem, you’ve got somebody who has your<br />

back as far as helping you through those cases.<br />

28<br />

– www.inclusivemagazine.com –

DW: Right. The thing that you gain most from those experiences is the ability to<br />

recognize when you’re in over your head a little bit, perhaps. There are people<br />

out there who are great at it, who have a natural instinct for it and can take<br />

right to it. But every day someone runs into a challenge that they either haven’t<br />

experienced before or they’re a little uncomfortable handing, or it’s something<br />

that they just would rather not deal with. So, when you are presented with a case<br />

that’s too challenging, there’s no shame in referring it out. Anyone out there who<br />

has had that experience and feels comfortable handling those challenges only<br />

got that way by having gone through it themselves. There’s no reason to feel that<br />

this is a knock against you as a surgeon in any way. It’s just recognizing that you<br />

haven’t seen this before, and figuring out how you’re going to handle it.<br />

BB: It’s part of your learning curve.<br />

DW: Absolutely.<br />

BB: One of the main things that you’ve been doing since you joined us is placing<br />

Inclusive ® Tapered Implants. Can you tell us a little bit about what you think of that<br />

system compared to other ones you have worked with in the past?<br />

DW: Sure. The system has all the advantages that the test of time has proven<br />

with implants of old — the internal hex being the most popular connection out<br />

there in dentistry. It’s got a thread design that maximizes your initial stability and<br />

helps promote osseointegration. It’s intuitively very easy to use. Anyone who<br />

has had experience with any of the large systems out there is going to be very<br />

comfortable using it and is going to be able to transition into Inclusive Tapered<br />

Implants very easily.<br />

The entire<br />

process from<br />

start to finish —<br />

from implant<br />

placement to<br />

the definitive<br />

restoration — is<br />

controlled, very<br />

predictable and<br />

optimal in terms<br />

of improving<br />

your chances<br />

of success.<br />

BB: It’s a system put together by a very experienced team. We have a lot of engineers<br />

and technicians who actually came from the implant industry. Key to being the first<br />

laboratory to introduce an implant system, though, is that we can encompass a full<br />

package. We can help with everything from planning the case to the final restoration,<br />

which leads into one of the major projects we’ve been working on, which is the<br />

Inclusive ® Tooth Replacement Solution. Can you tell us a little bit about that?<br />

DW: It’s basically a comprehensive package that has the full <strong>Glidewell</strong> expertise<br />

and experience behind it. In addition to the implant, the dentist receives up front<br />

a prosthetic guide, a custom healing abutment, a custom temporary abutment<br />

and BioTemps ® provisional crown (<strong>Glidewell</strong> Laboratories) to provide early<br />

contouring of the soft tissue, a matching custom impression coping, as well as<br />

the final prosthesis. So, the entire process from start to finish — from implant<br />

placement to the definitive restoration — is controlled, very predictable and<br />

optimal in terms of improving your chances of success. It’s a comprehensive<br />

package that you have laid out before you, before you ever get started. I think<br />

clinicians are really going to take to it.<br />

BB: Right. I think core to this solution is versatility. At implant placement, you’ll<br />

have a custom healing abutment that was made for you pre-surgery, a custom<br />

temporary abutment, a BioTemps crown and a matching impression coping. A<br />

surgical specialist who has a restorative-driven surgical practice can start<br />

sculpting those soft tissues correctly, making it easier for his restorative dentist.<br />

He can then either immediately provisionalize it, or he can put the healing abutment<br />

on it. And later, he can send that custom impression coping to the restorative<br />

dentist, who can then transfer those contours correctly to the laboratory. One of<br />

the biggest challenges for the lab is clinicians using narrow, round impression<br />

copings, and then trying to make an anatomically shaped tooth. This issue is core<br />

to the Inclusive Tooth Replacement Solution, so maybe you can expand on that.<br />

– Implant Q&A: An Interview with Dr. Darrin Wiederhold – 29

We’re excited about<br />

all the upcoming<br />

courses, and how<br />

we can gear them<br />

toward general<br />

practitioners and<br />

specialists alike to<br />

work hand-in-hand<br />

with us to improve<br />

their efficacy<br />

and efficiency.<br />

DW: Sure. For general practitioners who are doing both the surgery and the<br />

restorative procedures, it’s certainly a comprehensive package. If you are a surgical<br />

specialist looking to develop your referral base, then you have the advantage of<br />

being able to communicate to your general practitioner: “I’m not only going to<br />

place the implant for you, I’m going to start the restorative process. I’m going<br />

to place the healing abutment for you, so it can begin the soft tissue contour, to<br />

make your life much easier down the road — predictably.” It is something that<br />

can be easily reproduced. And the additional components can be forwarded to<br />

the restorative dentist, as you mentioned. When the time comes, they can place<br />

the custom impression coping that matches that emergence profile that’s been<br />

developed. So, there’s predictability and a great sense of continuity there. It’s<br />

also a great builder for a referral base for specialists who want to help out in the<br />

process beyond just placing implants.<br />

BB: And then, ultimately, it provides the final restoration — a superior restoration —<br />

which means better patient care.<br />

DW: Absolutely.<br />

BB: Let’s move on to other technologies: guided surgery. Can you tell us what your<br />

background was before and what you’re doing now with digital treatment planning<br />

and guided surgery?<br />

DW: I’ve been doing guided surgery for about six months now, since coming to<br />

<strong>Glidewell</strong>. Prior to that, I was doing freehand almost exclusively — reflecting a<br />

flap, going in there and eyeballing it, and performing the surgeries. The guided<br />

surgery is great, though. Not only does it allow you to take advantage of Cone<br />