December 2005 — Vol. 22, No. 12 - RC Soaring - RCSoaring.com

December 2005 — Vol. 22, No. 12 - RC Soaring - RCSoaring.com

December 2005 — Vol. 22, No. 12 - RC Soaring - RCSoaring.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

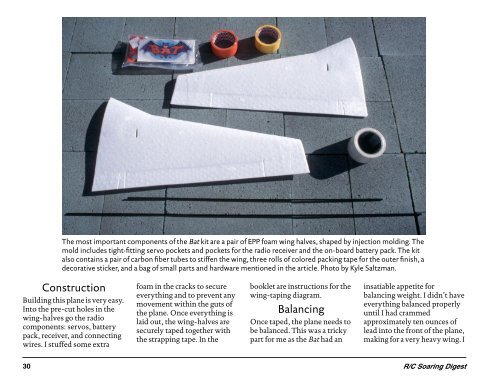

The most important <strong>com</strong>ponents of the Bat kit are a pair of EPP foam wing halves, shaped by injection molding. The<br />

mold includes tight-fitting servo pockets and pockets for the radio receiver and the on-board battery pack. The kit<br />

also contains a pair of carbon fiber tubes to stiffen the wing, three rolls of colored packing tape for the outer finish, a<br />

decorative sticker, and a bag of small parts and hardware mentioned in the article. Photo by Kyle Saltzman.<br />

Construction<br />

Building this plane is very easy.<br />

Into the pre-cut holes in the<br />

wing-halves go the radio<br />

<strong>com</strong>ponents: servos, battery<br />

pack, receiver, and connecting<br />

wires. I stuffed some extra<br />

foam in the cracks to secure<br />

everything and to prevent any<br />

movement within the guts of<br />

the plane. Once everything is<br />

laid out, the wing-halves are<br />

securely taped together with<br />

the strapping tape. In the<br />

booklet are instructions for the<br />

wing-taping diagram.<br />

Balancing<br />

Once taped, the plane needs to<br />

be balanced. This was a tricky<br />

part for me as the Bat had an<br />

insatiable appetite for<br />

balancing weight. I didn’t have<br />

everything balanced properly<br />

until I had crammed<br />

approximately ten ounces of<br />

lead into the front of the plane,<br />

making for a very heavy wing. I<br />

30 R/C <strong>Soaring</strong> Digest