Burns Catalog 2005xxxxxx.qxd - Visiter le site web de l'utilisateur ...

Burns Catalog 2005xxxxxx.qxd - Visiter le site web de l'utilisateur ...

Burns Catalog 2005xxxxxx.qxd - Visiter le site web de l'utilisateur ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

variety of applications including pump housings,<br />

transmission cases, cylin<strong>de</strong>r blocks.<br />

As previously mentioned, heat-treating improves the<br />

strength of aluminum alloys through a process known as<br />

"precipitation har<strong>de</strong>ning." In simp<strong>le</strong> terms, precipitation<br />

har<strong>de</strong>ning is a process that occurs during the heating and<br />

cooling of an aluminum alloy in which minute partic<strong>le</strong>s or<br />

"precipitates" are formed in the aluminum matrix. These<br />

partic<strong>le</strong>s reduce slippage between "grains" which in turns<br />

increases material hardness and strength.<br />

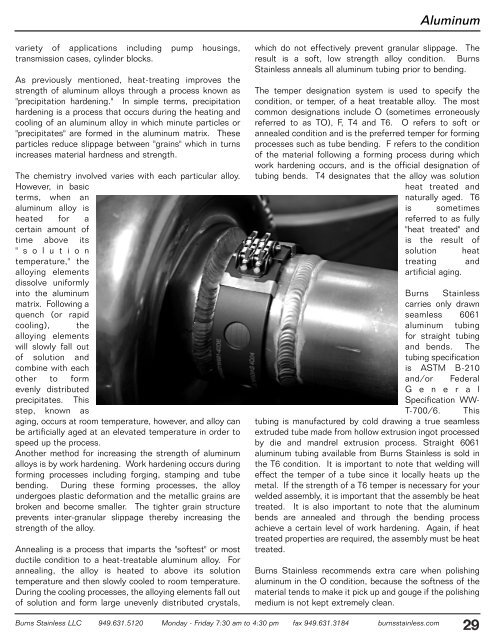

The chemistry involved varies with each particular alloy.<br />

However, in basic<br />

terms, when an<br />

aluminum alloy is<br />

heated for a<br />

certain amount of<br />

time above its<br />

" s o l u t i o n<br />

temperature," the<br />

alloying e<strong>le</strong>ments<br />

dissolve uniformly<br />

into the aluminum<br />

matrix. Following a<br />

quench (or rapid<br />

cooling), the<br />

alloying e<strong>le</strong>ments<br />

will slowly fall out<br />

of solution and<br />

combine with each<br />

other to form<br />

evenly distributed<br />

precipitates. This<br />

step, known as<br />

aging, occurs at room temperature, however, and alloy can<br />

be artificially aged at an e<strong>le</strong>vated temperature in or<strong>de</strong>r to<br />

speed up the process.<br />

Another method for increasing the strength of aluminum<br />

alloys is by work har<strong>de</strong>ning. Work har<strong>de</strong>ning occurs during<br />

forming processes including forging, stamping and tube<br />

bending. During these forming processes, the alloy<br />

un<strong>de</strong>rgoes plastic <strong>de</strong>formation and the metallic grains are<br />

broken and become smal<strong>le</strong>r. The tighter grain structure<br />

prevents inter-granular slippage thereby increasing the<br />

strength of the alloy.<br />

Annealing is a process that imparts the "softest" or most<br />

ducti<strong>le</strong> condition to a heat-treatab<strong>le</strong> aluminum alloy. For<br />

annealing, the alloy is heated to above its solution<br />

temperature and then slowly coo<strong>le</strong>d to room temperature.<br />

During the cooling processes, the alloying e<strong>le</strong>ments fall out<br />

of solution and form large unevenly distributed crystals,<br />

which do not effectively prevent granular slippage. The<br />

result is a soft, low strength alloy condition. <strong>Burns</strong><br />

Stain<strong>le</strong>ss anneals all aluminum tubing prior to bending.<br />

The temper <strong>de</strong>signation system is used to specify the<br />

condition, or temper, of a heat treatab<strong>le</strong> alloy. The most<br />

common <strong>de</strong>signations inclu<strong>de</strong> O (sometimes erroneously<br />

referred to as TO), F, T4 and T6. O refers to soft or<br />

annea<strong>le</strong>d condition and is the preferred temper for forming<br />

processes such as tube bending. F refers to the condition<br />

of the material following a forming process during which<br />

work har<strong>de</strong>ning occurs, and is the official <strong>de</strong>signation of<br />

tubing bends. T4 <strong>de</strong>signates that the alloy was solution<br />

heat treated and<br />

naturally aged. T6<br />

is sometimes<br />

referred to as fully<br />

"heat treated" and<br />

is the result of<br />

solution heat<br />

treating and<br />

artificial aging.<br />

<strong>Burns</strong> Stain<strong>le</strong>ss<br />

carries only drawn<br />

seam<strong>le</strong>ss 6061<br />

aluminum tubing<br />

for straight tubing<br />

and bends. The<br />

tubing specification<br />

is ASTM B-210<br />

and/or Fe<strong>de</strong>ral<br />

G e n e r a l<br />

Specification WW-<br />

T-700/6. This<br />

tubing is manufactured by cold drawing a true seam<strong>le</strong>ss<br />

extru<strong>de</strong>d tube ma<strong>de</strong> from hollow extrusion ingot processed<br />

by die and mandrel extrusion process. Straight 6061<br />

aluminum tubing availab<strong>le</strong> from <strong>Burns</strong> Stain<strong>le</strong>ss is sold in<br />

the T6 condition. It is important to note that welding will<br />

effect the temper of a tube since it locally heats up the<br />

metal. If the strength of a T6 temper is necessary for your<br />

wel<strong>de</strong>d assembly, it is important that the assembly be heat<br />

treated. It is also important to note that the aluminum<br />

bends are annea<strong>le</strong>d and through the bending process<br />

achieve a certain <strong>le</strong>vel of work har<strong>de</strong>ning. Again, if heat<br />

treated properties are required, the assembly must be heat<br />

treated.<br />

<strong>Burns</strong> Stain<strong>le</strong>ss LLC 949.631.5120 Monday - Friday 7:30 am to 4:30 pm fax 949.631.3184 burnsstain<strong>le</strong>ss.com<br />

Aluminum<br />

<strong>Burns</strong> Stain<strong>le</strong>ss recommends extra care when polishing<br />

aluminum in the O condition, because the softness of the<br />

material tends to make it pick up and gouge if the polishing<br />

medium is not kept extremely c<strong>le</strong>an.<br />

29