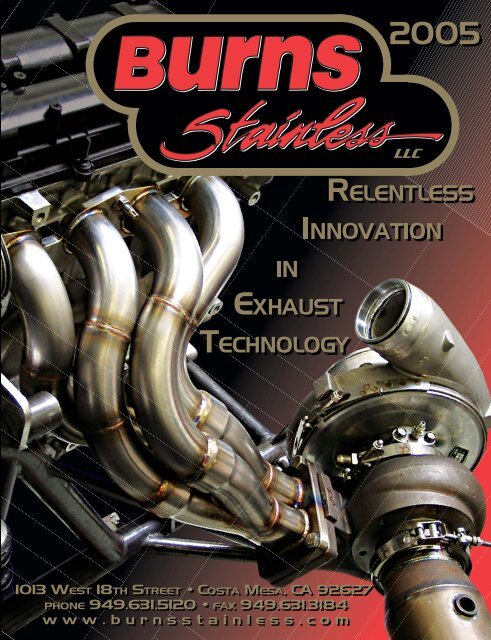

Burns Catalog 2005xxxxxx.qxd - Visiter le site web de l'utilisateur ...

Burns Catalog 2005xxxxxx.qxd - Visiter le site web de l'utilisateur ...

Burns Catalog 2005xxxxxx.qxd - Visiter le site web de l'utilisateur ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Due to increasing materials costs, <strong>Burns</strong> Stain<strong>le</strong>ss may impose a surcharge on products at any time without notice<br />

Contents<br />

304 Stain<strong>le</strong>ss Steel U-bends . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2<br />

304 Stain<strong>le</strong>ss Steel J-bends . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3<br />

304 Stain<strong>le</strong>ss Steel 90º and 15º Bends . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4<br />

304 Stain<strong>le</strong>ss Steel 45º bends and Straight Tubing . . . . . . . . . . . . . . . . . . . . . . 5<br />

304 Stain<strong>le</strong>ss Oval Tubing, Mandrel Bends and Transitions . . . . . . . . . . . . . . . . 6<br />

321 Stain<strong>le</strong>ss Steel U-bends and 90º Bends . . . . . . . . . . . . . . . . . . . . . . . . . . . 7<br />

321 Stain<strong>le</strong>ss Steel Straight tubing, Service Costs . . . . . . . . . . . . . . . . . . . . . . 8<br />

6061 Aluminum U-bends, 90º Bends, and 45º Bends . . . . . . . . . . . . . . . . . . . . . 9<br />

6061 Aluminum Straight Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10<br />

Inconel Tubing and Mandrel Bends . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11<br />

Racing Merge Col<strong>le</strong>ctors - General Information . . . . . . . . . . . . . . . . . . . . . . . . 12<br />

Base Merge Col<strong>le</strong>ctors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13<br />

Doub<strong>le</strong>-Slip Turbo Col<strong>le</strong>ctors and Splayed Col<strong>le</strong>ctor Options . . . . . . . . . . . . . 14<br />

Transitions and Megaphones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15<br />

X-Design TM Computer Analysis Service for Racing Exhaust Systems . . . . . . . . 16<br />

DynoSYS TM and B-TEC TM Adjustab<strong>le</strong> Col<strong>le</strong>ctors . . . . . . . . . . . . . . . . . . . . . . . . 17<br />

X-pipes, Y-pipes and V-Band Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18<br />

Flat-band Clamps, Silicone Hose, Hump Hose and Reducers . . . . . . . . . . . . . . 19<br />

A<strong>de</strong>l Wiggins F<strong>le</strong>xib<strong>le</strong> Tube Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20<br />

Turbo In<strong>le</strong>t, Downpipe and Wastegate Flanges, 3-Bolt Flanges, Head Flanges . 21<br />

Col<strong>le</strong>ctor Tabs, O2 Rings, Hea<strong>de</strong>r Bolts, Solar Flux, and TIG Welding Rod . . . 22<br />

UltraLight Stain<strong>le</strong>ss Motorsports Muff<strong>le</strong>rs . . . . . . . . . . . . . . . . . . . . . . . . . . . 23<br />

BurnSonic TM DR-1 Lightweight Col<strong>le</strong>ctor Muff<strong>le</strong>r . . . . . . . . . . . . . . . . . . . . . . . 24<br />

Stain<strong>le</strong>ss Steel, Inconel and Aluminum Technical Artic<strong>le</strong>s . . . . . . . . . . . . . 25 - 29<br />

Reference Tab<strong>le</strong>s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 - 31<br />

Race Engine Specification Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32<br />

<strong>Burns</strong> Stain<strong>le</strong>ss LLC 949.631.5120 Monday - Friday 7:30 am to 4:30 pm fax 949.631.3184 burnsstain<strong>le</strong>ss.com<br />

1

304 Stain<strong>le</strong>ss Steel U-bends Surcharge may apply<br />

U-Bends 304 Stain<strong>le</strong>ss - 16 gage (.065)<br />

O. D. Part Number Legs Wt. lbs Each<br />

3/4 UB-075-20-16-304 6 x 6 0.72 $ 22.46<br />

1 UB-100-25-16-304 6 x 6 1.07 $ 25.00<br />

1 1/4 UB-125-20-16-304 6 x 6 1.25 $ 28.01<br />

1 3/8 UB-138-25-16-304 6 x 6 1.50 $ 29.27<br />

1 1/2 UB-150-25-16-304 6 x 6 1.65 $ 29.17<br />

1 1/2 UB-150-40-16-304 6 x 6 1.99 $ 31.94<br />

1 5/8 UB-163-25-16-304 6 x 6 1.79 $ 33.49<br />

1 5/8 UB-163-40-16-304 6 x 6 2.17 $ 37.13<br />

1 3/4 UB-175-25-16-304 6 x 6 1.94 $ 30.64<br />

1 3/4 UB-175-30-16-304 6 x 6 2.09 $ 32.04<br />

1 3/4 UB-175-40-16-304 6 x 6 2.34 $ 33.71<br />

1 7/8 UB-188-30-16-304 6 x 6 2.24 $ 38.77<br />

1 7/8 UB-188-40-16-304 6 x 6 2.57 $ 49.02<br />

1 7/8 UB-188-60-16-304 5.5 x 5.5 3.13 $ 52.24<br />

2 UB-200-30-16-304 6 x 6 2.40 $ 34.63<br />

2 UB-200-40-16-304 6 x 6 2.75 $ 36.56<br />

2 UB-200-60-16-304 5.5 x 5.5 3.34 $ 49.40<br />

2 1/8 UB-213-30-16-304 6 x 6 2.55 $ 46.39<br />

2 1/8 UB-213-40-16-304 6 x 6 2.93 $ 48.18<br />

2 1/8 UB-213-60-16-304 5.5 x 5.5 3.56 $ 56.41<br />

2 1/4 UB-225-40-16-304 6 x 6 3.11 $ 46.65<br />

2 1/2 UB-250-40-16-304 6 x 6 3.46 $ 50.20<br />

2 3/4 UB-275-40-16-304 6 x 6 3.82 $ 73.53<br />

3 UB-300-45-16-304 6 x 6 4.44 $ 84.50<br />

3 1/2 UB-350-45-16-304 6 x 6 5.19 $ 98.35<br />

U-Bends 304 Stain<strong>le</strong>ss - 18 gage (.049)<br />

O. D. Part Number Legs Wt. lbs Each<br />

1 1/4 UB-125-20-18-304 6 x 6 0.96 $ 26.30<br />

1 3/8 UB-138-25-18-304 6 x 6 1.16 $ 28.48<br />

1 1/2 UB-150-25-18-304 6 x 6 1.26 $ 29.70<br />

1 5/8 UB-163-25-18-304 6 x 6 1.36 $ 30.96<br />

1 3/4 UB-175-25-18-304 6 x 6 1.47 $ 28.85<br />

1 3/4 UB-175-40-18-304 6 x 6 1.82 $ 31.56<br />

1 7/8 UB-188-30-18-304 6 x 6 1.71 $ 35.09<br />

1 7/8 UB-188-40-18-304 6 x 6 1.96 $ 46.55<br />

1 7/8 UB-188-60-18-304 5.5 x 5.5 2.38 $ 49.71<br />

2 UB-200-30-18-304 6 x 6 1.82 $ 31.75<br />

2 UB-200-40-18-304 6 x 6 2.09 $ 33.40<br />

2 UB-200-60-18-304 5.5 x 5.5 2.54 $ 47.41<br />

2 1/8 UB-213-30-18-304 6 x 6 1.94 $ 43.51<br />

2 1/8 UB-213-40-18-304 6 x 6 2.22 $ 45.76<br />

2 1/8 UB-213-60-18-304 5.5 x 5.5 2.70 $ 54.43<br />

2 1/4 UB-225-40-18-304 6 x 6 2.36 $ 47.28<br />

2 3/8 UB-238-35-18-304 6 x 6 2.33 $ 47.51<br />

2 1/2 UB-250-40-18-304 6 x 6 2.63 $ 66.02<br />

U-Bends 304 Stain<strong>le</strong>ss - 20 gage (.035)<br />

O. D. Part Number Legs Wt. lbs Each<br />

1 1/2 UB-150-25-20-304 6 x 6 0.91 $ 25.69<br />

1 3/4 UB-175-30-20-304 6 x 6 1.14 $ 29.97<br />

2 UB-200-30-20-304 6 x 6 1.31 $ 30.49<br />

2 UB-200-40-20-304 6 x 6 1.50 $ 32.00<br />

Use 308 fil<strong>le</strong>r rod to<br />

weld 304 to 304<br />

Use 309 fil<strong>le</strong>r rod to<br />

weld 304 to mild steel<br />

Note: Tubing sizes are<br />

always <strong>de</strong>scribed by<br />

outsi<strong>de</strong> diameter.<br />

Leg <strong>le</strong>ngths are<br />

approximate,<br />

usually within<br />

+/- .25”<br />

Custom bending is<br />

availab<strong>le</strong> for quantities of<br />

50 pieces or more.<br />

2<br />

<strong>Burns</strong> Stain<strong>le</strong>ss LLC 949.631.5120 Monday - Friday 7:30 am to 4:30 pm fax 949.631.3184 burnsstain<strong>le</strong>ss.com

Surcharge may apply<br />

304 Stain<strong>le</strong>ss Steel J-bends<br />

304 Stain<strong>le</strong>ss Steel tubing combines excel<strong>le</strong>nt physical properties with a remarkab<strong>le</strong> resistance to corrosive<br />

agents found in automotive exhaust emissions. It is the most cost-effective gra<strong>de</strong> of nonmagnetic stain<strong>le</strong>ss<br />

steel for general applications, but some professional racing teams use the higher heat-resistant properties of<br />

aircraft gra<strong>de</strong> 321 stain<strong>le</strong>ss steel.<br />

We have years of<br />

experience with stain<strong>le</strong>ss<br />

hea<strong>de</strong>r fabrication and<br />

will be happy to advise<br />

our valued customers.<br />

J-Bends 304 Stain<strong>le</strong>ss - 16 gage (.065)<br />

O. D. Part Number Legs Wt. lbs Each<br />

1 3/4 JB-175-25-16-304 6 x 12 2.52 $35.76<br />

1 3/4 JB-175-30-16-304 6 x 12 2.67 $38.31<br />

1 7/8 JB-188-30-16-304 6 x 12 2.87 $47.50<br />

2 JB-200-30-16-304 6 x 12 3.07 $41.87<br />

2 1/8 JB-213-30-16-304 6 x 12 3.27 $51.67<br />

2 1/4 JB-225-40-16-304 6 x 12 3.86 $50.24<br />

2 1/2 JB-250-40-16-304 6 x 12 4.30 $53.77<br />

Stain<strong>le</strong>ss<br />

Tech Artic<strong>le</strong><br />

on page 25<br />

J-Bends 304 Stain<strong>le</strong>ss - 18 gage (.049)<br />

O. D. Part Number Legs Wt. lbs Each<br />

1 3/4 JB-175-30-18-304 6 x 12 2.03 $ 35.63<br />

1 7/8 JB-188-30-18-304 6 x 12 2.18 $ 42.50<br />

2 JB-200-30-18-304 6 x 12 2.33 $ 37.92<br />

2 1/8 JB-213-30-18-304 6 x 12 2.48 $ 49.69<br />

2 1/4 JB-225-40-18-304 6 x 12 2.93 $ 50.64<br />

2 3/8 JB-238-35-18-304 6 x 12 2.94 $ 50.97<br />

2 1/2 JB-250-40-18-304 6 x 12 3.27 $ 72.74<br />

For U-bends and J-bends you can <strong>de</strong>termine the CenterLine Radius<br />

(CLR) by measuring across the outsi<strong>de</strong> edges of the bend,<br />

subtracting the tubing O.D., and dividing by 2.<br />

A JB-225-40-16-304, for examp<strong>le</strong>, measures 10 1/4" across the<br />

outsi<strong>de</strong> edges, and has an O.D. of 2 1/4". Subtracting 2 1/4" from<br />

10 1/4" gives 8", and dividing by 2 equals 4"; so the CLR is 4 inches.<br />

UB: equal <strong>le</strong>g 180º<br />

JB: unequal <strong>le</strong>g 180º<br />

LB: 90º<br />

45: 45º<br />

15: 15º<br />

ST: straight<br />

Part Number System for Bends<br />

UB - 225 - 40 - 16 - 304<br />

Material:<br />

304 Stain<strong>le</strong>ss<br />

321 Stain<strong>le</strong>ss<br />

6061 Aluminum<br />

TItanium<br />

INCOnel<br />

Outsi<strong>de</strong> Diameter of Tubing<br />

Examp<strong>le</strong>: 225 = 2 1/4<br />

CLR: Center Line Radius<br />

Bend radius from center<br />

of bend to center of tube.<br />

Examp<strong>le</strong>: 40 = 4.0” CLR<br />

Gage, wall thickness<br />

16 = .065” 14 = .083”<br />

18 = .049” 17 = .058”<br />

20 = .035”<br />

<strong>Burns</strong> Stain<strong>le</strong>ss LLC 949.631.5120 Monday - Friday 7:30 am to 4:30 pm fax 949.631.3184 burnsstain<strong>le</strong>ss.com<br />

3

304 Stain<strong>le</strong>ss Steel 90º and 15º Bends Surcharge may apply<br />

90º Bends 304 Stain<strong>le</strong>ss - 16 gage (.065)<br />

O. D. Part Number Legs Wt. lbs Each<br />

3/4 LB-075-20-16-304 4 x 12 0.76 $ 23.05<br />

1 LB-100-25-16-304 4 x 12 1.08 $ 25.00<br />

1 1/4 LB-125-20-16-304 4 x 12 1.31 $ 29.06<br />

1 3/8 LB-138-25-16-304 4 x 12 1.51 $ 29.27<br />

1 1/2 LB-150-25-16-304 4 x 12 1.65 $ 29.17<br />

1 5/8 LB-163-25-16-304 4 x 12 1.80 $ 33.49<br />

1 3/4 LB-175-30-16-304 4 x 12 2.02 $ 32.04<br />

1 7/8 LB-188-30-16-304 4 x 12 2.17 $ 38.77<br />

2 LB-200-20-16-304 6 x 6 1.69 $ 55.74<br />

2 LB-200-30-16-304 4 x 12 2.32 $ 34.63<br />

2 1/8 LB-213-30-16-304 4 x 12 2.47 $ 46.39<br />

2 1/4 LB-225-22-16-304 6 x 6 1.57 $ 56.53<br />

2 1/4 LB-225-40-16-304 4 x 12 2.82 $ 46.65<br />

2 3/8 LB-238-30-16-304 4 x 12 2.77 $ 68.15<br />

2 1/2 LB-250-25-16-304 4 x 6 1.96 $ 60.69<br />

2 1/2 LB-250-40-16-304 4 x 12 3.14 $ 50.20<br />

3 LB-300-30-16-304 3 x 6 2.33 $ 62.46<br />

3 LB-300-40-16-304 6 x 12 3.78 $ 55.72<br />

3 1/2 LB-350-35-16-304 4 x 8 3.48 $ 69.97<br />

4 LB-400-40-16-304 4 x 8 4.39 $ 78.27<br />

4 1/2 LB-450-45-16-304 8 x 8 5.92 $ 97.48<br />

5 LB-500-52-16-304 6 x 9 6.66 $130.45<br />

90º Bends 304 Stain<strong>le</strong>ss - 18 gage (.049)<br />

O. D. Part Number Legs Wt. lbs Each<br />

1 1/4 LB-125-20-18-304 4 x 12 1.00 $ 27.22<br />

1 3/8 LB-138-25-18-304 4 x 12 1.16 $ 28.48<br />

1 1/2 LB-150-25-18-304 4 x 12 1.26 $ 29.70<br />

1 5/8 LB-163-25-18-304 4 x 12 1.37 $ 30.96<br />

15º Bends 304 Stain<strong>le</strong>ss - 16 gage (.065)<br />

O. D. Part Number Legs Wt. lbs Each<br />

1 1/2 15-150-25-16-304 3 x 4 0.64 $ 20.85<br />

1 3/4 15-175-30-16-304 3.5 x 4.5 0.86 $ 22.39<br />

1 7/8 15-188-30-16-304 4 x 5 1.03 $ 26.06<br />

2 15-200-30-16-304 4 x 5 1.10 $ 24.16<br />

2 1/8 15-213-30-16-304 4 x 5 1.17 $ 32.65<br />

2 1/4 15-225-40-16-304 4 x 5 1.27 $ 33.23<br />

2 1/2 15-250-40-16-304 4 x 5 1.41 $ 38.03<br />

3 15-300-40-16-304 4 x 5 1.71 $ 47.61<br />

15º Bends 304 Stain<strong>le</strong>ss - 18 gage (.049)<br />

O. D. Part Number Legs Wt. lbs Each<br />

1 1/4 15-125-20-18-304 3 x 4 0.39 $ 20.07<br />

2 15-200-30-18-304 4 x 5 0.83 $ 22.84<br />

2 1/8 15-213-30-18-304 4 x 5 0.89 $ 31.34<br />

2 1/4 15-225-40-18-304 4 x 5 0.96 $ 33.53<br />

2 3/8 15-238-35-18-304 4 x 5 1.01 $ 41.06<br />

2 1/2 15-250-40-18-304 4 x 5 1.07 $ 33.90<br />

4<br />

<strong>Burns</strong> Stain<strong>le</strong>ss LLC 949.631.5120 Monday - Friday 7:30 am to 4:30 pm fax 949.631.3184 burnsstain<strong>le</strong>ss.com

Surcharge may apply<br />

304 Stain<strong>le</strong>ss Steel 45º Bends and Straight Tubing<br />

45º Bends 304 Stain<strong>le</strong>ss - 16 gage (.065)<br />

O. D. Part Number Legs Wt. lbs Each<br />

1 1/2 45-150-25-16-304 6 x 6 1.16 $ 25.09<br />

1 3/4 45-175-30-16-304 6 x 6 1.40 $ 26.81<br />

2 45-200-30-16-304 6 x 6 1.61 $ 28.59<br />

2 1/4 45-225-40-16-304 6 x 6 1.91 $ 37.04<br />

2 1/2 45-250-40-16-304 6 x 6 2.13 $ 42.27<br />

3 45-300-40-16-304 6 x 6 2.57 $ 49.64<br />

Straight tubing is sold by<br />

the foot, based on the<br />

total <strong>le</strong>ngth of the tubing.<br />

It is cut to the <strong>le</strong>ngth you<br />

specify.<br />

Lengths up to 8 feet can<br />

be shipped UPS.<br />

Straight 304 Stain<strong>le</strong>ss - 16 gage (.065)<br />

O. D. Part Number Lbs / ft. per foot<br />

3/4 ST-075-16-304 0.48 $ 4.65<br />

1 ST-100-16-304 0.65 $ 5.82<br />

1 1/4 ST-125-16-304 0.82 $ 8.25<br />

1 3/8 ST-138-16-304 0.91 $ 8.38<br />

1 1/2 ST-150-16-304 1.00 $ 8.32<br />

1 5/8 ST-163-16-304 1.08 $ 10.91<br />

1 3/4 ST-175-16-304 1.17 $ 9.20<br />

1 7/8 ST-188-16-304 1.26 $ 12.90<br />

2 ST-200-16-304 1.34 $ 10.63<br />

2 1/8 ST-213-16-304 1.43 $ 13.95<br />

2 1/4 ST-225-16-304 1.52 $ 12.81<br />

2 3/8 ST-238-16-304 1.60 $ 16.48<br />

2 1/2 ST-250-16-304 1.69 $ 14.26<br />

2 5/8 ST-263-16-304 1.78 $ 18.28<br />

2 3/4 ST-275-16-304 1.86 $ 16.63<br />

3 ST-300-16-304 2.04 $ 16.22<br />

3 1/4 ST-325-16-304 2.21 $ 31.34<br />

3 1/2 ST-350-16-304 2.39 $ 20.59<br />

4 ST-400-16-304 2.73 $ 24.26<br />

4 1/2 ST-450-16-304 3.08 $ 27.40<br />

5 ST-500-16-304 3.43 $ 31.78<br />

For quantities exceeding 15 feet,<br />

p<strong>le</strong>ase call for pricing.<br />

Straight 304 Stain<strong>le</strong>ss - 18 gage (.049)<br />

O. D. Part Number Lbs / ft. per foot<br />

1 1/4 ST-125-18-304 0.63 $ 7.15<br />

1 3/8 ST-138-18-304 0.70 $ 7.91<br />

1 1/2 ST-150-18-304 0.76 $ 8.63<br />

1 5/8 ST-163-18-304 0.82 $ 9.39<br />

1 3/4 ST-175-18-304 0.89 $ 8.13<br />

1 7/8 ST-188-18-304 0.96 $ 10.88<br />

2 ST-200-18-304 1.02 $ 9.04<br />

2 1/8 ST-213-18-304 1.09 $ 12.37<br />

2 1/4 ST-225-18-304 1.15 $ 13.12<br />

2 3/8 ST-238-18-304 1.22 $ 13.85<br />

2 1/2 ST-250-18-304 1.28 $ 9.93<br />

3 ST-300-18-304 1.54 $ 17.58<br />

Straight 304 Stain<strong>le</strong>ss - 20 gage (.035)<br />

O. D. Part Number Lbs / ft. per foot<br />

1 1/2 ST-150-20-304 0.55 $ 6.23<br />

1 3/4 ST-175-20-304 0.64 $ 8.06<br />

2 ST-200-20-304 0.73 $ 8.35<br />

2 1/8 ST-213-20-304 0.78 $ 10.28<br />

<strong>Burns</strong> Stain<strong>le</strong>ss LLC 949.631.5120 Monday - Friday 7:30 am to 4:30 pm fax 949.631.3184 burnsstain<strong>le</strong>ss.com<br />

5

304 Stain<strong>le</strong>ss Oval Tubing, Mandrel Bends and Transitions<br />

Surcharge may apply<br />

304 Stain<strong>le</strong>ss oval tubing is availab<strong>le</strong> in three sizes.<br />

The “Size” listed in the tab<strong>le</strong>s indicates<br />

that the oval tubing area is roughly<br />

equal to that size in round tubing.<br />

“Size” Height Width<br />

3 " 2 1/8” 3 1/2”<br />

3 1/2" 2 3/8” 4 1/8”<br />

4" 2 1/2” 4 3/4”<br />

Transitions from round to oval are availab<strong>le</strong> for each<br />

size, in either butt-weld or slip-over configurations.<br />

We make both long ( 12” ) and short ( 6” ) versions.<br />

Transitions - Round to Oval<br />

304 SS - 16 gage<br />

Size Part Number Short Long Short-slip Long-slip<br />

3 ROV-300-300 $ 50.00 $ 65.00 $ 75.00 $ 90.00<br />

3 1/2 ROV-350-350 $ 50.00 $ 65.00 $ 75.00 $ 90.00<br />

4 ROV 400-400 $ 50.00 $ 65.00 $ 75.00 $ 90.00<br />

Straight Oval 304 SS - 16 gage (.065)<br />

O. D. Part Number Lbs / ft. per foot<br />

3 ST-300-304OVAL 2.21 $ 34.26<br />

3 1/2 ST-350-304OVAL 2.39 $ 38.67<br />

4 ST-400-304OVAL 2.73 $ 41.19<br />

Oval Bends Oval 304 SS - 16 gage (.065)<br />

Size Part Number Ang<strong>le</strong> CLR Legs Wt./lbs Each<br />

3 45-300-S-304OVAL 45º 4.5 6 x 10 3.52 $ 80.83<br />

3 60-300-S-304OVAL 60º 4.5 6 x 10 3.78 $ 83.70<br />

3 90-300-S-304OVAL 90º 4.5 6 x 10 4.32 $ 83.70<br />

3 1/2 45-350-S-304OVAL 45º 5.5 6 x 10 4.12 $ 83.70<br />

3 1/2 60-350-S-304OVAL 60º 5.5 6 x 10 4.43 $ 87.63<br />

3 1/2 90-350-S-304OVAL 90º 5.5 6 x 10 5.05 $ 87.63<br />

3 1/2 45-350-L-304OVAL 45º 9 6 x 10 4.82 $ 87.63<br />

3 1/2 60-350-L-304OVAL 60º 9 6 x 10 5.37 $ 93.12<br />

3 1/2 90-350-L-304OVAL 90º 9 6 x 10 6.46 $ 93.12<br />

6<br />

<strong>Burns</strong> Stain<strong>le</strong>ss LLC 949.631.5120 Monday - Friday 7:30 am to 4:30 pm fax 949.631.3184 burnsstain<strong>le</strong>ss.com

Surcharge may apply<br />

321 Stain<strong>le</strong>ss Steel U-bends and 90º Bends<br />

U-Bends 321 Stain<strong>le</strong>ss - 16 gage (.065)<br />

O. D. Part Number Legs Wt. lbs Each<br />

1 1/2 UB-150-25-16-321 6 x 6 1.65 $ 57.26<br />

1 5/8 UB-163-25-16-321 6 x 6 1.80 $ 42.87<br />

1 3/4 UB-175-25-16-321 6 x 6 1.94 call for price<br />

1 3/4 UB-175-30-16-321 6 x 6 2.09 call for price<br />

1 3/4 UB-175-40-16-321 6 x 6 2.40 call for price<br />

1 7/8 UB-188-30-16-321 6 x 6 2.24 call for price<br />

1 7/8 UB-188-40-16-321 6 x 6 2.57 call for price<br />

1 7/8 UB-188-60-16-321 5.5 x 5.5 3.13 call for price<br />

2 UB-200-30-16-321 6 x 6 2.40 $ 67.48<br />

2 UB-200-40-16-321 6 x 6 2.75 $ 70.62<br />

2 UB-200-60-16-321 5.5 x 5.5 3.34 $ 83.99<br />

2 1/4 UB-225-40-16-321 6 x 6 3.11 $ 99.21<br />

2 1/2 UB-250-40-16-321 6 x 6 3.46 $ 78.04<br />

Use 347 fil<strong>le</strong>r rod to<br />

weld 321 to 321<br />

Use 308 fil<strong>le</strong>r rod to<br />

weld 321 to 304<br />

Use 309 fil<strong>le</strong>r rod to<br />

weld 321 to mild steel<br />

U-Bends 321 Stain<strong>le</strong>ss - 18 gage (.049)<br />

O. D. Part Number Legs Wt. lbs Each<br />

1 5/8 UB-163-25-18-321 6 x 6 1.36 $ 65.17<br />

1 3/4 UB-175-25-18-321 6 x 6 1.47 $ 49.67<br />

1 3/4 UB-175-30-18-321 6 x 6 1.59 $ 52.80<br />

1 3/4 UB-175-40-18-321 6 x 6 1.82 $ 56.55<br />

1 7/8 UB-188-30-18-321 6 x 6 1.71 $ 57.04<br />

1 7/8 UB-188-40-18-321 6 x 6 1.96 $ 63.87<br />

1 7/8 UB-188-60-18-321 5.5 x 5.5 2.38 $ 69.62<br />

2 UB-200-30-18-321 6 x 6 1.82 $ 59.00<br />

2 UB-200-40-18-321 6 x 6 2.09 $ 61.29<br />

2 UB-200-60-18-321 5.5 x 5.5 2.54 $ 72.32<br />

2 1/8 UB-213-30-18-321 6 x 6 1.94 $ 78.22<br />

U-Bends 321 Stain<strong>le</strong>ss - 20 gage (.035)<br />

O. D. Part Number Legs Wt. lbs Each<br />

1 3/4 UB-175-30-20-321 6 x 6 1.14 $ 52.07<br />

1 3/4 UB-175-40-20-321 6 x 6 1.31 $ 55.75<br />

1 7/8 UB-188-30-20-321 6 x 6 1.23 call for price<br />

1 7/8 UB-188-40-20-321 6 x 6 1.41 call for price<br />

1 7/8 UB-188-60-20-321 5.5 x 5.5 1.71 call for price<br />

2 UB-200-30-20-321 6 x 6 1.31 $ 56.84<br />

2 UB-200-40-20-321 6 x 6 1.50 $ 58.96<br />

Note: <strong>le</strong>g <strong>le</strong>ngths<br />

are approximate,<br />

usually within<br />

+/- .25”<br />

90º Bends 321 Stain<strong>le</strong>ss - 20 gage (.035)<br />

O. D. Part Number Legs Wt. lbs Each<br />

1 7/8 LB-188-40-20-321 6 x 6 1.05 call for price<br />

1 7/8 LB-188-60-20-321 6 x 6 1.23 call for price<br />

2 LB-200-40-20-321 6 x 6 1.12 $ 50.45<br />

2 LB-200-60-20-321 6 x 6 1.31 $ 61.63<br />

2 1/8 LB-213-60-20-321 6 x 6 1.39 $ 78.86<br />

<strong>Burns</strong> Stain<strong>le</strong>ss LLC 949.631.5120 Monday - Friday 7:30 am to 4:30 pm fax 949.631.3184 burnsstain<strong>le</strong>ss.com<br />

7

321 Stain<strong>le</strong>ss Steel Straight Tubing, Service Costs<br />

Surcharge may apply<br />

321 Stain<strong>le</strong>ss exhibits superior resistance to fatigue and cracking at e<strong>le</strong>vated temperatures compared to 304.<br />

It is highly recommen<strong>de</strong>d for turbo- and super-charged applications, in racing and street applications, and is<br />

frequently the material of choice of Winston Cup and Pro Stock fabricators because 321 can be used<br />

effectively in thinner gages than 304, reducing the weight of a set of hea<strong>de</strong>rs by 25% or more.<br />

Stain<strong>le</strong>ss<br />

Tech Artic<strong>le</strong><br />

on page 25<br />

Straight tubing is sold by<br />

the foot, based on the<br />

total <strong>le</strong>ngth of the tubing.<br />

It is cut to the <strong>le</strong>ngth you<br />

specify.<br />

Lengths up to 8 feet can<br />

be shipped UPS.<br />

For quantities exceeding 15 feet,<br />

p<strong>le</strong>ase call for pricing.<br />

Straight 321 Stain<strong>le</strong>ss - 16 gage (.065)<br />

O. D. Part Number Lbs / ft. per foot<br />

1 1/2 ST-150-16-321 1.00 $ 24.16<br />

1 5/8 ST-163-16-321 1.09 $ 15.75<br />

1 3/4 ST-175-16-321 1.17 call for price<br />

1 7/8 ST-188-16-321 1.26 call for price<br />

2 ST-200-16-321 1.34 $ 32.24<br />

2 1/4 ST-225-16-321 1.52 $ 44.50<br />

2 1/2 ST-250-16-321 1.69 $ 33.60<br />

Straight 321 Stain<strong>le</strong>ss - 18 gage (.049)<br />

O. D. Part Number Lbs / ft. per foot<br />

1 1/2 ST-150-18-321 0.76 $ 34.60<br />

1 5/8 ST-163-18-321 0.82 $ 32.42<br />

1 3/4 ST-175-18-321 0.89 $ 19.64<br />

1 7/8 ST-188-18-321 0.96 $ 21.92<br />

2 ST-200-18-321 1.02 $ 23.97<br />

Straight 321 Stain<strong>le</strong>ss - 20 gage (.035)<br />

O. D. Part Number Lbs / ft. per foot<br />

1 1/2 ST-150-20-321 0.55 $ 17.52<br />

1 3/4 ST-175-20-321 0.64 $ 19.26<br />

1 7/8 ST-188-20-321 0.69 call for price<br />

2 ST-200-20-321 0.73 $ 21.76<br />

2 1/8 ST-213-20-321 0.78 $ 34.22<br />

2 1/4 ST-225-20-321 0.83 $ 25.71<br />

2 1/2 ST-250-20-321 0.92 $ 32.43<br />

3 ST-300-20-321 1.11 $ 31.12<br />

3 1/2 ST-350-20-321 1.30 $ 34.50<br />

Service Costs<br />

Welding sing<strong>le</strong> weld, including hand fitting<br />

mild steel $10.00<br />

stain<strong>le</strong>ss $15.00<br />

Welding and cutting ho<strong>le</strong> for O2 ring, stain<strong>le</strong>ss $40.00<br />

Welding stain<strong>le</strong>ss bracket to col<strong>le</strong>ctor $10.00<br />

Cutting straight tubing or tailpipe rings, per cut $5.00<br />

Special cutting on transition or megaphone, per cut $10.00<br />

Add reverse cone on megaphone $60.00<br />

Expand tubing for slip joint, up to 2 1/4” $5.00<br />

Expand tubing for slip joint, over 2 1/4” $8.00<br />

8<br />

<strong>Burns</strong> Stain<strong>le</strong>ss LLC 949.631.5120 Monday - Friday 7:30 am to 4:30 pm fax 949.631.3184 burnsstain<strong>le</strong>ss.com

Surcharge may apply<br />

6061 Aluminum U-bends, 90º Bends, and 45º Bends<br />

U-Bends<br />

6061 Aluminum - O condition<br />

O. D. Part Number Legs Wt. lbs Each<br />

3/4 UB-075-20-16-6061 4 x 4 0.20 $ 23.72<br />

1 UB-100-25-16-6061 4 x 4 0.30 $ 26.02<br />

1 1/4 UB-125-20-18-6061 4 x 4 0.26 $ 26.91<br />

1 3/8 UB-138-25-16-6061 4 x 4 0.42 $ 27.62<br />

1 1/2 UB-150-25-16-6061 4 x 4 0.46 $ 27.58<br />

1 5/8 UB-163-25-17-6061 4 x 4 0.44 $ 29.22<br />

1 3/4 UB-175-30-16-6061 4 x 4 0.59 $ 30.49<br />

1 7/8 UB-188-30-17-6061 4 x 4 0.57 $ 31.48<br />

2 UB-200-30-16-6061 4 x 4 0.67 $ 32.57<br />

2 1/8 UB-213-30-16-6061 4 x 4 0.72 $ 43.18<br />

2 1/4 UB-225-40-16-6061 4 x 4 0.90 $ 43.13<br />

2 1/2 UB-250-40-16-6061 5.7 x 5.7 1.17 $ 52.21<br />

2 3/4 UB-275-40-16-6061 5.7 x 5.7 1.11 $ 83.41<br />

3 UB-300-45-16-6061 6 x 6 1.54 $ 91.71<br />

4 UB-400-60-16-6061 8 x 5 2.53 $ 132.43<br />

For intake and cooling<br />

systems 6061 aluminum is the<br />

<strong>le</strong>ast expensive and most<br />

versati<strong>le</strong> of the heat treatab<strong>le</strong><br />

alloys.<br />

In the annea<strong>le</strong>d “0” condition it<br />

has good formability for<br />

bending. The full-temper T6<br />

properties may be obtained by<br />

solution heat treating and<br />

artificial aging after welding. If<br />

you need advice about<br />

working with aluminum,<br />

p<strong>le</strong>ase give us a call.<br />

90º Bends 6061 Aluminum - O condition<br />

O. D. Part Number Legs Wt. lbs Each<br />

3/4 LB-075-20-16-6061 4 x 12 0.26 $ 26.96<br />

1 LB-100-25-16-6061 4 x 12 0.37 $ 28.91<br />

1 1/4 LB-125-20-18-6061 4 x 12 0.35 $ 31.59<br />

1 3/8 LB-138-25-16-6061 4 x 12 0.52 $ 30.97<br />

1 1/2 LB-150-25-16-6061 4 x 12 0.57 $ 30.92<br />

1 5/8 LB-163-25-17-6061 4 x 12 0.56 $ 33.03<br />

1 3/4 LB-175-25-16-6061S 3 x 6 0.44 $ 26.32<br />

1 3/4 LB-175-25-16-6061 4 x 12 0.67 $ 32.49<br />

1 7/8 LB-188-30-17-6061 4 x 12 0.67 $ 33.77<br />

2 LB-200-30-16-6061 4 x 12 0.80 $ 35.02<br />

2 1/8 LB-213-30-16-6061 4 x 12 0.85 $ 46.33<br />

2 1/4 LB-225-40-16-6061 4 x 12 0.97 $ 46.40<br />

2 1/2 LB-250-40-16-6061 4 x 12 1.09 $ 51.78<br />

2 3/4 LB-275-40-16-6061 6 x 12 1.29 $ 75.11<br />

3 LB-300-30-16-6061 3 x 6 0.81 $ 75.50<br />

3 LB-300-40-16-6061 5.5 x 12 1.40 $ 65.05<br />

3 1/2 LB-350-35-16-6061 4 x 8 1.31 $ 84.60<br />

4 LB-400-40-16-6061 4 x 11 1.68 $101.60<br />

4 1/2 LB-450-45-16-6061 5 x 9 1.87 $143.10<br />

5 LB-500-53-11-6061 5 x 6 3.47 $128.87<br />

See the Aluminum<br />

Tech Artic<strong>le</strong> on<br />

page 28<br />

Note: Tubing sizes are<br />

always <strong>de</strong>scribed by<br />

outsi<strong>de</strong> diameter.<br />

45º Bends 6061 Aluminum - O condition<br />

O. D. Part Number Legs Wt. lbs Each<br />

1 1/2 45-150-25-16-6061 5.5 x 5.5 0.37 $25.32<br />

1 3/4 45-175-25-16-6061 5.5 x 5.5 0.44 $26.32<br />

2 45-200-30-16-6061 5.5 x 5.5 0.50 $27.84<br />

2 1/4 45-225-40-16-6061 5.5 x 5.5 0.62 $36.51<br />

2 1/2 45-250-40-16-6061 5.5 x 5.5 0.69 $41.10<br />

3 45-300-40-16-6061 5.5 x 5.5 0.83 $52.73<br />

<strong>Burns</strong> Stain<strong>le</strong>ss LLC 949.631.5120 Monday - Friday 7:30 am to 4:30 pm fax 949.631.3184 burnsstain<strong>le</strong>ss.com<br />

9

6061 Aluminum Straight Tubing<br />

Surcharge may apply<br />

Use 5356 rod for<br />

maximum strength<br />

Use 4043 rod for max<br />

corrosion resistance<br />

Aluminum is not recommen<strong>de</strong>d<br />

as an exhaust system material.<br />

Straight 6061 Aluminum - T 6<br />

O. D. Part Number Lbs / ft. per foot<br />

3/4 ST-075-16-6061 0.16 $ 3.54<br />

1 ST-100-16-6061 0.22 $ 4.55<br />

1 1/4 ST-125-18-6061 0.22 $ 6.20<br />

1 3/8 ST-138-16-6061 0.31 $ 5.76<br />

1 1/2 ST-150-16-6061 0.34 $ 5.72<br />

1 5/8 ST-163-17-6061 0.34 $ 6.96<br />

1 3/4 ST-175-16-6061 0.40 $ 6.64<br />

1 7/8 ST-188-17-6061 0.39 $ 7.31<br />

2 ST-200-16-6061 0.46 $ 8.03<br />

2 1/8 ST-213-16-6061 0.50 $ 11.29<br />

2 1/4 ST-225-16-6061 0.52 $ 9.42<br />

2 1/2 ST-250-16-6061 0.58 $ 10.40<br />

2 3/4 ST-275-16-6061 0.64 $ 11.57<br />

3 ST-300-16-6061 0.70 $ 14.17<br />

3 1/2 ST-350-16-6061 0.82 $ 18.09<br />

4 ST-400-16-6061 0.95 $ 22.55<br />

4 1/2 ST-450-16-6061 1.06 $ 38.74<br />

5 ST-500-16-6061 1.18 $ 38.74<br />

10<br />

<strong>Burns</strong> Stain<strong>le</strong>ss LLC 949.631.5120 Monday - Friday 7:30 am to 4:30 pm fax 949.631.3184 burnsstain<strong>le</strong>ss.com

Surcharge may apply<br />

Inconel Tubing and Mandrel Bends<br />

U-Bends Inconel - 18 gage (.049)<br />

O. D. Part Number<br />

1 3/4 UB-175-30-18-INCO<br />

1 3/4 UB-175-40-18-INCO<br />

1 7/8 UB-188-30-18-INCO<br />

1 7/8 UB-188-40-18-INCO<br />

2 UB-200-30-18-INCO<br />

2 UB-200-40-18-INCO<br />

90º Bends Inconel - 20 gage (.035)<br />

O. D. Part Number<br />

1 3/4 LB-175-30-20-INCO<br />

1 3/4 LB-175-40-20-INCO<br />

1 7/8 LB-188-30-20-INCO<br />

1 7/8 LB-188-40-20-INCO<br />

2 LB-200-30-20-INCO<br />

2 LB-200-40-20-INCO<br />

110º Bends Inconel - 22 gage<br />

O. D. Part Number<br />

1 7/8 110-188-20-22-INCO<br />

1 7/8 110-188-25-22-INCO<br />

1 7/8 110-188-30-22-INCO<br />

1 7/8 110-188-40-22-INCO<br />

1 7/8 110-188-50-22-INCO<br />

2 110-200-20-22-INCO<br />

2 110-200-25-22-INCO<br />

2 110-200-30-22-INCO<br />

2 110-200-40-22-INCO<br />

2 110-200-50-22-INCO<br />

2 110-200-60-22-INCO<br />

2 1/8 110-213-21-22-INCO<br />

2 1/8 110-213-25-22-INCO<br />

2 1/8 110-213-30-22-INCO<br />

2 1/8 110-213-40-22-INCO<br />

2 1/8 110-213-50-22-INCO<br />

2 1/8 110-213-60-22-INCO<br />

This range<br />

of 110º<br />

thin-wall<br />

bends are<br />

also availab<strong>le</strong><br />

in 20 gage<br />

Inconel.<br />

P<strong>le</strong>ase call<br />

for price and<br />

<strong>de</strong>livery.<br />

Inconel 625 excels in<br />

applications such as Rotary<br />

engines and extreme duty<br />

turbocharger exhausts. It<br />

maintains its strength at<br />

temperatures greater than<br />

1800º F, where 321 SS is<br />

unsuitab<strong>le</strong>.<br />

Inconel can be used in thinner<br />

gages in hea<strong>de</strong>r systems,<br />

compared to 304 or 321<br />

stain<strong>le</strong>ss, resulting in a lighter<br />

weight product with equal or<br />

better mechanical properties.<br />

See the Inconel technical paper<br />

on page 27.<br />

The Inconel parts listed in this<br />

section are normally special<br />

or<strong>de</strong>r items. We may have<br />

stock on some items from time<br />

to time. P<strong>le</strong>ase call for price<br />

and availability. Lead-time for<br />

special or<strong>de</strong>r items is<br />

approximately 2-3 weeks and<br />

is <strong>de</strong>pen<strong>de</strong>nt on material<br />

availability and production<br />

schedu<strong>le</strong>.<br />

Straight<br />

Inconel-18,20 and 22 gage<br />

O. D. Part Number Lbs / ft per foot<br />

1 3/4 ST-175-22-INCO 0.55 call for price<br />

1 3/4 ST-175-20-INCO 0.69 call for price<br />

1 3/4 ST-175-18-INCO 0.96 call for price<br />

1 7/8 ST-188-22-INCO 0.59 call for price<br />

1 7/8 ST-188-20-INCO 0.74 call for price<br />

1 7/8 ST-188-18-INCO 1.03 call for price<br />

2 ST-200-22-INCO 0.63 call for price<br />

2 ST-200-20-INCO 0.79 call for price<br />

2 ST-200-18-INCO 1.10 call for price<br />

2 1/8 ST-213-22-INCO 0.69 call for price<br />

2 1/8 ST-213-20-INCO 0.42 call for price<br />

Inconel pricing is extremely volati<strong>le</strong>. P<strong>le</strong>ase call for current prices and availability.<br />

<strong>Burns</strong> Stain<strong>le</strong>ss LLC 949.631.5120 Monday - Friday 7:30 am to 4:30 pm fax 949.631.3184 burnsstain<strong>le</strong>ss.com<br />

11

Racing Merge Col<strong>le</strong>ctors - General Information<br />

Surcharge may apply<br />

<strong>Burns</strong> Stain<strong>le</strong>ss Merge Col<strong>le</strong>ctors are in wi<strong>de</strong>spread use by top engine buil<strong>de</strong>rs in NHRA Pro Stock Car,<br />

Bike, and most other classes, and are very popular in NASCAR, ALMS, FIA-GT, Trans-Am, and IRL.<br />

Fabricated from pre-bent tubing to form a pyramid insi<strong>de</strong>, <strong>Burns</strong> Stain<strong>le</strong>ss merge<br />

col<strong>le</strong>ctors combine high flow and high velocity to increase and broa<strong>de</strong>n an<br />

engine's torque curve all the way to the horsepower peak and beyond.<br />

They feature the highest quality fabrication and welding, and each one is<br />

comp<strong>le</strong>tely hand finished insi<strong>de</strong> for proper flow.<br />

For drag racing and similar applications where a tailpipe is not required,<br />

megaphones fitted with reverse cones are invariably the best option. They make<br />

the most horsepower, maintain the highest and smoothest torque curve, and, on<br />

well <strong>de</strong>veloped engine combinations with optimally short hea<strong>de</strong>r tube <strong>le</strong>ngths and<br />

a well chosen col<strong>le</strong>ctor out<strong>le</strong>t diameter, offer the highest potential power past the<br />

peak without sacrificing the lower end.<br />

Here are our five common col<strong>le</strong>ctor out<strong>le</strong>t options.<br />

Each is availab<strong>le</strong> with 2 into 1, 3 into 1, 4 into 1, 5 into 1, and 6 into 1 col<strong>le</strong>ctors.<br />

To fulfull your col<strong>le</strong>ctor or<strong>de</strong>r, we need to <strong>de</strong>termine 4 basic dimensions.<br />

( 5 into 1 and 6 into 1 col<strong>le</strong>ctors<br />

are special or<strong>de</strong>r items;<br />

p<strong>le</strong>ase call for price and info )<br />

1<br />

1<br />

In<strong>le</strong>t Diameter - the outsi<strong>de</strong> diameter of your final hea<strong>de</strong>r tubes.<br />

straight extension<br />

2<br />

Col<strong>le</strong>ctor Out<strong>le</strong>t Diameter - normally <strong>de</strong>termined by our X-<strong>de</strong>sign<br />

computer program ( see page 16 ). There is no standard out<strong>le</strong>t size;<br />

each col<strong>le</strong>ctor system is based on your engine’s specs.<br />

2<br />

V-Band Flange<br />

3<br />

Sty<strong>le</strong> of Out<strong>le</strong>t - Long or Short Transition, or Megaphone.<br />

Generally, if your vehic<strong>le</strong> uses a tailpipe, a transition and<br />

tailpipe ring will be nee<strong>de</strong>d.<br />

If you don’t have to run a tailpipe, we recommend using a<br />

megaphone for maximum horsepower and powerband.<br />

3<br />

Short Transition<br />

4<br />

4<br />

Final Out<strong>le</strong>t Diameter and Configuration -<br />

usually a tailpipe ring for use with a<br />

transition. A tailpipe ring is <strong>de</strong>scribed by its<br />

outsi<strong>de</strong> diameter; it slips insi<strong>de</strong> your tailpipe,<br />

and is normally 2” long.<br />

If you plan on a megaphone, a reverse cone is<br />

highly recommen<strong>de</strong>d.<br />

Long Transition<br />

Megaphone<br />

The best way to or<strong>de</strong>r merge col<strong>le</strong>ctors:<br />

1. Fill out the Race Engine Spec. Form on the last<br />

page of the catalog, or on our <strong>web</strong>-<strong>site</strong>, and<br />

fax,mail or email it to us.<br />

2. We’ll analyze your engine with X-<strong>de</strong>sign and call<br />

you with the results and our recommendation.<br />

3. Your custom col<strong>le</strong>ctor or<strong>de</strong>r can then be comp<strong>le</strong>ted<br />

to your specs and shipped, usually within 14 days.<br />

12<br />

<strong>Burns</strong> Stain<strong>le</strong>ss LLC 949.631.5120 Monday - Friday 7:30 am to 4:30 pm fax 949.631.3184 burnsstain<strong>le</strong>ss.com

Surcharge may apply<br />

Base Merge Col<strong>le</strong>ctors<br />

4-into-1 Base Col<strong>le</strong>ctors<br />

Primary OD Part Number Mild Steel 304 SS 321 SS<br />

1 1/4 MC4-125 $ 250.00 $ 278.00 $ 307.00<br />

1 3/8 MC4-138 $ 253.00 $ 282.00 $ 311.00<br />

1 1/2 MC4-150 $ 253.00 $ 282.00 $ 311.00<br />

1 5/8 MC4-163 $ 260.00 $ 290.00 $ 319.00<br />

1 3/4 MC4-175 $ 260.00 $ 290.00 $ 319.00<br />

1 7/8 MC4-188 $ 259.00 $ 289.00 $ 319.00<br />

2 MC4-200 $ 260.00 $ 291.00 $ 320.00<br />

2 1/8 MC4-213 $ 280.00 $ 312.00 $ 343.00<br />

2 1/4 MC4-225 $ 278.00 $ 311.00 $ 342.00<br />

2 3/8 MC4-238 $ 307.00 $ 339.00 $ 372.00<br />

2 1/2 MC4-250 $ 290.00 $ 322.00 $ 356.00<br />

2 5/8 MC4-263 $ 359.00 $ 400.00 n/a<br />

2 3/4 MC4-275 $ 370.00 $ 412.00 n/a<br />

3-into-1 Base Col<strong>le</strong>ctors<br />

Primary OD Part Number Mild Steel 304 SS 321 SS<br />

1 1/4 MC3-125 $ 205.00 $ 235.00 $ 266.00<br />

1 3/8 MC3-138 $ 207.00 $ 238.00 $ 270.00<br />

1 1/2 MC3-150 $ 207.00 $ 238.00 $ 270.00<br />

1 5/8 MC3-163 $ 212.00 $ 245.00 $ 276.00<br />

1 3/4 MC3-175 $ 212.00 $ 245.00 $ 276.00<br />

1 7/8 MC3-188 $ 212.00 $ 245.00 $ 276.00<br />

2 MC3-200 $ 213.00 $ 246.00 $ 277.00<br />

2 1/8 MC3-213 $ 228.00 $ 263.00 $ 297.00<br />

2 1/4 MC3-225 $ 227.00 $ 261.00 $ 295.00<br />

2 3/8 MC3-238 $ 264.00 $ 303.00 $ 342.00<br />

2 1/2 MC3-250 $ 236.00 $ 271.00 $ 307.00<br />

Base Col<strong>le</strong>ctors are availab<strong>le</strong><br />

in 304 Stain<strong>le</strong>ss and Mild<br />

Steel. We also make all sizes<br />

except 2 5/8 and 2 3/4 in<br />

321 SS.<br />

Col<strong>le</strong>ctors are ma<strong>de</strong> to<br />

or<strong>de</strong>r. P<strong>le</strong>ase call for <strong>le</strong>ad<br />

time on col<strong>le</strong>ctors.<br />

The standard wall thickness is<br />

.065” (16 gage), and we can<br />

supply many thin wall 321<br />

sizes.<br />

Inconel col<strong>le</strong>ctors are availab<strong>le</strong><br />

by special or<strong>de</strong>r in some sizes.<br />

P<strong>le</strong>ase call for <strong>de</strong>tails.<br />

2-into-1 Base Col<strong>le</strong>ctors<br />

Primary OD Part Number Mild Steel 304 SS 321 SS<br />

1 1/4 MC2-125 $ 91.00 $ 110.00 $ 139.00<br />

1 3/8 MC2-138 $ 91.00 $ 110.00 $ 139.00<br />

1 1/2 MC2-150 $ 91.00 $ 110.00 $ 139.00<br />

1 5/8 MC2-163 $ 98.00 $ 116.00 $ 145.00<br />

1 3/4 MC2-175 $ 98.00 $ 122.00 $ 151.00<br />

1 7/8 MC2-188 $ 104.00 $ 127.00 $ 156.00<br />

2 MC2-200 $ 104.00 $ 133.00 $ 162.00<br />

2 1/8 MC2-213 $ 110.00 $ 139.00 $ 168.00<br />

2 1/4 MC2-225 $ 116.00 $ 145.00 $ 174.00<br />

2 3/8 MC2-238 $ 139.00 $ 168.00 $ 197.00<br />

2 1/2 MC2-250 $ 139.00 $ 169.00 $ 197.00<br />

2 5/8 MC2-263 $ 163.00 $ 203.00 n/a<br />

2 3/4 MC2-275 $ 162.00 $ 203.00 n/a<br />

3 MC2-300 $ 145.00 $ 173.00 $ 203.00<br />

3 1/2 MC2-350 $ 162.00 $ 203.00 $ 261.00<br />

5 into 1 and 6 into 1 merge<br />

col<strong>le</strong>ctors are special or<strong>de</strong>rs.<br />

If you’re consi<strong>de</strong>ring a 6 into<br />

1, p<strong>le</strong>ase call to discuss the<br />

options. We build lots of 6<br />

into 1 col<strong>le</strong>ctors, especially for<br />

turbo applications, but the<br />

performance of a 6-2-1<br />

system is far superior to a 6-<br />

into-1 in almost all cases.<br />

If horsepower and power<br />

bandwidth are your primary<br />

goals, think about a 6-2-1<br />

setup.<br />

<strong>Burns</strong> Stain<strong>le</strong>ss LLC 949.631.5120 Monday - Friday 7:30 am to 4:30 pm fax 949.631.3184 burnsstain<strong>le</strong>ss.com<br />

13

Doub<strong>le</strong>-Slip Turbo Col<strong>le</strong>ctors and Splayed Col<strong>le</strong>ctor Options<br />

Surcharge may apply<br />

Doub<strong>le</strong>-Slip Turbo Col<strong>le</strong>ctors achieve a tight, weld-free seal at the<br />

hea<strong>de</strong>r-col<strong>le</strong>ctor junction by providing exterior slip tubes, which are<br />

wel<strong>de</strong>d to your existing hea<strong>de</strong>r tubes.<br />

The slip tubes provi<strong>de</strong> an extra seat and sealing surface for the<br />

col<strong>le</strong>ctor, and allow the hea<strong>de</strong>r system to grow and shrink over a<br />

wi<strong>de</strong> temperature range whi<strong>le</strong> greatly reducing the potential stress<br />

and cracking which is typical of wel<strong>de</strong>d stain<strong>le</strong>ss turbo hea<strong>de</strong>rs.<br />

Both the col<strong>le</strong>ctor, and the hea<strong>de</strong>r tubes in<br />

this system are spaced 1/8” farther apart<br />

to accommodate the additional slip tubes.<br />

Weld the slips to your existing hea<strong>de</strong>r<br />

tubes using the col<strong>le</strong>ctor as a jig.<br />

321 Stain<strong>le</strong>ss is the standard material<br />

for our Doub<strong>le</strong>-Slip Turbo Col<strong>le</strong>ctors.<br />

T3, T4, and V-band<br />

flanges are in stock.<br />

We can usually<br />

fabricate a col<strong>le</strong>ctor<br />

for your particular<br />

in<strong>le</strong>t flange.<br />

In addition to our standard, high-velocity<br />

15º merge col<strong>le</strong>ctors, we offer a shorter,<br />

25º turbo col<strong>le</strong>ctor for applications where<br />

space is limited. They’re about 2/3 the<br />

<strong>le</strong>ngth of our standard col<strong>le</strong>ctors.<br />

We recommend our 15º turbo col<strong>le</strong>ctors<br />

for extreme output, high rpm use.<br />

4-into-1 Doub<strong>le</strong>-Slip Col<strong>le</strong>ctors<br />

In<strong>le</strong>t Size Part Number each<br />

1 1/2 MC4-150-DST $ 366.00<br />

1 5/8 MC4-163-DST $ 375.00<br />

1 3/4 MC4-175-DST $ 375.00<br />

1 7/8 MC4-188-DST $ 375.00<br />

2 MC4-200-DST $ 376.00<br />

2 1/8 MC4-213-DST $ 399.00<br />

2 1/4 MC4-225-DST $ 398.00<br />

2 3/8 MC4-238-DST $ 427.00<br />

2 1/2 MC4-250-DST $ 412.00<br />

3-into-1 Doub<strong>le</strong>-Slip Col<strong>le</strong>ctors<br />

In<strong>le</strong>t Size Part Number each<br />

1 1/2 MC3-150-DST $ 312.00<br />

1 5/8 MC3-163-DST $ 318.00<br />

1 3/4 MC3-175-DST $ 318.00<br />

1 7/8 MC3-188-DST $ 318.00<br />

2 MC3-200-DST $ 319.00<br />

2 1/8 MC3-213-DST $ 339.00<br />

2 1/4 MC3-225-DST $ 337.00<br />

2 3/8 MC3-238-DST $ 384.00<br />

2 1/2 MC3-250-DST $ 349.00<br />

2-into-1 Doub<strong>le</strong>-Slip Col<strong>le</strong>ctors<br />

In<strong>le</strong>t Size Part Number each<br />

1 1/2 MC2-150-DST Surcharge may apply $ 166.00<br />

1 5/8 MC2-163-DST $ 172.00<br />

1 3/4 MC2-175-DST $ 179.00<br />

1 7/8 MC2-188-DST $ 184.00<br />

2 MC2-200-DST $ 189.00<br />

2 1/8 MC2-213-DST $ 195.00<br />

2 1/4 MC2-225-DST $ 202.00<br />

2 3/8 MC2-238-DST $ 225.00<br />

2 1/2 MC2-250-DST $ 225.00<br />

All of our merge col<strong>le</strong>ctors are availab<strong>le</strong><br />

with splayed in<strong>le</strong>ts at no extra cost.<br />

Splayed Col<strong>le</strong>ctor options<br />

Splayed in<strong>le</strong>ts allow the hea<strong>de</strong>r buil<strong>de</strong>r<br />

an additional <strong>de</strong>gree of freedom in<br />

routing the tubes, and are often<br />

necessary for high rpm, short-<strong>le</strong>ngth<br />

<strong>de</strong>signs, as well as turbo hea<strong>de</strong>rs with<br />

tight space requirements.<br />

full-splayed<br />

half-splayed<br />

2-into-1 configurations can be full-splayed (with a<br />

30º inclu<strong>de</strong>d ang<strong>le</strong>), or half-splayed, with one splayed<br />

<strong>le</strong>g and one conventional <strong>le</strong>g (15º inclu<strong>de</strong>d ang<strong>le</strong>).<br />

14<br />

<strong>Burns</strong> Stain<strong>le</strong>ss LLC 949.631.5120 Monday - Friday 7:30 am to 4:30 pm fax 949.631.3184 burnsstain<strong>le</strong>ss.com

Surcharge may apply<br />

Transitions and Megaphones,<br />

Transitions<br />

Transitions are swaged tubes that taper from a small diameter to<br />

a larger diameter. We make them with either 14º ( Long taper ) or<br />

30º ( Short taper ) inclu<strong>de</strong>d ang<strong>le</strong>s, and normally provi<strong>de</strong> a 2” long<br />

straight section at the small end.<br />

Transitions<br />

Mild Steel, 304, 321 Stain<strong>le</strong>ss<br />

Small Dia. Part Number Max Big End Mild Stl 304 SS 321 SS<br />

1 1/4 RD-125- 1 3/4 $ 20.41 $ 25.66 n/a<br />

1 3/8 RD-138- 2 $ 21.50 $ 26.75 n/a<br />

1 1/2 RD-150- 2 1/4 $ 21.50 $ 26.75 $ 32.21<br />

1 5/8 RD-163- 2 3/8 $ 22.05 $ 27.30 $ 32.76<br />

1 3/4 RD-175- 2 1/2 $ 22.05 $ 27.30 $ 32.76<br />

1 7/8 RD-188- 2 5/8 $ 22.60 $ 27.85 $ 33.31<br />

2 RD-200- 2 3/4 $ 22.60 $ 27.85 $ 33.31<br />

2 1/8 RD-213- 2 7/8 $ 23.14 $ 28.39 $ 33.85<br />

2 1/4 RD-225- 3 $ 23.14 $ 28.39 $ 33.85<br />

2 3/8 RD-238- 3 1/8 $ 24.78 $ 30.03 n/a<br />

2 1/2 RD-250- 3 1/4 $ 24.78 $ 30.03 $ 35.49<br />

2 5/8 RD-263- 3 3/8 $ 25.33 $ 30.58 n/a<br />

2 3/4 RD-275- 3 1/2 $ 25.33 $ 30.58 n/a<br />

3 RD-300- 3 3/4 $ 25.33 $ 30.58 $ 36.04<br />

3 1/4 RD-325- 4 $ 27.51 $ 37.13 n/a<br />

3 1/2 RD-350- 4 1/4 $ 29.69 $ 34.94 $ 40.40<br />

4 RD-400- 4 3/4 $ 31.88 $ 37.13 $ 42.59<br />

To or<strong>de</strong>r, pick your small diameter and a large diameter not<br />

larger than the “max big end”, and specify either Long or Short<br />

taper by adding L or S to the part number.<br />

Examp<strong>le</strong>: RD-250-325-L has a 2 1/2 small end, a 3 1/4 big end,<br />

and a long taper.<br />

Megaphones<br />

In the tab<strong>le</strong> here, the Small Dia. is the outsi<strong>de</strong><br />

diameter of the tubing the transition is ma<strong>de</strong><br />

from, and the Max Big End is the largest<br />

diameter to which it can be swaged. The large<br />

diameter of your transition can be anything up<br />

to the Max Big End.<br />

To calculate the <strong>le</strong>ngth of the tapered section,<br />

subtract the small diameter from the large<br />

diameter and multiply by 4.07 ( Long ) or 1.87<br />

( Short ).<br />

Typically, the tapered section of a Long<br />

Transition is around 3”, and a Short one is<br />

about 1.4”.<br />

Transitions<br />

6061 Aluminum<br />

Small dia. Part Number Max Big End 6061<br />

1 1/4 RD-125- 1 3/4 $ 25.66<br />

1 3/8 RD-138- 1 7/8 $ 26.21<br />

1 1/2 RD-150- 2 $ 26.21<br />

1 5/8 RD-163- 2 1/8 $ 26.75<br />

1 3/4 RD-175- 2 1/4 $ 26.75<br />

1 7/8 RD-188- 2 3/8 $ 27.30<br />

2 RD-200- 2 1/2 $ 27.30<br />

2 1/8 RD-213- 2 5/8 $ 27.85<br />

2 1/4 RD-225- 2 3/4 $ 27.85<br />

2 1/2 RD-250- 3 $ 28.39<br />

2 3/4 RD-275- 3 1/4 $ 30.58<br />

3 RD-300- 3 1/2 $ 30.58<br />

3 1/2 RD-350- 4 $ 31.67<br />

4 RD-400- 4 1/2 $ 35.18<br />

Megaphones are recommen<strong>de</strong>d for most applications that do not use tailpipes. They frequently augment the<br />

entire power curve, and enhance power above the peak rpm. Our Megaphones are rol<strong>le</strong>d and seam wel<strong>de</strong>d,<br />

in mild steel or 20 gage 304 Stain<strong>le</strong>ss.<br />

Megaphones<br />

Mild Steel, 304 Stain<strong>le</strong>ss<br />

Part Number Small dia. Large dia. Length Ang<strong>le</strong> Mild Steel 304 20 g.<br />

MEG-15035 1 1/2 3 1/2 17.5 6.5º $ 24.57 $ 30.03<br />

MEG-24115 2 4 11.5 9º $ 20.20 n/a<br />

MEG-24175 2 4 17.5 6.5º $ 24.57 $ 30.03<br />

MEG-25045 2 1/2 4 1/2 14.5 8 º $ 27.30 $ 32.76<br />

MEG-35145 3 5 14.5 8 º $ 27.30 $ 32.76<br />

This is our typical drag race setup - merge<br />

col<strong>le</strong>ctor / megaphone / reverse-cone, and<br />

it’s very successful in all kinds of<br />

competition, from Pro Stock to Truck Pulling<br />

to Air racing.<br />

A megaphone/reverse-cone wel<strong>de</strong>d unit<br />

is availab<strong>le</strong> only as part of<br />

a comp<strong>le</strong>te, engineered<br />

merge col<strong>le</strong>ctor system.<br />

<strong>Burns</strong> Stain<strong>le</strong>ss LLC 949.631.5120 Monday - Friday 7:30 am to 4:30 pm fax 949.631.3184 burnsstain<strong>le</strong>ss.com<br />

15

X-Design TM Computer Analysis Service for Racing Exhaust Systems<br />

X-<strong>de</strong>sign - <strong>Burns</strong> Stain<strong>le</strong>ss’ unique exhaust system computer analysis program.<br />

X-<strong>de</strong>sign has evolved from our extremely successful compared to a mass-produced “cannister” sty<strong>le</strong><br />

DesignSYS program in response to a growing need in setup.<br />

the community of motorsports racers and engine The rub is that the merge col<strong>le</strong>ctor must be <strong>de</strong>signed<br />

buil<strong>de</strong>rs to effectively manage the incredib<strong>le</strong> amount for your particular engine. Your camshaft and valves,<br />

of information and data essential to a competitive your combustion chamber, compression ratio, exhaust<br />

effort.<br />

port, and your hea<strong>de</strong>r configuration, all communicate<br />

intimately with the merge col<strong>le</strong>ctor, especially when<br />

Our core business of <strong>de</strong>signing and building racing your motor is working at greater than 100%<br />

merge col<strong>le</strong>ctors and hea<strong>de</strong>r systems has<br />

<strong>de</strong>monstrated that current race engines respond<br />

dramatically to small variations in the exhaust tract<br />

when volumetric efficiency exceeds 100%.<br />

The most critical area is the out<strong>le</strong>t of the merge<br />

col<strong>le</strong>ctor - its shape and diameter. In a highly<br />

<strong>de</strong>veloped racing engine, the col<strong>le</strong>ctor out<strong>le</strong>t interacts<br />

strongly with e<strong>le</strong>ments as far removed as the intake<br />

valve and camshaft and all the way to the tailpipe.<br />

In a typical mass-produced drag hea<strong>de</strong>r, for instance,<br />

the hea<strong>de</strong>r tubes are frequently about 10 to 20%<br />

longer than necessary and joined into a large,<br />

straight, “cannister” sty<strong>le</strong> col<strong>le</strong>ctor. This setup can<br />

produce good horsepower in a relatively narrow rpm<br />

range, and is usually sized to maximize the<br />

horsepower peak.<br />

Assuming you can live with a relatively narrow power<br />

band, you can win races with hea<strong>de</strong>rs like this, but<br />

conditions have to be just right, and you may need to<br />

play around with 2 or 3 different sets of hea<strong>de</strong>rs<br />

during a weekend of racing.<br />

Merge col<strong>le</strong>ctors change the game fundamentally.<br />

When properly <strong>de</strong>signed, they keep or augment the<br />

horsepower peak, and fill in the power curve from the<br />

torque peak on up. It is not uncommon to see gains<br />

of 15 to 25 hp with a good merge col<strong>le</strong>ctor system,<br />

volumetric efficiency. If the basic col<strong>le</strong>ctor<br />

parameters are not <strong>de</strong>signed with these factors in<br />

mind, your motor won’t realize its potential.<br />

X-<strong>de</strong>sign, used in conjunction with our Race Engine<br />

Specification Form, virtually assures you ( and us at<br />

<strong>Burns</strong> Stain<strong>le</strong>ss ) that our merge col<strong>le</strong>ctors will<br />

provi<strong>de</strong> you with state-of-the-art performance. We<br />

are constantly refining and updating the program, and<br />

based on feedback each week from our customers,<br />

the success rate is very high. In a community where<br />

the state of the art changes at a dizzying pace,<br />

X-<strong>de</strong>sign is an essential tool in the quest to compete.<br />

P<strong>le</strong>ase take a look at the Race Engine Specification<br />

Form on page 32. If you think there might be some<br />

more ponies hiding in your race engine, fill out the<br />

form and fax or mail it to us. We’ll get back to you,<br />

usually within 48 hours, and help you <strong>de</strong>ci<strong>de</strong> how to<br />

get the best results for your competitive effort.<br />

The one thing that X-<strong>de</strong>sign doesn’t take into account is the changing conditions<br />

during your day or weekend at the races. When track or atmospheric factors call for<br />

a change of tune, our B-TEC adjustab<strong>le</strong> race col<strong>le</strong>ctors are the answer. See page 17.<br />

16<br />

<strong>Burns</strong> Stain<strong>le</strong>ss LLC 949.631.5120 Monday - Friday 7:30 am to 4:30 pm fax 949.631.3184 burnsstain<strong>le</strong>ss.com

Surcharge may apply<br />

DynoSYS TM and B-TEC TM Adjustab<strong>le</strong> Col<strong>le</strong>ctors<br />

DynoSYS<br />

DynoSYS is a unique adjustab<strong>le</strong> venturi stain<strong>le</strong>ss steel merge col<strong>le</strong>ctor system that simplifies<br />

dyno testing, enabling you to quickly and pain<strong>le</strong>ssly tune your hea<strong>de</strong>r dimensions and<br />

<strong>de</strong>termine the correct col<strong>le</strong>ctor out<strong>le</strong>t size for various engine combinations.<br />

DynoSYS offers these distinct advantages<br />

● Saves cost when compared to buying separate col<strong>le</strong>ctors for back to back testing.<br />

● Allows easier, simp<strong>le</strong>r R&D testing when tuning hea<strong>de</strong>r system to new engine<br />

configurations.<br />

● Eliminates the hass<strong>le</strong> of changing hot col<strong>le</strong>ctors on dyno hea<strong>de</strong>rs - just sli<strong>de</strong> out one<br />

venturi group and sli<strong>de</strong> in another - <strong>le</strong>aving the col<strong>le</strong>ctors in place.<br />

● Custom built to your primary and out<strong>le</strong>t size specifications.<br />

● Venturi ang<strong>le</strong>s, both convergent and divergent, have been<br />

extensively tested.<br />

● Venturi sized to your specification<br />

(your choice, but p<strong>le</strong>ase consi<strong>de</strong>r X-<strong>de</strong>sign recommendation).<br />

● Exhaust system <strong>de</strong>sign consulting using our X-<strong>de</strong>sign<br />

parametric software (see page 16 for <strong>de</strong>tails ).<br />

● Price quote on request<br />

B-TEC Adjustab<strong>le</strong> Col<strong>le</strong>ctors<br />

B-TEC, the <strong>Burns</strong> Tunab<strong>le</strong> Exhaust Col<strong>le</strong>ctor, is the on-track evolution of our DynoSYS<br />

adjustab<strong>le</strong> merge col<strong>le</strong>ctor, originally <strong>de</strong>signed to assist in the dyno testing of col<strong>le</strong>ctors on<br />

different engine combinations.<br />

In the last coup<strong>le</strong> of years, our B-TEC adjustab<strong>le</strong> col<strong>le</strong>ctor system has established its reputation<br />

as an indispensab<strong>le</strong> tool for serious drag racers. It is used by many of the fastest NHRA Pro<br />

Stock Cars, and some of the top Pro Stock Motorcyc<strong>le</strong>s, and is becoming increasingly popular in<br />

Competition and Sportsman classes.<br />

Availab<strong>le</strong> in 2, 3, 4, and 5 into 1 configurations, B-TEC adds about 8 to<br />

10 ounces of extra weight to each col<strong>le</strong>ctor. The minimum set consists<br />

of a merge col<strong>le</strong>ctor with adapter neck, one venturi insert, and a special<br />

slip megaphone with reverse cone.<br />

This setup can usually accommodate 3 different venturi diameters, but<br />

sometimes the smal<strong>le</strong>r venturi se<strong>le</strong>ctions need extra <strong>le</strong>ngth, and an<br />

extension collar is nee<strong>de</strong>d.<br />

You gain the ability to quickly and precisely tune your torque curve based on track and<br />

atmospheric conditions, and to fine-tune the hea<strong>de</strong>r system to mechanical changes at the track<br />

on race day.<br />

<strong>Burns</strong> Stain<strong>le</strong>ss LLC 949.631.5120 Monday - Friday 7:30 am to 4:30 pm fax 949.631.3184 burnsstain<strong>le</strong>ss.com<br />

17

X-pipes,Y-pipes and V-Band Clamps<br />

Surcharge may apply<br />

X-Pipes<br />

X-Pipes are produced using the same techniques as our 2-1 merge col<strong>le</strong>ctors.<br />

They are availab<strong>le</strong> with paral<strong>le</strong>l in<strong>le</strong>ts, splayed in<strong>le</strong>ts, or a combination of the<br />

two. In addition, you can specify the center to center distance for both the<br />

in<strong>le</strong>t and out<strong>le</strong>t pipes, and the <strong>le</strong>g <strong>le</strong>ngths can be staggered if necessary.<br />

The junction area can be round or oval, but the<br />

actual shape and area at the junction is critical for<br />

optimum performance.P<strong>le</strong>ase call for our<br />

recommendation.<br />

The price of an X-pipe is calculated by taking the price of<br />

two 2-into-1 Base Col<strong>le</strong>ctors (page 13) and adding<br />

$50.00 finishing cost.<br />

Y-Pipes<br />

Y-Pipes are nearly i<strong>de</strong>ntical to our 2-1 merge col<strong>le</strong>ctors, and are<br />

availab<strong>le</strong> with paral<strong>le</strong>l, splayed, or half-splayed in<strong>le</strong>ts. The center<br />

to center distance is your option, but the choice of out<strong>le</strong>t (neckdown)<br />

diameter is very important for peak performance. A<br />

transition and tailpipe ring are the usual out<strong>le</strong>t options.<br />

In general, to calculate the price of your Y-Pipe, find the price of<br />

the appropriate 2-into-1 col<strong>le</strong>ctor, and add $65.00 for stain<strong>le</strong>ss,<br />

or $55.00 for mild steel.<br />

V-Band Clamps<br />

For a close to<strong>le</strong>rance, gasket<strong>le</strong>ss tube coupling, V-Band clamps are the high-tech alternative to the standard<br />

3-bolt flange.<br />

Stain<strong>le</strong>ss V-Band Assemblies<br />

Size Part Number Assembly Clamp Only Flange Only<br />

2 VB-200-ASSY $ 78.40 $46.70 $30.90<br />

2 1/4 VB-225-ASSY $ 78.40 $46.70 $30.90<br />

2 1/2 VB-250-ASSY $ 78.40 $46.70 $30.90<br />

3 VB-300-ASSY $ 78.40 $46.70 $30.90<br />

3 1/2 VB-350-ASSY $ 78.40 $46.70 $30.90<br />

4 VB-400-ASSY $ 87.60 $46.70 $39.20<br />

Inclu<strong>de</strong>d are two V-Band weld-on<br />

flanges and one V-Band clamp per<br />

assembly. All stain<strong>le</strong>ss<br />

construction.Flange or clamp<br />

availab<strong>le</strong> separately - see price list.<br />

To achieve close to<strong>le</strong>rance alignment<br />

between the tubes being joined, <strong>le</strong>t one<br />

of the tubes protru<strong>de</strong> about 1/4” when<br />

welding the flange. It will then register<br />

nicely into the opposing flange.<br />

.25 min.<br />

18<br />

<strong>Burns</strong> Stain<strong>le</strong>ss LLC 949.631.5120 Monday - Friday 7:30 am to 4:30 pm fax 949.631.3184 burnsstain<strong>le</strong>ss.com

Surcharge may apply<br />

Flat-band Clamps, Silicone Hose, Hump Hose and Reducers<br />

T-bolt flat band clamps are an alternative<br />

to U-bolt muff<strong>le</strong>r clamps for<br />

clamping close to<strong>le</strong>rance slip<br />

connections on tubing.<br />

Flat band clamps do not<br />

permanently crimp the slit<br />

tubing, allowing easier<br />

removal after assembly.<br />

Stain<strong>le</strong>ss steel strap, plated<br />

steel T-bolt and nut<br />

Flat Band Clamps ( T-bolt )<br />

Flat Band Clamps<br />

304 Stain<strong>le</strong>ss<br />

Size Part Number Min. dia. Max dia. Silicone Hose Size Each<br />

1 3/4 FB-175 1.75 2.00 SH-150 $ 9.49<br />

2 FB-200 2.00 2.25 SH-175 $ 9.49<br />

2 1/4 FB-225 2.25 2.56 SH-200 $ 9.49<br />

2 1/2 FB-250 2.50 2.81 SH-225 $ 9.49<br />

2 3/4 FB-275 2.75 3.00 SH-250 $ 9.49<br />

3 FB-300 3.00 3.31 SH-275 $ 9.49<br />

3 1/4 FB-325 3.25 3.56 SH-300 $ 9.49<br />

3 1/2 FB-350 3.50 3.81 SH-325 $ 9.49<br />

3 3/4 FB-375 3.75 4.06 SH-350 $ 9.49<br />

4 FB-400 4.00 4.31 SH-375 $ 10.49<br />

4 1/2 FB-450 4.31 4.62 SH-400 $ 10.49<br />

Silicone Hose , Hump Hose and Reducers- Silicone High Perf, 4 ply<br />

Silicone Hose - High Performance 4 ply<br />

ID Part Number OD Per / foot<br />

1/2 SH-050 7/8 $ 8.96<br />

3/4 SH-075 1 1/8 $ 10.94<br />

1 SH-100 1 3/8 $ 12.89<br />

1 1/4 SH-125 1 5/8 $ 14.87<br />

1 1/2 SH-150 1 7/8 $ 16.84<br />

1 3/4 SH-175 2 1/8 $ 18.82<br />

2 SH-200 2 3/8 $ 20.79<br />

2 1/4 SH-225 2 5/8 $ 22.77<br />

2 1/2 SH-250 2 7/8 $ 24.74<br />

2 3/4 SH-275 3 1/8 $ 26.72<br />

3 SH-300 3 3/8 $ 28.69<br />

3 1/4 SH-325 3 5/8 $ 30.64<br />

3 1/2 SH-350 3 7/8 $ 32.64<br />

3 3/4 SH-375 4 1/8 $ 34.61<br />

4 SH-400 4 3/8 $ 36.59<br />

● 4 ply silicone<br />

coolant hose<br />

reinforced with<br />

polyester fabric<br />

and coated with<br />

specially<br />

compoun<strong>de</strong>d<br />

silicone elastomer.<br />

● Continuous<br />

operating<br />

temperature -65ºF<br />

(-54ºC) to 350ºF<br />

(177ºC).<br />

● Resists<br />

chemicals, steam,<br />

ozone, coolants<br />

and aging<br />

conditions<br />

normally found in<br />

the engine<br />

environment.<br />

Reducers<br />

Size Part Number Each<br />

1.5 to 2 SR-150-200 $ 17.77<br />

2 to 2.5 SR-200-250 $ 19.37<br />

2 to 3 SR-200-300 $ 20.00<br />

2.5 to 3 SR-250-300 $ 20.00<br />

3 to 3.5 SR-300-350 $ 22.45<br />

3 to 4 SR-300-400 $ 24.25<br />

3.5 to 4 SR-350-400 $ 24.25<br />

Hump Hose<br />

Size Part Number Each<br />

2 HH-200 $ 17.43<br />

2 1/4 HH-225 $ 18.09<br />

2 1/2 HH-250 $ 18.73<br />

2 3/4 HH-275 $ 19.37<br />

3 HH-300 $ 20.00<br />

3 1/2 HH-350 $ 23.30<br />

4 HH-400 $ 27.14<br />

<strong>Burns</strong> Stain<strong>le</strong>ss LLC 949.631.5120 Monday - Friday 7:30 am to 4:30 pm fax 949.631.3184 burnsstain<strong>le</strong>ss.com<br />

19

A<strong>de</strong>l Wiggins F<strong>le</strong>xib<strong>le</strong> Tube Connectors<br />

Surcharge may apply<br />

A<strong>de</strong>l Wiggins F<strong>le</strong>xib<strong>le</strong> Tube Connectors, or Wiggins Clamps, provi<strong>de</strong> an i<strong>de</strong>al method for quickly and<br />

efficiently connecting and sealing two tubes. They are availab<strong>le</strong> in aluminum with a stain<strong>le</strong>ss two-finger latch,<br />

and are frequently used for vacuum lines, water lines, and turbo intake plumbing. All are qualified to AS1650<br />

and MIL-C-22263 specs., and are tested to greater than 125 psi. operating pressure, at temperatures up to<br />

450º F <strong>de</strong>pending mainly on the o-ring material.<br />

Our Wiggins Coupling Assembly is<br />

comprised of one Clamshell Assembly<br />

(clamp and s<strong>le</strong>eve), and two Weld Ferru<strong>le</strong>s.<br />

O-rings are not inclu<strong>de</strong>d.<br />

S<strong>le</strong>eve<br />

Clamp<br />

Comp<strong>le</strong>te Coupling Assembly, minus O-rings<br />

Tube OD Part Number Wt. - lbs Assembly<br />

1/2 W991-8DE-050-A 0.054 $ 65.95<br />

5/8 W991-10DE-063-A 0.062 $ 72.35<br />

3/4 W991-12DE-075-A 0.075 $ 77.00<br />

1 W991-16DE-100-A 0.096 $ 83.50<br />

1 1/4 W991-20DE-125-A 0.112 $ 90.00<br />

1 1/2 W991-24DE-150-A 0.128 $ 123.10<br />

1 3/4 W991-28DE-175-A 0.146 $ 136.00<br />

2 W991-32DE-200-A 0.177 $ 140.25<br />

2 1/2 W991-40DE-250-A 0.209 $ 155.00<br />

3 W991-48DE-300-A 0.282 $ 172.45<br />

3 1/2 W991-56DE-350-A 0.338 $ 260.00<br />

4 W991-64DE-400-A 0.385 $ 327.00<br />

Weld<br />

Ferru<strong>le</strong><br />

O-rings<br />

(not supplied)<br />

Weld<br />

Ferru<strong>le</strong><br />

Whi<strong>le</strong> <strong>Burns</strong> Stain<strong>le</strong>ss does not supply<br />

O-rings, Wiggins Clamps use industry<br />

standard O-rings, <strong>de</strong>fined by the SAE.<br />

In the reference tab<strong>le</strong> below, the O-ring<br />

size co<strong>de</strong> is AS568A followed by the dash<br />

number indicating the part’s dimensions.<br />

Tube Use O-ring Nominal Nominal<br />

OD AS568A- Insi<strong>de</strong> dia. Cross section<br />

1/2 -015 9/16 1/16<br />

5/8 -017 11/16 1/16<br />

3/4 -117 13/16 3/32<br />

1 -214 1 1/8<br />

1 1/4 -218 1 1/4 1/8<br />

1 1/2 -222 1 1/2 1/8<br />

1 3/4 -224 1 3/4 1/8<br />

2 -226 2 1/8<br />

2 1/2 -230 2 1/2 1/8<br />

3 -234 3 1/8<br />

3 1/2 -238 3 1/2 1/8<br />

4 -242 4 1/8<br />

Clamshell Assembly<br />

(clamp with s<strong>le</strong>eve)<br />

Tube OD Part Number Wt. - lbs Each<br />

1/2 W991-8DE-050 0.034 $ 39.45<br />

5/8 W991-10DE-063 0.038 $ 43.35<br />

3/4 W991-12DE-075 0.043 $ 46.00<br />

1 W991-16DE-100 0.052 $ 48.00<br />

1 1/4 W991-20DE-125 0.058 $ 48.00<br />

1 1/2 W991-24DE-150 0.062 $ 52.00<br />

1 3/4 W991-28DE-175 0.07 $ 58.00<br />

2 W991-32DE-200 0.083 $ 62.25<br />

2 1/2 W991-40DE-250 0.097 $ 77.00<br />

3 W991-48DE-300 0.144 $ 94.45<br />

3 1/2 W991-56DE-350 0.176 $ 160.00<br />

4 W991-64DE-400 0.201 $ 215.00<br />

Weld Ferru<strong>le</strong> ( 2 required per connection )<br />

Tube OD Part Number Wt. - lbs Each<br />

1/2 W903B8D-050 0.01 $ 13.25<br />

5/8 W903B10D-063 0.012 $ 14.50<br />

3/4 W903B12D-075 0.016 $ 15.50<br />

1 W903B16D-100 0.022 $ 17.75<br />

1 1/4 W903B20D-125 0.027 $ 21.00<br />

1 1/2 W903B24D-150 0.033 $ 35.55<br />

1 3/4 W903B28D-175 0.038 $ 39.00<br />

2 W903B32D-200 0.047 $ 39.00<br />

2 1/2 W903B40D-250 0.056 $ 39.00<br />

3 W903B48D-300 0.069 $ 39.00<br />

3 1/2 W903B56D-350 0.081 $ 50.00<br />

4 W903B64D-400 0.092 $ 56.00<br />

Common O-ring materials are Buna-N, Viton, and Silicone.<br />

If you don’t have a source for O-rings, McMaster Carr (www.macmastercarr.com) maintains a large stock.<br />

For tech info on the internet, see www.marcorubber.com, www.afmusa.com or www.pspglobal.com.<br />

20<br />

<strong>Burns</strong> Stain<strong>le</strong>ss LLC 949.631.5120 Monday - Friday 7:30 am to 4:30 pm fax 949.631.3184 burnsstain<strong>le</strong>ss.com

Turbo In<strong>le</strong>t, Downpipe and Wastegate Flanges, 3-Bolt Flanges, Head Flanges<br />

Turbo In<strong>le</strong>t Flanges<br />

T3 and T4 Turbo In<strong>le</strong>t Flanges - CNC Machined 304 Stain<strong>le</strong>ss<br />

304 Stain<strong>le</strong>ss<br />

ID Height ID Width Bolt Center Bolt Center Tang. Flange<br />

Type Part Number (A) (B) Width (C) Height (D) Port Width (E) Thickness Each<br />

T03 T3F-RECT-304 1.94 2.31 3.40 1.75 N/A 3/8” $ 43.55<br />

T04 T4F-RECT-304 1.94 2.94 3.25 2.75 N/A 1/2” $ 55.02<br />

T04 Tangential (1.88”) T4T-188-304 2.06 N/A 3.25 2.75 1.45” 1/2” $ 65.00<br />

T04 Tangential (2.00”) T4T-200-304 2.15 N/A 3.25 2.75 1.52” 1/2” $ 65.00<br />

T100 (88-106mm) T100-RECT-304 2.45 3.65 4.45 2.75 N/A 1/2” $ 67.05<br />

C<br />

B<br />

Downpipe Flanges<br />

Type Part Number Each<br />

HKS 100mm 3” DPF-HKS-300-304 $ 57.42<br />

T04 Rnd 2.75” DPF-T4-275-304 $ 72.92<br />

T04 Rnd 3” DPF-T4-300-304 $ 72.92<br />

A<br />

E<br />

D<br />

Wastegate Flanges<br />

Type Part Number Each<br />

Deltagate WDF-150-304 $ 26.50<br />

Racegate WRF-175-304 $ 27.00<br />

Our turbo flanges are CNC machined insi<strong>de</strong> and out, with a generous chamfer on the outsi<strong>de</strong> edge.<br />

Downpipe flanges are 1/2” thick. Wastegate flanges are 3/8” thick.<br />

3 Bolt Flanges - 304 Stain<strong>le</strong>ss, CNC Machined<br />

These high quality flanges<br />

are CNC machined from<br />

3/8 thick, 304 stain<strong>le</strong>ss plate.<br />

With a 3/32 chamfer all around<br />

the perimeter, they look good<br />

and are nice to your knuck<strong>le</strong>s.<br />

Head Flanges for Race Applications<br />

3 Bolt Flanges 304 Stain<strong>le</strong>ss<br />

Size Part Number Each<br />

2 3BF-200-304 $ 34.50<br />

2 1/4 3BF-225-304 $ 34.50<br />

2 1/2 3BF-250-304 $ 38.25<br />

3 3BF-300-304 $ 40.75<br />

3 1/2 3BF-350-304 $ 47.50<br />

CNC machined from 3/8” mild steel to resist warping. Recommen<strong>de</strong>d for stain<strong>le</strong>ss and mild steel hea<strong>de</strong>rs<br />

1 7/8", 18 <strong>de</strong>gree Chev V-8, individual flanges<br />

Part Number<br />

Price per set<br />

CHF-188-1 $ 95.00<br />

Set inclu<strong>de</strong>s 2 center flanges<br />

and 4 outsi<strong>de</strong> flanges<br />

1 7/8" SB-2 Chev V-8, square port, 4 port flange<br />

Part Number<br />

Price per set<br />

CHF-188-2 $ 95.00<br />

Set inclu<strong>de</strong>s 2 flanges<br />

1 3/4" Ford/Yates V-8, square port, individual flanges<br />

Part Number<br />

Price per set<br />

FHF-175-1 $ 95.00<br />

Set inclu<strong>de</strong>s 8<br />

individual flanges<br />

<strong>Burns</strong> Stain<strong>le</strong>ss LLC 949.631.5120 Monday - Friday 7:30 am to 4:30 pm fax 949.631.3184 burnsstain<strong>le</strong>ss.com<br />

21

Col<strong>le</strong>ctor Tabs, O2 Rings, Hea<strong>de</strong>r Bolts, Solar Flux, and TIG Welding Rod<br />

U-Bracket, Straight Overlapping A-B, and Cast Stain<strong>le</strong>ss Lug-Sty<strong>le</strong> Tabs<br />

● Precision stamped and<br />

formed from 304 Stain<strong>le</strong>ss.<br />

● Light-weight <strong>de</strong>sign looks good<br />

and resists warping and breaking.<br />

● 5/16" Ho<strong>le</strong> diameter.<br />

U-Bracket Tabs<br />

Each<br />

304 Stain<strong>le</strong>ss $ 2.50<br />

● Fabricated from .109” thick mild steel<br />

or 304 stain<strong>le</strong>ss, to align and affix the<br />

col<strong>le</strong>ctor slips to your hea<strong>de</strong>r tubes.<br />

● Step heights of .156 ( Type “A” )<br />

or .094 ( Type “B” ).<br />

A-B Tabs<br />

Each<br />

Mild Steel $ 1.88<br />

304 Stain<strong>le</strong>ss $ 3.00<br />

Part Number Centerline Bolt Height Length Bolt Size Each<br />

Cast Lug 0.52 0.6 1/4 $9.00<br />

Cast Lug 2A 0.36 0.7 1/4 $9.00<br />

Cast Lug 2B 0.31 0.7 1/4 $9.00<br />

A<br />

● Cast 304 Stain<strong>le</strong>ss tabs provi<strong>de</strong> robust slip<br />

tube fastening.<br />

● .600" long, with c<strong>le</strong>arance ho<strong>le</strong> for<br />

1/4"screws.<br />

B<br />

Cast Lug 1 Cast Lug 2<br />

● O2 Sensor Rings are precision<br />

machined 304 stain<strong>le</strong>ss with<br />

18mm x 1.5 thread to fit standard<br />

Bosch-type Lambda sensors.<br />

● Mild Steel Plugs for O2 rings<br />

come with a thick copper washer.<br />

O2 Sensor Rings and Plugs<br />

O2 Sensor Rings<br />

Each<br />

304 Stain<strong>le</strong>ss $ 14.00<br />

Plug for O2 ring<br />

Each<br />

Mild Steel $ 5.00<br />

304 Stain<strong>le</strong>ss Hea<strong>de</strong>r Bolts<br />

not<br />

shown<br />

Stain<strong>le</strong>ss 12 point, shoul<strong>de</strong>red<br />

hea<strong>de</strong>r bolts - 3/4” long<br />

Hea<strong>de</strong>r Bolts - Stain<strong>le</strong>ss Part Number Each<br />

5/16-18, 3/4 long HB-75-312SS $ 1.90<br />

3/8-16, 3/4 long HB-75-375SS $ 1.90<br />

Pipe Bungs & Nipp<strong>le</strong>s, Solar Flux, and Welding Rod<br />

1/2" Pipe Nipp<strong>le</strong>, 45º ang<strong>le</strong> cut $ 12.50 each<br />

1/8 Pipe Bung - 304 Stain<strong>le</strong>ss $ 2.95 each<br />

TIG Welding Rod<br />

Type Diameter Price / lb.<br />

308, 309, 347 SS .035 $23.50<br />

5356 Aluminum .062 $14.00<br />

Titanium .035 call<br />

Inconel 625 .030 call<br />

Solar Flux is perfect for welding<br />

all stain<strong>le</strong>ss and alloy steels.<br />

It takes the place of inert gas<br />

insi<strong>de</strong> the tube.<br />

1 lb. can $ 39.95<br />

22<br />

<strong>Burns</strong> Stain<strong>le</strong>ss LLC 949.631.5120 Monday - Friday 7:30 am to 4 pm fax 949.631.3184 burnsstain<strong>le</strong>ss.com

Surcharge may apply<br />

UltraLight Stain<strong>le</strong>ss Motorsports Muff<strong>le</strong>rs<br />

<strong>Burns</strong> Stain<strong>le</strong>ss UltraLight Stain<strong>le</strong>ss Race Muff<strong>le</strong>rs<br />

offer the greatest value in a race muff<strong>le</strong>r availab<strong>le</strong> to the motorsports community.<br />

● Remarkably light-weight<br />

● Extremely durab<strong>le</strong><br />

● Built to the highest quality standards.<br />

● 100% stain<strong>le</strong>ss construction<br />

● Comp<strong>le</strong>tely TIG wel<strong>de</strong>d<br />

● Easily replaceab<strong>le</strong> aerospace ceramic muffling cartridge*<br />

● Insi<strong>de</strong> diameters from 2” all the way to 5”<br />

● Can be built to custom <strong>le</strong>ngth (call for quote)<br />

● Optional Stain<strong>le</strong>ss scrubb<strong>le</strong> packing availab<strong>le</strong> (call for quote)<br />

If you need the highest performance and the lightest weight<br />

race muff<strong>le</strong>r you can get, at a price you can afford, here it is.<br />

UltraLight Stain<strong>le</strong>ss Muff<strong>le</strong>rs<br />

In<strong>le</strong>t dia. Part Number Case dia. Length Wt. Lbs. Each<br />

2 SM-200-450-14 4 1/2 14.00 2.96 $ 212.05<br />

2 1/4 SM-225-450-14 4 1/2 14.00 2.9 $ 213.69<br />

2 1/2 SM-250-350-12 3 1/2 12.00 1.87 $ 192.77<br />