Epoxy 17M ABC - Tambour Paints

Epoxy 17M ABC - Tambour Paints

Epoxy 17M ABC - Tambour Paints

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

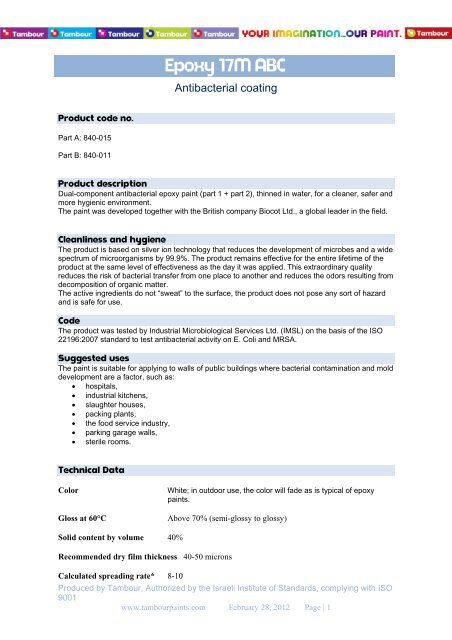

<strong>Epoxy</strong> <strong>17M</strong> <strong>ABC</strong><br />

Antibacterial coating<br />

Product code no.<br />

Part A: 840-015<br />

Part B: 840-011<br />

Product description<br />

Dual-component antibacterial epoxy paint (part 1 + part 2), thinned in water, for a cleaner, safer and<br />

more hygienic environment.<br />

The paint was developed together with the British company Biocot Ltd., a global leader in the field.<br />

Cleanliness and hygiene<br />

The product is based on silver ion technology that reduces the development of microbes and a wide<br />

spectrum of microorganisms by 99.9%. The product remains effective for the entire lifetime of the<br />

product at the same level of effectiveness as the day it was applied. This extraordinary quality<br />

reduces the risk of bacterial transfer from one place to another and reduces the odors resulting from<br />

decomposition of organic matter.<br />

The active ingredients do not “sweat” to the surface, the product does not pose any sort of hazard<br />

and is safe for use.<br />

Code<br />

The product was tested by Industrial Microbiological Services Ltd. (IMSL) on the basis of the ISO<br />

22196:2007 standard to test antibacterial activity on E. Coli and MRSA.<br />

Suggested uses<br />

The paint is suitable for applying to walls of public buildings where bacterial contamination and mold<br />

development are a factor, such as:<br />

hospitals,<br />

industrial kitchens,<br />

slaughter houses,<br />

packing plants,<br />

the food service industry,<br />

parking garage walls,<br />

sterile rooms.<br />

Technical Data<br />

Color<br />

Gloss at 60°C<br />

White; in outdoor use, the color will fade as is typical of epoxy<br />

paints.<br />

Above 70% (semi-glossy to glossy)<br />

Solid content by volume 40%<br />

Recommended dry film thickness 40-50 microns<br />

Calculated spreading rate* 8-10<br />

Produced by <strong>Tambour</strong>, Authorized by the Israeli Institute of Standards, complying with ISO<br />

9001<br />

www.tambourpaints.com February 28, 2012 Page | 1

(sq m/liter)<br />

Drying time**<br />

Hard coat drying time**<br />

Touch dry**: 4 hours<br />

For holding or manual conveyance**: 24 hrs.<br />

Dry to recoat<br />

Waiting time between coats:<br />

For epoxy or polyurethane thinned with water: at least 6, no more than 7 days<br />

For topcoat thinned with organic thinner: at least 24 hrs.<br />

For Dual Component Paint<br />

Mixing ratio by volume A:B – 4:1<br />

Waiting time before<br />

painting**<br />

Shelf life after mixing<br />

Shelf life**<br />

30 min.<br />

4 hrs.<br />

24 months<br />

Surface and paint preparation<br />

Remove laitance, and loose particles to achieve a stable surface. Surface must have cured for at<br />

least 14 days.<br />

Primer: Aquapoxy <strong>17M</strong> <strong>ABC</strong> thinned with 20% water or Aquapoxy 15M to a 30-micron thickness<br />

(~4-7 sq m/liter, depending on penetration).<br />

Continue by painting 1-2 coats of Aquapoxy <strong>17M</strong> <strong>ABC</strong>.<br />

For applying to existing acrylic paint:<br />

Make sure surface is free of dust, dirt, grease and any loose particles. Gentle abrasion of existing<br />

paint using fine sandpaper is recommended.<br />

Apply primer coat of binding Aquapoxy M15 thinned 10-15%.<br />

Walls, concrete floors in residential parking garages (medium traffic) and stable plaster:<br />

Mechanical roughening and removal of all loose particles, laitance and impurities until the original,<br />

stable concrete surface is exposed. Apply primer of binding Aquapoxy M15 thinned 10-15% at<br />

quantities of 4-5 sq m/liter, depending on penetration.<br />

Paint application method<br />

Paint<br />

method<br />

Brush/<br />

roller<br />

Regular<br />

spraying<br />

Airless<br />

spraying<br />

Atmospheric<br />

pressure<br />

Nozzle<br />

diameter<br />

Thinner Thinning<br />

percentage<br />

by volume<br />

Water 5-10%<br />

3 Water 10-25%<br />

3-4 15-21”<br />

OR<br />

0.015-<br />

0.021<br />

inch<br />

Water 5%<br />

Produced by <strong>Tambour</strong>, Authorized by the Israeli Institute of Standards, complying with ISO<br />

9001<br />

www.tambourpaints.com February 28, 2012 Page | 2

Cleaning thinner<br />

Water<br />

Application remarks<br />

Stir well before and during use.<br />

Part B should be well stirred into Part A before thinning.<br />

Drying rate depends greatly on temperature and relative humidity. Use only in well-ventilated areas.<br />

Safety measures<br />

The use of this product and its application must be in accordance with the applicable safety, health<br />

and environmental regulations in force in Israel.<br />

Please read the safety precautions and warnings appearing in the Safety Data Sheet, available at<br />

<strong>Tambour</strong>’s Safety Department, tel. +972-4-987-7483 as well as on the product label. Keep away<br />

from fire and sparks. Do not ingest. Keep working area well ventilated. While spraying do not inhale<br />

the fumes. Use proper protective gear; see Safety Data Sheet.<br />

General comments<br />

The data presented herein are based on the knowledge and experience acquired over many years.<br />

We reserve the right to update and/or alter the data without prior notice. Achieving the best results<br />

depends on the proper application of the product and on the strict compliance with our instructions<br />

and safety measures. Before application, the user should verify that the product is designed for the<br />

intended usage and that the surfaces to be painted are properly prepared and suitable for the<br />

product’s application. For additional information, please contact our Technical Service Department.<br />

* The practical spreading rate may vary depending on the surface, the application mode, the<br />

painter’s skills, and weather conditions at the site. Assume approximately 75% of the<br />

calculated spreading rate.<br />

** At 25°C and 65% relative humidity<br />

Produced by <strong>Tambour</strong>, Authorized by the Israeli Institute of Standards, complying with ISO<br />

9001<br />

www.tambourpaints.com February 28, 2012 Page | 3