SHOPPING CART CONVEYOR - DARROTT

SHOPPING CART CONVEYOR - DARROTT

SHOPPING CART CONVEYOR - DARROTT

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

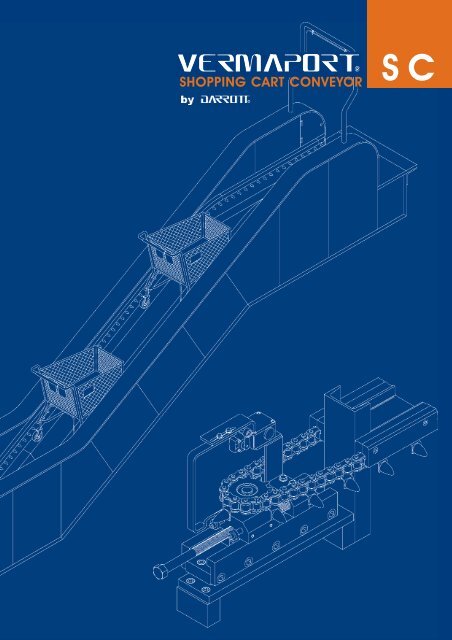

<strong>SHOPPING</strong> <strong>CART</strong> <strong>CONVEYOR</strong><br />

SC

2<br />

Notes

THE COMPANY<br />

ABOUT US<br />

Our company is focusing on development and<br />

sales as well as manufacturing supervising of the<br />

VERMAPORT ® Shopping Cart Conveyors; and last but<br />

not least set up and maintenance.<br />

In the 70ties the first VERMAPORT ® Shopping Cart<br />

Conveyors have been manufactured and set in duty in<br />

supermarkets and shopping centers. By the way, the<br />

trade name VERMAPORT ® is based on using some syllables<br />

of the German words "VERbraucherMArkt<br />

TransPORTeinrichtung, meaning nothing less the<br />

Conveyors for Shopping Centers and Supermarkets ….<br />

Our design department stands for permanent development,<br />

improvements and implementing of latest technology<br />

to the VERMAPORTs ® . For sure tasks are being<br />

supported by up to date computer systems and CAD<br />

software. It is our philosophy to achieve a perfect tuning<br />

with shop designers and architects when it comes to<br />

introduce VERMAPORT ® Shopping Cart Conveyors for<br />

Supermarkets and Shopping Malls.<br />

Our experienced sales department will advise you from<br />

planning till set up.<br />

Manufacturing of VERMAPORTs ® takes place in modern<br />

facilities and permanent supervising will guaranty high<br />

quality standards.<br />

For set up of the VERMAPORT ® Shopping Cart Conveyors<br />

as well as for maintenance and service sophisticated<br />

crews are available.<br />

Would be a pleasure for us to be at your service.<br />

Darrott-Transporttechnik GmbH<br />

3

4<br />

VERMAPORT®<br />

<strong>SHOPPING</strong> <strong>CART</strong> <strong>CONVEYOR</strong>S<br />

<strong>CART</strong> FEEDING CONVIENIENT TRAVEL <strong>CART</strong> RETRIEVING<br />

Inserting a cart is very simple and<br />

easy.<br />

While shoppers ride on escalator<br />

cart is being moved alongside<br />

The VERMAPORT ® Shopping Cart<br />

Conveyors are designated for use<br />

in Department stores, Supermarkets<br />

and multilevel Shopping<br />

Malls. The conveyors are intended<br />

for moving the shopper’s carts<br />

between levels.<br />

VERMAPORT ® Shopping Cart<br />

Conveyors are easy to use and no<br />

shop attendants are required. The<br />

conveyors are equipped with<br />

most recent electronics and are<br />

being controlled over appropriate<br />

software.<br />

The conveyor delivers the cart for<br />

easy take over.

VERMAPORT®<br />

<strong>SHOPPING</strong> <strong>CART</strong> <strong>CONVEYOR</strong>S<br />

Carts are being moved automatically<br />

up or down after shoppers<br />

inserted them to the VERMAPORTs ®<br />

Thanks to VERMAPORT ® Shopping<br />

Cart Conveyors shoppers are<br />

able to take them to every level<br />

of the store.<br />

Most common VERMAPORTs ® are<br />

being installed alongside of<br />

escalators. For most effective<br />

client flow the travel speed between<br />

VERMAPORT ® and escalator<br />

is synchronized.<br />

VERMAPORTs ® are designed for<br />

moving up to 800 carts per hour.<br />

5

6<br />

TECHNICAL<br />

ARRANGEMENTS<br />

VERMAPORTs ® IN COMBINATION WITH ESCALATORS<br />

VERMAPORTS ®<br />

6.1<br />

6.2<br />

BETWEEN ESCALATORS<br />

ESCALATORS BETWEEN VERMAPORTS ®<br />

In respect of the arrangement of<br />

VERMPORTs ® in combination with<br />

escalators or staircases there are<br />

no limitations, and adoption to<br />

(existing) building requirements is<br />

possible. The most common<br />

arrangements are shown by the<br />

drawings. As far as installation of<br />

VERMAPORTs between escalators<br />

(6.1) or escalators between<br />

common pit alternatively<br />

R S<br />

slab recess<br />

6.1.1<br />

6.2.1<br />

VERMAPORT ® s (6.2) is involved,<br />

both of the arrangements are<br />

fine (no advantage or disadvantage),<br />

meaning the shop designer<br />

is free in his choice.<br />

However the shown criss-cross<br />

arrangement (7.1) is possible and<br />

it is needed when it comes to pile<br />

up that combination over more<br />

than 2 levels.<br />

6.1.2<br />

common pit alternatively<br />

R S<br />

slab recess<br />

6.2.2<br />

It is worth to mention that<br />

VERMAPORT ® Shopping Cart<br />

Conveyors are available as "slab<br />

recess" and / or "sill-support"<br />

design. Also here the shop designers<br />

are free in their choice.<br />

However the VERMAPORT ® sill support<br />

version does have the<br />

advantage for installing the conveyors<br />

within the widened support

TECHNICAL<br />

ARRANGEMENTS<br />

VERMAPORTs ® IN COMBINATION WITH ESCALATORS<br />

OR STAIRCASES<br />

VERMAPORT ®<br />

/ESCALATORS COMB. CRISS-CROSS<br />

7.1<br />

VERMAPORT ®<br />

7.2<br />

BESIDE FIXED STAIRS<br />

pockets of the escalators alongside.<br />

On sill support on the lower<br />

end VERMAPORT ® and escalator<br />

are sitting in a "common pit". The<br />

drawings (6.1.1, 6.2.1, and 7.1.1)<br />

do refer to that.<br />

In case it is preferred to run with<br />

"slab recess" it comes to the situation<br />

as shown by the drawings<br />

common pit alternatively<br />

R S<br />

slab recess<br />

7.1.1<br />

R<br />

7.2.1<br />

having the title "slab recess"<br />

(6.1.2, 6.2.2 and 7.1.2). For running<br />

VERMAPORTS ® alongside of<br />

staircases (7.2) the "slab recess"<br />

version will be the right choice.<br />

7.1.2<br />

7

8<br />

TECHNICAL<br />

OVERVIEW<br />

8.1<br />

TECHNICAL DATA VERMAPORT ® WITH SLAB RECESS<br />

E<br />

762<br />

1624 on 30° a= H x 1,73205<br />

on 35° a= H x 1,4281<br />

1274<br />

F2<br />

750<br />

115<br />

F3<br />

D<br />

+ upper ext.<br />

systemline<br />

intermediale<br />

support column<br />

lower truss ext. L1<br />

upper ext.<br />

A<br />

minimum conveyor lenght = 1624+a+1274<br />

L2<br />

w+2x50mm<br />

B<br />

pit<br />

face to face of support<br />

(lower ext.+L1+upper ext.+80)<br />

DETAIL X DETAIL Y<br />

8.1.1 8.1.2<br />

R<br />

H<br />

floor to floor<br />

F1<br />

762<br />

H<br />

concrete support beam concrete support beam<br />

(also available as steel frame support beam)<br />

30° 35°<br />

D ceiling opening min. 5700 mm D ceiling opening min. 5000 mm<br />

R<br />

W s. verity table page 13<br />

mm mm kN kN mm kN kN<br />

1000<br />

1500<br />

2000<br />

2500<br />

3000<br />

3500<br />

4000<br />

4500<br />

5000<br />

5500<br />

6000<br />

6500<br />

7000<br />

A<br />

B<br />

E<br />

L1<br />

total length<br />

F1<br />

upper force reaction<br />

includes live loads<br />

F2<br />

lower force reaction<br />

L1<br />

floor to floor<br />

F1<br />

upper force reaction<br />

F2<br />

lower force reaction<br />

4630<br />

11,3<br />

12,4<br />

4326<br />

10,7<br />

11,8<br />

5496<br />

13,1<br />

14,3<br />

5040<br />

12,4<br />

13,4<br />

6362<br />

15,0<br />

16,3<br />

5754<br />

13,9<br />

15,2<br />

7228<br />

16,8<br />

18,4<br />

6468<br />

15,6<br />

17,0<br />

8094<br />

19,3<br />

21,1<br />

7182<br />

17,8<br />

19,3<br />

8960<br />

21,1<br />

23,0<br />

7897<br />

19,3<br />

21,1<br />

9826<br />

23,0<br />

25,1<br />

8611<br />

20,9<br />

22,8<br />

10692<br />

25,4<br />

27,8<br />

9325<br />

23,0<br />

25,2<br />

11558<br />

27,4<br />

29,8<br />

10039<br />

24,7<br />

27,0<br />

12424<br />

29,2<br />

31,8<br />

10753<br />

26,3<br />

28,7<br />

13290<br />

31,1<br />

33,8<br />

11467<br />

28,0<br />

30,5<br />

14156<br />

32,9<br />

35,9<br />

12181<br />

29,5<br />

32,3<br />

For floor to floorheights grater than 6,5 m, intermediate support maybe required 12895 31,1 33,0<br />

For floor to floorheights grater than 7 m, intermediate support maybe required<br />

recess width =W+50, vaies with cart width<br />

recess length 2100 mm may increase if lower extension is required to align with escalator<br />

ceiling thickness max 500 mm

TECHNICAL<br />

OVERVIEW<br />

9.1<br />

TECHNICAL DATA VERMAPORT ® WITH SILL SUPPORT<br />

E<br />

762<br />

265<br />

F2<br />

lower truss ext.<br />

1624 on 30° a= H x 1,73205<br />

on 35° a= H x 1,4281<br />

1274<br />

750 115<br />

F3<br />

D<br />

+ upper ext.<br />

L1<br />

min. conveyor length= 1624+a+1274<br />

L2<br />

systemline<br />

intermediate<br />

support column<br />

face to face of support<br />

(lower ext.+L1+upper ext.+80)<br />

DETAIL X DETAIL Y<br />

F1<br />

H<br />

upper ext.<br />

W s. verity table page 13<br />

A<br />

w+2x50mm<br />

lower support beam concrete support beam concrete support beam<br />

9.1.1 9.1.2<br />

(also available as steel frame support beam)<br />

S<br />

H<br />

floor to floor<br />

30° 35°<br />

D ceiling opening min. 5700 mm D ceiling opening min. 5000 mm<br />

mm mm kN kN mm kN kN<br />

1000<br />

1500<br />

2000<br />

2500<br />

3000<br />

3500<br />

4000<br />

4500<br />

5000<br />

5500<br />

6000<br />

6500<br />

7000<br />

A<br />

E<br />

L1<br />

total length<br />

F1<br />

upper force reaction<br />

F2<br />

lower force reaction<br />

L1<br />

total length<br />

F1<br />

upper force reaction<br />

includes live loads includes live loads<br />

4630<br />

14,3<br />

15,6<br />

4326<br />

13,7<br />

14,9<br />

5496<br />

16,1<br />

17,5<br />

5040<br />

15,4<br />

16,7<br />

6362<br />

18,0<br />

19,6<br />

5754<br />

16,9<br />

18,5<br />

7228<br />

19,9<br />

21,6<br />

6468<br />

18,5<br />

20,2<br />

8094<br />

22,3<br />

24,2<br />

7182<br />

20,6<br />

22,6<br />

8960<br />

24,1<br />

26,3<br />

7897<br />

22,6<br />

24,4<br />

9826<br />

25,9<br />

28,3<br />

8611<br />

23,9<br />

26,0<br />

10692<br />

28,4<br />

31,1<br />

9325<br />

26,0<br />

28,4<br />

11558<br />

30,2<br />

33,0<br />

10039<br />

27,7<br />

30,5<br />

12424<br />

32,2<br />

35,0<br />

10753<br />

29,3<br />

31,9<br />

13290<br />

34,0<br />

37,1<br />

11467<br />

30,8<br />

33,7<br />

14156<br />

35,9<br />

39,1<br />

12181<br />

32,5<br />

35,4<br />

For floor to floorheights grater than 6,5 m, intermediate support maybe required 12895 34,2 37,6<br />

For floor to floorheights grater than 7 m, intermediate support maybe required<br />

recess width =W+50, vaies with cart width<br />

ceiling thickness max 500 mm<br />

S<br />

F2<br />

lower force reaction<br />

9

10<br />

VERMAPORT ®<br />

OVERVIEW<br />

10.1<br />

DETAILS<br />

1. Key switch<br />

on / off function. Available on the<br />

upper and lower end of each<br />

conveyor<br />

2 Access check light beams,<br />

shut down the conveyor when<br />

people entering on inlet or outlet.<br />

Available on both ends of every<br />

conveyor.<br />

3 Emergency Stop<br />

placed underneath a liftable<br />

transparent cover, stops conveyor<br />

immediately. Sound signal on<br />

unauthorized use. Available on<br />

the upper and lower end of<br />

each conveyor.<br />

4 LED read out<br />

numbers shown refer to present<br />

mode or faults like flashing "0"<br />

means auto on / off active<br />

(verify 15). Available on both<br />

ends of every conveyor.<br />

5 Chain entry flaps<br />

supervising device checking<br />

position where chain enters the<br />

balustrade.<br />

6 Brake<br />

is activated in case of a conveyor<br />

mal function.<br />

7 Cart checking sensors<br />

double check if carts suitable for<br />

the conveyor. If carts not suitable<br />

conveyor chain will stop.<br />

8 Speed sensor<br />

check over or under speed of<br />

conveyor.<br />

9 Chain tension indicators<br />

on green LED chain tension ok,<br />

on red LED chain tension to be<br />

adjusted.<br />

10 Locker pin (on down only)<br />

makes sure the gap between<br />

inserted carts. Protects conveyor<br />

and carts.<br />

11 Swing doors (option)<br />

close the inlet and outlet of the<br />

conveyor.<br />

12 Partitions (option)<br />

balustrade raised poly carbonate<br />

screens, avoid reaching people<br />

to the carts<br />

13 Signage<br />

user information over head signs<br />

14 Portal frames<br />

loading limitation barriers<br />

15 auto on /off<br />

(only on inlet) activates conveyor<br />

when needed, shuts down conveyor<br />

when carts have been<br />

moved.

TECHNICAL<br />

S<br />

11.1<br />

R<br />

11.2<br />

11.3<br />

11.4<br />

TRANSPORT DIMENSIONS AND RELATED REMARKS<br />

W<br />

W<br />

optional split version<br />

H<br />

floor to floor<br />

mm<br />

1000<br />

1500<br />

2000<br />

2500<br />

3000<br />

3500<br />

4000<br />

4500<br />

5000<br />

5500<br />

6000<br />

6500<br />

7000<br />

K<br />

mm<br />

5000<br />

6000<br />

7000<br />

8000<br />

9000<br />

10000<br />

11000<br />

12000<br />

13000<br />

14000<br />

15000<br />

16000<br />

-<br />

K<br />

K<br />

T<br />

T<br />

In standard VERMAPORT ® Shopping Cart<br />

Conveyors are prepared for cargo on truck or<br />

container. The table below refers to the approximate<br />

length and weight of VERMAPORTs ® related<br />

to the rise and travel angle. The cargo width of<br />

VERMAPORTs ® varies in respect of the cart size<br />

(type) the conveyor is made for. The approximate<br />

cargo width can be calculated by adding 5<br />

to 10 cm on the dimension "W" shown (on the<br />

last column) of the table on page 13.<br />

In case it is required and or wanted<br />

VERMAPORTs ® can be manufactured in multi<br />

piece mode. For cargo the conveyor will come<br />

as shown on drawing (11.3). As dimensions and<br />

weight vary the table indeed does not refer to<br />

the split version VERMAPORTs ® .<br />

The 11.3 drawing shows the title split version,<br />

option.<br />

All cargo ready VERMAPORTs ® are furnished with<br />

appropriate stands and brackets.<br />

Lifting of VERMAPORTs ® exclusively done by<br />

means of the brackets. Ropes slinging around<br />

the VERMAPORTs ® is prohibited.<br />

On split version VERMAPORTs ® stand provisons are<br />

made for easy re-assembling (see drawing<br />

11.4).<br />

30° R 35° R 30° S 35° S<br />

T<br />

mm<br />

1600<br />

1680<br />

1750<br />

1780<br />

1800<br />

1830<br />

1850<br />

1860<br />

1880<br />

1890<br />

1900<br />

1920<br />

-<br />

weight<br />

kg<br />

1800<br />

2100<br />

2460<br />

2700<br />

3060<br />

3300<br />

3600<br />

3960<br />

4260<br />

4560<br />

4860<br />

5160<br />

-<br />

K<br />

mm<br />

4500<br />

5500<br />

6500<br />

7500<br />

8500<br />

9500<br />

10500<br />

11500<br />

12500<br />

13500<br />

14500<br />

15500<br />

16500<br />

T<br />

mm<br />

1620<br />

1700<br />

1770<br />

1800<br />

1820<br />

1850<br />

1870<br />

1880<br />

1900<br />

1910<br />

1920<br />

1940<br />

1960<br />

weight<br />

kg<br />

1680<br />

1980<br />

2220<br />

2460<br />

2820<br />

3060<br />

3300<br />

3660<br />

3900<br />

4140<br />

4380<br />

4620<br />

4860<br />

K<br />

mm<br />

6300<br />

7200<br />

8200<br />

9200<br />

10200<br />

11200<br />

12100<br />

13000<br />

14000<br />

15000<br />

16100<br />

16900<br />

-<br />

T<br />

mm<br />

1730<br />

1810<br />

1900<br />

1950<br />

1990<br />

2010<br />

2030<br />

2040<br />

2060<br />

2070<br />

2080<br />

2100<br />

-<br />

weight<br />

kg<br />

2340<br />

2640<br />

2820<br />

3240<br />

3600<br />

3900<br />

4200<br />

4560<br />

4860<br />

5100<br />

5400<br />

5700<br />

-<br />

K<br />

mm<br />

6500<br />

6800<br />

7100<br />

7900<br />

9600<br />

10500<br />

11400<br />

12200<br />

13100<br />

14000<br />

14800<br />

15700<br />

16600<br />

T<br />

mm<br />

1670<br />

1770<br />

1970<br />

2010<br />

2060<br />

2090<br />

2120<br />

2130<br />

2150<br />

2160<br />

2170<br />

2190<br />

2200<br />

weight<br />

kg<br />

2280<br />

2520<br />

2760<br />

3000<br />

3360<br />

3600<br />

3840<br />

4200<br />

4440<br />

4680<br />

4920<br />

5160<br />

5400<br />

11

12<br />

<strong>SHOPPING</strong> <strong>CART</strong>S<br />

on 35°<br />

SUITABLE FOR VERMAPORT ®<br />

u-CHASSIS <strong>SHOPPING</strong> <strong>CART</strong><br />

WITH WIRE BASKET<br />

for sample DTG# 5 (cart)<br />

<strong>SHOPPING</strong> <strong>CART</strong>S ENGAGED<br />

IN INCLINED TRACK<br />

UP TRACK WITH HORIZONTAL<br />

KEPT <strong>CART</strong><br />

12.1 12.2<br />

n-CHASSIS <strong>SHOPPING</strong> <strong>CART</strong><br />

WITH WIRE BASKET<br />

for sample DTG# 24 (cart)<br />

DOWN TRACK WITH HORIZONTAL<br />

KEPT <strong>CART</strong><br />

on 35°<br />

u-CHASSIS <strong>SHOPPING</strong> <strong>CART</strong><br />

WITH PLASTIC BASKET<br />

for sample DTG# 33 (cart)<br />

guide pin guide pin guide pin<br />

VERMAPORT ® -<br />

SUITABLE <strong>CART</strong>S<br />

For use on VERMAPORTs ® adopted<br />

carts are being needed. All<br />

known cart makers (verify table)<br />

do have VERMAPORT ® -suitable<br />

carts in their program. For use on<br />

VERMAPORTs ® simple standard<br />

rubber or plastic wheels are sufficient.<br />

There is no need for braked<br />

wheels but VERMAPORT ® can<br />

deal with them.

<strong>SHOPPING</strong> <strong>CART</strong>S<br />

SUITABLE FOR VERMAPORT ®<br />

SOME WORDS FOR UNDERSTANDING<br />

Because level held shopping<br />

carts (like on the floor) are being<br />

moved on up 35 degree tilted<br />

path, for physical reasons the<br />

shopping carts have to be adopted<br />

to the run pad.<br />

The drawings (12.1 and 12.2)<br />

show how the cart chassis has to<br />

be designed for making it possible<br />

to move them on both, the<br />

up and down track.<br />

Based on that needed physical<br />

conditions the cart makers mentioned<br />

on the table below do<br />

have Vermaport ® -suitable carts<br />

within their program.<br />

Europa<br />

For precise guiding of the carts<br />

while riding on the track between<br />

the front wheels there is a guide<br />

pin furnished (see photographs).<br />

In case a prospective customer<br />

likes to work with cart makers not<br />

mentioned within the table<br />

below, documents are available<br />

showing the physicals requirements<br />

for VERMAPORTs ® -suitable<br />

carts enable other cart makers to<br />

manufacture fitting carts.<br />

maker production factory no basket capacity<br />

ltr.<br />

Darrott cart no.<br />

VPO<br />

Darrott drawing Vermaport<br />

width<br />

mm<br />

Wanzl<br />

Germany ELT-7<br />

102 oder 152<br />

24 VPO.24.00.000.A3/00.II 1058<br />

Wanzl<br />

Germany ELT-6<br />

75 oder 90<br />

29 VPO.29.00.000.A3/00.I 996<br />

Wanzl<br />

Germany ELT-9F<br />

185<br />

50 VPO.50.00.000.A3/00.II 1152<br />

Caddie<br />

France<br />

7.789.20.03<br />

125<br />

24 VPO.24.00.000.A3/00.V 1058<br />

Caddie<br />

France<br />

7.789.01.03<br />

100<br />

24 VPO.24.00.000.A3/00.IV 1058<br />

Siegel<br />

Germany EKW-130<br />

130<br />

24 VPO.24.00.000.A3/00.III 1058<br />

Clarecart<br />

USA<br />

England 1001<br />

180<br />

39 VPO.39.00.000.A3/00.I 1101<br />

United Steel & Wire<br />

USA<br />

587-98<br />

160<br />

35 VPO.35.00.000.A3/00.II 1187<br />

United Steel & Wire<br />

USA<br />

41-237-000<br />

160<br />

49 VPO.49.00.000.A3/00.I 1140<br />

Rehrig<br />

USA<br />

2100-70<br />

150<br />

33 VPO.33.00.000.A3/00.I 1101<br />

Rehrig<br />

USA<br />

Vista<br />

190<br />

58 VPO.58.00.000.A3/00.I 1185<br />

Precision Wire USA PS-771 165 36 VPO.36.00.000.A3/00.II 1101<br />

Technibilt USA 3541 190 53 VPO.53.00.000.A3/00.I 1187<br />

Tote USA 1010 140 48 VPO.48.00.000.A3/00.I<br />

1070<br />

13

14<br />

REFERENCES<br />

VERMAPORT ® LOCATIONS<br />

EXCERPT FROM THE REFERENCE LIST<br />

Land Ort Lage Kunde/Objekt<br />

Austria<br />

Wien<br />

Center<br />

BILLA<br />

Switzerland Zermatt<br />

Canton Wallis<br />

MIGROS<br />

Neuhausen Canton Schaffhausen MIGROS<br />

Fleurier<br />

Canton Neuenburg<br />

MIGROS<br />

Davos<br />

Canton Graubünden COOP<br />

Germany Würzburg<br />

Bavaria<br />

FEGRO-SELGROS<br />

Viernheim<br />

Baden-Württemberg TOYS R US<br />

Sonthofen<br />

Bavaria<br />

ESSEN UND TRINKEN<br />

Rottach-Egern Bavaria<br />

EDEKA<br />

Regensburg Bavaria<br />

TOYS R US<br />

Lippstadt<br />

North-Rhine-Westphalia ZENTRALMARKT LIPPSTADT<br />

Lenggries<br />

Bavaria<br />

EDEKA NEUKAUF<br />

Kommern<br />

North-Rhine-Westphalia OPTIMA REWE<br />

Harrislee<br />

Schleswig-Holstein<br />

POETZSCH<br />

Hamburg Altstadt Europa Passage<br />

BUDNIKOWSKI<br />

Eschwege<br />

Hesse<br />

HERKULES MARKT<br />

Braunschweig Lower Saxony<br />

REAL KAUF<br />

Bochum<br />

North-Rhine-Westphalia TOYS R US<br />

Berlin<br />

Berlin-Lankwitz<br />

REICHELT<br />

Ahrweiler<br />

Rhineland-Palatinate EDEKA NEUKAUF<br />

Spain<br />

Madrid<br />

Castilla-La Mancha<br />

CHAMPION<br />

Cordoba<br />

Andalucia<br />

CHAMPION<br />

France<br />

Versailles<br />

SUPER-U<br />

Rueil-Malmaison<br />

LECLERC<br />

Paris<br />

INNO NATION<br />

Paris<br />

G20<br />

Paris<br />

LEADER PRICE<br />

England<br />

Kensington<br />

London<br />

WHOLE FOODS<br />

Huddersfield<br />

TESCO STORES<br />

China<br />

Hong Kong Pioneer Centre<br />

IKEA<br />

Hong Kong<br />

CARREFOUR<br />

Hong Kong<br />

MILLENIUM CITY<br />

Netherlands Groningen<br />

IKEA<br />

New Zealand Hamilton<br />

THE WARE HOUSE<br />

Taiwan<br />

Taipei<br />

RT MART<br />

Cyprus<br />

Larnaca<br />

ALPHA MEGA<br />

Canada<br />

Toronto<br />

CANADIAN TIRE<br />

USA<br />

Seattle<br />

Washington<br />

SAFEWAY<br />

San Francisco California<br />

BED BATH & BEYOND<br />

New York City New York<br />

HOME DEPOT<br />

New York City New York<br />

WHOLE FOODS<br />

Albany<br />

California<br />

TARGET

Notes<br />

15

TRANSPORTTECHNIK GMBH INCORPORATED<br />

Mühlenstraße 25<br />

D-58285 Gevelsberg/<br />

Germany<br />

Fon: 02332 5587-0<br />

Fax: 02332 5587-20<br />

eMail: info@darrott.de<br />

Website: www.darrott.com<br />

Property rights:<br />

Darrott ® and Vermaport ® are<br />

registered trade marks<br />

Roxbury Business Park<br />

1705 US Hwy 46, Ste.4<br />

Ledgewood, NJ 07852 USA<br />

Phone: 973-691-4500<br />

Fax: 973-691-4555<br />

eMail: inquiries@darrott.com<br />

Website: www.darrott.com<br />

VA1.09JAN08