Fixed ladders - National Safety Council

Fixed ladders - National Safety Council

Fixed ladders - National Safety Council

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>National</strong> <strong>Safety</strong> <strong>Council</strong><br />

Data Sheet 606 Rev. August 2007<br />

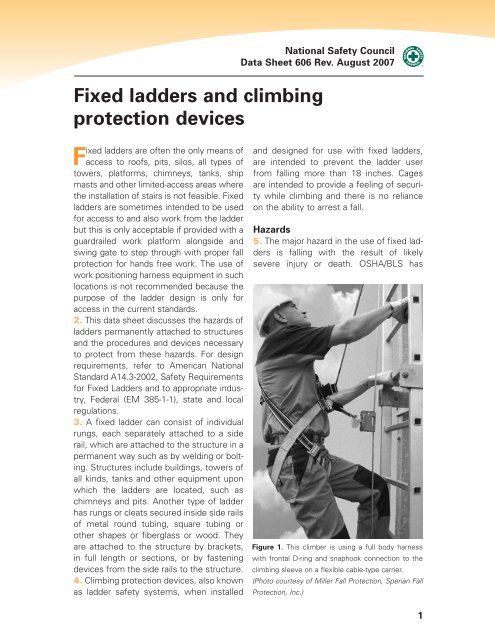

<strong>Fixed</strong> <strong>ladders</strong> and climbing<br />

protection devices<br />

<strong>Fixed</strong> <strong>ladders</strong> are often the only means of<br />

access to roofs, pits, silos, all types of<br />

towers, platforms, chimneys, tanks, ship<br />

masts and other limited-access areas where<br />

the installation of stairs is not feasible. <strong>Fixed</strong><br />

<strong>ladders</strong> are sometimes intended to be used<br />

for access to and also work from the ladder<br />

but this is only acceptable if provided with a<br />

guardrailed work platform alongside and<br />

swing gate to step through with proper fall<br />

protection for hands free work. The use of<br />

work positioning harness equipment in such<br />

locations is not recommended because the<br />

purpose of the ladder design is only for<br />

access in the current standards.<br />

2. This data sheet discusses the hazards of<br />

<strong>ladders</strong> permanently attached to structures<br />

and the procedures and devices necessary<br />

to protect from these hazards. For design<br />

requirements, refer to American <strong>National</strong><br />

Standard A14.3-2002, <strong>Safety</strong> Requirements<br />

for <strong>Fixed</strong> Ladders and to appropriate industry,<br />

Federal (EM 385-1-1), state and local<br />

regulations.<br />

3. A fixed ladder can consist of individual<br />

rungs, each separately attached to a side<br />

rail, which are attached to the structure in a<br />

permanent way such as by welding or bolting.<br />

Structures include buildings, towers of<br />

all kinds, tanks and other equipment upon<br />

which the <strong>ladders</strong> are located, such as<br />

chimneys and pits. Another type of ladder<br />

has rungs or cleats secured inside side rails<br />

of metal round tubing, square tubing or<br />

other shapes or fiberglass or wood. They<br />

are attached to the structure by brackets,<br />

in full length or sections, or by fastening<br />

devices from the side rails to the structure.<br />

4. Climbing protection devices, also known<br />

as ladder safety systems, when installed<br />

and designed for use with fixed <strong>ladders</strong>,<br />

are intended to prevent the ladder user<br />

from falling more than 18 inches. Cages<br />

are intended to provide a feeling of security<br />

while climbing and there is no reliance<br />

on the ability to arrest a fall.<br />

Hazards<br />

5. The major hazard in the use of fixed <strong>ladders</strong><br />

is falling with the result of likely<br />

severe injury or death. OSHA/BLS has<br />

Figure 1. This climber is using a full body harness<br />

with frontal D-ring and snaphook connection to the<br />

climbing sleeve on a flexible cable-type carrier.<br />

(Photo courtesy of Miller Fall Protection, Sperian Fall<br />

Protection, Inc.)<br />

1

<strong>National</strong> <strong>Safety</strong> <strong>Council</strong><br />

Data Sheet 606 Rev. August 2007<br />

behind rungs. Training-related hazards are:<br />

Carrying objects such as papers, tools and<br />

equipment; holding side rails; leaning too<br />

far to the side of the ladder and failure to<br />

use three-point contact which optimizes<br />

lower risk factors.<br />

6. Other hazards include:<br />

a. Scratch and puncture wounds from<br />

burrs on the ladder, corrosion, poor<br />

splices or foreign materials that are not a<br />

part of the ladder<br />

b. Incorrect climbing procedures, such as<br />

sliding the rails or failure to use installed<br />

fall protection systems<br />

7. The fall hazard can be offset by installation<br />

and proper use of available climbing<br />

protection devices (Figure 1).<br />

8. Other hazards can be minimized by<br />

properly documented maintenance, proper<br />

training of personnel and by review of proper<br />

design prior to installation of fixed <strong>ladders</strong><br />

(Figure 2).<br />

Figure 2. Three-point contact must always be used<br />

when climbing <strong>ladders</strong>, using two hands and one foot<br />

or two feet and one hand to maintain prudent contact<br />

with the ladder at all times. (Illustration courtesy of<br />

Construction <strong>Safety</strong> Association of Ontario.) Note:<br />

Ten feet is the trigger height for fall protection on supported<br />

scaffolds.<br />

recorded 26 fall deaths from fixed <strong>ladders</strong><br />

during an 11-year period. Fall hazards are<br />

either design or training related. Designrelated<br />

hazards are: Non-uniform spacing<br />

of rungs attached by methods other than<br />

drilling each side rail and welding the rung<br />

on each side; rungs other than round; failure<br />

to provide horizontal grab bars for<br />

extension side rails (including roof hatches)<br />

and failure to provide 7 inches of toe space<br />

Selection of personnel<br />

9. Some individuals experience a feeling of<br />

instability or panic when climbing <strong>ladders</strong><br />

and can become disoriented. Others<br />

become frightened and suddenly aware of<br />

the fall hazard and freeze on the ladder. In<br />

such instances, the climber must be talked<br />

down, assisted and sometimes forcibly<br />

removed from the ladder. Persons with<br />

such tendencies should be disqualified as<br />

potential fixed ladder users unless their<br />

fears can be overcome by training. The<br />

higher the ladder, the higher the risk.<br />

10. Potential ladder users must be physically<br />

capable of the exertion required. They<br />

should be medically certified to be free<br />

from a history of heart disease, vertigo,<br />

seizures, fainting spells or other physical<br />

impairments that might make climbing particularly<br />

dangerous.<br />

• Climb deliberately and without haste.<br />

2

<strong>National</strong> <strong>Safety</strong> <strong>Council</strong><br />

Data Sheet 606 Rev. August 2007<br />

• Never run up or down a ladder and never<br />

slide down a ladder.<br />

• Never jump from a ladder.<br />

• Check footing before alighting from a<br />

ladder.<br />

• Wear shoes with heels and keep<br />

footwear clean.<br />

• See Training section to meet 1926.1060.<br />

Design and installation<br />

11. The design of fixed ladder systems<br />

must be under the supervision of a qualified,<br />

registered structural engineer or architect<br />

skilled in safe design of fixed <strong>ladders</strong>.<br />

12. Anyone responsible for the design,<br />

construction and installation of fixed <strong>ladders</strong><br />

must be familiar with the provisions of the<br />

American <strong>National</strong> Standard A14.3-2002,<br />

<strong>Safety</strong>, Requirements for <strong>Fixed</strong> Ladders: In<br />

addition, review the applicable regulations<br />

promulgated in the United States under the<br />

Occupational <strong>Safety</strong> and Health Act, as well<br />

as Federal Administration, (EM385-1-1<br />

(11/03) Corps of Engineers App. J), state or<br />

provincial and local regulations.<br />

13. The minimum open width for a rung<br />

length, 16 inches, is required in Standard<br />

A14.3-2002 and is of particular importance<br />

for <strong>ladders</strong> equipped with acceptable<br />

climbing protection devices to allow foot<br />

space. Rungs must be 3 ⁄4 inch or 1 inch in<br />

diameter depending on likelihood for corrosion.<br />

Side rails should be 1 ⁄2 inch by 2 1 ⁄2 inches<br />

so extension side rails need not be<br />

supported for stability. Horizontal grab bars<br />

are necessary for momentary grabbing the<br />

rung or equivalent if the foot slips. Side<br />

rails should be bar stock but never angle<br />

iron or channel that cannot be gripped<br />

effectively under fall conditions.<br />

14. A fixed ladder must never be installed in<br />

a manner detrimental to personnel who may<br />

be on the underside of a ladder when climbing.<br />

Reverse climbing slopes are prohibited.<br />

15. <strong>Fixed</strong> <strong>ladders</strong> (at least the extension<br />

Figure 3. A typical elevated platform ladder has a<br />

guardrail and a fall protection system such as a selfretracting<br />

lanyard mounted above the platform.<br />

(Courtesy Sellstrom/RTC.)<br />

side rails) must extend a minimum of 42<br />

inches above the landings they serve. They<br />

should be equipped with horizontal grab<br />

bars in case the feet slip from the rungs so<br />

the hands can be used effectively.<br />

According to U.S. Army EM 385-1-1 4(d):<br />

“Horizontal grab bars shall be provided to<br />

facilitate grip. Grab bar diameters shall be<br />

spaced by a continuation of the rung spacing.<br />

Grab bar diameters shall be the equivalent<br />

of round rung diameters.”<br />

16. All roof access <strong>ladders</strong> with point of<br />

access at an elevated location should have<br />

a cage and/or ladder safety devices to deter<br />

or protect against falls (Figures 3 and 4).<br />

Ladders with a length of climb of more<br />

than 24 feet must have a cage or climbing<br />

protection (Figure 4). The cage must start 7<br />

to 8 feet above the ground or the platform<br />

3

<strong>National</strong> <strong>Safety</strong> <strong>Council</strong><br />

Data Sheet 606 Rev. August 2007<br />

Figure 4. This fixed ladder has a cage. Note: There<br />

must be a platform for every 50 feet of ladder, as<br />

given in ANSI A14.3-2002 “shall be of a type which<br />

can be operated entirely hands-free by the person<br />

using the ladder safety system. It shall permit the<br />

person using the ladder safety system to ascend or<br />

descend without having to continually manipulate the<br />

safety sleeve.”<br />

Note: Some climbing protection devices may stick<br />

due to lack of oils particularly low temperature silicones<br />

in cold icy weather or from ambient dust and<br />

dirt around sliding or rotating parts.<br />

(Courtesy Sellstrom/RTC.)<br />

landing where the ladder begins. CFR<br />

1910.27(d)(ii) regulations are similar cages<br />

or ladder safety systems at 20 feet.<br />

17. Provide adequate illumination to safeguard<br />

personnel where necessary. A minimum<br />

lighting intensity of five foot-candles<br />

is suggested per IES Chapter 29, 9 th edition.<br />

Install lamps so they do not glare. All<br />

lighting fixtures must be guarded from vandalism,<br />

electrically insulated and grounded.<br />

18. Where environmental conditions are<br />

oily, icy or wet, completely enclose fixed<br />

<strong>ladders</strong> if possible. Note: Some manufacturers<br />

of climbing protection rail systems provide<br />

a heating wire to melt ice on the rail<br />

19. If fixed <strong>ladders</strong> are on structure exteriors<br />

accessible to the public, the bottom 7<br />

to 8 feet must be excluded from public<br />

access. A fence with locked gates may be<br />

feasible, or the unguarded portion made<br />

removable and used only as needed such<br />

as many transmission or telecommunication<br />

towers.<br />

20. At the base of each fixed ladder, there<br />

must be a warning sign to prohibit use by<br />

unauthorized personnel.<br />

21. Warning! <strong>Fixed</strong> <strong>ladders</strong> must not be<br />

installed within reach of existing electrical<br />

conductors nor should new electrical conductors<br />

be installed near a fixed ladder.<br />

Long tools or jets of water may cause<br />

grounding and warnings may be needed if<br />

the hazards are analyzed carefully and cannot<br />

be eliminated.<br />

22. Item 7.3.1 of the <strong>Safety</strong> Requirements<br />

for <strong>Fixed</strong> Ladders reads as follows: “The<br />

safety sleeve shall be above the top for<br />

proper dismount and subsequent access.<br />

23. Acceptable types of climbing protection<br />

systems are as follows:<br />

a. A rail or wire cable fixed to the ladder, on<br />

which a sleeve travels. Rails provide<br />

more stability and are less easily damaged<br />

by wind vibration. Cable stays are<br />

required every 40 feet apart to avoid<br />

wind vibration contact damage. Workers<br />

may fail to reinstall them properly leading<br />

to broken cable wires that could<br />

affect the smooth operation of the climbing<br />

protection device.<br />

b. A sleeve fastened to the climber’s full<br />

body harness by snaphook and/or a<br />

4

<strong>National</strong> <strong>Safety</strong> <strong>Council</strong><br />

Data Sheet 606 Rev. August 2007<br />

short connector; the total length of<br />

which should be 9 inches. Note: For harness<br />

connection at the chest, a 12-inch<br />

connection may be required for proper<br />

climbing if the manufacturer has tested<br />

for a 24-inch free fall. Make sure the connection<br />

does not twist the device so it<br />

locks too quickly.<br />

c. A roof hatch that opens onto a flat commercial<br />

roof needs to be strong enough<br />

for a security barrier and rigid enough to<br />

act as an anchorage point for fall arrest<br />

devices. Exterior extension side rails<br />

equipped with horizontal grab bars are<br />

required in the U.S. Army <strong>Safety</strong> Manual<br />

EM385-1-1 (11/03) standard for proper<br />

access and especially descent from the<br />

roof. Appendix J 3h: “Openings shall be<br />

provided with elevated horizontal grab<br />

bars to facilitate access and exit from<br />

upper levels”<br />

24. The need for a flared upper extension<br />

side rail section depends on whether the<br />

climber has tools around his/her waistline<br />

on a tool belt. It is normally sufficient to<br />

have an 18-inch opening for persons to<br />

step through and little need for the 24 to<br />

36-inch openings once required when<br />

cranes or hoists were not available for lifting<br />

tool boxes and equipment onto platforms<br />

overhead.<br />

25. Install these devices according to the<br />

manufacturer’s instructions. Note: Climbing<br />

protection systems are intended for maintenance<br />

work and possibly operations in<br />

some applications where practical. These<br />

systems are only applicable for emergency<br />

escape when sufficient harnesses and<br />

climbing protection devices with connecting<br />

means exist in a secured and protected<br />

enclosure for a stated capacity. Remote<br />

climbing locations, such as telecommunications<br />

towers should have secured and protective<br />

containers at the base of each<br />

ladder with user documentation.<br />

26. At a steady climbing speed, the sleeve<br />

slides up and down without hindrance. If<br />

the climber falls, however, a locking cam or<br />

friction brake is activated to automatically<br />

stop the fall. Climbing down too quickly<br />

often causes the sensitive climbing protection<br />

device to lock causing unnecessary<br />

aggravation with the system.<br />

27. The top side of the rail or cable (bracket)<br />

must extend 3 feet above the top landing<br />

for proper dismount and subsequent<br />

access.<br />

28. Sufficiently close distances are<br />

required to allow the climber to alight from<br />

the ladder and position behind a protective<br />

gate or barrier before disengaging from the<br />

climbing protection device, or to reattach<br />

the climbing protection device before stepping<br />

onto the ladder. A ladder safety gate is<br />

required to provide protection on the platform<br />

and to allow detachment or reattachment<br />

to the safety device before the<br />

exposure of the opening is permitted.<br />

Users must hold different rungs in each<br />

hand as they climb in case corrosion has<br />

occurred.<br />

29. Item 4.1.4.2 of ANSI A14.3-2002, <strong>Safety</strong><br />

Requirements for <strong>Fixed</strong> Ladders, reads as<br />

follows: “Ladder safety systems shall be<br />

used when the length of climb of a ladder or<br />

section <strong>ladders</strong> exceeds 50 feet in a single<br />

length of climb and rest platforms shall be<br />

provided at maximum intervals of 150 feet.”<br />

Note: OSHA 1910.27(d)(2) states 20 feet<br />

without a cage and 30 feet with a cage, rest<br />

or landing platforms must be provided.<br />

Inspection and maintenance<br />

30. Before general use is permitted, an<br />

inspection must be made and documented<br />

of every new fixed ladder installation to<br />

determine that it has been installed in<br />

accordance with the provisions of the<br />

American <strong>National</strong> Standards Institute and<br />

the applicable federal, state or provincial,<br />

5

<strong>National</strong> <strong>Safety</strong> <strong>Council</strong><br />

Data Sheet 606 Rev. August 2007<br />

and local regulations and the instructions<br />

climbing protection system manufacturer.<br />

A checklist containing the requirements in<br />

this data sheet is recommended. Inspect<br />

all <strong>ladders</strong> regularly, such as every six<br />

months determining the intervals between<br />

inspection by use and exposure but no<br />

period greater than 12 months.<br />

31. A warning and sign shall be posted<br />

that a proper harness with a frontal D-ring<br />

and 9-inch connection shall only be used,<br />

and that full-body harnesses and 6-foot,<br />

shock-absorbing lanyards or their equivalent<br />

are prohibited for use with the climbing<br />

protection system. Periodic inspection<br />

of all fixed <strong>ladders</strong>, cages and climbing protection<br />

devices, and the prompt correction<br />

of any defects are imperative to their continued<br />

use.<br />

32. Some hazards to look for during periodic<br />

inspections are:<br />

• Loose, worn and damaged or corroded<br />

rungs or side rails<br />

• Damaged or corroded parts of the cage<br />

• Corroded or loose bolts and rivet heads,<br />

especially on the inside of metal stacks<br />

• Damaged or corroded handrails and<br />

brackets on platforms<br />

• Deteriorated masonry where fixed ladder<br />

anchorages are secured to a structure<br />

• Defects in climbing device tolerances,<br />

including damaged snaphooks, loose or<br />

damaged carrier rails or cables<br />

• Unauthorized parts in the system, such as<br />

incompatible snaphooks or connectors<br />

• Smooth rungs in the center portion must<br />

be made slip-resistant<br />

• Lack of horizontal grab bars in the area of<br />

extension side rails<br />

• Objects and pipes within 27 inches of<br />

the climbing face of the ladder that may<br />

interfere with climbing<br />

• Sufficient foot space either side of the<br />

carrier for safe climbing<br />

• No obstruction behind the ladder for<br />

seven inches at any location during the<br />

climb<br />

33. Training: To meet 1926.1060:<br />

• Proper climbing: use of flexible gloves<br />

with adequate friction<br />

• Boots with steel or synthetic spine or<br />

shank and a well-defined heel<br />

• Grasp rungs with full-hand rounded grip<br />

only, never side rails, to avoid catastrophic<br />

fall consequences.<br />

• Do not climb <strong>ladders</strong> with sharp edge<br />

rungs that could cut or injure the hands<br />

grip capacity in a fall or during repeat<br />

climbing usage.<br />

• Climb with face toward ladder only.<br />

• Step on rungs between the ball of the<br />

sole and the heel.<br />

• Only hold one particular rung with a<br />

hand; grasp another rung with the other<br />

hand<br />

• Do not sit on a ladder platform guardrail<br />

or stand up on a midrail.<br />

• Practice three-point climbing with close<br />

observation of a supervisor or trainer.<br />

(Note: this is a counterintuitive technique<br />

and must be regularly practiced<br />

with supervision)<br />

34. Rescue: Tested climbing protection<br />

systems are certified to have survived a 500<br />

pounds free-fall through 18 inches or the<br />

distance of free fall dictated by twice the<br />

connecting distance between the harness<br />

and the climbing protection device. The reason<br />

that 500 pounds was chosen for the<br />

test in the 1940s was based on rescue by a<br />

government climber who would piggyback<br />

under a stricken climber, lifting his connecting<br />

device to permit both climbers to<br />

descend. Thus two climbers at 250 pounds<br />

each would equal 500 pounds between<br />

attachments of the ladder to the structure.<br />

That concept has been abandoned in the<br />

past 20 years (but not the test) due to diffi-<br />

6

<strong>National</strong> <strong>Safety</strong> <strong>Council</strong><br />

Data Sheet 606 Rev. August 2007<br />

culty by trained climber rescuers. Thus pulleys<br />

and rope rescue and self-retracting lanyards<br />

have become more popular as tools<br />

for prompt rescue with suitable front or<br />

back D-ring suspension points. Where<br />

heights are several hundred feet, it is not<br />

enough to designate the local fire departments<br />

that are often under-equipped and<br />

lack speedy provision of manpower. Hence<br />

rope access systems used by trained technicians<br />

in a crew are becoming the option<br />

of choice throughout the world for climbing<br />

and emergency descent.<br />

35. Scaffold <strong>ladders</strong>: portable, hook-on,<br />

attachable or integral frame access is permitted<br />

by OSHA 1926.451(e) with reference<br />

to Subpart X for portable <strong>ladders</strong>.<br />

However, integral frame <strong>ladders</strong> must have<br />

horizontal members less than 16 3 ⁄4 inches<br />

apart and be uniformly spaced except<br />

between frames, at least 8 inches in<br />

length. No access using cross-braces is<br />

permitted. Fall protection is required over<br />

10 feet for access and a competent person<br />

must determine feasibility for erection,<br />

moving or dismantling. Self-retracting lanyards<br />

installed above shoulder height are<br />

recommended for tube and coupler<br />

attached <strong>ladders</strong> and integral frame <strong>ladders</strong><br />

36. Non-compliant Ladders: some structures<br />

like grain silos offer door handles for<br />

climbing and an aluminum or concrete<br />

enclosure for grain pouring that can act as<br />

a cage. Others are 12-inches rung width for<br />

ladder access to railroad signals. Some<br />

water tower manufacturers and merchant<br />

marine shipbuilders provide diamond<br />

shape rungs on fixed <strong>ladders</strong>. Helicopter<br />

maintenance access to the rotor blades<br />

have recessed steps and grab bars.<br />

Scaffold ladder frames may not be classified<br />

as a fixed ladder; likewise trailers and<br />

tankers for road and rail. Rebar mattes are<br />

similar to fixed <strong>ladders</strong>. Curved water tank<br />

bowl <strong>ladders</strong> and astronomy dishes with<br />

flat angles less than 70 degrees pose posture<br />

and connection length problems for<br />

climbers. For all these types of climbing<br />

structures the answer may be back-up fall<br />

protection both before and after the <strong>ladders</strong><br />

are standardized in respective industry<br />

standards. Step bolts are occasionally an<br />

alternative to <strong>ladders</strong> with offset or parallel<br />

steps consisting of bolts with heads to limit<br />

side slipping but pose a severe injury hazard<br />

if a faller catches a bolt under a body<br />

part, and are known to fail on transmission<br />

towers from time to time while climbing<br />

and should be proof-tested periodically.<br />

Sources of information<br />

American <strong>National</strong> Standards Institute, 25 West 43 rd<br />

Street, 4 th floor, New York, NY 10036.<br />

<strong>Safety</strong> Requirements for <strong>Fixed</strong> Ladders, A14.3-2002.<br />

U.S. Army <strong>Safety</strong> and Health Requirements Manual<br />

EM 385-1-1 (11/03).<br />

HSE Report on caged <strong>ladders</strong>: Preliminary investigation<br />

into the fall-arresting effectiveness of ladder safety<br />

hoops. HSE Research Report 258 (<strong>Safety</strong> Squared<br />

2004), http://www.hse.gov.uk/research/rrpdf/rr258.pdf.<br />

Acknowledgment<br />

This data sheet was revised by the<br />

Construction Division membership, of the<br />

<strong>National</strong> <strong>Safety</strong> <strong>Council</strong>, 1121 Spring Lake<br />

Drive, Itasca, IL 60143.<br />

Copyright 2008 <strong>National</strong> <strong>Safety</strong> <strong>Council</strong>.<br />

All rights reserved.<br />

Although the information and recommendations contained<br />

in this publication have been compiled from<br />

sources believed to be reliable, the <strong>National</strong> <strong>Safety</strong><br />

<strong>Council</strong> makes no guarantee as to, and assumes no<br />

responsibility for, the correctness, sufficiency or<br />

completeness of such information or recommendations.<br />

Other or additional safety measures may be<br />

required under particular circumstances.<br />

7