Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

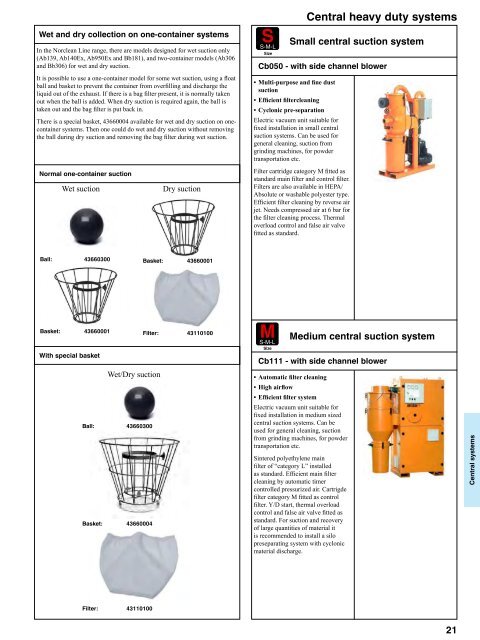

Wet and dry collection on one-container systems<br />

In the <strong>Norclean</strong> <strong>Line</strong> range, there are models designed for wet suction only<br />

(Ab139, Ab140Ex, Ab950Ex and Bb181), and two-container models (Ab306<br />

and Bb306) for wet and dry suction.<br />

It is possible to use a one-container model for some wet suction, using a float<br />

ball and basket to prevent the container from overfilling and discharge the<br />

liquid out of the exhaust. If there is a bag filter present, it is normally taken<br />

out when the ball is added. When dry suction is required again, the ball is<br />

taken out and the bag filter is put back in.<br />

There is a special basket, 43660004 available for wet and dry suction on onecontainer<br />

systems. Then one could do wet and dry suction without removing<br />

the ball during dry suction and removing the bag filter during wet suction.<br />

Normal one-container suction<br />

Wet suction<br />

Dry suction<br />

S<br />

S-M-L<br />

Size<br />

Central heavy duty systems<br />

Small central suction system<br />

Cb050 - with side channel blower<br />

• Multi-purpose and fine dust<br />

suction<br />

• Efficient filtercleaning<br />

• Cyclonic pre-separation<br />

Electric vacuum unit suitable for<br />

fixed installation in small central<br />

suction systems. Can be used for<br />

general cleaning, suction from<br />

grinding machines, for powder<br />

transportation etc.<br />

Filter cartridge category M fitted as<br />

standard main filter and control filter.<br />

Filters are also available in HEPA/<br />

Absolute or washable polyester type.<br />

Efficient filter cleaning by reverse air<br />

jet. Needs compressed air at 6 bar for<br />

the filter cleaning process. Thermal<br />

overload control and false air valve<br />

fitted as standard.<br />

Ball: 43660300<br />

Basket: 43660001<br />

Basket: 43660001<br />

Filter: 43110100<br />

With special basket<br />

Wet/Dry suction<br />

Ball: 43660300<br />

Basket: 43660004<br />

M<br />

S-M-L<br />

Size<br />

Medium central suction system<br />

Cb111 - with side channel blower<br />

• Automatic filter cleaning<br />

• High airflow<br />

• Efficient filter system<br />

Electric vacuum unit suitable for<br />

fixed installation in medium sized<br />

central suction systems. Can be<br />

used for general cleaning, suction<br />

from grinding machines, for powder<br />

transportation etc.<br />

Sintered polyethylene main<br />

filter of “category L” installed<br />

as standard. Efficient main filter<br />

cleaning by automatic timer<br />

controlled pressurized air. Cartrigde<br />

filter category M fitted as control<br />

filter. Y/D start, thermal overload<br />

control and false air valve fitted as<br />

standard. For suction and recovery<br />

of large quantities of material it<br />

is recommended to install a silo<br />

preseparating system with cyclonic<br />

material discharge.<br />

Central systems<br />

Filter: 43110100<br />

21