SSR ULTRA-PLUS COOLANT - Ingersoll Rand

SSR ULTRA-PLUS COOLANT - Ingersoll Rand

SSR ULTRA-PLUS COOLANT - Ingersoll Rand

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

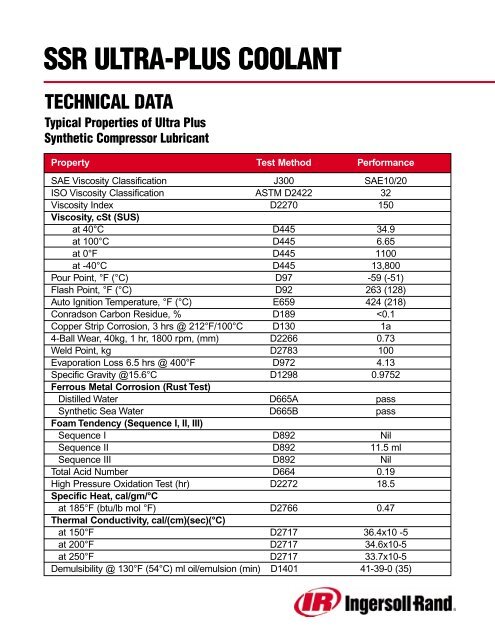

<strong>SSR</strong> <strong>ULTRA</strong>-<strong>PLUS</strong> <strong>COOLANT</strong><br />

TECHNICAL DATA<br />

Typical Properties of Ultra Plus<br />

Synthetic Compressor Lubricant<br />

Property Test Method Performance<br />

SAE Viscosity Classification J300 SAE10/20<br />

ISO Viscosity Classification ASTM D2422 32<br />

Viscosity Index D2270 150<br />

Viscosity, cSt (SUS)<br />

at 40°C D445 34.9<br />

at 100°C D445 6.65<br />

at 0°F D445 1100<br />

at -40°C D445 13,800<br />

Pour Point, °F (°C) D97 -59 (-51)<br />

Flash Point, °F (°C) D92 263 (128)<br />

Auto Ignition Temperature, °F (°C) E659 424 (218)<br />

Conradson Carbon Residue, % D189

Technical Data<br />

TOXICITY:<br />

Please refer to the Material Safety Data Sheet<br />

for Ultra Plus (Form APDD-772).<br />

COMPATIBILITY:<br />

The following lists serve as a guide for the<br />

material compatibility of various seals,<br />

plastics, and paints with Ultra Plus*.<br />

ACCEPTABLE:<br />

Seals: Fluorocarbon (Viton ® ), High Nitrile<br />

Buna-N, Florosilicone Rubber,<br />

Polysulfide, Hytrel ® , Kalrez ® , CPM<br />

Plastics: Nylon, Teflon ® , Deltrin ® , Celcon ® ,<br />

PBT, HD-PPE, Ryton ® (oil-less)<br />

Paints: Epoxy, Baked Phenolic, 2-Comp<br />

Urethane, MC-Urethane,<br />

Oil-Resistant Alkyd<br />

NOT RECOMMENDED:<br />

Seals: Neoprene, Natural Rubber, SBR,<br />

Buna-S, Butyl Rubber,<br />

Chlorosulfonated polyethylene,<br />

Low Nitrile Buna-N<br />

Plastics: Polystyrene, PVC, ABS<br />

Paints: Acrylic, Latex (household), Vinyl,<br />

Varnish, Lacquer<br />

*Under normal circumstances. In extreme<br />

conditions, such as high temperatures<br />

(over 250°F) and/or high stress, compatibility<br />

should be re-evaluated.<br />

Note: In the case of employment of new seal<br />

composition, lubricant compatibility should be<br />

evaluated. Please refer to <strong>Ingersoll</strong>-<strong>Rand</strong><br />

Contract Service, Davidson, North Carolina.<br />

APPLICATION DEPENDENT:<br />

Seals: Med Nitrile Buna-N, Polyurethane,<br />

EPDM, Epichlorohydrin, Polyacrylate<br />

Rubber, Silicone Rubber<br />

Plastics: Polyurethane, Polyethylene, Noryl ® ,<br />

Lexan ® , Lucite ® , Polysulfone,<br />

Polycarbonate (type)<br />

Paints: Alkyds, Phenolic, SC-Urethane,<br />

Industrial Latex<br />

MORE THAN AIR.<br />

SOLUTIONS.<br />

Online solutions: www.air.ingersoll-rand.com<br />

<strong>Ingersoll</strong>-<strong>Rand</strong> compressors are not designed, intended or approved for breathing air applications. <strong>Ingersoll</strong>-<strong>Rand</strong> does not approve<br />

specialized equipment for breathing air applications and assumes no responsibility or liability for compressors used for breathing<br />

air service.<br />

Nothing contained on these pages is intended to extend any warranty or representation, expressed or implied, regarding the product<br />

described herein. Any such warranties or other terms and conditions of sale of products shall be in accordance with <strong>Ingersoll</strong>-<strong>Rand</strong>’s<br />

standard terms and conditions of sale for such products, which are available upon request.<br />

<strong>Ingersoll</strong>-<strong>Rand</strong> Company<br />

Air Solutions Group<br />

800-C Beaty Street<br />

Davidson, NC 28036<br />

©2001 <strong>Ingersoll</strong>-<strong>Rand</strong> Company Form SCD-964 Printed in USA 05515184