D2.1 - EU Project Neptune

D2.1 - EU Project Neptune

D2.1 - EU Project Neptune

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

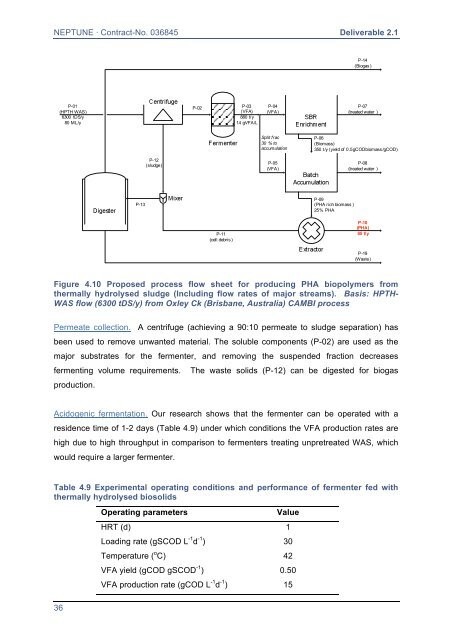

NEPTUNE · Contract-No. 036845 Deliverable 2.1<br />

Figure 4.10 Proposed process flow sheet for producing PHA biopolymers from<br />

thermally hydrolysed sludge (Including flow rates of major streams). Basis: HPTH-<br />

WAS flow (6300 tDS/y) from Oxley Ck (Brisbane, Australia) CAMBI process<br />

Permeate collection. A centrifuge (achieving a 90:10 permeate to sludge separation) has<br />

been used to remove unwanted material. The soluble components (P-02) are used as the<br />

major substrates for the fermenter, and removing the suspended fraction decreases<br />

fermenting volume requirements. The waste solids (P-12) can be digested for biogas<br />

production.<br />

Acidogenic fermentation. Our research shows that the fermenter can be operated with a<br />

residence time of 1-2 days (Table 4.9) under which conditions the VFA production rates are<br />

high due to high throughput in comparison to fermenters treating unpretreated WAS, which<br />

would require a larger fermenter.<br />

Table 4.9 Experimental operating conditions and performance of fermenter fed with<br />

thermally hydrolysed biosolids<br />

36<br />

Operating parameters<br />

Value<br />

HRT (d) 1<br />

Loading rate (gSCOD L -1 d -1 ) 30<br />

Temperature ( o C) 42<br />

VFA yield (gCOD gSCOD -1 ) 0.50<br />

VFA production rate (gCOD L -1 d -1 ) 15