MECHATRONICS - CEERI, Pilani

MECHATRONICS - CEERI, Pilani

MECHATRONICS - CEERI, Pilani

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

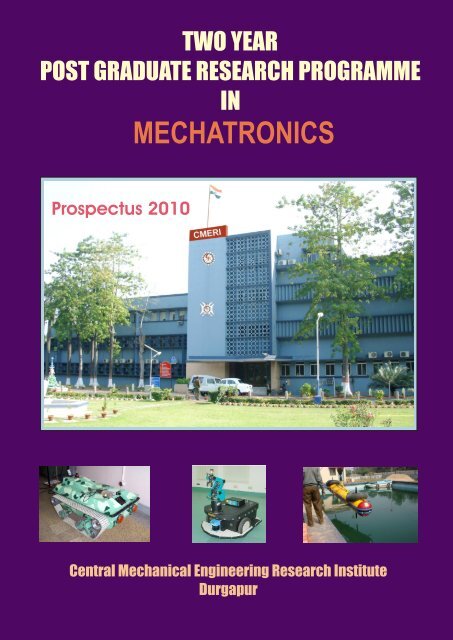

TWO YEAR<br />

POST GRADUATE RESEARCH PROGRAMME<br />

IN<br />

<strong>MECHATRONICS</strong><br />

Prospectus 2010<br />

Central Mechanical Engineering Research Institute<br />

Durgapur

Two Year<br />

Post Graduate Research Programme in Engineering<br />

in<br />

Mechatronics<br />

at<br />

CMERI, Durgapur<br />

(2010 2011)<br />

Mechatronics is a design philosophy which encourages engineers to concurrently integrate precision<br />

mechanical engineering, digital and analog electronics, control theory and computer engineering in the<br />

design of “intelligent” products, systems and processes rather than engineering each set or<br />

requirements separately. The advantages of the Mechatronics approach to design are shorter design<br />

cycles, lower costs, and elegant solutions to design problems that cannot easily be solved by staying<br />

within the bounds of the traditional engineering disciplines. Mechatronics further relates to a<br />

multidisciplinary approach to product and manufacturing system design. It represents the next<br />

generation machines, robots, automotive and aerospace systems, reprography, medicine,<br />

manufacturing machinery and smart mechanisms for carrying out work in a variety of environments.<br />

The Post Graduate Research Programme in Mechatronics intends<br />

to acquaint students with the fundamentals of mechatronics<br />

through pedagogy on current theoretical and practical<br />

developments in this area. The programme traverses a wide<br />

range of applications that comprise robotics, product design,<br />

instrumentation, manufacturing methods, computer integration<br />

and process & device control, with specific emphasis on<br />

innovative engineering. Students undergoing this course are<br />

expected to emerge properly equipped to confront challenges<br />

across the industrial environment and academic research<br />

spectrum.<br />

The Two Year PG Research Training Programme aims to provide in-depth exposure to the engineering<br />

concepts, scientific principles, research methodology and hands-on experience on advanced real-life<br />

R&D projects in different specializations related to Mechatronics. Students completing this two-year<br />

programme are expected to be fully research-enabled and industry-ready.<br />

The first semester of the programme focuses on core subjects and associated laboratories related to<br />

Mechatronics. The second and third semesters offer elective courses for specialization in different areas<br />

falling within the broad domain of Mechatronics. The third and fourth semesters provide opportunity to<br />

the candidates to effectively utilize the knowledge acquired through the courses towards advanced R&D<br />

project work and dissertation in their specialization areas.

Eligibility for Admission<br />

B.E. / B. Tech or equivalent with 70 % marks or 7.0 CGPA completed during 2009 and 2010 in<br />

Mechanical / Electrical / Electronics / Electronics & Communication / Electronics & Telecommunication /<br />

Electronics & Instrumentation / Computer Science & Engineering/Technology / Radio Physics /<br />

Mechatronics.<br />

Mode of Payment<br />

The fees/charges need to be deposited at CMERI, Durgapur before the start of every semester using the<br />

following modes:<br />

<br />

For NEFT bank transfer, please transfer the amount to the saving account number 30280331299 of<br />

CMERI at SBI, Durgapur (RTGS code SBIN0000074) with appropriate narration statement.<br />

<br />

In case of Demand Draft, please get it issued in favour of “Director, CMERI” payable at Durgapur and<br />

post it by speed post or registered letter to “Director, CMERI, Durgapur 713 209” with your name<br />

written in pencil on the reverse side of the demand draft.<br />

For other details (Admission Process, Eligibility, Fellowship, Important Dates, fee structure and<br />

online application)<br />

Please visit the CSIR website http://www.csir.res.in/

Semester-wise Scheme for Mechatronics<br />

SEMESTER I<br />

Sl. SUBJECT CODE HOURS/WEEK CREDITS<br />

L* T* S* Total<br />

1. Introduction to mechatronic<br />

MEC – 101 2 1 1 4 3<br />

systems<br />

2. Advanced control system MEC – 102 2 1 1 4 3<br />

3. Computer aided design, simulation MEC – 103 2 1 1 4 3<br />

& visualization<br />

4. Electronic devices MEC – 104 2 1 1 4 3<br />

5. Machines & mechanisms MEC - 105 2 1 1 4 3<br />

6. Technical communications MEC – 106 1 1 0 2 1<br />

TOTAL 11 6 5 22 16<br />

SEMESTER II<br />

Sl. SUBJECT CODE HOURS/WEEK CREDITS<br />

L T S Total<br />

1. Robotics MEC – 201 2 1 1 4 3<br />

2. Micro controllers &<br />

MEC – 202 2 1 1 4 3<br />

embedded system design<br />

3. Elective I MEC – 203/i 2 1 1 4 3<br />

4. Elective II MEC – 203/i 2 1 1 4 3<br />

5. Elective III MEC - 203/i 2 1 1 4 3<br />

6. Project management<br />

techniques<br />

MEC – 204 1 1 0 2 1<br />

TOTAL 11 6 5 22 16<br />

L* = Lectures T* = Tutorial S* = Sessional / Lab

ELECTIVES I, II & III: THREE SUBJECTS TO BE CHOSEN FROM THE FOLLOWING<br />

SUBJECT<br />

CODE<br />

Electromechanical system design MEC – 203/1<br />

Introduction to computer vision MEC – 203/2<br />

Robotics & machine intelligence MEC – 203/3<br />

Introduction to navigation & data fusion MEC – 203/4<br />

Microsystems technology MEC – 203/5<br />

Advanced materials MEC – 203/6<br />

Optimal control MEC – 203/7<br />

Precision machine design MEC – 203/8<br />

Numerical Methods & Computer Programming MEC – 203/9<br />

Digital signal processing and applications MEC – 203/10<br />

SEMESTER III<br />

Sl. SUBJECT CODE HOURS/WEEK CREDITS<br />

L T S Total<br />

1. Elective IV MEC – 301/i 3 1 1 5 4<br />

2. Project Work & Seminar MEC – 351 0 0 20 20 12<br />

TOTAL 3 1 21 25 16

ELECTIVE IV: ONE SUBJECT TO BE CHOSEN FROM THE FOLLOWING<br />

SUBJECT<br />

CODE<br />

Advanced communication systems MEC – 301/1<br />

Advanced computer vision MEC – 301/2<br />

Distributed control system MEC – 301/3<br />

Advanced navigation & data fusion MEC – 301/4<br />

Computer-aided metrology & machine vision MEC – 301/5<br />

Nano-tribology & its application to MEMS/NEMS MEC – 301/6<br />

Human computer Interfacing (HCI) MEC – 301/7<br />

Mobile robotics MEC – 301/8<br />

Soft computing techniques MEC – 301/9<br />

SEMESTER IV<br />

Sl. SUBJECT CODE HOURS/WEEK CREDITS<br />

L T S Total<br />

1. Project & Thesis MEC – 451 0 0 26 26 12<br />

2. Seminar & Viva Voce MEC – 452 0 0 - - 4<br />

TOTAL 0 0 26 26 16

COURSE DETAILS<br />

MEC- 101: INTRODUCTION TO <strong>MECHATRONICS</strong> SYSTEM<br />

Course Coordinator: S.N. Shome<br />

Module I<br />

Overview of Mechatronics: What is Mechatronics? Instrumentation and Control System.<br />

Module II<br />

Sensor and Actuators: Introduction-- Physical Principles & Basic mechanisms in sensor systems, static<br />

and dynamics performance characteristics, type of sensors based on principles, Different type of<br />

Sensors, Actuators: Electro-mechanical Actuators, Electrical Machines, Piezoelectric Actuators, Hydraulic<br />

and Pneumatic Actuation Systems.<br />

Module III<br />

Mathematical Modeling of Physical Systems: Modeling Electromechanical Systems. Structures and<br />

Materials, Modeling of Mechanical Systems for Mechatronics Applications, Fluid Power, Using MATLAB<br />

SIMULINK for modeling and simulation Mechatronics systems.<br />

Module IV<br />

Electronics and hardware components for Mechatronics: Computer interfacing, hardware for<br />

digital/analog interfacing, devices for data conversion<br />

Module V<br />

Future Trends, Applications, Tutorial & Labwork<br />

MEC-102: ADVANCED CONTROL SYSTEM<br />

Coordinator: S. Nandy<br />

Module I<br />

Introduction to Control System: Role of Controls in Mechatronics, Analog vs Digital, open loop vs<br />

feedback control, continuous vs discrete time control. Signals and Systems. Transfer Functions and<br />

Laplace transforms.<br />

Module II<br />

Control System Design: Time domain and frequency domain analysis; Root Locus Method; Nyquist<br />

Criteria. Lyapunov stability; structural properties (controllability and observability), Industrial motion<br />

control – PID controllers; controller tuning;<br />

Module III<br />

State Space Design.<br />

Module IV<br />

Digital Control: Discrete time mathematics, z- transforms, sampling rates, zero and first order hold, time<br />

delays, computer control implementation concepts, state space realization.

Module V<br />

Advance Controller Design: Kalman Filters as Dynamic System State Observers; LQ optimization-LQR,<br />

LQG, LTR design; Feedback Linearization, H 2 and Ho control; Adaptive and Nonlinear Control Design;<br />

Introduction to adaptive and intelligent Control.<br />

Module VI<br />

Future Trends, Applications, Tutorial & Labwork<br />

MEC- 103: COMPUTER AIDED DESIGN SIMULATION AND VISUALIZATION<br />

Coordinator: Avik Chatterjee<br />

Module I<br />

Introduction to the Module: Introduction to Computer Aided Design(CAD) , Simulation and Visualization,<br />

Genesis of CAD, Concepts of Computer Aided Engineering (CAE) and Virtual Prototyping(VP)<br />

Module II<br />

Geometric Object Modeling – Parametric Representation of Curves & Surfaces, Types of Curves and<br />

Surfaces (B-spline /Beizer/ NURBS), Intersection calculations , Assembly Modeling Techniques,<br />

Applications<br />

Module III<br />

Computer Graphics - Preliminaries Linear Algebra, Screen Coordinates ,Window Coordinates, Graphics<br />

Libraries , Rendering Pipeline Architecture(RPA) , Homogeneous Coordinates and Transformation<br />

Matrices , Quaternion , Projection Matrices , Types of Buffers , Display.<br />

Interpolation Techniques , Lightning , Wireframe , Shading Models , Texture Mapping , Ray Casting, Ray<br />

Tracing . Normal Vectors , Evaluators and NURBS, Modeling of Sculptured Surface , Selection and<br />

Feedback , Concepts of Scenes and Scene Graphs, Hierarchical Modeling Concepts, Kinematics of an<br />

Hierarchical model, Stereo Visualization, Applications<br />

Module IV<br />

Applications, Tutorial & Labwork<br />

MEC-104: ELECTRONIC DEVICES<br />

Coordinators: Ms. Uma Datta, J. Roy Choudhury<br />

Module I<br />

Electric Circuits and Components: Introduction, Basic Electrical Elements, Voltage and Current Sources<br />

and Meters, Thevenin and Norton Equivalent Circuits, Alternating Current Circuit Analysis, Power in<br />

Electrical Circuits, transformer, Impedance Matching, Grounding and Electrical Interference, Electrical<br />

Safety.<br />

Semiconductor Electronics: Review Semiconductors devices: Junction Diode – Zener Diode, Collage<br />

Regulators, Optoelectronics Diodes, Analysis of Diode Circuit, Three terminal devices-BJT, JFET, MOSFET,<br />

Four terminal devices, SCR, Diac,Triac – photo devices:- photo diode photo transistor, photo SCR,LED,

LCD, Opto-isolator and photo Coupled Pairs. Amplifiers: Transistor as an amplifier, BJT, FET amplifier –<br />

single stage, multistage Power Amplifiers, Operational amplifiers.<br />

Module II<br />

Introduction to computing: Number, system and code conversion, Logic gates, Boolean algebra,<br />

Combinational Logic circuits, Sequential Logic circuits – Latch, RS-, JK-, T-, D-, Flip flops, Buffer Register,<br />

Counters, Shift registers. Decoder, Encoder, MUX, DMUX, RAM, ROM, PROM, EPROM, EEPROM,<br />

Programmable logic devices.<br />

Module III<br />

Future Trends, Applications, Tutorial & Labwork<br />

MEC-105: MACHINES and MECHANISMS<br />

Coordinators: P.S. Banerjee, Dr. R. Sen<br />

Module I<br />

Review of basic engineering mechanics; Stress-strain under different types of loading, Kinematics and<br />

Dynamics, Mechanisms and Machines, Plane and Space Mechanisms, Kinematic Pairs, Kinematic Chains,<br />

Kinematic Diagrams, Kinematic Inversion, Four Link Planar Mechanisms and their Inversions, Mobility<br />

and range of movement - Kutzbach and Grubler’s criterion, Number Synthesis, Grashof’s criterion,<br />

Displacement analysis of plane mechanisms– graphical and analytical methods<br />

Plane motion of a rigid body, Instantaneous Centre (IC) of Velocity, Velocity analysis using IC Velocity<br />

and Acceleration Diagrams, Velocity and Acceleration Images, Corioli’s component of acceleration.<br />

Dimensional synthesis of mechanism; motion, path and function generation, precision point approach,<br />

Chebyshev spacing, Three position synthesis, graphical approach for four link mechanisms.<br />

Special Mechanisms - Indicator Diagram Mechanisms, Steering Mechanism, Hookes Joint.<br />

Module II<br />

Introduction to Machine Elements Gears, belts,cams,chain drives,couplings,clutches,brakes etc.<br />

Cams – classification of cams and followers, nomenclature, description and analysis of follower motion,<br />

pressure angle. Determine of basic dimensions and synthesis of cam profiles, graphical and analytical<br />

methods. Gears – terminology, fundamental law of gearing, involute profile. Interference and<br />

undercutting, minimum number of teeth, contact ratio, Gear Trains – simple, compound and epicyclic<br />

gear trains.<br />

Module III<br />

Future Trends, Applications, Tutorial<br />

MEC-106: TECHNICAL COMMUNICATIONS<br />

Coordinator: S. Sen Sharma<br />

Module I<br />

Role and importance of communication; Effective oral and written communication;

Module II<br />

Technical Report / R&D Proposal Formulation & Preparation, Research paper writing; Letter writing and<br />

official correspondence; Notices, agenda, minutes;<br />

Module III<br />

Oral communication in meetings, seminars, group discussions; Use of modern aids.<br />

MEC-201: ROBOTICS<br />

Coordinator: S.N. Shome<br />

Module I<br />

Introduction: History of development of robots, Basic components of robotic systems, Anatomy and<br />

structural design of robot, manipulation, arm geometry, drives and control (hardware) for motions, End<br />

effectors and grippers.<br />

Module II<br />

Coordinate Transformations and Robot Kinematics: Degrees of freedom, constraints, translation,<br />

orientation of rigid bodies, Modelling of robots, Representation of links and joints, workspace, velocities,<br />

manipulator Jacobian, singularities of robots and mechanisms, Kinematics for manipulators, selection of<br />

coordinate frames, Homogenous transformation, DH parameters, solution of kinematics.<br />

Module III<br />

Robot Dynamics: Introduction to Robot Dynamics, Lagrange-Euler Dynamic formulation.<br />

Module IV<br />

Trajectory planning and Motion Control: Introduction to trajectory planning, various trajectory<br />

functions, position, velocity and force control, computed torque control, Linear and non-linear controller<br />

design of robot, Feedback Linearization,.<br />

Module V<br />

Robotic Sensors, Position sensors, Accelerometers, Proximity and range Sensors, Introduction to<br />

computer vision,<br />

Biomechanics, Prosthetics & Orthotics Science, Mobility and Rehabilitation Aids.<br />

Module VI<br />

Future Trends, Applications, Tutorial & Laboratory<br />

MEC-202: MICROCONTROLLERS & EMBEDDED SYSTEM DESIGN<br />

Coordinator: J. Roy Chaudhuri<br />

Module I<br />

Introduction to embedded systems and architecture, System design using specification and modeling<br />

tools<br />

Module II<br />

Overview of embedded computing platforms; Microprocessors, Microcontrollers, DSP’s and SoC’s,<br />

Hardware – Software design and partitioning

Module III<br />

Design issues, consideration and trade–offs: Performance memory, power, timing, cost, and<br />

development time. Memory hierarchy, System Interfaces and Communication with peripheral units,<br />

timers counters, Introduction to Real-time system and Real-time Scheduling<br />

Module IV<br />

Real – time software development: High level languages and Programming issues, Systems performance:<br />

Networked embedded systems<br />

Module V<br />

Future Trends, Applications, Tutorial & Laboratory<br />

MEC-203/1: ELECTRO-MECHANICAL SYSTEMS DESIGN<br />

Coordinator: Dr. Nagahanumaiah<br />

Module I<br />

Introduction: Electro-Mechanical systems, applications, design and analysis approach for multi-physics<br />

problems<br />

Module II<br />

Design and Analysis of micro-nano positioning platforms: Ultra precision screw drives, Dual drive<br />

positioning systems, Design of multi-axis nano positioning table using flexural joints and dual drives,<br />

Design and kinematics analysis of parallel kinematics platforms<br />

Module III<br />

High speed power systems: Kinematics joints distributed loads in electro-mechanical motion drives,<br />

Design and dynamic analysis of high spindle<br />

Module IV<br />

Analysis and synthesis of fluid mechanical systems: Introduction to hydraulic actuators, multi-scale<br />

fluidic flow problems, solving micro pump system design<br />

Module V<br />

Instrumentation: Sensors, actuators, encoders, servo mechanisms, laser interferometery and other<br />

position calibration techniques<br />

Module VI<br />

Future Trends, Applications, Tutorial & Laboratory<br />

MEC- 203/2: INTRODUCTION TO COMPUTER VISION<br />

Coordinator: Dr. S. Majumdar<br />

Module I<br />

Fundamentals of Computer Vision: Role of vision to achieve simple goals. High level capabilities of<br />

vision using cognitive processes, geometric models, low level capability for object perception.<br />

Representation of images. Computer Vision Research and Application.

Image Formation, Camera Model, Properties of Projection, Interaction of Light and its Modeling,<br />

Perspective Model of Imaging, Homogeneous Coordinate, Lens Equation:Types of image digitizers.Image<br />

digitizing components.Imaging geometry-monocular imaging, binocular imaging, perspective<br />

transformations, camera model and camera calibrations,reflectance, image irradiance,effects of<br />

geometry of an imaging system.<br />

Module II<br />

Image and Scene Radiance : Reflectivity functions,surface gradient,photometric stereo<br />

Module III<br />

Feature Extraction, Filtering and Edge Detection: Feature selection using parameter modeling, size<br />

measurements, shape, colour, texture measurements, feature correlation, class separation, dimension<br />

reduction. Examples of common filters,optimal filter design, digital filtering-template matching,<br />

histogram transform, background substraction. Finding local edges,types of edge operators,edge<br />

thresholding strategies,curve detection.<br />

Module IV<br />

Fourier Transformation: Texture; More features beyond filters: Fourier series, 1D Fourier transform, 2D<br />

Fourier transform, Discrete Fourier transform, examples and properties of DFT, correlation of power<br />

spectrum. What is texture? Texture primitives, structure models of texel placement, texture as a<br />

pattern recognition problem, texture gradient. Spatial filtering, spatial frequency filtering, nonlinear<br />

spatial filters based on order statistics, nonlinear mean filters, adaptive filters, homomorphic filter,<br />

morphological filters - dilation, erosion, edge detection, skeletonization, thinning, thickening, pruning,<br />

granulometrics and pattern spectrum<br />

Module V<br />

Wavelets and Multiresolution Processing: Image Pyramids, Subband coding, Harr Transform;<br />

Multiresolution Expansions – Series expansion, Scaling Functions, Wavlet Functions; Wavelet Transforms<br />

in 1D & 2D – Discrete and Continuous Wavelet Transform; Fast Wavelet Transform<br />

Colour Processing: color spaces, color perception, examples of color image processing, pseudo coloring<br />

and color displays<br />

Module VI<br />

Tutorial on Matlab platform & Project<br />

MEC-203/3: ROBOTICS AND MACHINE INTELLIGENCE<br />

Coordinator: J. Roy Choudhury<br />

Module I<br />

Artificial Intelligence, Computational Intelligence, Various Machine Learning Algorithms ,Pattern<br />

Reorganization, Computer Vision, Fuzzy Expert System, Fuzzy Automata.<br />

Module II<br />

Fundamentals Of Robotics & Automation., Intelligent Robots, Control Systems and Components .

Module III<br />

Robot Motion Analysis and Control,Robot End Effectors,tactile and vision sensors in robotics<br />

Module IV<br />

Cognitive system for Human machine interaction.<br />

Module V<br />

Future Trends, Applications, Tutorial & Laboratory<br />

MEC- 203/4: INTRODUCTION TO NAVIGATION & DATA FUSION<br />

Coordinator: Dr. S. Majumdar<br />

Module I<br />

Sensors, Sensing, Model of Sensors & Process, uncertainties<br />

Module II<br />

Introduction to Estimation, Estimation Methods & relation between different estimators<br />

Module III<br />

State Space Modelling, LTI Systems & Kalman Filter & Extended Kalman Filter<br />

Module IV<br />

Other Navigation Filters, Bayesian Filters, Information Filters, Particle Filter etc.<br />

Module V<br />

Various Sensors used in Robotics: Accelerometer, Gyro, Compass, Encoder, Laser, Ultrasonic Sensor,<br />

Camera, Sonar, InfraRed Sensor, Tactile Sensor etc.<br />

Module VI<br />

Multisensor Data Fusion Fundamentals; INS, GPS Aided Navigation & Data Fusion<br />

Module VII<br />

Future Trends, Applications, Tutorial & Laboratory<br />

MEC-203/5: MICRO SYSTEMS TECHNOLOGIES<br />

Coordinator: Dr. Nagahanumaiah<br />

Module I<br />

Introduction: Precision engineering, precision manufacturing, historical developments, multi-scale<br />

product manufacturing paradigms<br />

Module II<br />

Micro machining technologies: micro manufacturing, MEMS, micro mechanical processes, micro milling,<br />

micro turning, micro-EDM, micro-ECM, laser machining

Module III<br />

Regenerative micro manufacturing technologies: micro injection molding, micro forming, hot<br />

embossing, rapid prototyping, micro tooling technologies<br />

Module IV<br />

Modeling of micro mfg. processes: material removal mechanics in micro milling, material erosion in<br />

micro EDM, laser ablation under ultra short pulsed laser, Applications of FEA and molecular dynamics<br />

based simulations<br />

Module V<br />

Design of ultra precision meso-micro machine tools: sources of error, Mechanical linkage error,<br />

Compliance and vibration error, Thermal error, error mapping, precision drives and selection of standard<br />

items and precision control systems<br />

Module VI<br />

Sensors for precision manufacturing: sensor systems for process monitoring, intelligent sensors, multi<br />

sensor approaches, acoustic sensor, signal processing and machine vision systems<br />

Module VII<br />

Precision Metrology: Definitions, laser interferometer, AFM, SEM, TEM, microscopes, material<br />

characterization techniques<br />

Module VIII<br />

Micro Factory concepts: micro assembly, composite molding, micro robots, geometric analysis, decision<br />

systems, process planning and micro factory layout designs; Module Applications of Precision<br />

Engineering: Micro-nano scale product design, applications in bio-medical, sensors, and nano<br />

technology.<br />

Module IX<br />

Tutorials and Lab<br />

MEC 203/6: ADVANCED MATERIALS<br />

Coordinator: A. Chaudhuri<br />

Module I<br />

Basics: Mechanics of materials, mechanical properties, dislocation theory, mechanical testing methods,<br />

creep and relaxation behaviour of common engineering materials<br />

Module II<br />

Advanced materials: Polymers, conductive polymers, ceramics, composites, nano-composites, smart<br />

materials, high temperature materials, bearing materials, materials for sensors and actuators<br />

Module III<br />

Material characterization: Optical and X-ray spectroscopy, diffraction methods (X-ray diffraction,<br />

Crystallographic texture measurements, electron microscopy (SEM, TEM, EBSD, etc.), Atomic probe<br />

micro analysis (AFM), Thermo gravity analysis

Module VI<br />

Future Trends, Applications, Tutorial & Laboratory<br />

MEC- 203/7: OPTIMAL CONTROL<br />

Coordinator: S. Nandy<br />

Module I<br />

Introduction to optimal control: Problem formulation – Mathematical model – Physical constraints –<br />

Performance measure Optimal control problem. Form of optimal control. Performance measures for<br />

optimal control problem. Selection of a performance measure. Static optimization, Linear programming,<br />

Simplex methods.<br />

Module II<br />

Dynamic Programming and related topics: Introduction to Dynamic Programming –– Principle of<br />

optimality. An optimal control system. Hamilton – Jacobi – Bellman equation. Continuous linear<br />

regulator problems. Pontryagin’s maximum principle, control with constrains, time optimal control.<br />

Optimal tracking control problem.<br />

Module III<br />

Variational Approaches: Calculus of variations – Fundamental concepts, Functionals, Euler’s equation,<br />

Lagrangian, application to control problems, Piecewise – smooth extremals Constrained extrema.<br />

Variational approach to optimal control problems – Optimal control law - Necessary conditions for<br />

optimal control – Linear regulator problems. Linear tracking problems, Multi-variable Optimization<br />

problem, Linear Quadratic Regulator(LQR) for system with input derivatives.<br />

Module IV<br />

Optimization Methods: Minimum time problems – Minimum control – effort problems. Singular<br />

intervals in optimal control problems. Continuous Kalman Filter, Square root Kalman filter. Non-linear<br />

system optimization, Gradient optimization techniques, steepest ascent and decent in parameter plane,<br />

Rosenbrock’s conjugate gradient method, David-Fletcher-Power method, etc.<br />

Module V<br />

Applications, Tutorial & Labwork<br />

MEC- 203/8: PRECISION MACHINE DESIGN<br />

Coordinator: N.C. Murmu<br />

Module I<br />

Introduction to machine design: The meaning of design, mechanical engineering design, design<br />

consideration, factor of safety, precision and rounding off quantities.<br />

Module II<br />

Stress Analysis preliminaries: stress, elastic strain, stress and strain relation, shear and moment, shear<br />

stresses in rectangular section beams, press and shrink fits, Hertz contact stress. Materials and their

properties: static strength, strength and hardness, impact properties, creep and temperature properties,<br />

plastics and elastomer.<br />

Module III<br />

Statistical considerations: Random variable, arithmetic mean, variance, standard deviation, normal<br />

distribution, dimensioning –definition and standards, statistical tolerancing, Weibull distribution.<br />

Module IV<br />

Design for static strength: Static loads and factor of safety, failure theories, maximum normal stress<br />

theory, maximum shear stress theory, distortion energy theory, stress concentration, Principle of<br />

accuracy, repeatability and resolution: introduction, formulating system error, quasi-static mechanical<br />

errors, errors caused by dynamic forces, design case study-carriage straightness errors caused by lead<br />

screw misalignment.<br />

Module V<br />

System design consideration: Introduction, manufacturing considerations, materials, structural design,<br />

joint design, support system, kinematic coupling design.<br />

Module VI<br />

Bearing: Introduction, sliding contact bearing, rolling contact bearings, rolling element rotary motion<br />

bearings, flexural bearings, design to limit of thermal effects on bearing performance, case study:<br />

measurement of spindle errors motions. hydrostatic, aerostatic and magnetic bearings. Power<br />

generation and transmission: Introduction, dynamic matching of components, fluid power system, linear<br />

and rotary power transmission elements.<br />

Module VII<br />

Future Trends, Applications, Tutorial & Laboratory<br />

MEC:203/9: NUMERICAL METHODS & COMPUTER PROGRAMMING<br />

Coordinator: Dr. Partha Bhattacharya<br />

Module I<br />

Numerical differentiation and integration of functions: Classical formula for equally spaced abscissa,<br />

Romberg integration, Gauss quadrature, Adaptive quadrature, Monte-Carlo method for<br />

multidimensional integrals.<br />

Module II<br />

Solution of differential equations: Ordinary first order differential equations. Difference equation. Single<br />

and multistep methods, Runga-Kurta method, Predictor corrector methods. Automatic error monitoring.<br />

Stability and solutions. Interpolation and approximation: Difference table, Polynomial interpolation –<br />

Newton, Lagrange etc, Piecewise polynomial and spline interpolation; Approximation of functions by<br />

Taylor’s series and Chebyshev’s polynomials.<br />

Module III<br />

Statistical Computing: Graphical representation of statistical data, Frequency distribution, Measures of<br />

central tendency and dispersion, Random variable and it’s expectation and variance, Probability models<br />

– Binomial, Poission and normal. Bivariate Frequency Distributions. Scatter Diagram, Product Moment,

Correlation coefficient and its properties (statements only), regression lines, correlation index and<br />

correlation ratio, Spearman rank correlation. Multiple linear regression, multiple correlation, partial<br />

correlation (without derivation). Random sampling (with replacement and without replacement),<br />

expectations and standard error of sampling mean (without derivation), expectation and standard error<br />

of sampling proportions. Point of estimation of parameters, Maximum likelihood estimation, interval<br />

estimate of parameters, test of significance based on t, F and CHI square distribution.<br />

Large sample tests, Tests based on Pearsonian frequency CHI-square.<br />

Module IV<br />

Future Trends, Applications, Tutorial & Labwork<br />

MEC-203/10: Digital Signal Processing & Applications<br />

Coordinators: J. Roy Choudhury<br />

Module I<br />

Introduction: Elements of a Digital Processing system, advantage of digital processing over analog<br />

processing, continuous time signals, discrete time signals, sampling of analog signals, sampling theorem.<br />

Discrete time signals and systems: Classification, block diagram representation, analysis of linear<br />

systems, response of LTI systems to arbitrary inputs, convolution, causal systems, stability, finite<br />

duration and infinite duration impulse response, recursive and non-recursive systems, description by<br />

difference equations.<br />

Z transform: Direct and inverse Z transform, properties, poles and zeros, techniques of finding inverse Z-<br />

transform, analysis of LTI systems in z-domain. Frequency Analysis: Fourier series of continuous and<br />

discrete-time signals, power density spectrum, Fourier transform, cestrum, frequency-domain<br />

characteristics of LTI systems, LTI systems as filters.<br />

Discrete Fourier Transform: Frequency domain sampling properties of DFT, Linear filtering methods<br />

based on the DFT, frequency analysis of signals using DFT, FFT algorithms. Design of digital filter:<br />

Characteristics & design of filters.DSP Hardware: Introduction to DSP processors, their architecture<br />

Module III<br />

Future Trends, Applications, Tutorial & Labwork<br />

MEC-204: PROJECT MANAGEMENT TECHNIQUES<br />

Coordinator: Dr. B.N. Mondal<br />

Module I<br />

Concepts and techniques of project formulation.<br />

Module II<br />

Project evaluation, planning, scheduling & implementation<br />

Module III<br />

Resource allocation & time management

Module IV<br />

Project monitoring, control & documentation.<br />

MEC-301/1 : ADVANCED COMMUNICATION SYSTEMS<br />

Coordinator: Ms. U. Datta<br />

Module I<br />

Introduction to Analog and Digital Communication-Functional architecture of coded and uncoded digital<br />

communication systems – Power bandwidth relation – Various bandwidth definitions- Signal – Noise<br />

ratio as performance criterion, Shannon’s capacity theorem – Signal space representation – M-ary<br />

signals Characterization of band limited Channel – ISI – Nyquist criterion for Zero ISI – Eye pattern –<br />

encoding – Equalization techniques zero forcing. M ary modulation – M ary PSK, QAM, FSK, -<br />

Comparison Power spectra QPSK, MSK, M ary – Bandwidth efficiency.<br />

Module II<br />

Light wave generation systems, System components, Optical fibers – Step Index & Graded index – Fiber<br />

modes – Dispersion in fibers, limitations due to dispersion – Attenuation – Non-linear effects,Light<br />

Sources: Basic concepts, LED’s structures – Spectral Distribution - Semiconductor lasers, structures –<br />

SLM and STM operation – Transmitter design. Light Detectors: Basic Concepts – PIN and APD diodes<br />

structures, Photo detector Noise, Amplifiers: Basic concepts – Semiconductor optical amplifiers ;<br />

Module III<br />

Principles of Cellular Networks. First Generation Analog. Second Generation TDMA. CDMA. Third<br />

Generation Systems. History and evolution of mobile radio systems. Types of mobile wireless services /<br />

systems - Cellular, WLL, Paging, Satellite systems, Standards, Future trends in personal wireless<br />

systems,Cellular concept and frequency reuse, Multiple Access Schemes, Channel assignment and<br />

handoff, Interference and system capacity, Trunking and Erlang capacity calculations Mobile Radio<br />

Propagation models, and their issues. Multipath fading and base band impulse response models,<br />

Parameters of mobile multipath channels: Mobile Radio signals. Attenuation Due to Distance. Slow<br />

Fading Due to Random Environmental Effects. Rayleigh Fading Due to Motion of Terminals. Intersymbol<br />

Interference Due to Different Signal Paths. Technology Implications, Detailed review of GSM,GPRS and<br />

3G standards, Multiple Access Techniques – FDMA, TDMA and CDMA systems, Operational systems,<br />

Wireless networking, design issues in personal wireless systems. . Cordless Systems and Wireless Local<br />

Loop. Cordless Systems. Wireless Local Loop. IEEE 802.16 Fixed Broadband Wireless Access Standard.<br />

Mobile IP and Wireless Access Protocol. Mobile IP. Wireless Application Protocol.<br />

Module IV<br />

Tutorial & Lab<br />

MEC- 301/2: ADVANCED COMPUTER VISION<br />

Coordinator: Dr. S. Majumdar<br />

Module I<br />

Review of Computer Vision Fundamentals, Computer Vision: Model Fitting: Bilinear models based on<br />

content and style parameters of the observed image, symmetric model, asymmetric model,<br />

classification, extrapolation, translation of the data set.<br />

Module II<br />

Stereo Vision: Range information from geometry, stereo & triangulation. Relaxation algorithm.

Module III<br />

Structure from Motion & Image Motion: Domain dependent & domain independent motion<br />

understanding. Understanding optical flow-adjacency, depth and collision, surface orientation and edge<br />

detection. Egomotion,understanding image sequences<br />

Module IV<br />

Probability Theory for Clustering, Review of Bayes Theorem: Statistical decision theory, Bayes Theorem,<br />

Classifier Types-Parametric, nonparametric. Classifier training-supervised,unsupervised. Maximum<br />

likelihood estimation, Bayesian estimation.<br />

Module V<br />

Object Recognition Pose Estimation: Basic concepts of pattern recognition, pattern classification using<br />

distance function, likelihood function, trainable pattern classifiers, pattern preprocessing, feature<br />

selection and verification. Methods for pose estimation-analytical or geometrical methods and learning<br />

based methods. Pose estimation using parameter sensitive hashing.<br />

Module VI<br />

Object Tracking: Adaptive background generation & shadow removal, single & multi camera tracking<br />

techniques, object-based summary generation using multi-camera tracking information. Accurate object<br />

segmentation and tracking under low computational complexity, camera motion estimation, examples<br />

of simple motion models, components of a visual tracking system - target representation & localization –<br />

Blob & Contour tracking, Kernel-based tracking, Visual feature matching, Common algorithms for<br />

Filtering and Data Association, - Kalman & Particle filter. Face Recognition: Brief history, predominant<br />

techniques – traditional, 3-D, Skin texture analysis, effectiveness.<br />

Module VII<br />

Lab. &Tutorial on Matlab platform<br />

MEC 301/3: DISTRIBUTED CONTROL SYSTEM<br />

Coordinator: J. Roy Chaudhuri<br />

Module I<br />

Distributed controls system Basics of process dynamics Integral and instantaneous balances - Material<br />

and Energy balances -General form of dynamic models<br />

Module II<br />

Linearization of nonlinear systems in state space form Response of lead-lag modules -Self-regulating<br />

system –transfer function analysis of higher order systems. Review of computers in process control:<br />

Module III<br />

Design of real time Data loggers, Data Acquisition Systems (DAS), Direct Digital Control (DDC).<br />

Supervisory Control and Data Acquisition Systems (SCADA),

Module IV<br />

Sampling considerations. Distributed control systems (DCS): Definition, Local Control (LCU) architecture,<br />

LCU languages, LCU - Process interfacing issues, communication facilities, configuration of DCS, displays,<br />

redundancy.<br />

Module V<br />

Future Trends, Lab and Tutorial<br />

MEC- 301/4: ADVANCED NAVIGATION & DATA FUSION<br />

Coordinator: Dr. S. Majumdar<br />

Module I<br />

Review of Navigation Sensors & Navigation methods<br />

Module II<br />

Probabilistic modeling & its applications to Navigation & Data Fusion (Bayes Filter)<br />

Module III<br />

Feature detection & Representation & Map building<br />

Module IV<br />

Data Association methods: Innovation Gate, Probabilistic Data Association, Joint Probabilistic Data<br />

Association, Multiple Tracking, Correlation based method<br />

Module V<br />

Simultaneous Localization and Map Building:<br />

Behaviour based Navigation<br />

Theory & Application to Navigation, Qualitative and<br />

Module VI<br />

Lab and Tutorial<br />

MEC-301/5: COMPUTER AIDED METROLOGY AND MACHINE VISION<br />

Coordinator: Dr. R. Sen<br />

Module I<br />

Modern Measurement Technique: Overview of modern measuring equipment & processes, improved<br />

precision & accuracy, modular strategy, contact and noncontact measurement, challenges of<br />

temperature, probes and environment.<br />

Module II<br />

Co-ordinate Measuring Machine: Introduction to CMM and its construction, Coordinate measuring<br />

process, probing and software, Qualification of probes, geometry alignment on parts, relations & GD&T<br />

measurements, trigger & scan probes, kinematics and strain gauge, laser and optical probes, prismatic<br />

component inspection, profile and surface measurement concepts, reverse engineering.

Module III<br />

Application of Laser Micrometer, interferometer & scanning gauges: Basics of laser, digital micrometers,<br />

Interference of two rays, Light sources for interferometry, interformetry applied to flatness testing,<br />

surface contour test, laser interferometers, heterodyne interferometry technique, scales and gratings,<br />

Moire scales and Moire fringes, Diffraction measurement technique<br />

Module IV<br />

Non-contact and in-process inspection: Introduction and advantages, airgauging, backpressure gage<br />

system, air gauge tool, laser systems, scanning, scanning operation, triangulation, triangulation<br />

operation, applications<br />

Module V<br />

Computer Aided Measurement Techniques: Custom software for measurement activities, software type<br />

and operation mode, calibration software, data acquisition software, gage repeatability and<br />

reproducibility software, procedure software, simulation software, Robotic gauging and inspection<br />

system, automatic inspection machines, expert knowledge based real time inspection system.<br />

Module VI<br />

Vision based inspection system: Introduction to vision system, principle of working, fields of machine<br />

vision system, development programmes, gray scale vs binary imaging, gray scale image processing<br />

techniques, mathematical morphology for shape analysis, circular scanning, photogrammetry, visual<br />

inspection.<br />

Module VII<br />

Lab and Tutorial<br />

MEC 301/6: Nanotribology and its application to MEMS/NEMS<br />

Coordinator: N. C. Murmu<br />

Module I<br />

Introduction to Tribology: Overview of surface roughness, adhesion, friction, interface temperature,<br />

wear and lubrication<br />

Module II<br />

Adhesion and Stiction: Introduction, mechanisms, mechanisms of solid-solid adhesion, mechanism of<br />

liquid medicated contact, adhesion measurement techniques, lubrication approaches and typical<br />

stiction data<br />

Module III<br />

Experimental Techniques: Nano-tribology, nano-mechanics and material characterization studies using<br />

scanning probe microscopy. Overview of surface imaging, adhesion, friction, scratching, wears<br />

indentation/ local deformation, nanofabrication and lubrication. Nano-indentation techniques, nanoindenter<br />

and examples<br />

Module IV<br />

Application to MEMS/NEMS : Nano-tribology of MEMS/NEMS devices. Definition of MEMS/NEMS and<br />

characterizations, examples of with tribological issues. Nano-tribological studies of MEMS/NEMS

materials and lubricants, super-lubricity (Lotus effect), Reversible adhesion (Gecko Effect) etc. Nanomechanics<br />

of Nanostructure: Importance of Mechanics in Nanostructure, measurement of mechanical<br />

properties of Nano-structure, FEM analysis of Nano-beams with roughness etc.<br />

Module V<br />

Future trends, tutorial & Lab<br />

MEC 301/7: HUIMAN COMPUTER INTERACTION (HCI)<br />

Coordinator: Avik Chatterjee<br />

Module I<br />

What is HCI? Difference of HCI and MMI (Man Machine Interface), Areas of HCI, Usability, Task &<br />

Machine Environment, Areas of Interface, Input & Outflow Flow, Feedback, Real Time Processing, Virtual<br />

& Augmented Reality, File Readers, Concepts of Scenes and Scene Graphs, Hierarchical Modeling<br />

Concepts, Creation of Graphical Objects, Manipulation of Graphical Objects, Creation of Virtual world,<br />

Navigation in Virtual World - Applications.<br />

Module II<br />

Interface Design, Types of Interfaces, Input and Output Flow Sensing, Sensors, Signal Processing, Signal<br />

Conditioning, Data Acquisition, Examples of multi sensor and multichannel data acquisition, Actuators,<br />

Overview of Control System. Overview of Tele-Operation.<br />

Module III<br />

Introduction to Haptics, Overview, Fundamentals in Haptic Rendering, Touch perception & design<br />

guideline, Haptic Algorithims, Collision detection principles, Elements of Contact Mechanics,<br />

Deformation Theory & Inelasticity, Modeling of Deformable objects, Design of real-time model for<br />

deformable objects, Wearable Haptics, Experimental Haptics, Fundamentals of Force feedback, Haptic<br />

Toolkits, Motion Tracking,<br />

Module IV<br />

Future Trends, Applications & Tutorials / Lab Sessions<br />

MEC 301/8: MOBILE ROBOTICS<br />

Coordinator: D. Banerjee<br />

Module I<br />

Overview: Review of conventional robotics, History of development of mobile robots, Types and<br />

Applications, Basic components of mobile robotic systems, Design considerations of mobile robots.<br />

Module II<br />

Sensor and Actuators: Sensors for mobile robots: Interoceptive sensors, Exteroceptive sensors. Sensor<br />

for dead reckoning, Heading sensors, Ground based beacons and GPS, Vision Sensor, INS (Gyros and<br />

accelerometer), URF, LRF, Bumpers and Contact switches.

Module III<br />

Modeling of Mobile robots: Degrees of freedom, constraints, Holonomic and Nonholonomic Systems,<br />

Vehicle kinematics, dynamics, example with two wheeled mobile robots.<br />

Module IV<br />

Systems and methods for mobile robot positioning: Navigation and guidance, Odometry and other dead<br />

reckoning methods, Active beacon navigation system, Land mark navigation, Map based positioning,<br />

Vision based positioning, Pose estimation through Kalman Filter.<br />

Module V<br />

Motion control: Path planning, Obstacle Avoidance, Classical control methods (PID, Feedback<br />

Linearization etc.), AI based methods (Fuzzy Logic, ANN etc.).<br />

Module VI<br />

Future Trends, Applications, Tutorial & Laboratory<br />

MEC 301/9: SOFT COMPUTING TECHNIQUES<br />

Coordinator: D. Banerjee<br />

Module I<br />

Introduction to soft Computing. Various soft computing tools. Advantages and disadvantages of soft<br />

computing tools over the classical tools, Applications.<br />

Module II<br />

Introduction to Fuzzy Sets, Operations on Fuzzy sets, Fuzzy Relations, Fuzzy Measures, Applications of<br />

Fuzzy Set Theory to different branches of Science and Engineering. Fuzzy Logic Based Control: Fuzzy<br />

Controllers: – simulation studies – case studies – fuzzy control for mobile robots.<br />

Module III<br />

Neural Model and Network Architectures, Perceptron Learning, Supervised Hebbian Learning,<br />

Backpropagation, Associative Learning, Competitive Networks, Hopfield Network, Computing with<br />

Neural Nets and applications of Neural Network. Neural Networks Based Control: ANN based control:<br />

Introduction: Representation and identification, modeling the plant, control structures – supervised<br />

control, Model reference control, Internal model control, Predictive control.<br />

Module IV<br />

Introduction to Genetic Algorithm, Genetic Operators and Parameters, Genetic Algorithms in Problem<br />

Solving, Theoretical Foundations of Genetic Algorithms, Implementation Issues.<br />

Module V<br />

Hybrid systems: Neuro – Fuzzy and Fuzzy – Neural Controllers: Neuro – fuzzy systems. Fuzzy-Neuro-GA<br />

based systems.<br />

Module VI<br />

Future Trends, Lab and Tutorial

Faculty List<br />

Sl. Name Designation Discipline<br />

1 Sh. S. N. Shome Scientist G Mechanical System Design, Mechatronics & Robotics<br />

2 Dr. S. Majumder Scientist G Navigation, Guidance & Data Fusion, Computer Vision & AI<br />

3 Dr. K.P. Roy Sarkar Scientist G Machine Design & Dynamics<br />

4 Dr. R. Sen Scientist F Precision Measurement Science & Computer Aided<br />

Metrology<br />

5 Smt. U. Datta Scientist F Electronics & Instrumentation, Communication<br />

6 Dr. B.N. Mondal Scientist F Advanced Materials & Processing<br />

7 Sh. A.K. Shukla Scientist F Material Science & RLA<br />

8 Sh. A. J. Banerjee Scientist F CAD/CAM, Advance & Precision Manufacturing<br />

9 Sh. A. Choudhury Scientist F Advanced Manufacturing & Materials<br />

10 Sh. S. Sen Sharma Scientist EII Electrical Machines, Drives, Energy Systems<br />

11 Sh. J. Roy Chaudhury Scientist EII Real Time Embedded Systems & Control<br />

12 Dr. P. Bhattacharya Scientist EII Automation, Internet Technology<br />

13 Sh. U.S. Ghosh Scientist EII Solid State Physics & Stress Analysis<br />

14 Sh. U. Nandy Scientist EII Engineering Design & Dynamics<br />

15 Sh. D. Banerjee Scientist EII Mobile Robotics, Navigation<br />

16 Smt. S. Datta Scientist EII Computer Vision & Navigation<br />

17 Sh. A. Chatterjee Scientist EII Simulation, Modelling & Visualization<br />

18 Sh. P.S. Banerjee Scientist EII Applied Mechanics, CAD & RP<br />

19 Smt. M. Nandy Sarkar Scientist EII Process Plant & Reliability Engineering<br />

20 Dr. D. Chatterjee Scientist EII Chemical Sciences<br />

21 Sh. A. Maity Scientist EI Machine Design, CAD, Modelling & Simulation<br />

22 Dr. Nagahanumaiah Scientist EI Microsystems Technology, Precision Manufacturing<br />

23 Sh. N.C. Murmu Scientist EI Tribology, Computational Techniques & CAD<br />

24 Smt. M. Singh Scientist EI Near Net-shape Manufacturing & Materials<br />

25 Sh. T. Gangopadhyay Scientist EI Design, CAE<br />

26 Sh. S. Nandy Scientist EI Robotics, Mechanical System Design & Control<br />

27 Sh. Sampath Kumar Scientist EI CAD & Production Technologies<br />

28 Sh. A.K. Lohar Scientist C Foundry Technology<br />

29 Dr. Ranjit Ray Scientist C Mechatronics, Computer Vision

ABOUT CMERI<br />

AT THE INCEPTION<br />

A recognized strategy for economic development of a country is the promotion of research and<br />

developmental activities. In a country like India, limited availability of resources for R&D renders<br />

imperative the provision of proper motivation and direction, so that these efforts can contribute<br />

significantly to the overall economic growth of the country. Mechanical engineering technology accounts<br />

for a significant portion of the import, in terms of process know-how, engineering hardware and<br />

equipment. It was to foster indigenous development of mechanical engineering technology for the<br />

industry in attaining self-reliance that the Central Mechanical Engineering Research Institute was<br />

established in Durgapur, West Bengal in 1958. The major task which the Institute addressed itself was<br />

the indigenization and effective development of mechanical engineering technology, through proper<br />

industrial orientation of R&D activities.<br />

The economic and social reality of India in the first decade after independence was perhaps best<br />

symbolized by the legendary figure of Janus, the god of doors in ancient Roman mythology, one of<br />

whose profiles faced east while the other pointed to the west. The urban and industrialized face of<br />

India looked eagerly towards an ambience of enhanced prosperity, while rural and underdeveloped<br />

India languished in darkness. Any comprehensive policy in this situation – be it at the national level or<br />

at the level of individual R&D institutes – had therefore to address both these realities and seek to<br />

ameliorate the objective problems of the later strata, while paving the way for realizing the aspirations<br />

of the former section.<br />

This objective guided our decisions for orientating its R&D activities. Since its inception, CMERI has<br />

been involved in R&D activities ranging from the design and development of products and systems to<br />

the development of analytical and experimental methodologies involving a high degree of sophistication<br />

for supporting thorough and in-depth design evaluation. It combined under its aegis R&D efforts on<br />

high and technology intensive frontier areas with those directed towards the evolution of ‘soft’<br />

technological options in response to the demands and dictates of the rural sector and the small-scale<br />

industries. CMERI adopted a two-pronged strategy for achieving its goals: concentrating its best efforts<br />

for keeping abreast of the developments in the emerging and sunshine areas of technology, and aiming<br />

towards proper diffusion of end results of research and development for societal utilization.<br />

SURGING SIXTIES<br />

The decade of the sixties saw the Institute holding a unique position in the country considering the<br />

vast investments that a rejuvenating country had already made towards industrialization. The basic<br />

priority at that period of time was indigenization and import substitution, since there existed<br />

innumerable problems related to technology, materials, plants and processes, machinery, etc. for which<br />

the country had still to depend on foreign assistance and imports. In keeping with its objective, in less<br />

than a decade the Institute designed a number machinery and equipment, all of which reached the<br />

production stage. In addition, through its R&D inputs the Institute could successfully explode the myth<br />

of superiority of foreign know-how for which the country was being bled dry.<br />

EIGHTIES<br />

The decade of the eighties witnessed a tangible change in perception about the role of science and<br />

technology relative to society. In response to the dictates of the changing times, CMERI undertook a<br />

major reorganization of the R&D activities to bridge the existing technology gap and reinforce the high<br />

technology supports in thrust and mission areas. The Institute structured new technological groups<br />

and activities of immediate relevance and long-term viability were incorporated in the programmes of<br />

these groups to cater to the transitioning industrial requirements and trends. The areas of design

engineering, design analysis, reliability evaluation and advanced manufacturing technology were<br />

combined to render more assistance to industries through collective efforts in these areas. The capability<br />

profile of the Institute was augmented in the fields of electronics and automation to meet the challenging<br />

tasks on robotics, artificial intelligence, image-processing and manipulator development. Side by side,<br />

the Institute also geared its resources and human capital to undertake as lead laboratory the societal<br />

and mission-mode tasks in response to the-then requirements.<br />

NINETIES<br />

Research and development in India before the nineties was shrouded in mystery and appeared exotic<br />

and alien to the outsider. What the insular institutes did was strictly off-limits to the larger section of<br />

the society. This even included the industry, with who the R&D institutes were supposed to work in<br />

close collaboration. Accountability at the individual or the collective level was noticeably absent. As a<br />

result, the aggregate output from the laboratories, when weighed against the social cost towards<br />

manpower and resources, or when calibrated against industrial utility, fared rather poorly. This, to a<br />

large extent, rendered the R&D efforts amateurish in nature and not keeping with the internationally<br />

acceptable standards.<br />

The move towards an open market economy during the nineties and concomitant alignment of the<br />

national economy with the forces of the world market changed this scenario. This, in its turn, introduced<br />

yet another change in the perception about the role of research and development in the society, which<br />

demanded accountability of the R&D efforts. To sustain, survive and continue to grow in the face of<br />

challenges thrown up by the changed circumstances, where all outputs had to be quantified in terms of<br />

tangible assets and continuously benchmarked against global standards, CMERI thoroughly examined<br />

its past and evolved explicit strategic and action plans to exploit to the best advantage the opportunities<br />

available. Renewed emphasis was laid on identifying niche areas of activity that could be best addressed<br />

with the facilities already at the Institute’s disposal. A change was brought about in the overall policy in<br />

deciding upon expertise, infrastructure and resource addition. Previous policies relied exclusively upon<br />

the development of infrastructure and expertise bases in response to and in terms of randomly chosen<br />

projects. This gave rise to a high degree of ambivalence and contributed to the eventual non-utilization<br />

of expertise whenever a project was concluded. The new policy took into account the resources available<br />

and maximized its end-utilization through the proper selection of projects. Renewal efforts for forging<br />

closer ties with industries were also undertaken. Side by side a major component of its research activities<br />

was directed towards the provision of R&D inputs to society through participation in different mission<br />

mode and societal programmes.<br />

And in the new millennium, the Institute is continuing in the same vein.<br />

The Mandates<br />

Mandates of R&D institutes must change with time and must faithfully reflect the changes in the<br />

global economic scenario, the economic realities of the country, the industrial climate of the country<br />

and the perception about R&D, its utility and social justification. This is evident in the charters and<br />

mandates of CMERI. Viewed chronologically in the order of its presentation, one might perceive the<br />

transition of Indian industry through the reflections that are carried in these mandates.<br />

1958- the year of foundation<br />

The mandate of CMERI was in substance to:<br />

* Serving industry<br />

* Developing mechanical engineering technology to reduce India’s dependence on foreign<br />

collaborations<br />

* Developing innovations and inventions

* Establishing the claim of Indian talent in international fields where Indian products shall<br />

ultimately compete<br />

A decade after foundation<br />

* Scientific research work in designing most economic and efficient machines and production<br />

processes for the development of industries, especially heavy machines.<br />

* Design, construction and operation of pilot plants for the processes and products developed<br />

and their commercial utilization<br />

* Evolution of indigenous designs for the benefit of industrial units<br />

* Testing of indigenously manufactured machines and their components<br />

* Research on raw materials and substitutes, production techniques, precision<br />

measurements, quality control, etc<br />

1983- The Silver Jubilee Year<br />

* New product & process development<br />

* Product and process innovation<br />

* Import substitution and export promotion<br />

* Waste recovery and utilization<br />

* Increasing productivity & reducing costs<br />

* Quality control of products & materials<br />

* Standardization<br />

1998- The Year of ISO 9001 Accreditation<br />

Design, development and manufacturing of:<br />

* Industrial machines and automation products<br />

* Farm machinery and post harvest technology<br />

* Process plant and equipment<br />

* Manufacturing technology including rapid prototyping & tooling, precision casting and<br />

foundry<br />

·* Testing, evaluation and assessment of engineering materials, components & selective<br />

products, calibration instruments & gauges and manpower training.<br />

CMERI AT THE GOLDEN JUBILEE YEAR<br />

The Central Mechanical Engineering Research Institute (CMERI) is the apex R&D institute for mechanical<br />

engineering. As a constituent member under the Council of Scientific & Industrial Research, the ambit<br />

of the Central Mechanical Engineering Research Institute (CMERI) – a premier establishment dedicated<br />

to research and development – extends over mechanical and allied engineering fields.<br />

In India, mechanical engineering technology has accounted for nearly half of the total technology<br />

imported. In terms of products, nearly one third of the value of total imports is for mechanical<br />

engineering equipment. In order to develop indigenously mechanical engineering technology for the<br />

industries so that R&D can play a key role in self-reliance, the Central Mechanical Engineering Research<br />

Institute at Durgapur, West Bengal was established in February 1958 with the specific task of<br />

development of mechanical engineering technology.<br />

Besides conducting frontline research in the varied areas related to mechanical engineering, the Institute<br />

dedicates it R&D efforts towards different mission mode programmes to disseminate appropriate<br />

technological solutions for poverty alleviation and societal improvement.

CMERI has developed as many as 150 products and processes. More than 120 licensees have obtained<br />

know-how for various products and processes developed by CMERI for commercial exploitation. CMERI<br />

has filed more than 100 patents, and in recognition to its pioneering role, the Institute has been awarded<br />

26 prestigious national awards for product and process development.<br />

CMERI has a dedicated team well balanced in terms of youth and experience of highly qualified<br />

professionals and supporting staff spanning the various disciplines under mechanical engineering. The<br />

manpower at CMERI’s command is comparable to the very best available in this country.<br />

The Institute employs around 400 scientific and technical staff with a rich blend of expertise and<br />

experience in different disciplines of engineering sciences.<br />

MAJOR OPPORTUNITIES<br />

Mechanical Science and engineering is a vast domain for developing expertise and opportunities exist<br />

in the sub disciplines of mechanical engineering and allied fields where CMERI has already ventured.<br />

A major opportunity exists in MANUFACTURING, <strong>MECHATRONICS</strong>, CLEAN ENERGY, etc. where CMERI<br />

can become the lead laboratory and conduct high-end cutting edge R&D<br />

In addition, opportunities exist for CMERI to step into new core, subsidiary and interdisciplinary areas.<br />

MISSION<br />

* To constantly identify and create new niche and challenging domains<br />

* To develop and disseminate knowledge in core competence areas through well-directed,<br />

multidisciplinary research programmes<br />

* To address the societal needs through appropriate research initiatives<br />

* To provide quality R&D services to industry with a view to enhancing their competitiveness<br />

VISION<br />

To emerge as an internationally recognized R&D laboratory in mechanical sciences and engineering<br />

through excellence in research, fostering innovation and evolving integrated solutions<br />

NICHE DOMAINS & KEY TECHNOLOGY AREAS<br />

In order to concentrate research focus, the thrust areas of the Institute were revisited. The following<br />

key technology areas were defined afresh:<br />

* Robotics & Mechatronics<br />

* Advanced Manufacturing<br />

* Clean Energy Technology<br />

* Microsystems Technology<br />

* Farm Machinery & Post Harvest Technology<br />

INTERDSICIPLINARY RESEARCH AREAS<br />

New interdisciplinary research areas are needed to complement, support and carry forward the main<br />

R&D initiatives. Some areas have already emerged, and others have R&D thrusts. These are:<br />

* Materials including polymers and composites<br />

* Electronics Instrumentation and Control

* Mechatronics & Robotics<br />

* Virtual Reality & Prototyping<br />

THRUST AREAS<br />

Mechatronics<br />

CMERI has acquired expertise in the field of Robotic Systems, Control Engineering & Design Analysis in<br />

the course of continued involvement with different project modules conducted under the Polymetallic<br />

Nodule Programme of the Department of Ocean Development, Government of India. Even before such<br />

large-scale involvement, CMERI had undertaken the development of a vacuum mopping system for<br />

spilled heavy water for atomic power plants. Subsequently, CMERI has developed ‘Remotely Operated<br />

Vehicles’ that are exploring marine-wealth in the depths of the Indian Ocean and the Arabian Sea.<br />

CMERI has developed the requisite infrastructure and initiated human resource in the course of these<br />

projects. The specific areas where the expertise has been acquired includes design of underwater robotic<br />

components, synthesis of intelligent control algorithms, navigational algorithms, software development<br />

on various platforms, distributed network systems, etc. Side by side, the experience was fed back for<br />

the development of conventional robotic elements and the provision of tailored solutions for industrial<br />

automation projects. Currently CMERI in undertaking extensive research in the design and development<br />

of All terrain Robots, Autonomous Underwater Vehicle, Autonomous Mobile Robot for Manufacturing<br />

Applications, Subterranian Robots, etc.<br />

Mechanical Design & Manufacturing<br />

CMERI possesses a comprehensive CAD tools environment that supports collaborative design through<br />

concurrent consideration of trade-offs to satisfy contrary design and manufacturing requirements. This<br />

environment allows early insight into the constraints of downstream activities and enables the designer<br />

to control the total design process upfront.<br />

With the help of the latest generation of CAD and associated facilities, it is possible to analyse<br />

mechanisms, tolerances, interference of the designated parts and components in an assembly and<br />

verify the geometric and functional relationship between them. The object-oriented database enables<br />

the designer to simplify the design process by modifying, tracking, and assuming control of the complex<br />

relationships existing between individual parts in a complex assembly. Further with these enabling<br />

technologies, automatic generation of tool paths, tool changes, table rotation and tool cycles is possible.<br />

The activities carried out in the design group also include design analysis and process simulation through<br />

static and dynamic analysis of the systems and optimization of the design parameters. It further covers<br />

the simulation of some engineering processes to optimise design of components from the<br />

manufacturability angle such as tooling, methoding and process parameters. Finally, the hazard and<br />

safety requirements are analysed using various tools including high end computer software.<br />

Rapid Prototyping is a new and powerful tool for rapid product development. A class of technologies<br />

has emerged during the last decade by which a CAD file of an object can be converted into a physical<br />

model through special material sintering, layering or deposition techniques. The major application of<br />

this technology is for early verification of product designs and quick production of prototypes for testing.<br />

Multiple prototypes can now be reproduced more economically by using the RP master as pattern for<br />

creating moulded or soft tooling. It has been established that rapid prototyping technology, in<br />

conjunction with investment casting can substantially reduce the cost of producing a prototype metal<br />

casting.

One of the best combinations of Layered Manufacturing System (LOM) and Stereolithography Apparatus<br />

(SLA-250) for direct conversion of CAD solid models into physical models has been installed at CMERI.<br />

Also available are downstream processes like Vacuum Casting for RTV Silicon Rubber Moulds, TAFA<br />

Process, Spin Casting, Investment Casting, etc. to convert RP models into components of desired<br />

materials. This combination has given CMERI a unique capability for bringing about large time<br />

compression into the product development process. For Rapid Tooling, another very important and<br />

imperative feature, HEK Vacuum Casting and TAFA High Velocity Metal Arc Spraying System has been<br />

integrated with the existing facilities.<br />

Virtual Prototyping (VP) programs provides a means of rapidly developing system concepts and analyzing<br />

them for form, fit, function, logistics, human factors integration, and general feasibility analysis. The<br />

resulting models can be studied, viewed from different angles, and even “entered” (Integrating with<br />

Virtual Reality) by multidisciplinary design teams working in an integrated product development<br />

environment.<br />

CMERI has a rich working background in Computer Aided Design (CAD) and Computer Aided Engineering<br />

(CAE), and its expertise in visualization is being augmented with the induction of state-of-the-art facilities<br />

in Virtual Prototyping and Virtual Reality, which facilitates working in the full 1:1 scale assembly level<br />

rather than at the conventional component level.<br />

Simulation of the functional behavior of the full scale digital prototypes help in identifying the design<br />

flaws at the early stage of product development and has the direct effect on reducing the number of<br />

development of actual physical prototypes, which, in its turn, reduces the lead time for product<br />

development and the time to market the product.<br />

The Advance Simulation and Immersive Visualization Facility is equipped with very powerful computing<br />

platform for full-scale multi-physics analysis (fluid, structural or thermal) with integrated multi-piped<br />

graphics subsystem for real time rendering and visualization of large datasets.<br />

Manufacturing of hard prototypes is an essential part of product development that requires high-grade<br />

capability for manufacturing precision and reliable components. To facilitate this, CMERI has equipped<br />

itself with state-of-the-art machines such as CNC Lathes, EDM Die Sinking Machine, 3-Axis DRO System,<br />

Precision Cylindrical Grinder, Very High Speed Grinding and Milling Spindles, CNC Retrofits, Tool Presetter,<br />

Centre Hole Grinding Machine, Jig Grinder Attachment, etc. have been inducted in the Prototype<br />

Fabrication Workshop of the Institute to facilitate the downstream processes of product development.<br />

A modern and versatile Heat Treatment Furnace with fluidised heating media has also been installed<br />

for carrying out different types of heat treatment and surface treatment of the components of prototypes<br />

and tooling.<br />

CMERI boasts a modern foundry comprising facilities such as Induction Melting Furnace, Core Baking<br />

Oven, Shot Blasting Machine, and advanced facilities for Investment and Spin Casting. SOFTCAST and<br />

AFS software have been introduced for complete computerisation of foundry methoding, namely gating<br />

and sintering system, solidification simulation, etc.<br />

From the technological point of view, prototypes help in verifying the form, fit and function of the part,<br />

and as models for assembly checks, stress analysis and wind tunnel testing. Prototypes are also useful<br />

as masters for development of tooling.<br />

To reduce product development lead-time and to impart greater flexibility in incorporating client<br />

customisations, CMERI has replaced the traditional and wasteful methods of prototype development<br />

based, to a large extent, on manual skills.<br />

A Center for Advanced Materials Processing (CAMP) has been established at CMERI for dedicating<br />

research efforts for the development of high-technology materials processing relevant to manufacturing<br />

aspects and is focused on industrial concerns and meeting industrial needs.

Presently CAMP involves itself in developing capabilities of Advanced Materials Processing Technology<br />

for manufacturing of engineering and biocompatible components through different materials processing<br />

techniques. It caters to present scope of activities with future developmental work in the advanced<br />

materials processing in the following areas:<br />

* Metals, alloys, and metal matrix composites through Investment casting /Rapid Prototype<br />

Integrated Investment Casting (RPIC)<br />

* Ceramics, ceramic matrix composites, cermets etc for structural, cutting tools and<br />

other engineering applications.<br />

* Net Shape processing of advanced ceramic engineering components / bio- implants<br />

through RPIC / Gel Casting & Sol-gel process<br />

* Sol-gel processing for coating application<br />

* Synthesis of ultrafine / nano-powders through wet chemical processing for development<br />

of advanced engineering and bio-medical components.<br />

* Smart Materials Processing for self-adjustment of humidity and temperature<br />

10 th. FYP Initiative for Capability Development in Advanced Manufacturing Technology<br />

The major R&D areas for this generic project comprises Manufacturing Automation, Virtual Prototyping<br />

and Near-net-shape Manufacturing Processes like squeeze casting, injection molding, and forging. They<br />

are important because of the large number of products passing through such manufacturing processes,<br />

and their superior efficiency with respect to time and material exploitation. The project consists of<br />

nine sub projects as listed below enablimg CSIR to be in a position to address the major issues of<br />

production and competitiveness of the Indian manufacturing sector:<br />

* Autonomous Mobile Robots for Factory Environment<br />

* Customised bio-implants and engineering components from advanced ceramics and<br />

metals<br />

* Near Net Shape manufacturing of Components of Al-Alloy by Squeeze Casting<br />

* Technology for Production of Wide Ferro magnetic Metallic Glass Ribbons<br />

* Development of process technology and manufacturing of Austemperd Ductile Iron<br />

(ADI) components for engineering application<br />

* Technology of Metal Injection Moulding process for production of complex engineering<br />

components<br />

* Net shape manufacturing of Ceramic Particulate Reinforced Al-alloy matrix composites<br />

components by Investment Casting Process<br />

* Development of Robocasting (Mouldless Casting) Technology For Advanced Ceramic<br />

Materials<br />

* Developing Rapid Tooling Methods for Injection Molding and Pressure Die Casting.<br />

CLEAN ENERGY TECHNOLOGY<br />

The Heat Power Engineering Group of CMERI is a major R&D group having wide experience in the<br />

broad field of Thermal & Fluid Engineering. Credit of good standard of applied research and R&D work<br />

and publications in journals of national and international repute has endowed the Group with a strong<br />

expertise base for offering quality research and technical support to the industries.<br />

The Group has at its command quality manpower and state-of-the-art computational, experimentation<br />