combustion process in si engines - National Institute of Technology

combustion process in si engines - National Institute of Technology

combustion process in si engines - National Institute of Technology

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

INTERNAL COMBUSTION ENGINES (ELECTIVE) (ME667)<br />

SIXTH SEMESTER<br />

COMBUSTION PROCESS IN SI ENGINES<br />

Combustion may be def<strong>in</strong>ed as a relatively rapid chemical comb<strong>in</strong>ation <strong>of</strong> hydrogen<br />

and carbon <strong>in</strong> fuel with oxygen <strong>in</strong> air result<strong>in</strong>g <strong>in</strong> liberation <strong>of</strong> energy <strong>in</strong> the form <strong>of</strong><br />

heat.<br />

Follow<strong>in</strong>g conditions are necessary for <strong>combustion</strong> to take place<br />

1. The presence <strong>of</strong> combustible mixture<br />

2. Some means to <strong>in</strong>itiate mixture<br />

3. Stabilization and propagation <strong>of</strong> flame <strong>in</strong> Combustion Chamber<br />

In S I Eng<strong>in</strong>es, carburetor supplies a combustible mixture <strong>of</strong> petrol and air and<br />

spark plug <strong>in</strong>itiates <strong>combustion</strong><br />

IGNITION LIMITS<br />

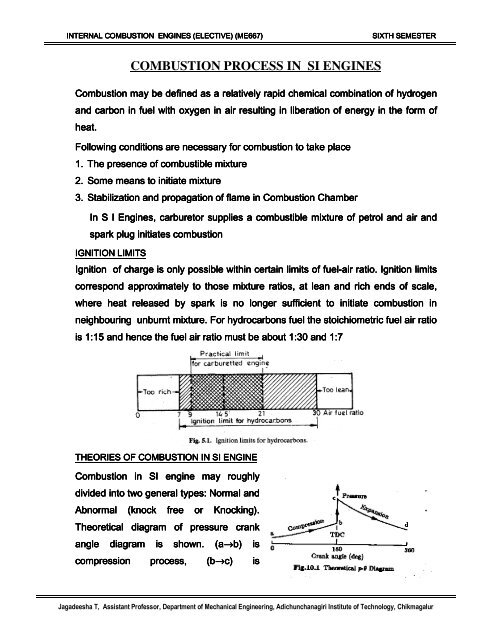

Ignition <strong>of</strong> charge is only pos<strong>si</strong>ble with<strong>in</strong> certa<strong>in</strong> limits <strong>of</strong> fuel-air ratio. Ignition limits<br />

correspond approximately to those mixture ratios, at lean and rich ends <strong>of</strong> scale,<br />

where heat released by spark is no longer sufficient to <strong>in</strong>itiate <strong>combustion</strong> <strong>in</strong><br />

neighbour<strong>in</strong>g unburnt mixture. For hydrocarbons fuel the stoichiometric fuel air ratio<br />

is 1:15 and hence the fuel air ratio must be about 1:30 and 1:7<br />

THEORIES OF COMBUSTION IN SI ENGINE<br />

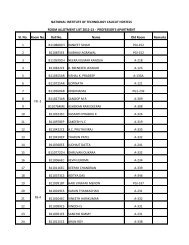

Combustion <strong>in</strong> SI eng<strong>in</strong>e may roughly<br />

divided ided <strong>in</strong>to two general types: Normal and<br />

Abnormal<br />

(knock free or Knock<strong>in</strong>g).<br />

Theoretical diagram <strong>of</strong> pressure crank<br />

angle diagram is shown. (a→b)<br />

is<br />

compres<strong>si</strong>on <strong>process</strong>, (b→c) is<br />

Jagadeesha T, As<strong>si</strong>stant Pr<strong>of</strong>essor, Department <strong>of</strong> Mechanical Eng<strong>in</strong>eer<strong>in</strong>g, Adichunchanagiri <strong>Institute</strong> <strong>of</strong> <strong>Technology</strong>, Chikmagalur

INTERNAL COMBUSTION ENGINES (ELECTIVE) (ME667)<br />

SIXTH SEMESTER<br />

<strong>combustion</strong> <strong>process</strong> and (c→d) is an expan<strong>si</strong>on <strong>process</strong>. In an ideal cycle it can be<br />

seen from the diagram, the entire pressure rise dur<strong>in</strong>g <strong>combustion</strong> takes place at<br />

constant volume i.e., at TDC. However, <strong>in</strong> actual cycle this does not happen.<br />

RICHARD’S THEORY OF COMBUSTION.<br />

Sir Ricardo, known as father <strong>of</strong> eng<strong>in</strong>e research describes the <strong>combustion</strong> <strong>process</strong><br />

can be imag<strong>in</strong>ed as if it is develop<strong>in</strong>g <strong>in</strong> two stages:<br />

1. Growth and development <strong>of</strong> a self propagat<strong>in</strong>g nucleus flame. ( Ignition lag)<br />

2. Spread <strong>of</strong> flame through the <strong>combustion</strong> chamber<br />

THREE STAGE OF COMBUSTION (VTU July/Aug 05/Feb 06/July 06)<br />

Accord<strong>in</strong>g to Ricardo, There are three stages <strong>of</strong> <strong>combustion</strong> <strong>in</strong> SI Eng<strong>in</strong>e as shown<br />

1. Ignition lag stage<br />

2. Flame propagation stage<br />

3. After burn<strong>in</strong>g stage<br />

1. Ignition lag stage: There is a certa<strong>in</strong><br />

time <strong>in</strong>terval between <strong>in</strong>stant <strong>of</strong> spark<br />

and <strong>in</strong>stant where there e is a noticeable<br />

rise <strong>in</strong> pressure due to <strong>combustion</strong>.<br />

This time lag is called IGNITION LAG.<br />

Ignition lag is the time <strong>in</strong>terval <strong>in</strong> the <strong>process</strong> <strong>of</strong> chemical reaction dur<strong>in</strong>g which<br />

molecules get heated up to self ignition temperature , get ignited and produce a<br />

self propagat<strong>in</strong>g nucleus <strong>of</strong> flame. The ignition lag is generally expressed <strong>in</strong><br />

terms <strong>of</strong> crank angle (θ1). (<br />

The period <strong>of</strong> ignition lag is shown by path ab. Ignition<br />

lag is very small and lies between 0.00015 to 0.0002 seconds. An ignition lag <strong>of</strong><br />

0.002 seconds s corresponds to 35 deg crank rotation when the eng<strong>in</strong>e is runn<strong>in</strong>g<br />

at 3000 RPM. Angle <strong>of</strong> advance <strong>in</strong>crease with the speed. This is a chemical<br />

<strong>process</strong> depend<strong>in</strong>g upon the nature <strong>of</strong> fuel, temperature and pressure,<br />

proportions <strong>of</strong> exhaust gas and rate <strong>of</strong> oxidation or burn<strong>in</strong>g.<br />

Jagadeesha T, As<strong>si</strong>stant Pr<strong>of</strong>essor, Department <strong>of</strong> Mechanical Eng<strong>in</strong>eer<strong>in</strong>g, Adichunchanagiri <strong>Institute</strong> <strong>of</strong> <strong>Technology</strong>, Chikmagalur

INTERNAL COMBUSTION ENGINES (ELECTIVE) (ME667)<br />

SIXTH SEMESTER<br />

2. Flame propagation stage:<br />

Once the flame is formed at “b”, it should be self susta<strong>in</strong>ed and must be able to<br />

propagate through the mixture. This is pos<strong>si</strong>ble when the rate <strong>of</strong> heat generation by<br />

burn<strong>in</strong>g is greater than heat lost by flame to surround<strong>in</strong>g.<br />

s<br />

After the po<strong>in</strong>t “b”, the flame propagation is abnormally low at the beg<strong>in</strong>n<strong>in</strong>g as heat<br />

lost is more than heat generated. Therefore pressure rise is also slow as mass <strong>of</strong><br />

mixture burned is small. Therefore it is necessary to provide angle <strong>of</strong> advance ance 30 to<br />

35 deg, if the peak pressure to be atta<strong>in</strong>ed 5-10 deg after TDC. The time required<br />

for crank to rotate through an angle θ2 2 is known as <strong>combustion</strong> period dur<strong>in</strong>g which<br />

propagation <strong>of</strong> flame takes place.<br />

3.After burn<strong>in</strong>g:<br />

Combustion will not stop at po<strong>in</strong>t “c” but cont<strong>in</strong>ue after atta<strong>in</strong><strong>in</strong>g peak pressure and<br />

this <strong>combustion</strong> is known as after burn<strong>in</strong>g. This generally happens when the rich<br />

mixture is supplied to eng<strong>in</strong>e.<br />

FACTORS AFFCTING THE FLAME PROPAGATION<br />

(VTU Aug 06/July 07/Jan 07)<br />

Rate <strong>of</strong> flame propagation affects the <strong>combustion</strong> <strong>process</strong> <strong>in</strong> SI eng<strong>in</strong>es. Higher<br />

<strong>combustion</strong> efficiency and fuel economy can be achieved by higher flame<br />

propagation velocities. Unfortunately flame velocities for most <strong>of</strong> fuel range between<br />

10 to 30 m/second.<br />

The factors which affect the flame propagations are<br />

1. Air fuel ratio<br />

2. Compres<strong>si</strong>on ratio<br />

3. Load on eng<strong>in</strong>e<br />

4. Turbulence and eng<strong>in</strong>e speed<br />

5. Other factors<br />

1. A : F ratio. The mixture strength <strong>in</strong>fluences the rate <strong>of</strong> <strong>combustion</strong> and amount <strong>of</strong><br />

heat generated. The maximum flame speed for all hydrocarbon fuels occurs at<br />

nearly 10% rich mixture. Flame speed is reduced both b<br />

for lean and as well as for<br />

very rich mixture. Lean mixture releases less heat result<strong>in</strong>g lower flame temperature<br />

Jagadeesha T, As<strong>si</strong>stant Pr<strong>of</strong>essor, Department <strong>of</strong> Mechanical Eng<strong>in</strong>eer<strong>in</strong>g, Adichunchanagiri <strong>Institute</strong> <strong>of</strong> <strong>Technology</strong>, Chikmagalur

INTERNAL COMBUSTION ENGINES (ELECTIVE) (ME667)<br />

SIXTH SEMESTER<br />

and lower flame speed. Very rich mixture results <strong>in</strong>complete <strong>combustion</strong> (C CO<br />

<strong>in</strong>stead <strong>of</strong> C0 and also results <strong>in</strong> production <strong>of</strong> less heat and flame speed rema<strong>in</strong>s<br />

low. The effects <strong>of</strong> A: F ratio on p-v p<br />

diagram and p-0 p<br />

diagram am are shown below :<br />

2. Compres<strong>si</strong>on ratio: The higher compres<strong>si</strong>on<br />

ratio <strong>in</strong>creases the pressure and temperature<br />

<strong>of</strong> the mixture and also decreases the<br />

concentration <strong>of</strong> re<strong>si</strong>dual gases. All these<br />

factors reduce the ignition lag and help to<br />

speed up the second phase <strong>of</strong> <strong>combustion</strong>.<br />

The maximum pressure <strong>of</strong> the cycle as well as<br />

mean effective ective pressure <strong>of</strong> the cycle with <strong>in</strong>crease <strong>in</strong> compres<strong>si</strong>on ratio. Figure above<br />

shows the effect <strong>of</strong> compres<strong>si</strong>on ratio on pressure (<strong>in</strong>directly on the speed <strong>of</strong><br />

<strong>combustion</strong>) with respect to crank angle for same A: F ratio and same angle <strong>of</strong> advance.<br />

Higher compres<strong>si</strong>on ratio <strong>in</strong>creases the surface to volume ratio and thereby <strong>in</strong>creases<br />

the part <strong>of</strong> the mixture which after-burns <strong>in</strong> the third phase.<br />

3. Load on Eng<strong>in</strong>e. . With <strong>in</strong>crease <strong>in</strong> load, the cycle pressures <strong>in</strong>crease and the flame<br />

speed also <strong>in</strong>creases.<br />

In S.I. eng<strong>in</strong>e, , the power developed by an eng<strong>in</strong>e is controlled by throttl<strong>in</strong>g. At lower<br />

load and higher throttle, the <strong>in</strong>itial and f<strong>in</strong>al pressure <strong>of</strong> the mixture after compres<strong>si</strong>on<br />

decrease and mixture is also diluted by the more re<strong>si</strong>dual gases. This reduces the flame<br />

Jagadeesha T, As<strong>si</strong>stant Pr<strong>of</strong>essor, Department <strong>of</strong> Mechanical Eng<strong>in</strong>eer<strong>in</strong>g, Adichunchanagiri <strong>Institute</strong> <strong>of</strong> <strong>Technology</strong>, Chikmagalur

INTERNAL COMBUSTION ENGINES (ELECTIVE) (ME667)<br />

SIXTH SEMESTER<br />

propagation and prolongs the ignition lag. . This is the reason, the advance mechanism is<br />

also provided with change <strong>in</strong> load on the eng<strong>in</strong>e. This difficulty can be partly overcome<br />

by provid<strong>in</strong>g rich mixture at part loads but this def<strong>in</strong>itely <strong>in</strong>creases the chances <strong>of</strong> after-<br />

burn<strong>in</strong>g. The after burn<strong>in</strong>g is prolonged with richer mixture. In fact, poor <strong>combustion</strong> at<br />

part loads and neces<strong>si</strong>ty <strong>of</strong> provid<strong>in</strong>g richer mixture are the ma<strong>in</strong> disadvantages <strong>of</strong> S,I.<br />

eng<strong>in</strong>es which causes wastage <strong>of</strong> fuel and discharge <strong>of</strong> large amount <strong>of</strong> CO with<br />

exhaust gases.<br />

4. Turbulence : Turbulence plays very important role <strong>in</strong> <strong>combustion</strong> <strong>of</strong> fuel as the flame<br />

speed is directly proportional to the turbulence <strong>of</strong> the mixture. This is because, the<br />

turbulence <strong>in</strong>creases the mix<strong>in</strong>g and heat transfer coefficient or heat transfer rate<br />

between the burned and unburned mixture. The turbulence <strong>of</strong> the mixture can be<br />

<strong>in</strong>creased at the end <strong>of</strong> compres<strong>si</strong>on by suitable de<strong>si</strong>gn <strong>of</strong> the <strong>combustion</strong> chamber<br />

(geometry <strong>of</strong> cyl<strong>in</strong>der head and piston crown).<br />

Insufficient turbulence provides low flame velocity and <strong>in</strong>complete <strong>combustion</strong> and<br />

reduces the power output. But exces<strong>si</strong>ve turbulence is also not de<strong>si</strong>rable as it <strong>in</strong>creases<br />

the <strong>combustion</strong> rapidly and leads to detonation. Exces<strong>si</strong>ve turbulence causes to cool<br />

the flame generated and flame propagation is reduced.<br />

Moderate turbulence is always de<strong>si</strong>rable as it accelerates the chemical reaction,<br />

reduces ignition lag, <strong>in</strong>creases flame propagation and even allows weak mixture to burn<br />

efficiently.<br />

Eng<strong>in</strong>e Speed<br />

The turbulence <strong>of</strong> the mixture <strong>in</strong>creases with an <strong>in</strong>crease <strong>in</strong> eng<strong>in</strong>e speed. For this<br />

reason the flame speed almost <strong>in</strong>creases l<strong>in</strong>early with eng<strong>in</strong>e speed. If the eng<strong>in</strong>e<br />

speed is doubled, flame to traverse the <strong>combustion</strong> chamber is halved. Double the<br />

orig<strong>in</strong>al speed and half the orig<strong>in</strong>al time give the same number <strong>of</strong> crank degrees for<br />

flame propagation. The crank angle required for the flame propagation , which is ma<strong>in</strong><br />

phase <strong>of</strong> <strong>combustion</strong> will rema<strong>in</strong> almost constant at all speeds. This is an important<br />

characteristics <strong>of</strong> all petrol eng<strong>in</strong>es.<br />

Jagadeesha T, As<strong>si</strong>stant Pr<strong>of</strong>essor, Department <strong>of</strong> Mechanical Eng<strong>in</strong>eer<strong>in</strong>g, Adichunchanagiri <strong>Institute</strong> <strong>of</strong> <strong>Technology</strong>, Chikmagalur

INTERNAL COMBUSTION ENGINES (ELECTIVE) (ME667)<br />

SIXTH SEMESTER<br />

Eng<strong>in</strong>e Size<br />

Eng<strong>in</strong>es <strong>of</strong> <strong>si</strong>milar de<strong>si</strong>gn generally run at the same piston speed. This is achieved by<br />

us<strong>in</strong>g small eng<strong>in</strong>es hav<strong>in</strong>g larger RPM and larger eng<strong>in</strong>es hav<strong>in</strong>g smaller RPM. Due<br />

to same piston speed, the <strong>in</strong>let velocity, degree <strong>of</strong> turbulence and flame speed are<br />

nearly same <strong>in</strong> <strong>si</strong>milar eng<strong>in</strong>es regardless <strong>of</strong> the <strong>si</strong>ze. However, <strong>in</strong> small eng<strong>in</strong>es the<br />

flame travel is small and <strong>in</strong> large eng<strong>in</strong>es large. Therefore, if the eng<strong>in</strong>e <strong>si</strong>ze is doubled<br />

the time required for propagation <strong>of</strong> flame through <strong>combustion</strong> space is also doubled.<br />

But with lower RPM <strong>of</strong> large eng<strong>in</strong>es the time for flame propagation <strong>in</strong> terms <strong>of</strong> crank<br />

would be nearly same as <strong>in</strong> small eng<strong>in</strong>es. In other words, the number <strong>of</strong> crank degrees<br />

required for flame travel will be about the same irrespective <strong>of</strong> eng<strong>in</strong>e <strong>si</strong>ze provided the<br />

eng<strong>in</strong>es are <strong>si</strong>milar.<br />

5. . Other Factors. Among the other factors, the factors which <strong>in</strong>crease the flame speed<br />

are supercharg<strong>in</strong>g <strong>of</strong> the eng<strong>in</strong>e, spark tim<strong>in</strong>g and re<strong>si</strong>dual gases left <strong>in</strong> the eng<strong>in</strong>e at<br />

the end <strong>of</strong> exhaust stroke. The air humidity also affects the flame velocity but its exact<br />

effect is not known. Anyhow, its effect is not large compared with A :F ratio and<br />

turbulence.<br />

PHENOMENON OF KNOCKING IN SI<br />

ENGINE<br />

(VTU July06/Jan 07)<br />

Knock<strong>in</strong>g is due to auto ignition <strong>of</strong> end<br />

portion <strong>of</strong> unburned charge<br />

<strong>in</strong><br />

<strong>combustion</strong> chamber. As the normal<br />

flame proceeds across the chamber,<br />

pressure and temperature <strong>of</strong> unburned<br />

charge <strong>in</strong>crease due to compres<strong>si</strong>on by<br />

burned portion <strong>of</strong> charge. This unburned<br />

compressed charge may auto ignite<br />

under certa<strong>in</strong> temperature condition and<br />

release the energy at a very rapid rate<br />

compared to normal <strong>combustion</strong><br />

Jagadeesha T, As<strong>si</strong>stant Pr<strong>of</strong>essor, Department <strong>of</strong> Mechanical Eng<strong>in</strong>eer<strong>in</strong>g, Adichunchanagiri <strong>Institute</strong> <strong>of</strong> <strong>Technology</strong>, Chikmagalur

INTERNAL COMBUSTION ENGINES (ELECTIVE) (ME667)<br />

SIXTH SEMESTER<br />

<strong>process</strong> <strong>in</strong> cyl<strong>in</strong>der. This rapid release <strong>of</strong> energy dur<strong>in</strong>g auto ignition causes a high<br />

pressure differential <strong>in</strong> <strong>combustion</strong> chamber and a high pressure wave is released from<br />

auto ignition region. The motion <strong>of</strong> high pressure compres<strong>si</strong>on waves <strong>in</strong><strong>si</strong>de the cyl<strong>in</strong>der<br />

causes vibration <strong>of</strong> eng<strong>in</strong>e parts and p<strong>in</strong>g<strong>in</strong>g noise and it is known as knock<strong>in</strong>g or<br />

detonation. This pressure frequency or vibration frequency <strong>in</strong> SI eng<strong>in</strong>e can be up to<br />

5000 0 Cycles per second.<br />

Denotation is unde<strong>si</strong>rable as it affects the eng<strong>in</strong>e performance and life, as it abruptly<br />

<strong>in</strong>creases sudden large amount <strong>of</strong> heat energy. It also put a limit on compres<strong>si</strong>on ratio<br />

at which eng<strong>in</strong>e can be operated which directly affects the eng<strong>in</strong>e efficiency and output.<br />

AUTO IGINITION (VTU July 2007)<br />

A mixture <strong>of</strong> fuel and air can react spontaneously and produce heat by chemical<br />

reaction <strong>in</strong> the absence <strong>of</strong> flame to <strong>in</strong>itiate the <strong>combustion</strong> or self-ignition.<br />

This type <strong>of</strong><br />

self-ignition <strong>in</strong> the absence a<br />

<strong>of</strong> flame is known as Auto-Ignition<br />

Ignition. . The temperature at<br />

which the self-ignition takes place is known as self-ignit<strong>in</strong>g temperature. The pressure<br />

and temperature abruptly <strong>in</strong>crease due to auto-ignition because <strong>of</strong> sudden release <strong>of</strong><br />

chemical energy.<br />

This auto-ignition leads to abnormal <strong>combustion</strong> known as detonation which is<br />

unde<strong>si</strong>rable because its bad effect on the eng<strong>in</strong>e performance and life as it abruptly<br />

<strong>in</strong>creases sudden large amount <strong>of</strong> heat energy. In addition to this knock<strong>in</strong>g puts a limit<br />

on the compres<strong>si</strong>on ratio at which an eng<strong>in</strong>e can be operated which directly affects the<br />

eng<strong>in</strong>e efficiency and output.<br />

Jagadeesha T, As<strong>si</strong>stant Pr<strong>of</strong>essor, Department <strong>of</strong> Mechanical Eng<strong>in</strong>eer<strong>in</strong>g, Adichunchanagiri <strong>Institute</strong> <strong>of</strong> <strong>Technology</strong>, Chikmagalur

INTERNAL COMBUSTION ENGINES (ELECTIVE) (ME667)<br />

SIXTH SEMESTER<br />

Auto-ignition<br />

<strong>of</strong> the mixture does not occur<br />

<strong>in</strong>stantaneously as soon as its temperature rises<br />

above the self-ignition temperature. Auto-ignition<br />

occurs only when the mixture stays at a temperature<br />

equal to or higher than the self-ignition temperature<br />

for a “f<strong>in</strong>ite time”. This time is known as delay period<br />

or reaction time for auto-ignition. This delay time as<br />

a function <strong>of</strong> compres<strong>si</strong>on ratio is shown <strong>in</strong> adjacent<br />

figure.<br />

As the compres<strong>si</strong>on ratio <strong>in</strong>creases, the delay period<br />

decreases and this is because <strong>of</strong> <strong>in</strong>crease <strong>in</strong> <strong>in</strong>itial<br />

(before <strong>combustion</strong>) pressure and temperature <strong>of</strong> the<br />

charge. The self-ignition temperature is a characteristic <strong>of</strong> fuel air mixture and it varies<br />

from fuel to fuel and mixture strength to mixture - strength <strong>of</strong> the same fuel.<br />

PRE -IGINITION (VTU July 2007)<br />

Pre-ignition is the ignition <strong>of</strong> the homogeneous mixture <strong>of</strong> charge as it comes <strong>in</strong> contact<br />

with hot surfaces, <strong>in</strong> the absence <strong>of</strong> spark .<br />

Auto ignition may overheat the spark plug and exhaust valve and it rema<strong>in</strong>s so hot that<br />

its temperature is sufficient to ignite the charge <strong>in</strong> next cycle dur<strong>in</strong>g the compres<strong>si</strong>on<br />

stroke before spark occurs and this causes the pre-ignition<br />

<strong>of</strong> the charge.<br />

Pre-ignition is <strong>in</strong>itiated by some overheated project<strong>in</strong>g part such as the spark<strong>in</strong>g plug<br />

electrodes, exhaust valve head, metal corners <strong>in</strong> the <strong>combustion</strong> chamber, carbon<br />

depo<strong>si</strong>ts or protrud<strong>in</strong>g cyl<strong>in</strong>der head gasket rim etc.<br />

pre-ignition is also caused by per<strong>si</strong>stent detonat<strong>in</strong>g pressure shockwaves scor<strong>in</strong>g away<br />

the stagnant gases which normally protect the <strong>combustion</strong> chamber walls. The result<strong>in</strong>g<br />

<strong>in</strong>creased heat flow through the walls, raises the surface temperature <strong>of</strong> any protrud<strong>in</strong>g<br />

poorly cooled part <strong>of</strong> the chamber, and this there fore provides a focal po<strong>in</strong>t for pre-<br />

ignition.<br />

Jagadeesha T, As<strong>si</strong>stant Pr<strong>of</strong>essor, Department <strong>of</strong> Mechanical Eng<strong>in</strong>eer<strong>in</strong>g, Adichunchanagiri <strong>Institute</strong> <strong>of</strong> <strong>Technology</strong>, Chikmagalur

INTERNAL COMBUSTION ENGINES (ELECTIVE) (ME667)<br />

SIXTH SEMESTER<br />

Effects <strong>of</strong> Pre-ignition<br />

• It <strong>in</strong>crease the tendency <strong>of</strong> denotation <strong>in</strong> the eng<strong>in</strong>e<br />

• It <strong>in</strong>creases heat transfer to cyl<strong>in</strong>der walls because high temperature gas<br />

rema<strong>in</strong>s <strong>in</strong> contact with for a longer time<br />

t<br />

• Pre-ignition <strong>in</strong> a s<strong>in</strong>gle cyl<strong>in</strong>der will reduce the speed and power output<br />

• Pre-ignition may cause seizer <strong>in</strong> the multi-cyl<strong>in</strong>der eng<strong>in</strong>es, only if only cyl<strong>in</strong>ders<br />

have pre-ignition<br />

DIFFERENCE BETWEEN NORMAL/ABNORMAL COMBUSTION AND PRE- INGINITON<br />

Jagadeesha T, As<strong>si</strong>stant Pr<strong>of</strong>essor, Department <strong>of</strong> Mechanical Eng<strong>in</strong>eer<strong>in</strong>g, Adichunchanagiri <strong>Institute</strong> <strong>of</strong> <strong>Technology</strong>, Chikmagalur

INTERNAL COMBUSTION ENGINES (ELECTIVE) (ME667)<br />

SIXTH SEMESTER<br />

EFFECT OF DETONATION (VTU Jan 2006)<br />

The harmful effects <strong>of</strong> detonation are as follows:<br />

1. Noise and Roughness. Knock<strong>in</strong>g produces a loud pulsat<strong>in</strong>g noise and pressure<br />

waves. These waves which vibrates back and forth across the cyl<strong>in</strong>der. The presence <strong>of</strong><br />

vibratory motion causes crankshaft vibrations and the eng<strong>in</strong>e runs rough.<br />

2. Mechanical Damage.<br />

(a)High pressure waves generated dur<strong>in</strong>g knock<strong>in</strong>g can <strong>in</strong>crease rate <strong>of</strong> wear <strong>of</strong> parts<br />

<strong>of</strong> <strong>combustion</strong> chamber. Sever ero<strong>si</strong>on <strong>of</strong> piston crown( <strong>in</strong> a manner <strong>si</strong>milar to that <strong>of</strong><br />

mar<strong>in</strong>e propeller blades by cavitation),<br />

cyl<strong>in</strong>der head and pitt<strong>in</strong>g <strong>of</strong> <strong>in</strong>let and outlet<br />

valves may result <strong>in</strong> complete wreckage <strong>of</strong> the eng<strong>in</strong>e.<br />

(b) Detonation is very dangerous <strong>in</strong> eng<strong>in</strong>es hav<strong>in</strong>g high noise level. In small eng<strong>in</strong>es<br />

the knock<strong>in</strong>g noise is ea<strong>si</strong>ly detected and the corrective measures can be taken but <strong>in</strong><br />

aero-eng<strong>in</strong>es eng<strong>in</strong>es it is difficult to detect knock<strong>in</strong>g noise and hence corrective measures<br />

cannot be taken. Hence severe detonation may per<strong>si</strong>st for a long time which may<br />

ultimately result <strong>in</strong> complete wreckage <strong>of</strong> the piston.<br />

3. . Carbon depo<strong>si</strong>ts. . Detonation results <strong>in</strong> <strong>in</strong>creased carbon depo<strong>si</strong>ts.<br />

4. Increase <strong>in</strong> heat transfer. . Knock<strong>in</strong>g is accompanied by an <strong>in</strong>crease <strong>in</strong> the rate <strong>of</strong> heat<br />

transfer to the <strong>combustion</strong> chamber walls.<br />

The <strong>in</strong>crease <strong>in</strong> heat transfer is due to two reasons.<br />

• The m<strong>in</strong>or reason is that the maximum temperature <strong>in</strong> a detonat<strong>in</strong>g eng<strong>in</strong>e is<br />

about 150°C higher than <strong>in</strong> a non-detonat<strong>in</strong>g eng<strong>in</strong>e, due to rapid completion <strong>of</strong><br />

<strong>combustion</strong><br />

• The major reason for <strong>in</strong>creased heat transfer is the t<br />

scour<strong>in</strong>g away <strong>of</strong> protective<br />

layer <strong>of</strong> <strong>in</strong>active stagnant gas on the cyl<strong>in</strong>der walls due to pressure waves. The<br />

<strong>in</strong>active layer <strong>of</strong> gas normally reduces the heat transfer by protect<strong>in</strong>g the<br />

<strong>combustion</strong> and piston crown from direct contact with flame.<br />

5. Decrease <strong>in</strong> power output and efficiency. . Due to <strong>in</strong>crease <strong>in</strong> the rate <strong>of</strong> heat transfer<br />

the power output as well as efficiency <strong>of</strong> a detonat<strong>in</strong>g eng<strong>in</strong>e decreases.<br />

Jagadeesha T, As<strong>si</strong>stant Pr<strong>of</strong>essor, Department <strong>of</strong> Mechanical Eng<strong>in</strong>eer<strong>in</strong>g, Adichunchanagiri <strong>Institute</strong> <strong>of</strong> <strong>Technology</strong>, Chikmagalur

INTERNAL COMBUSTION ENGINES (ELECTIVE) (ME667)<br />

SIXTH SEMESTER<br />

6 Pre-ignition.<br />

The <strong>in</strong>crease <strong>in</strong> the rate <strong>of</strong> heat transfer to the walls has yet another<br />

effect. It may cause local overheat<strong>in</strong>g, especially <strong>of</strong> the spark<strong>in</strong>g plug, which may reach<br />

a temperature high enough to ignite the charge before the passage <strong>of</strong> spark, thus<br />

caus<strong>in</strong>g pre-ignition. An eng<strong>in</strong>e detonat<strong>in</strong>g for a long period would most probably lead to<br />

pre-ignition<br />

and this is the real danger <strong>of</strong> detonation.<br />

EFFECT OF ENGINE OPERATING VARIABLES ON THE ENGINE KNOCKING<br />

DETONATION (VTU July 2005)<br />

The<br />

various eng<strong>in</strong>e variable affect<strong>in</strong>g knock<strong>in</strong>g can be clas<strong>si</strong>fied as :<br />

• Temperature factors<br />

• Den<strong>si</strong>ty factors<br />

• Time factors<br />

• Compo<strong>si</strong>tion factors<br />

(A) TEMPERATURE FACTORS.<br />

Increas<strong>in</strong>g the temperature <strong>of</strong> the unburned mixture <strong>in</strong>crease the pos<strong>si</strong>bility <strong>of</strong> knock <strong>in</strong><br />

the SI eng<strong>in</strong>e We shall now discuss the effect <strong>of</strong> follow<strong>in</strong>g eng<strong>in</strong>e parameters on the<br />

t<br />

temperature <strong>of</strong> the unburned mixture:<br />

RAISING THE COMPRESSION RATIO. Increas<strong>in</strong>g the compres<strong>si</strong>on ratio <strong>in</strong>creases<br />

both the temperature and pressure (den<strong>si</strong>ty <strong>of</strong> the unburned mixture). Increase <strong>in</strong><br />

temperature reduces the t<br />

delay period <strong>of</strong> the end gas which <strong>in</strong> turn <strong>in</strong>creases the<br />

tendency to knock.<br />

SUPERCHARGING<br />

CHARGING. It also <strong>in</strong>creases es both temperature and den<strong>si</strong>ty, which <strong>in</strong>crease<br />

the knock<strong>in</strong>g tendency <strong>of</strong> eng<strong>in</strong>e<br />

COOLANT TEMPERATURE Delay period decreases with <strong>in</strong>crease <strong>of</strong> coolant<br />

temperature , decreased delay period <strong>in</strong>crease the tendency to knock<br />

TEMPERATURE OF THE CYLINDERC<br />

AND COMBUSTION CHAMBER WALLS : The<br />

temperature <strong>of</strong> the end gas depends on the de<strong>si</strong>gn <strong>of</strong> <strong>combustion</strong> chamber.<br />

Spark<strong>in</strong>g plug and exhaust valve are two hottest parts <strong>in</strong> the <strong>combustion</strong><br />

chamber and uneven temperature leads to pre-ignition and hence the t<br />

knock<strong>in</strong>g.<br />

Jagadeesha T, As<strong>si</strong>stant Pr<strong>of</strong>essor, Department <strong>of</strong> Mechanical Eng<strong>in</strong>eer<strong>in</strong>g, Adichunchanagiri <strong>Institute</strong> <strong>of</strong> <strong>Technology</strong>, Chikmagalur

INTERNAL COMBUSTION ENGINES (ELECTIVE) (ME667)<br />

SIXTH SEMESTER<br />

(B) DENSITY FACTORS.<br />

Increas<strong>in</strong>g the den<strong>si</strong>ty <strong>of</strong> unburnt mixture will <strong>in</strong>crease the pos<strong>si</strong>bility <strong>of</strong> knock <strong>in</strong> the<br />

eng<strong>in</strong>e. The eng<strong>in</strong>e parameters which affect the den<strong>si</strong>ty are as follows:<br />

Increased compres<strong>si</strong>on ratio <strong>in</strong>crease the den<strong>si</strong>ty<br />

Increas<strong>in</strong>g the load opens the throttle valve more and thus the den<strong>si</strong>ty<br />

Supercharg<strong>in</strong>g <strong>in</strong>crease the den<strong>si</strong>ty <strong>of</strong> the mixture<br />

Increas<strong>in</strong>g the <strong>in</strong>let pressure <strong>in</strong>creases the overall pressure dur<strong>in</strong>g the cycle. The<br />

high pressure end gas decreases the delay period which <strong>in</strong>crease the t<br />

tendency<br />

<strong>of</strong> knock<strong>in</strong>g.<br />

Advanced spark tim<strong>in</strong>g : quantity <strong>of</strong> fuel burnt per cycle before and after TDC<br />

po<strong>si</strong>tion depends on spark tim<strong>in</strong>g. The temperature <strong>of</strong> charge <strong>in</strong>creases by<br />

<strong>in</strong>creas<strong>in</strong>g the spark advance and it <strong>in</strong>creases with rate <strong>of</strong> burn<strong>in</strong>g and does not<br />

allow sufficient time to the end mixture to dis<strong>si</strong>pate the heat and <strong>in</strong>crease the<br />

knock<strong>in</strong>g tendency<br />

(C) TIME FACTORS.<br />

Increas<strong>in</strong>g the time <strong>of</strong> exposure <strong>of</strong> the unburned mixture to auto-ignition conditions<br />

<strong>in</strong>crease the pos<strong>si</strong>bility <strong>of</strong> knock <strong>in</strong> SI eng<strong>in</strong>es.<br />

Flame travel distance: : If the distance <strong>of</strong> flame travel is more, then pos<strong>si</strong>bility <strong>of</strong><br />

knock<strong>in</strong>g is also more. This problem can be solved by <strong>combustion</strong> chamber<br />

de<strong>si</strong>gn, spark plug location and eng<strong>in</strong>e <strong>si</strong>ze. Compact <strong>combustion</strong> chamber will<br />

have better anti-knock characteristics, s<strong>in</strong>ce the flame travel and <strong>combustion</strong><br />

time will be shorter. Further, if the <strong>combustion</strong> chamber is highly turbulent, the<br />

<strong>combustion</strong> rate is high and consequently <strong>combustion</strong> time is further reduced;<br />

this further reduces the tendency to knock.<br />

Location <strong>of</strong> sparkplug. . A spark plug which is centrally located <strong>in</strong> the <strong>combustion</strong><br />

chamber has m<strong>in</strong>imum tendency to knock as the flame travel is m<strong>in</strong>imum. The<br />

flame travel can be reduced by us<strong>in</strong>g two or more spark plugs.<br />

Location <strong>of</strong> exhaust valve. . The exhaust valve v<br />

should be located close to the<br />

spark plug so that it is not <strong>in</strong> the end gas region; ; otherwise there will be a<br />

tendency to knock.<br />

Jagadeesha T, As<strong>si</strong>stant Pr<strong>of</strong>essor, Department <strong>of</strong> Mechanical Eng<strong>in</strong>eer<strong>in</strong>g, Adichunchanagiri <strong>Institute</strong> <strong>of</strong> <strong>Technology</strong>, Chikmagalur

INTERNAL COMBUSTION ENGINES (ELECTIVE) (ME667)<br />

SIXTH SEMESTER<br />

Eng<strong>in</strong>e <strong>si</strong>ze. . Large eng<strong>in</strong>es have a greater knock<strong>in</strong>g tendency because flame<br />

requires a longer time to travel across the <strong>combustion</strong> chamber. In SI eng<strong>in</strong>e<br />

therefore , generally limited to 100mm<br />

Turbulence <strong>of</strong> mixture decreas<strong>in</strong>g the turbulence <strong>of</strong> the mixture decreases the<br />

flame speed and hence <strong>in</strong>creases the tendency to knock. Turbulence depends<br />

on the de<strong>si</strong>gn <strong>of</strong> <strong>combustion</strong> chamber and one eng<strong>in</strong>e speed.<br />

(D) COMPOSITION.<br />

( Influence <strong>of</strong> chemical structure on knock<strong>in</strong>g – VTU August 2005)<br />

The properties <strong>of</strong> fuel and A/F ratio are primary means to control knock :<br />

(a) Molecular Structure. The knock<strong>in</strong>g tendency is markedly affected by the type <strong>of</strong><br />

the fuel used. Petroleum fuels usually con<strong>si</strong>st <strong>of</strong> many hydro-carbons <strong>of</strong> different<br />

molecular structure. The structure <strong>of</strong> the fuel molecule has enormous effect on<br />

knock<strong>in</strong>g tendency. Increas<strong>in</strong>g the carbon-cha<strong>in</strong> cha<strong>in</strong> <strong>in</strong>creases the knock<strong>in</strong>g<br />

tendency and centraliz<strong>in</strong>g<br />

<strong>in</strong>g the carbon atoms decreases the knock<strong>in</strong>g tendency.<br />

Unsaturated hydrocarbons have less knock<strong>in</strong>g tendency than saturated hydro-<br />

carbons.<br />

Paraff<strong>in</strong>s<br />

Increas<strong>in</strong>g the length <strong>of</strong> carbon cha<strong>in</strong> <strong>in</strong>creases the knock<strong>in</strong>g tendency.<br />

Centralis<strong>in</strong>g the carbon atoms decreases s the knock<strong>in</strong>g tendency.<br />

Add<strong>in</strong>g methyl group (CH to the <strong>si</strong>de <strong>of</strong> the carbon cha<strong>in</strong> <strong>in</strong> the centre po<strong>si</strong>tion<br />

decreases the knock<strong>in</strong>g tendency.<br />

Olef<strong>in</strong>s<br />

Introduction <strong>of</strong> one double bond has little effect on anti-knock quality but two or three<br />

double bond results less knock<strong>in</strong>g tendency except C and C<br />

Napthenes and Aromatics<br />

Napthenes have greater knock<strong>in</strong>g tendency than correspond<strong>in</strong>g aromatics.<br />

With <strong>in</strong>creas<strong>in</strong>g double-bonds, bonds, the knock<strong>in</strong>g tendency is reduced.<br />

Lengthen<strong>in</strong>g the <strong>si</strong>de cha<strong>in</strong>s <strong>in</strong>creases the knock<strong>in</strong>g tendency whereas<br />

branch<strong>in</strong>g <strong>of</strong> the <strong>si</strong>de cha<strong>in</strong> decreases the knock<strong>in</strong>g tendency.<br />

Jagadeesha T, As<strong>si</strong>stant Pr<strong>of</strong>essor, Department <strong>of</strong> Mechanical Eng<strong>in</strong>eer<strong>in</strong>g, Adichunchanagiri <strong>Institute</strong> <strong>of</strong> <strong>Technology</strong>, Chikmagalur

INTERNAL COMBUSTION ENGINES (ELECTIVE) (ME667)<br />

SIXTH SEMESTER<br />

(b) Fuel-air ratio. The most important effect <strong>of</strong> fuel-aft ratio is on the reaction time or<br />

ignition delay. When the mixture is nearly 10% richer than stoichiomiric (fuel-air ratio =<br />

0.08) ignition lag <strong>of</strong> the end gas is m<strong>in</strong>imum and the velocity <strong>of</strong> flame propagation is<br />

maximum. By mak<strong>in</strong>g the mixture leaner or richer (than F/A 0.08) the tendency to knock<br />

is decreased. A too rich mixture is especially effective <strong>in</strong> decreas<strong>in</strong>g or elim<strong>in</strong>at<strong>in</strong>g the<br />

knock due to longer delay and lower temperature <strong>of</strong> compres<strong>si</strong>on.<br />

(c)Humidity <strong>of</strong> air. . Increas<strong>in</strong>g atmospheric humidity decreases the tendency to knock<br />

by decreas<strong>in</strong>g the reaction time <strong>of</strong> the fuel<br />

The trends <strong>of</strong> the most <strong>of</strong> the above factors on knock<strong>in</strong>g tendency t<br />

<strong>of</strong> the eng<strong>in</strong>e is given<br />

below:<br />

Jagadeesha T, As<strong>si</strong>stant Pr<strong>of</strong>essor, Department <strong>of</strong> Mechanical Eng<strong>in</strong>eer<strong>in</strong>g, Adichunchanagiri <strong>Institute</strong> <strong>of</strong> <strong>Technology</strong>, Chikmagalur

INTERNAL COMBUSTION ENGINES (ELECTIVE) (ME667)<br />

SIXTH SEMESTER<br />

Table below gives the general summary <strong>of</strong> variables affect<strong>in</strong>g the knock <strong>in</strong> an SI eng<strong>in</strong>e<br />

Summary <strong>of</strong> Variables Affect<strong>in</strong>g Knock <strong>in</strong> an SI Eng<strong>in</strong>e<br />

Jagadeesha T, As<strong>si</strong>stant Pr<strong>of</strong>essor, Department <strong>of</strong> Mechanical Eng<strong>in</strong>eer<strong>in</strong>g, Adichunchanagiri <strong>Institute</strong> <strong>of</strong> <strong>Technology</strong>, Chikmagalur

INTERNAL COMBUSTION ENGINES (ELECTIVE) (ME667)<br />

SIXTH SEMESTER<br />

Effect <strong>of</strong> eng<strong>in</strong>e variables on Knock<strong>in</strong>g <strong>in</strong> SI eng<strong>in</strong>e ne ( VTU Jan 2007)<br />

1. Compres<strong>si</strong>on ratio: The pressure and temperature at the end <strong>of</strong> compres<strong>si</strong>on<br />

<strong>in</strong>creases with <strong>in</strong>crease <strong>in</strong> compres<strong>si</strong>on ratio. This <strong>in</strong> turn <strong>in</strong>crease the maximum<br />

pressure dur<strong>in</strong>g the <strong>combustion</strong> and creates a tendency to knock<br />

2. Supercharg<strong>in</strong>g : <strong>in</strong>crease the temperature and den<strong>si</strong>ty <strong>of</strong> mixture and thus the<br />

tendency to knock is <strong>in</strong>creased.<br />

3. Turbulence : decreas<strong>in</strong>g the turbulence <strong>of</strong> mixture decreases the flame speed<br />

and hence <strong>in</strong>crease the tendency to knock<br />

4. Octane rat<strong>in</strong>g <strong>of</strong> fuel : higher the octane number, less the tendency to knock.<br />

Paraf<strong>in</strong>s have maximum tendency to knock and aromatic series have m<strong>in</strong>imum<br />

tendency to knock . ( also see Influence <strong>of</strong> chemical structure on knock<strong>in</strong>g)<br />

Factors that limits the compres<strong>si</strong>on ratio <strong>in</strong> petrol eng<strong>in</strong>e ( VTU July 2007)<br />

In petrol eng<strong>in</strong>e we use the mixture <strong>of</strong> air and petrol and thermal efficiency <strong>of</strong> petrol<br />

eng<strong>in</strong>e <strong>in</strong>crease with <strong>in</strong>crease <strong>in</strong> compres<strong>si</strong>on ratio. But the value <strong>of</strong> compres<strong>si</strong>on ration<br />

is limited by phenomenon <strong>of</strong> knock<strong>in</strong>g. The pressure and temperature at the end <strong>of</strong><br />

compres<strong>si</strong>on <strong>in</strong>creases with <strong>in</strong>crease <strong>in</strong> compres<strong>si</strong>on ratio. This <strong>in</strong> turn <strong>in</strong>crease the<br />

maximum pressure dur<strong>in</strong>g the <strong>combustion</strong> and creates a tendency to knock. . Thus ,<br />

Higher compres<strong>si</strong>on ratio, higher is the tendency to knock, therefore the value <strong>of</strong><br />

compres<strong>si</strong>on ratio <strong>in</strong> petrol eng<strong>in</strong>e is limited to 6 to 10.<br />

Compres<strong>si</strong>on ratio can be marg<strong>in</strong>ally improved by us<strong>in</strong>g fuel with Tetra-ethyl ethyl lead. TEL<br />

delays the auto ignition and allows it to occur at higher temperature and thus reduces<br />

knock<strong>in</strong>g. The use <strong>of</strong> TEL is now <strong>in</strong> disfavor d<br />

because <strong>of</strong> atmospheric pollution ( lead is<br />

toxic and has serious environmental and health hazards).<br />

KNOCK RATING OF SI ENGINE FUELS ( OCTANE NUMBER ) ( VTU Jan 2006)<br />

The tendency to detonate depends on compo<strong>si</strong>tion <strong>of</strong> fuel. Fuel differ widely <strong>in</strong> their<br />

ability to re<strong>si</strong>st knock. The property <strong>of</strong> fuel which describes how fuel will or will nor self<br />

ignite is called the OCTANE NUMBER. It is def<strong>in</strong>ed as the percentage <strong>of</strong> Iso-octane octane by<br />

volume <strong>in</strong> a mixture <strong>of</strong> Iso-octane octane and n-heptane n<br />

which exactly matches the knock<strong>in</strong>g<br />

Jagadeesha T, As<strong>si</strong>stant Pr<strong>of</strong>essor, Department <strong>of</strong> Mechanical Eng<strong>in</strong>eer<strong>in</strong>g, Adichunchanagiri <strong>Institute</strong> <strong>of</strong> <strong>Technology</strong>, Chikmagalur

INTERNAL COMBUSTION ENGINES (ELECTIVE) (ME667)<br />

SIXTH SEMESTER<br />

tendency <strong>of</strong> a given fuel, <strong>in</strong> a standard fuel under given standard operat<strong>in</strong>g conditions.<br />

The rat<strong>in</strong>g <strong>of</strong> a particular SI fuel is done by compar<strong>in</strong>g its antiknock performance with<br />

that <strong>of</strong> standard reference fuel which is usually comb<strong>in</strong>ation <strong>of</strong> Iso-octa<br />

octane and n-<br />

n<br />

heptane. Iso-octane octane (C<br />

octane (C8H18<br />

18) ) which has a very high re<strong>si</strong>stance to knock and therefore it<br />

is arbitrarily as<strong>si</strong>gned a rat<strong>in</strong>g <strong>of</strong> 100 octane number. N-heptane (C7H16<br />

16) ) which is very<br />

prone to knock and therefore given a zero value.<br />

For example: Octane number 80 means that the fuel has same knock<strong>in</strong>g tendency as<br />

mixture <strong>of</strong> 80% iso-octane octane and 20% n-heptane n<br />

(by volume ba<strong>si</strong>s).<br />

A fuel hav<strong>in</strong>g an octane number <strong>of</strong> 110 means fuel has the same tendency to re<strong>si</strong>st as a<br />

mixture <strong>of</strong> 10 cc <strong>of</strong> Tetra ethyl lead (TEL) <strong>in</strong> one U.S gallon <strong>of</strong> Iso-octane.<br />

octane.<br />

16<br />

HIGHEST USEFUL COMPRESSION RATIO (HUCR) ( VTU July 2005)<br />

The thermal efficiency <strong>of</strong> IC eng<strong>in</strong>e <strong>in</strong>crease with <strong>in</strong>crease <strong>in</strong> Compres<strong>si</strong>on Ratio. The<br />

maximum compres<strong>si</strong>on ratio <strong>of</strong> any SI eng<strong>in</strong>e is limited by its tendency to knock. HUCR<br />

is the highest compres<strong>si</strong>on ratio employed at which a fuel can be used <strong>in</strong> a specified<br />

eng<strong>in</strong>e under specified set <strong>of</strong> operat<strong>in</strong>g conditions, at which detonation first becomes<br />

audible with both ignition and mixture strength adjusted to give highest efficiency.<br />

HUCR <strong>of</strong> different fuel<br />

Iso-octane<br />

octane 10.96<br />

n-heptane<br />

3.75<br />

Toulene 15<br />

Cyclo hexane 8.20<br />

Anti Knock Agents<br />

The knock re<strong>si</strong>stance tendency <strong>of</strong> a fuel can be <strong>in</strong>creased by add<strong>in</strong>g anti-knock agents.<br />

The anti knock agents are substances which decreases the rate <strong>of</strong> preflame reaction by<br />

delay<strong>in</strong>g the auto ignition <strong>of</strong> the end mixture <strong>in</strong> eng<strong>in</strong>e until flame generated by spark<br />

plug.<br />

P<br />

C H<br />

b is most powerful anti knock agents. TEL <strong>in</strong>crease the efficiency <strong>of</strong><br />

2 5<br />

TEL [ b P ( ) ]<br />

4<br />

eng<strong>in</strong>e and <strong>in</strong>crease the specific output <strong>of</strong> SI eng<strong>in</strong>e. Its use will not improve the<br />

performance <strong>of</strong> eng<strong>in</strong>e which is not knock<strong>in</strong>g unless the spark advanced. CR is<br />

Jagadeesha T, As<strong>si</strong>stant Pr<strong>of</strong>essor, Department <strong>of</strong> Mechanical Eng<strong>in</strong>eer<strong>in</strong>g, Adichunchanagiri <strong>Institute</strong> <strong>of</strong> <strong>Technology</strong>, Chikmagalur

INTERNAL COMBUSTION ENGINES (ELECTIVE) (ME667)<br />

SIXTH SEMESTER<br />

<strong>in</strong>creased or higher <strong>in</strong>let pressure is used to take advantage <strong>of</strong> an <strong>in</strong>crease <strong>in</strong> octane<br />

number. The use <strong>of</strong> leaded gasol<strong>in</strong>e. However is not perfect solution to problem. It<br />

leads to emis<strong>si</strong>on <strong>of</strong> lead <strong>in</strong>to atmosphere which is known to be very hazardous.<br />

The follow<strong>in</strong>g table shows some anti knock agents and effectiveness.<br />

Compound<br />

Chemical Symbol<br />

Weight for<br />

Relative<br />

given effect (gm)<br />

weight<br />

Tetraethyl ethyl lead<br />

Pb(C2H5)4 0.0295 1<br />

Anil<strong>in</strong>e<br />

C6H5NH<br />

NH2 1 34<br />

Ethyl Iodide C2H5 I 1.55 53<br />

Ethyl alcohol<br />

C2H5 OH<br />

OH 4.75 161<br />

Xylene [C6H4CH<br />

CH3]2 8.00 271<br />

Toluene<br />

C6H5CH<br />

CH3 8.8 298<br />

Benzene C6H6 9.8 332<br />

The follow<strong>in</strong>g table gives the relative effectiveness <strong>of</strong> anti knocks<br />

Compound<br />

Relative effectiveness<br />

Tetra ethyl lead (TEL) 100<br />

Methyl cyclo pentadienyl 65<br />

Manganese tricarbonyl Ironcarbonyl 43<br />

Copper methyl arn<strong>in</strong>o methyle necetate 40<br />

Nickel carbonyl 30<br />

Tri ethyl bismuth 20<br />

Tetra ethyl t<strong>in</strong> 3<br />

N-Methyl anil<strong>in</strong>e-Ethyl iodide 11<br />

The effect <strong>of</strong> anti knock agents on HUCR is shown below<br />

Jagadeesha T, As<strong>si</strong>stant Pr<strong>of</strong>essor, Department <strong>of</strong> Mechanical Eng<strong>in</strong>eer<strong>in</strong>g, Adichunchanagiri <strong>Institute</strong> <strong>of</strong> <strong>Technology</strong>, Chikmagalur

INTERNAL COMBUSTION ENGINES (ELECTIVE) (ME667)<br />

SIXTH SEMESTER<br />

S I eng<strong>in</strong>es are generally not supercharged.” Justify this statement.<br />

The factors which affect knock<strong>in</strong>g <strong>in</strong> S.I. eng<strong>in</strong>es<br />

— Compres<strong>si</strong>on ratio<br />

— Mixture strength<br />

— Fuel characteristics s (Octane number, ON)<br />

— Initial pressure.<br />

In these eng<strong>in</strong>es the limit <strong>of</strong> supercharg<strong>in</strong>g is fixed ma<strong>in</strong>ly by knock<strong>in</strong>g, because the<br />

knock<strong>in</strong>g tendency <strong>of</strong> most fuels is <strong>in</strong>creased by <strong>in</strong>creas<strong>in</strong>g the <strong>in</strong>let pressure and<br />

temperature, or both. At the same ON requirement, if the charge den<strong>si</strong>ty is <strong>in</strong>creased<br />

the compres<strong>si</strong>on ratio has to be decreased con<strong>si</strong>der<strong>in</strong>g the knock limits. Thus the power<br />

by the supercharged eng<strong>in</strong>e is <strong>in</strong>creased but at reduced thermal efficiency. Further,<br />

supercharged S.I. eng<strong>in</strong>es are usually to run on rich mixture, for maximum power. This<br />

also results <strong>in</strong> a higher S F C. Therefore, S.I. eng<strong>in</strong>es are not generally supercharged,<br />

except to compensate for loss <strong>of</strong> power at high altitudes.<br />

Jagadeesha T, As<strong>si</strong>stant Pr<strong>of</strong>essor, Department <strong>of</strong> Mechanical Eng<strong>in</strong>eer<strong>in</strong>g, Adichunchanagiri <strong>Institute</strong> <strong>of</strong> <strong>Technology</strong>, Chikmagalur