combustion process in si engines - National Institute of Technology

combustion process in si engines - National Institute of Technology

combustion process in si engines - National Institute of Technology

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

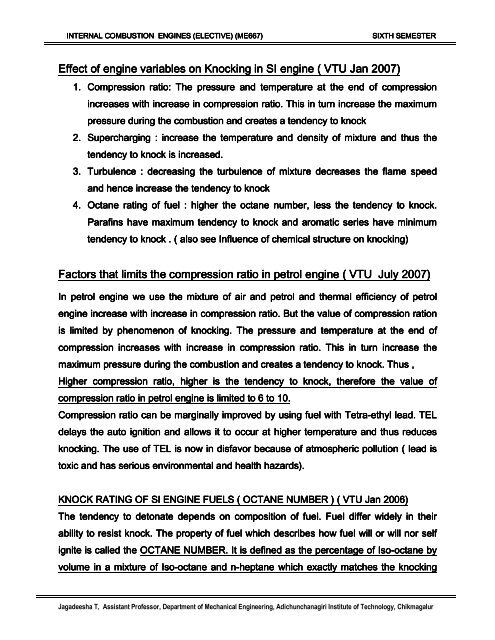

INTERNAL COMBUSTION ENGINES (ELECTIVE) (ME667)<br />

SIXTH SEMESTER<br />

Effect <strong>of</strong> eng<strong>in</strong>e variables on Knock<strong>in</strong>g <strong>in</strong> SI eng<strong>in</strong>e ne ( VTU Jan 2007)<br />

1. Compres<strong>si</strong>on ratio: The pressure and temperature at the end <strong>of</strong> compres<strong>si</strong>on<br />

<strong>in</strong>creases with <strong>in</strong>crease <strong>in</strong> compres<strong>si</strong>on ratio. This <strong>in</strong> turn <strong>in</strong>crease the maximum<br />

pressure dur<strong>in</strong>g the <strong>combustion</strong> and creates a tendency to knock<br />

2. Supercharg<strong>in</strong>g : <strong>in</strong>crease the temperature and den<strong>si</strong>ty <strong>of</strong> mixture and thus the<br />

tendency to knock is <strong>in</strong>creased.<br />

3. Turbulence : decreas<strong>in</strong>g the turbulence <strong>of</strong> mixture decreases the flame speed<br />

and hence <strong>in</strong>crease the tendency to knock<br />

4. Octane rat<strong>in</strong>g <strong>of</strong> fuel : higher the octane number, less the tendency to knock.<br />

Paraf<strong>in</strong>s have maximum tendency to knock and aromatic series have m<strong>in</strong>imum<br />

tendency to knock . ( also see Influence <strong>of</strong> chemical structure on knock<strong>in</strong>g)<br />

Factors that limits the compres<strong>si</strong>on ratio <strong>in</strong> petrol eng<strong>in</strong>e ( VTU July 2007)<br />

In petrol eng<strong>in</strong>e we use the mixture <strong>of</strong> air and petrol and thermal efficiency <strong>of</strong> petrol<br />

eng<strong>in</strong>e <strong>in</strong>crease with <strong>in</strong>crease <strong>in</strong> compres<strong>si</strong>on ratio. But the value <strong>of</strong> compres<strong>si</strong>on ration<br />

is limited by phenomenon <strong>of</strong> knock<strong>in</strong>g. The pressure and temperature at the end <strong>of</strong><br />

compres<strong>si</strong>on <strong>in</strong>creases with <strong>in</strong>crease <strong>in</strong> compres<strong>si</strong>on ratio. This <strong>in</strong> turn <strong>in</strong>crease the<br />

maximum pressure dur<strong>in</strong>g the <strong>combustion</strong> and creates a tendency to knock. . Thus ,<br />

Higher compres<strong>si</strong>on ratio, higher is the tendency to knock, therefore the value <strong>of</strong><br />

compres<strong>si</strong>on ratio <strong>in</strong> petrol eng<strong>in</strong>e is limited to 6 to 10.<br />

Compres<strong>si</strong>on ratio can be marg<strong>in</strong>ally improved by us<strong>in</strong>g fuel with Tetra-ethyl ethyl lead. TEL<br />

delays the auto ignition and allows it to occur at higher temperature and thus reduces<br />

knock<strong>in</strong>g. The use <strong>of</strong> TEL is now <strong>in</strong> disfavor d<br />

because <strong>of</strong> atmospheric pollution ( lead is<br />

toxic and has serious environmental and health hazards).<br />

KNOCK RATING OF SI ENGINE FUELS ( OCTANE NUMBER ) ( VTU Jan 2006)<br />

The tendency to detonate depends on compo<strong>si</strong>tion <strong>of</strong> fuel. Fuel differ widely <strong>in</strong> their<br />

ability to re<strong>si</strong>st knock. The property <strong>of</strong> fuel which describes how fuel will or will nor self<br />

ignite is called the OCTANE NUMBER. It is def<strong>in</strong>ed as the percentage <strong>of</strong> Iso-octane octane by<br />

volume <strong>in</strong> a mixture <strong>of</strong> Iso-octane octane and n-heptane n<br />

which exactly matches the knock<strong>in</strong>g<br />

Jagadeesha T, As<strong>si</strong>stant Pr<strong>of</strong>essor, Department <strong>of</strong> Mechanical Eng<strong>in</strong>eer<strong>in</strong>g, Adichunchanagiri <strong>Institute</strong> <strong>of</strong> <strong>Technology</strong>, Chikmagalur