DYNAMIC MEASUREMENT OF THE FORCES IN THE FRICTION ...

DYNAMIC MEASUREMENT OF THE FORCES IN THE FRICTION ...

DYNAMIC MEASUREMENT OF THE FORCES IN THE FRICTION ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

In the analyses of the brake disc is also apparent that the distribution of the surface pressing<br />

brake disc shielding will change by a blow or DTV.<br />

Thermal effects as e.g. the shielding<br />

of a brake disc (Fig. 5) let expect<br />

changes of the surface pressing of the<br />

clamping force as well.<br />

initial<br />

state<br />

after 3<br />

seconds<br />

after 7<br />

seconds<br />

Figures 2 to 5 show that inconsistent/not uniform surface pressing can be expected in a disc<br />

brake. According to (4) this would lead to a slanted wear of the brake pads. Furthermore, a<br />

higher energy expenditure results on the positions with higher surface pressing which leads to<br />

higher temperatures. On the other hand, according to (3), higher temperatures drop to lower<br />

friction coefficients and this reduces the efficiency of the brake. According to (4), the comfort<br />

of the brake is also reduced, since sloping worn pads increase the squealing sensibility.<br />

In order to avoid or reduce the problems mentioned, different measures are used in serial<br />

brakes. Nowadays piston offsets, cuttings in the metal sheet, shiftings of the centre of pressing<br />

of the piston, drawn pads (push-pull principle), two-piston calipers with different piston<br />

diameters and even further measures are used among other things to counteract these effects.<br />

In order to determine the influence of these measures and the actual surface pressing various<br />

methods were developed. State of the art are the tension-optical ball pressing process,<br />

pressure indication films of the company Fuji and electrical pressure indication films of the<br />

company Tekscan (18), for example.<br />

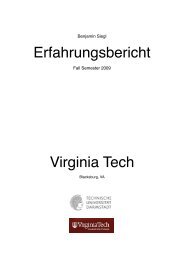

In the tension-optical ball pressing process of the company Girling (4) one 1.5 to 2 mm thick<br />

plastic plate with known tension-optical properties and a ball cage with balls with a diameter<br />

of 3 mm between brake pad and brake disc are laid. By increase of the hydraulic pressure of<br />

the brake system the balls are pressed into the plastic material. Tension curves, which help<br />

one to make statements about the transmitting force, can be seen under polarized light.<br />

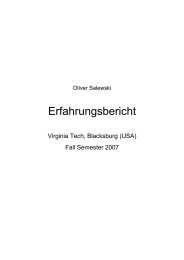

Photographs taken by the authors with electrical<br />

pressure indication films show an non-uniform<br />

surface pressing of a brake pad by a hydraulic<br />

pressure of 50bar and a stationary brake disc. The<br />

contact pressure distribution of the clamping force<br />

and the point of application of load calculated by the<br />

red-white rhomb are to be derived.<br />

Further researches with electrical pressure indication<br />

films can be found in (1 and 9), for example.<br />

- 4 -<br />

Fig. 5: Shielding of a brake disc (3)<br />

Fig. 6: A photograph of the fotostress-plastic<br />

plate for the ball pressing process of the<br />

company Girling under polarized light after<br />

load. The number of the interference rings on<br />

the particular ball indentation is a measure for<br />

the pressing dominating there. (4)<br />

⎡ g ⎤<br />

⎢ 2<br />

⎣ cm ⎥<br />

⎦<br />

Fig. 7: Surface pressing distribution<br />

under a brake pad (stationary brake disc)