Portable cutting and welding catalogue - KOIKE

Portable cutting and welding catalogue - KOIKE

Portable cutting and welding catalogue - KOIKE

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

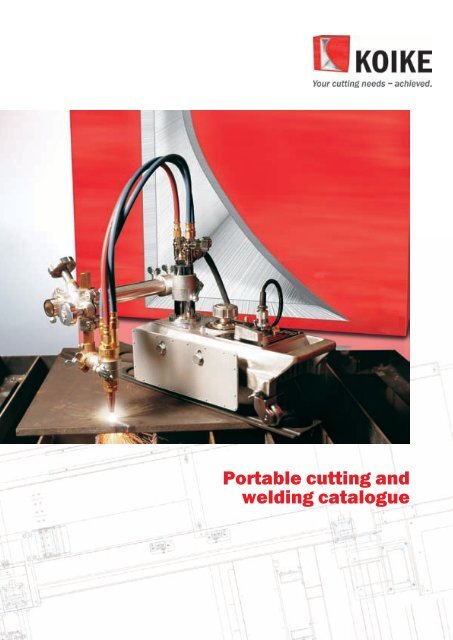

<strong>Portable</strong> <strong>cutting</strong> <strong>and</strong><br />

<strong>welding</strong> <strong>catalogue</strong>

Applications<br />

<strong>Portable</strong> <strong>cutting</strong><br />

Applications for <strong>cutting</strong><br />

H<strong>and</strong>y Auto<br />

H<strong>and</strong>y Auto Plus<br />

Pla-H<strong>and</strong>y<br />

Straigt Line Shape Hole Curved Line H-shape<br />

steel<br />

Various steel<br />

shape<br />

Pipe Square pipe Vertical<br />

surfaces<br />

IK-92 Puma – – – – – –<br />

Beaver – – – – –<br />

IK-12 Beetle – – – – – –<br />

IK-12 Max 3 – – – – – –<br />

Picle-1 – – – – – – – –<br />

Auto Picle-S – – – – – – – –<br />

Auto Picle-P – – – – – – – –<br />

KHC-600D – – – – – – –<br />

KHC-600P – – – – – – –<br />

IK-72T – – – – – –<br />

IK-70 – – – – – – – –<br />

Cir-Cut II – – – – – – – –<br />

IK-82 Series – – – – – – –<br />

Mini-Mantis II – – – – – –<br />

IK-54D – – – – –<br />

IK-05 Lug-Cut – – – – – – – –

Directory<br />

H<strong>and</strong>y Auto 6<br />

H<strong>and</strong>y Auto Plus 8<br />

Pla-H<strong>and</strong>y 10<br />

IK-92 Puma 12<br />

Beaver 14<br />

IK-12 Beetle 16<br />

IK-12 Max 3 18<br />

Picle-1 20<br />

Auto Picle-S 22<br />

Auto Picle-P 24<br />

KHC-600D 26<br />

KHC-600P 28<br />

IK-72T 30<br />

IK-70 32<br />

Cir-Cut II 34<br />

IK-82 Series 36<br />

Mini-Mantis II 38<br />

IK-54D 40<br />

IK-05 Lug-Cut 42<br />

IK-12 Max 3W 44<br />

Wel-H<strong>and</strong>y-Multi 46<br />

SilverCut-250 48<br />

MK-150 50<br />

MK-250 52<br />

MK-300 54

Directory<br />

Cutting nozzles 58<br />

Cutting nozzle 102 HC (Acetylene) 58<br />

Cutting nozzle 106 HC (Propane) 58<br />

Cutting nozzle 107 HC (Natural gas) 59<br />

Cutting nozzle 402 ST (Acetylene) 59<br />

Cutting nozzle 406 NT (Propane) 60<br />

Cutting nozzle 102 Lug-Cut (Acetylene) 60<br />

Cutting nozzle 106 Lug-Cut (Propane) 61<br />

Machine <strong>cutting</strong> nozzles 62<br />

Cutting nozzle 102 D5 (Acetylene) 62<br />

Cutting nozzle 102 D7 (Acetylene) 62<br />

Cutting nozzle 103 D7 (Ethylene) 63<br />

Cutting nozzle 106 D5 (Propane) 63<br />

Cutting nozzle 106 D7 (Propane) 64<br />

Cutting nozzle 107 D7 (Natural gas) 64

Notes<br />

5

H<strong>and</strong>y Auto<br />

H<strong>and</strong>y Auto<br />

<strong>Portable</strong> h<strong>and</strong> <strong>cutting</strong> torch with<br />

integrated drive system<br />

The H<strong>and</strong>y Auto is a portable h<strong>and</strong> held gas <strong>cutting</strong> torch<br />

with an integrated drive system. It ensures highest cut<br />

quality in vertical, circular <strong>and</strong> shape <strong>cutting</strong> as well as<br />

beveling. Besides <strong>cutting</strong> of flat surfaces it is also possible<br />

to perform curved contours on vertical surfaces like H-<br />

beams, pipes <strong>and</strong> bended plates. Thanks to the low weight<br />

of 2,7 kg H<strong>and</strong>y Auto can be used as simple as an ordinary<br />

h<strong>and</strong> <strong>cutting</strong> torch.<br />

n Easy to operate<br />

n Outst<strong>and</strong>ing quality of cut surfaces<br />

n Allows <strong>cutting</strong> in any direction<br />

n High accuracy <strong>and</strong> efficiency<br />

n Simple <strong>and</strong> fast accessory replacement<br />

6

Technical specifications<br />

Cutting thickness<br />

Cutting speed<br />

Type of drive<br />

Power supply<br />

Total length<br />

Type of gas<br />

Weight<br />

3-30 mm<br />

200-700 mm /min<br />

Transistor control /friction drive<br />

230 V AC /12 V DC<br />

500 mm<br />

Acetylene, propane, natural gas <strong>and</strong> mapp<br />

gas<br />

2,7 kg<br />

Types<br />

Description Art-No Alternative No.<br />

H<strong>and</strong>y Auto 580000101000 90005<br />

Please indicate type of gas with your order<br />

Circle Cutt. Attachm. 120-500 mm<br />

Scope of delivery<br />

<strong>Portable</strong> <strong>cutting</strong> machine H<strong>and</strong>y Auto<br />

Guide wheel for straight <strong>cutting</strong><br />

Guide wheel for bevel <strong>cutting</strong><br />

Circle <strong>cutting</strong> device (30-120 mm Ø)<br />

Guide arm<br />

Cutting nozzles (5-30 mm material thickness)<br />

Main lead (5 m)<br />

Tool set<br />

Operation instructions<br />

Transport box<br />

Battery Pack set (12 V)<br />

Accessories<br />

Description Art-No Alternative No.<br />

Circle Cutt. Attachm. 120-500 mm 580000101011 30106<br />

Battery Pack set (12 V) 580000101012 225.401.101<br />

Connecting bar (530 mm) 580000101013 30132<br />

Guide rail 500 mm 580000103002 30104<br />

Connecting bar (530 mm)<br />

Guide rail 500 mm<br />

7

H<strong>and</strong>y Auto Plus<br />

H<strong>and</strong>y Auto Plus<br />

<strong>Portable</strong> h<strong>and</strong> <strong>cutting</strong> torch with<br />

integrated drive system<br />

The H<strong>and</strong>y Auto Plus is a portable h<strong>and</strong> held gas <strong>cutting</strong><br />

machine with an integrated drive system, ignition device<br />

<strong>and</strong> Start-Stop-function for pre-heating flame. It ensures<br />

highest cut quality in vertical, circular <strong>and</strong> shape <strong>cutting</strong><br />

as well as beveling. Besides <strong>cutting</strong> of flat surfaces it is<br />

also possible to perform curved contours on vertical<br />

surfaces like H-beams, pipes <strong>and</strong> bended plates. Thanks<br />

to the low weight of 3,5 kg H<strong>and</strong>y Auto Plus can be used<br />

as simple as an ordinary h<strong>and</strong> <strong>cutting</strong> torch.<br />

n Auto ignition<br />

n Start-Stop-function for pre-heating flame<br />

n Outst<strong>and</strong>ing quality of cut surfaces<br />

n Allows <strong>cutting</strong> works in any direction<br />

n High accuracy <strong>and</strong> efficiency<br />

n Simple <strong>and</strong> fast accessory replacement<br />

8

Technical specifications<br />

Cutting thickness<br />

Cutting speed<br />

Type of drive<br />

Power supply<br />

Total length<br />

Type of gas<br />

Weight<br />

3-30 mm<br />

150-530 mm /min<br />

Transistor control /friction drive<br />

230 V AC /12 V DC<br />

500 mm<br />

Acetylene, propane, natural gas <strong>and</strong> mapp<br />

gas<br />

3,5 kg<br />

Types<br />

Description Art-No Alternative No.<br />

H<strong>and</strong>y Auto Plus 580000101001 90001<br />

Please indicate type of gas with your order<br />

Circle Cutt. Attachm. 120-500 mm<br />

Scope of delivery<br />

<strong>Portable</strong> <strong>cutting</strong> machine H<strong>and</strong>y Auto Plus<br />

Guide wheel for straight <strong>cutting</strong><br />

Guide wheel for bevel <strong>cutting</strong><br />

Circle <strong>cutting</strong> device (30-120 mm Ø)<br />

Guide arm<br />

Cutting nozzles (5-30 mm material thickness)<br />

Main lead (5 m)<br />

Tool set<br />

Operation instructions<br />

Transport box<br />

Battery Pack set (12 V)<br />

Accessories<br />

Description Art-No Alternative No.<br />

Circle Cutt. Attachm. 120-500 mm 580000101011 30106<br />

Battery Pack set (12 V) 580000101012 225.401.101<br />

Connecting bar (530 mm) 580000101013 30132<br />

Guide rail 500 mm 580000103002 30104<br />

Connecting bar (530 mm)<br />

Guide rail 500 mm<br />

9

Pla-H<strong>and</strong>y<br />

Pla-H<strong>and</strong>y<br />

H<strong>and</strong> <strong>cutting</strong> torch for plasma<br />

<strong>cutting</strong><br />

The Pla-H<strong>and</strong>y is a portable h<strong>and</strong> held, motorized <strong>cutting</strong><br />

torch for plasma <strong>cutting</strong> with integrated drive for all kind<br />

of <strong>cutting</strong> operations such as straight <strong>and</strong> curved lines in<br />

flat as well as bent plates, H-beams <strong>and</strong> pipes.<br />

The Pla-H<strong>and</strong>y enures highest quality in straight <strong>and</strong> bevel<br />

<strong>cutting</strong> at circular <strong>and</strong> shaped contours.<br />

Thanks to the low weight of 1,5 kg the Pla-H<strong>and</strong>y is as easy<br />

to use as a simple plasma <strong>cutting</strong> machine.<br />

n High quality cuts at all types of metal (steel, stainless steel,<br />

aluminum, etc.) due to plasma torch<br />

n Easy to use, one h<strong>and</strong> operation<br />

n Cutting in any position<br />

n High accuracy <strong>and</strong> efficiency<br />

n Easy <strong>and</strong> fast replacement of consumables<br />

n Suitable for Powermax PM65 /PM85 /PM1650<br />

Aluminum <strong>cutting</strong><br />

10

Technical specifications<br />

Cutting thickness<br />

Cutting speed<br />

Type of drive<br />

Power supply<br />

Total length<br />

Weight<br />

dependent on source of current<br />

100-2000 mm /min<br />

Transistor control, continuous adjustable<br />

230 V AC /12 V DC<br />

450 mm<br />

1,5 kg<br />

Types<br />

Description Art-No Alternative No.<br />

PLA-H<strong>and</strong>y (mild steel) 580000103000 90009<br />

PLA-H<strong>and</strong>y (stainless) 580000103003 90010<br />

Circle Cutt. Attachm. 120-500 mm<br />

Scope of delivery<br />

Base machine Pla-H<strong>and</strong>y<br />

Guide wheel for straight <strong>cutting</strong><br />

Circle <strong>cutting</strong> equipment (30-120 mm Ø)<br />

Magnetic centering pin for steel<br />

Centering pin with vacuum rubber for stainless steel<br />

Auxiliary wheel<br />

Connecting lead (5 m)<br />

Tool set<br />

Operation instructions<br />

Transport box<br />

Guide rail 500 mm<br />

Accessories<br />

Description Art-No Alternative No.<br />

Circle Cutt. Attachm. 120-500 mm 580000101011 30106<br />

Guide rail 500 mm 580000103002 30104<br />

Circle Cutt. Attachm. 120-500 mm* 580000103010 35584<br />

Suction holder f. large circle 580000103011 12377<br />

Bush f. small <strong>cutting</strong> attachm. 580000103012 12363<br />

Bevel <strong>cutting</strong> attachment 580000103013 12386<br />

Guide rail with suction holder 580000103014 35582<br />

* with suction holder<br />

11

IK-92 Puma<br />

IK-92 Puma<br />

<strong>Portable</strong> <strong>cutting</strong> machine<br />

The IK-92 Puma is a unique portable <strong>cutting</strong> machine for<br />

precise vertical, bevel <strong>and</strong> circle <strong>cutting</strong>. The design is boxshaped<br />

<strong>and</strong> has a low balance point. This guarantees a<br />

high stability <strong>and</strong> exact motion sequences.<br />

The machine is equipped with an efficient heat protection,<br />

consisting of a double heat shield <strong>and</strong> a cooling fan within<br />

the main body.<br />

n Ultra stable machine travel assures high-quality<br />

automatic <strong>cutting</strong><br />

n One h<strong>and</strong> operation <strong>and</strong> control of all functions<br />

n Heat prevention system<br />

n Easy maintenance due to simple, clean design<br />

12

Technical specifications<br />

Cutting thickness<br />

Cutting speed<br />

Type of drive<br />

Power supply<br />

Total length<br />

Track width<br />

Type of gas<br />

Weight<br />

3-100 mm<br />

100-1000 mm /min<br />

IC control, continuous adjustable<br />

42 V /115 V /230 V AC<br />

480 mm<br />

100 mm<br />

Acetylene, propane, natural gas <strong>and</strong> mapp<br />

gas<br />

8,0 kg<br />

Circle <strong>cutting</strong> attachment<br />

Types<br />

Description Art-No Alternative No.<br />

IK-92 Puma, 230 V 580000104000 90014<br />

IK-92 Puma, 115 V 580000104001 90013<br />

IK-92 Puma, 42 V 580000104002 90012<br />

Please indicate type of gas with your order<br />

Scope of delivery<br />

Cutting machine IK-92 Puma<br />

Cutting nozzles (5-30 mm material thickness)<br />

Connecting lead (5 m)<br />

Tool set<br />

Operation instructions<br />

Accessories<br />

Description Art-No Alternative No.<br />

Rail f. straight <strong>cutting</strong> (1800 mm) 580000104010 90018<br />

Circle <strong>cutting</strong> attachment 580000104011 33353<br />

Plate edge guide roller f. bevelling 580000104012 36959<br />

Transformer 230 V /42 V 580000104013 222.002.207<br />

Transformer 230 V /115 V 580000104014 90100<br />

13

Beaver<br />

Beaver<br />

Universal h<strong>and</strong> <strong>cutting</strong> machine<br />

The Beaver is an universal h<strong>and</strong> <strong>cutting</strong> machine for both<br />

straight line <strong>and</strong> curved line <strong>cutting</strong>. Bevel cuts are<br />

achieved by an angle tracing roller.<br />

The unique design <strong>and</strong> the adjustable distance between<br />

guide wheel <strong>and</strong> drive axle achieves best <strong>cutting</strong> results.<br />

A long distance between guide wheel <strong>and</strong> drive axle<br />

ensures accurate vertical <strong>and</strong> bevel cuts, a tighter<br />

distance guarantees exact scanning accuracy for curved<br />

line <strong>cutting</strong>.<br />

n Moveable guide wheel assures precision <strong>cutting</strong> of straight<br />

<strong>and</strong> curved lines<br />

n Single h<strong>and</strong> operation <strong>and</strong> control of all functions<br />

n Optional auto-stop function<br />

14

Technical specifications<br />

Cutting thickness<br />

Cutting speed<br />

Type of drive<br />

Power supply<br />

Total length<br />

Track width<br />

Type of gas<br />

Weight<br />

3-150 mm<br />

50-1000 mm /min<br />

IC control, continuous adjustable<br />

42 V /115 V /230 V AC<br />

430 mm<br />

100 mm<br />

Acetylene, propane, natural gas <strong>and</strong> mapp<br />

gas<br />

9,0 kg<br />

Circle <strong>cutting</strong> attachment<br />

Types<br />

Description Art-No Alternative No.<br />

Beaver, 230 V 580000105000 90015<br />

Beaver, 115 V 580000105001 90016<br />

Beaver, 42 V 580000105002 90017<br />

Please indicate type of gas with your order<br />

Scope of delivery<br />

Cutting machine Beaver<br />

Cutting nozzle (5-30 mm material thickness)<br />

Connecting lead (5 m)<br />

Tool set<br />

Operation instructions<br />

Angle tracing roller<br />

Accessories<br />

Description Art-No Alternative No.<br />

Rail f. straight <strong>cutting</strong> (1800 mm) 580000104010 90018<br />

Circle <strong>cutting</strong> attachment 580000104011 33353<br />

Transformer 230 V /42 V 580000104013 222.002.207<br />

Transformer 230 V /115 V 580000104014 90100<br />

Angle tracing roller 580000105012 33363<br />

Auto Stopping Device 580000105015 33364<br />

15

IK-12 Beetle<br />

IK-12 Beetle<br />

High quality motorized h<strong>and</strong> <strong>cutting</strong><br />

machine<br />

The IK 12 Beetle is a high quality motorized h<strong>and</strong> <strong>cutting</strong><br />

machine. The operator can perform all types of <strong>cutting</strong> with<br />

ease (vertical, circle <strong>and</strong> bevel <strong>cutting</strong>).<br />

The drive system (continuous mechanical feed change)<br />

guarantees a constant <strong>and</strong> stable movement of the<br />

machine. The travel functions (forwards, backwards, stop)<br />

are activated only by one operation element. The clutch<br />

control assures an trouble-free positioning of the<br />

machine. Bevel <strong>cutting</strong> is achieved by simply adjusting the<br />

torch holder at the bottom edge of the plate. A gear rack/<br />

bevel drive ensures an precise positioning of the machine<br />

torch (Y- <strong>and</strong> Z-axis).<br />

n The travel functions (forwards, backwards, stop) are activated<br />

only by one operation element.<br />

n The drive system (continuous mechanical feed change)<br />

guarantees a constant <strong>and</strong> stable movement of the machine.<br />

n Low weight of 9.5 kg (Easy h<strong>and</strong>ling <strong>and</strong> transport)<br />

n Attaching two machine torches allows parallel- <strong>and</strong><br />

Y-bevel <strong>cutting</strong>.<br />

16

Technical specifications<br />

Cutting thickness<br />

Cutting speed<br />

Type of drive<br />

Power supply<br />

Total length<br />

Track width<br />

Type of gas<br />

Weight<br />

3-150 mm<br />

150-880 mm /min<br />

Single cone speed system, mechanical<br />

regulation<br />

42 V /115 V /230 V AC<br />

480 mm<br />

140 mm<br />

Acetylene, Propane, natural gas <strong>and</strong> mapp<br />

gas<br />

9,5 kg<br />

Rail f. straight <strong>cutting</strong> (1800 mm)<br />

Types<br />

Description Art-No Alternative No.<br />

IK-12 Beetle, 230 V, Single 580000106000 90020<br />

IK-12 Beetle, 115 V, Single 580000106001 90021<br />

IK-12 Beetle, 42 V, Single 580000106002 90022<br />

IK-12 Beetle, 230 V, Duo 580000106003 90023<br />

IK-12 Beetle, 115 V, Duo 580000106004 90024<br />

IK-12 Beetle, 42 V, Duo 580000106005 90025<br />

Please indicate type of gas with your order<br />

Scope of delivery<br />

Cutting machine IK-12 Beetle<br />

Cutting nozzles (5-30 mm material thickness)<br />

Connecting lead (5 m)<br />

Operation instructions<br />

Beveling attachment<br />

Accessories<br />

Description Art-No Alternative No.<br />

Transformer 230 V /42 V 580000104013 222.002.207<br />

Transformer 230 V /115 V 580000104014 90100<br />

Rail f. straight <strong>cutting</strong> (1800 mm) 580000106010 30400<br />

Circle cutt. attachment 580000106011 31858<br />

Beveling attachment 580000107023 ON002<br />

17

IK-12 Max 3<br />

IK-12 Max 3<br />

Cutting <strong>and</strong> <strong>welding</strong> at highest<br />

quality<br />

The IK 12 Max 3 is the premium product of our assortment!<br />

This motorized h<strong>and</strong> <strong>cutting</strong> machine allows different<br />

types of oxy-fuel/plasma <strong>cutting</strong> <strong>and</strong> automated <strong>welding</strong>.<br />

There are three major parts to the system. The advanced<br />

motorized carriage, a <strong>cutting</strong> torch unit, the plate track <strong>and</strong><br />

accesories. All serving as independent units, the customer<br />

can choose the system for his specific requirements.<br />

The Speed Control utilizes an exclusive <strong>KOIKE</strong> Double<br />

Cone Stepless Speed System, which functions with a<br />

condensor motor rotating at regular speed to prevent heat<br />

<strong>and</strong> voltage problems. In addition, the condensor motor<br />

rotates at a constant low speed ( 1,500 rpm), extending<br />

the service life of bearings.<br />

n Outst<strong>and</strong>ing performance<br />

n Unrivaled robust <strong>and</strong> heat-proof machine<br />

n Excellent traction<br />

n Steady travel due to a well balanced center of gravity<br />

n Very high number of operation hours (more than 5000 h)<br />

due to the double cone drive<br />

n Speed (80-800 mm /min.) High Speed (240-2400 mm /<br />

min.)<br />

n Heat protection shield on the <strong>cutting</strong> side <strong>and</strong> the base plate<br />

n Gas <strong>and</strong> plasma <strong>cutting</strong> as well as automated <strong>welding</strong><br />

n Cutting area of 0,5 to 600 mm<br />

n Easy maintenance<br />

Rail f. straight <strong>cutting</strong> (1800 mm)<br />

Circle rail<br />

18

Technical specifications<br />

Cutting thickness<br />

0,5-600 mm<br />

Cutting speed (St<strong>and</strong>ard type) 80-800 mm /min<br />

Cutting Speed (High speed)<br />

Type of drive<br />

Power supply<br />

Total length<br />

Track width<br />

Type of gas<br />

Weight<br />

240-2400 mm /min<br />

Double cone speed system, mechanical<br />

regulation<br />

42 V /115 V /230 V AC<br />

430 mm<br />

140 mm<br />

Acetylene, propane, natural gas <strong>and</strong> mapp<br />

gas<br />

10,0 kg<br />

Torch Set S-100<br />

Types<br />

Description Art-No Alternative No.<br />

IK-12 MAX 3, 230 V 580000107000 90027<br />

IK-12 MAX 3, 115 V 580000107001 90028<br />

IK-12 MAX 3, 42 V 580000107002 90029<br />

IK-12 MAX 3, High Speed, 230 V 580000107003 90026<br />

IK-12 MAX 3, High Speed, 115 V 580000107004 90057<br />

IK-12 MAX 3, High Speed, 42 V 580000107005 90056<br />

Please indicate type of gas with your order<br />

Scope of delivery<br />

Base machine IK-12 Max 3<br />

Connecting lead<br />

Operation instructions<br />

Torch Set SP-100<br />

Accessories<br />

Description Art-No Alternative No.<br />

Torch Set S-100 580000107030 90036<br />

Torch Set SP-100 580000107032 90038<br />

Burner set L-100 heavy duty type 580000107036 90042<br />

Torch Set Epoch 300 580000107037 90043<br />

Torch Set S-200 580000107031 90037<br />

Torch Set SP-200 580000107033 90039<br />

Torch Set SP-300 580000107034 90040<br />

Torch Set SP-400 580000107035 90041<br />

Torch Set Epoch 600 580000107038 90046<br />

Transformer 230 V /42 V 580000104013 222.002.207<br />

Transformer 230 V /115 V 580000104014 90100<br />

Rail f. straight <strong>cutting</strong> (1800 mm) 580000106010 30400<br />

Magnet to fix rail 580000107010 D6010<br />

Heavy duty rail for thick plate <strong>cutting</strong> 580000107011 90044<br />

Circle rail 580000107012 30410<br />

Circle cutt. attachment 580000107013 30389<br />

Slide bar 250 mm 580000107014 30430<br />

Slide bar 300 mm 580000107015 30431<br />

Pipe arm 500 mm 580000107017 30321<br />

Pipe arm 1000mm 580000107018 30425<br />

Pipe arm 2500mm 580000107019 30429<br />

Hose set dist 1.2 meter 580000107020 222.023.926<br />

Hose set dist (2.7 meter length) 580000107021 222.023.931<br />

Snap Valve 580000107022 80512<br />

Beveling attachment 580000107023 ON002<br />

Burner set L-100 heavy duty type<br />

Torch Set Epoch 300<br />

19

Picle-1<br />

Picle-1<br />

Manually operated pipe <strong>cutting</strong><br />

machine<br />

The Picle-1 is a manually operated oxy-fuel pipe <strong>cutting</strong><br />

machine for trimming <strong>and</strong> beveling pipes. The chain drive<br />

is achieved by over a large worm <strong>and</strong> a worm wheel. The<br />

low transmission ratio leads to an absolutely frictionless<br />

feed.<br />

The transmission chain consists of simply constructed,<br />

smoothly interlocking chain links. Due to the chain links'<br />

easy insertion <strong>and</strong> removal, a fast exchange for varying<br />

pipe diameter is guaranteed. The adjustments for bevel<br />

<strong>cutting</strong> is ensured by an angle scale at the torch bracket.<br />

n St<strong>and</strong>ard chain for <strong>cutting</strong> pipe diameter of 114 - 600 mm<br />

n Extension chain (1 m) for large pipe diameter<br />

n The low transmission ratio leads to an absolutely<br />

frictionless feed.<br />

n The torch adjustments for bevel <strong>cutting</strong> is achieved<br />

by an angle scale.<br />

n Easy operation <strong>and</strong> maintenance<br />

n Low weight<br />

20

Technical specifications<br />

Cutting thickness<br />

Type of drive<br />

Height<br />

Track width<br />

Type of gas<br />

Weight<br />

5-50 mm<br />

manually<br />

400 mm<br />

230 mm<br />

Acetylene, propane, natural gas <strong>and</strong> mapp<br />

gas<br />

9,0 kg<br />

Types<br />

Description Art-No Alternative No.<br />

Picle-1 580000108000 90110<br />

Please indicate type of gas with your order<br />

Chain extension 1 m<br />

Scope of delivery<br />

Cutting machine Picle 1<br />

Cutting nozzles (5-30 mm material thickness)<br />

Tool set<br />

Operation instructions<br />

Accessories<br />

Description Art-No Alternative No.<br />

Chain extension 1 m 580000108010 31131<br />

21

Auto Picle-S<br />

Auto Picle-S<br />

Pipe <strong>cutting</strong> machine with<br />

motorized drive<br />

Auto Picle-S is a motorized oxy-fuel pipe <strong>cutting</strong> machine<br />

with remote control. The special guiding system with the<br />

fixed guiding rail for thr torch tip guarantees a high <strong>cutting</strong><br />

accuracy, especially when <strong>cutting</strong> large pipe diameters.<br />

By using the motorized drive for trimming <strong>and</strong> beveling<br />

pipes, highest quality will be achieved. The transmission<br />

chain consists of simply constructed, smoothly<br />

interlocking chain links. Due to the chain links' easy<br />

insertion <strong>and</strong> removal, a fast exchange for varying pipe<br />

diameter is guaranteed. The adjustments for bevel <strong>cutting</strong><br />

is ensured by an angle scale at the torchbracket.<br />

n Especially developed for pipe oxy-fuel <strong>cutting</strong><br />

n Guiding system with fixed guiding rail<br />

n Cutting of vertical pipes possible<br />

n Simple adjustment of varying pipe diameter<br />

n Operation by remote control<br />

22

Technical specifications<br />

Cutting thickness<br />

Cutting speed<br />

Type of drive<br />

Power supply<br />

Height<br />

Track width<br />

Type of gas<br />

Weight<br />

5-50 mm<br />

100-700 mm /min<br />

PWM with remote control<br />

42 V /115 V AC<br />

400 mm<br />

230 mm<br />

Acetylene, propane, natural gas <strong>and</strong> mapp<br />

gas<br />

15,0 kg<br />

Chain extension 1 m<br />

Types<br />

Description Art-No Alternative No.<br />

Auto Picle-S, 115 V 580000109001 90116<br />

Auto Picle-S, 42 V 580000109002 90117<br />

Please indicate type of gas with your order<br />

Scope of delivery<br />

Pipe <strong>cutting</strong> machine Auto Picle-S<br />

Chain 2400 mm length (Pipe diameter 600 mm)<br />

Cutting nozzle (5-30 mm material thickness)<br />

Connecting lead (5 m)<br />

Tool set<br />

Operation instructions<br />

Guide Rail D-600 incl. chain<br />

Accessories<br />

Description Art-No Alternative No.<br />

Transformer 230 V /42 V 580000104013 222.002.207<br />

Transformer 230 V /115 V 580000104014 90100<br />

Chain extension 1 m 580000108010 31131<br />

Guide Rail D-600 incl. chain 580000109010 90106<br />

Guide Rail D-900 incl. chain 580000109011 90107<br />

Guide Rail D-1200 incl. chain 580000109012 90108<br />

Guide Rail D-1500 incl. chain 580000109013 90109<br />

23

Auto Picle-P<br />

Auto Picle-P<br />

Pipe <strong>cutting</strong> machine for plasma<br />

<strong>cutting</strong><br />

Auto Picle-P is a motorized pipe <strong>cutting</strong> machine with<br />

remote control for <strong>cutting</strong> with plasma. The special guiding<br />

system with the fixed guiding rail for the torch tip<br />

guarantees a high <strong>cutting</strong> accuracy, especially when<br />

<strong>cutting</strong> large pipe diameters.<br />

By using the motorized drive for trimming <strong>and</strong> beveling<br />

pipes, highest quality will be achieved. The transmission<br />

chain consists of simply constructed, smoothly<br />

interlocking chain links. Due to the chain links' easy<br />

insertion <strong>and</strong> removal, a fast exchange for varying pipe<br />

diameter is guaranteed. The adjustments for bevel <strong>cutting</strong><br />

is ensured by an angle scale at the torchbracket.<br />

n Especially developed for pipe plasma <strong>cutting</strong><br />

n Guiding system with fixed guiding rail<br />

n Cutting of vertical pipes possible<br />

n Simple adjustment of varying pipe diameter<br />

n Operation by remote control<br />

n Suitable for Powermax PM65 /PM85 /PM1650<br />

24

Technical specifications<br />

Cutting thickness<br />

Cutting speed<br />

Type of drive<br />

Power supply<br />

Height<br />

Track width<br />

Weight<br />

dependent on power source<br />

500-3000 mm /min<br />

S.C.R. control with remote control<br />

115 V AC<br />

400 mm<br />

230 mm<br />

15,0 kg<br />

Types<br />

Description Art-No Alternative No.<br />

Auto Picle-P, 115 V 580000110000 90119<br />

Chain extension 1 m<br />

Scope of delivery<br />

Pipe <strong>cutting</strong> machine Auto Picle-P<br />

Chain 2400 mm length (Pipe diameter 600 mm)<br />

Connecting lead (5 m)<br />

Tool set<br />

Operation instructions<br />

Accessories<br />

Description Art-No Alternative No.<br />

Transformer 230 V /115 V 580000104014 90100<br />

Chain extension 1 m 580000108010 31131<br />

Guide Rail D-600 incl. chain 580000109010 90106<br />

Guide Rail D-900 incl. chain 580000109011 90107<br />

Guide Rail D-1200 incl. chain 580000109012 90108<br />

Guide Rail D-1500 incl. chain 580000109013 90109<br />

Guide Rail D-600 incl. chain<br />

25

KHC-600D<br />

KHC-600D<br />

Automatic pipe hole <strong>cutting</strong><br />

machine<br />

The KHC-600D is a portable automatic oxy-fuel pipe hole<br />

<strong>cutting</strong> machine. The main application is the accurate<br />

<strong>cutting</strong> of holes with or without bevel in pipes, highpressure<br />

storage tanks <strong>and</strong> heat exchangers. An eccentric<br />

mechanism guarantees an exact adjustment of the stroke<br />

(vertical travel of the torch). The rotational joint at the gas<br />

supply prevents entangling hoses <strong>and</strong> a repositioning of<br />

the machine to its home position.<br />

n Compact design<br />

n Cuts a vessel from the inside as well as from the outside<br />

n Easy positioning for <strong>cutting</strong> by the use of centering pin<br />

(circle diameter 60 - 600 mm)<br />

n Bevel cuts till 45° possible<br />

n No entangling hoses due to rotational joint<br />

26

Technical specifications<br />

Cutting thickness<br />

Cutting diameter<br />

Vertical torch stroke<br />

Type of drive<br />

Cutting speed<br />

Power supply<br />

5-50 mm<br />

60-600 mm<br />

0-100 mm<br />

SCR control<br />

0,12-1,2 rpm<br />

42 V /115 V AC<br />

Machine dimensions (WxHxD) 500 mm x 760 mm x 1050 mm<br />

Type of gas<br />

Weight<br />

Acetylene, propane, natural gas <strong>and</strong> mapp<br />

gas<br />

26,0 kg<br />

Transformer 230 V /42 V<br />

Types<br />

Description Art-No Alternative No.<br />

KHC-600D, 115 V 580000111001 90121<br />

KHC-600D, 42 V 580000111002 90122<br />

Please indicate type of gas with your order<br />

Scope of delivery<br />

Cutting machine KHC-600 D<br />

Cutting nozzles (5-30 mm material thickness)<br />

Connecting lead (5 m)<br />

Tool set<br />

Operation instructions<br />

Accessories<br />

Description Art-No Alternative No.<br />

Transformer 230 V /42 V 580000104013 222.002.207<br />

Transformer 230 V /115 V 580000104014 90100<br />

Fixture f. small diameters 580000111010 90123<br />

Over-Hang Kit 580000111011 90125<br />

27

KHC-600P<br />

KHC-600P<br />

Pipe hole <strong>cutting</strong> machine for<br />

plasma <strong>cutting</strong><br />

The KHC-600P is a portable automatic pipe hole <strong>cutting</strong><br />

machine. It can be equipped with plasma equipment. Main<br />

applications are the accurate <strong>cutting</strong> of holes with or<br />

without bevel, through the casing of the pipes, highpressure<br />

storage tanks <strong>and</strong> heat exchangers.<br />

An eccentric apparatus guarantees an exact adjustment<br />

of the stroke (vertical travel of the torch).<br />

n An eccentric shaft guarantees an exact adjustment<br />

of the stroke.<br />

n Compact Design<br />

n Suits for <strong>cutting</strong> inside as well as upon the pipe<br />

n Easy positioning for <strong>cutting</strong> by the use of centering pin<br />

n Bevel cuts up to 45° possible<br />

n Suitable for Powermax PM65 /PM85 /PM1650<br />

28

Technical specifications<br />

Cutting thickness<br />

Dependent on the current source<br />

Cutting diameter<br />

120-600 mm<br />

Vertical torch stroke<br />

0-100 mm<br />

Cutting speed<br />

0,24-2,42 rpm<br />

Type of drive<br />

SCR control<br />

Power supply<br />

42 V AC<br />

Machine dimensions (WxHxD) 500 mm x 980 mm x 1200 mm<br />

Weight<br />

52,0 kg<br />

Types<br />

Description Art-No Alternative No.<br />

KHC-600P 580000111003 90124<br />

Transformer 230 V /42 V<br />

Scope of delivery<br />

Base machine KHC 600 P<br />

Connecting lead (5 m)<br />

Tool set<br />

Operation instructions<br />

Accessories<br />

Description Art-No Alternative No.<br />

Transformer 230 V /42 V 580000104013 222.002.207<br />

Fixture f. small diameters 580000111010 90123<br />

Over-Hang Kit 580000111011 90125<br />

29

IK-72T<br />

IK-72T<br />

Three dimensional <strong>cutting</strong> machine<br />

The IK-72T is a portable automatic oxy-fuel <strong>cutting</strong><br />

machine for all positions (three dimensional). There are<br />

three different types of rails. The 1D extendable aluminum<br />

rail allows <strong>cutting</strong> of even surfaces. The extendable 2D/3D<br />

flex tracks made of hard rubber with flexible steel pipes in<br />

the inside allow cuts in the second <strong>and</strong> third dimension.<br />

All rails are delivered with magnetic holder enabling cuts<br />

in vertical <strong>and</strong> horizontal positions. The low weight (4,5 kg)<br />

<strong>and</strong> the outst<strong>and</strong>ing rigid mechanics (gear rack/bevel<br />

drive <strong>and</strong> lateral guide rolls) assure high quality <strong>cutting</strong><br />

accuracy.<br />

n Three rail types for a substantial working area<br />

n Easy to operate<br />

n Outst<strong>and</strong>ing rigid mechanics<br />

n High quality of <strong>cutting</strong> accuracy<br />

30

Technical specifications<br />

Cutting thickness<br />

Cutting speed<br />

Type of drive<br />

Power supply<br />

Type of gas<br />

Weight<br />

5-50 mm<br />

150-700 mm<br />

PWM<br />

42 V /115 V AC<br />

Acetylene, propane, natural gas <strong>and</strong> mapp<br />

gas<br />

4,5 kg<br />

Types<br />

Description Art-No Alternative No.<br />

IK-72 T, 115 V 580000113001 90151<br />

IK-72 T, 42 V 580000113002 90152<br />

Please indicate type of gas with your order<br />

1D-<strong>cutting</strong> rail 1.500 mm<br />

Scope of delivery<br />

Cutting machine IK-72T<br />

Cutting nozzles (5-30 mm material thickness)<br />

Connecting lead (5 m)<br />

Tool set<br />

Operation instructions<br />

Accessories<br />

Description Art-No Alternative No.<br />

Transformer 230 V /42 V 580000104013 222.002.207<br />

Transformer 230 V /115 V 580000104014 90100<br />

1D-<strong>cutting</strong> rail 1.500 mm 580000113010 90153<br />

2D-<strong>cutting</strong> rail 1.000 mm 580000113011 90154<br />

3D-<strong>cutting</strong> rail 1.000 mm 580000113012 90155<br />

Connection aluminium/rubber 580000113013 33107<br />

2D-<strong>cutting</strong> rail 1.000 mm<br />

3D-<strong>cutting</strong> rail 1.000 mm<br />

31

IK-70<br />

IK-70<br />

Automatic circle <strong>cutting</strong> machine<br />

The IK-70 is a portable automatic oxy-fuel circle <strong>cutting</strong><br />

machine, especially designed for <strong>cutting</strong> circles, with or<br />

without bevel, on even surfaces allowing to cut circles with<br />

a diameters of 30-1000 mm. The accordingly<br />

dimensioned base late rests upon four movable balls <strong>and</strong><br />

allows a fast positioning of the IK-70. Another advantage<br />

is the compact <strong>and</strong> solid control system which improves<br />

the speed stabilization especially at extremely low travel<br />

speeds.<br />

n Compact control unit<br />

n Low weight <strong>and</strong> high stability<br />

n No entangling hoses due to the rotating gas manifold<br />

n Simple positioning mechanism<br />

n Variable operation possibilities<br />

32

Technical specifications<br />

Cutting thickness<br />

Cutting diameter<br />

Cutting speed<br />

Type of drive<br />

Power supply<br />

Type of gas<br />

Weight<br />

5-50 mm<br />

30-1000 mm<br />

0,2-6 rpm or 0,04-1,5 rpm<br />

SCR Ward Leonard<br />

115 V AC<br />

Acetylene, propane, natural gas <strong>and</strong> mapp<br />

gas<br />

55,0 kg<br />

Types<br />

Description Art-No Alternative No.<br />

IK-70, 115 V 580000115001 90081<br />

Please indicate type of gas with your order<br />

Transformer 230 V /115 V<br />

Scope of delivery<br />

Cutting machine IK-70<br />

Cutting nozzles (5-30 mm material thickness)<br />

Connecting lead (5 m)<br />

Tool set<br />

Operation instructions<br />

Accessories<br />

Description Art-No Alternative No.<br />

Transformer 230 V /115 V 580000104014 90100<br />

33

Cir-Cut II<br />

Cir-Cut II<br />

<strong>Portable</strong> automatic circle <strong>cutting</strong><br />

machine<br />

Cir-Cut II is a portable automatic oxy-fuel circle <strong>cutting</strong><br />

machine especially designed for circle <strong>cutting</strong> with or<br />

without bevel, on even surfaces, in horizontal <strong>and</strong> vertical<br />

positions.<br />

A powerful electromagnet simplifies <strong>cutting</strong> in any<br />

position. The rotating gas manifold prevents from tangling<br />

hoses <strong>and</strong> a reset of the machine to its home position.<br />

n Low weight (simple operation <strong>and</strong> transport)<br />

n Easy positioning for <strong>cutting</strong> by the use of centering pin<br />

(circle diameter 40-200 mm)<br />

n Bevel cuts till 45° possible<br />

n No tangling hoses due to rotating gas manifold<br />

34

Technical specifications<br />

Cutting thickness<br />

Cutting diameter<br />

Cutting speed<br />

Type of drive<br />

Power supply<br />

Type of gas<br />

Weight<br />

5-50 mm<br />

40-200 mm<br />

0,5-7 rpm<br />

SCR Ward Leonard<br />

115 V AC<br />

Acetylene, propane, natural gas <strong>and</strong> mapp<br />

gas<br />

11,0 kg<br />

Types<br />

Description Art-No Alternative No.<br />

Cir-Cut II, 115 V 580000114001 90073<br />

Please indicate type of gas with your order<br />

Transformer 230 V /115 V<br />

Scope of delivery<br />

Cutting machine Cir-Cut II<br />

Cutting nozzles (5-30 mm material thickness)<br />

Connecting lead (5 m)<br />

Toolset<br />

Operation instructions<br />

Accessories<br />

Description Art-No Alternative No.<br />

Transformer 230 V /115 V 580000104014 90100<br />

35

IK-82 Series<br />

IK-82 Series<br />

Automatic joint arm <strong>cutting</strong><br />

machine<br />

The IK-82 is a powerful magnetic tracing type <strong>cutting</strong><br />

machine. The simple design <strong>and</strong> modular structure have<br />

substantially reduced the machine weight <strong>and</strong> provide a<br />

system configuration that ensures easy operation. The<br />

model comes in three types - S, M, <strong>and</strong> L, according to the<br />

effective <strong>cutting</strong> area. Types S <strong>and</strong> M have an<br />

interchangeable arm pipe, while type L has a rail pipe on<br />

the rail cart, <strong>and</strong> the length of the rail pipe can be changed<br />

according to the size of the material to be cut.<br />

n Rail carriage featuring adjustable rail length according to work<br />

piece (Type L).<br />

n Easy tip replacement<br />

n Tracer head for h<strong>and</strong>ling ease <strong>and</strong> high-precision <strong>cutting</strong>.<br />

n Light-weight <strong>and</strong> rugged arm by stainless steel pipe structure<br />

(Types S <strong>and</strong> M)<br />

n Magnetic roller selectable for your requirements<br />

(Types S <strong>and</strong> M)<br />

36

Technical specifications IK-82 S200<br />

Cutting thickness<br />

Cutting range<br />

Magnet roller<br />

Cutting speed<br />

Type of drive<br />

Power supply<br />

Type of gas<br />

Weight<br />

5-50 mm<br />

Circles up to 200 mm, ellipses up to 420 x<br />

160 mm<br />

25 mm Ø<br />

100-900 mm /min<br />

Transistor<br />

42 V /115 V AC<br />

Acetylene or propane<br />

7,5 kg<br />

Rail for IK-82 L900<br />

Technical specifications IK-82 M300<br />

Cutting thickness<br />

5-50 mm<br />

Cutting range<br />

Circles up to 300 mm, ellipses up tp 600 x<br />

200 mm<br />

Magnet roller<br />

16 mm ø<br />

Cutting speed<br />

100-600 mm /min<br />

Type of drive<br />

Transistor<br />

Power supply<br />

42 V /115 V AC<br />

Type of gas<br />

Acetylene or propane<br />

Weight<br />

9,5 kg<br />

Technical specifications IK-82 L900<br />

Cutting thickness<br />

5-50 mm<br />

Cutting range<br />

900 mm x needed length<br />

Magnet roller<br />

16 mm ø<br />

Cutting speed<br />

100-600 mm /min<br />

Type of drive<br />

Transistor<br />

Power supply<br />

115 V AC<br />

Type of gas<br />

Acetylene or propane<br />

Weight<br />

Machine 5,5 kg, carriage 4,0 kg<br />

Magnet roller 16 mm diameter<br />

Types<br />

Description Art-No Alternative No.<br />

IK-82 S-200, 115 V 580000116001 90060<br />

IK-82 S-200, 42 V 580000116002 90061<br />

IK-82 M-300, 115 V 580000116004 90063<br />

IK-82 M-300, 42 V 580000116005 90064<br />

IK-82 L-900, 115 V 580000116007 90065<br />

Please indicate type of gas with your order<br />

Scope of delivery<br />

Cutting machine<br />

Cutting nozzles (5-30 mm material thickness)<br />

Connecting lead (5m)<br />

Operation instructions<br />

Accessories<br />

Description Art-No Alternative No.<br />

Transformer 230 V /42 V 580000104013 222.002.207<br />

Transformer 230 V /115 V 580000104014 90100<br />

37

Mini-Mantis II<br />

Mini-Mantis II<br />

Automatic H-beam <strong>cutting</strong> machine<br />

The Mini-Mantis II is a portable automatic H-beam oxy-fuel<br />

<strong>cutting</strong> machine. It is possible to perform fast <strong>and</strong> precise<br />

web <strong>and</strong> flange cuts on beam profiles.<br />

The machine features two drive motors: one for web<br />

<strong>cutting</strong>, the other for flange <strong>cutting</strong>. For <strong>cutting</strong> webs the<br />

carriage travels along the guide rail, for <strong>cutting</strong> flanges the<br />

torch is moved by a vertical gear rack. It eliminates the<br />

need for secondary operations.<br />

n Guide rail <strong>and</strong> main unit are connected (short installation<br />

time)<br />

n Low weight (It is more economic to transport the<br />

machine to the work piece)<br />

n Diagonal cuts at the web <strong>and</strong> flange as well as beveling<br />

is possible till 45°<br />

n SCR control unit for steady feed<br />

38

Technical specifications<br />

Cutting thickness<br />

Cutting dimensions<br />

Cutting speed<br />

Type of drive<br />

Power supply<br />

5-40 mm<br />

See above<br />

100-700 mm /min<br />

SCR control<br />

115 V AC<br />

Machine dimensions (WxHxD) 500 mm x 760 mm x 1050 mm<br />

Type of gas<br />

Weight<br />

Acetylene, propane, natural gas <strong>and</strong> mapp<br />

gas<br />

20,0 kg<br />

Rail L900<br />

Types<br />

Description Art-No Alternative No.<br />

Mini-Mantis II, 115 V, 580000117004 90131<br />

Please indicate type of gas with your order<br />

Scope of delivery<br />

Cutting machine Mini Mantis II<br />

Cutting nozzles (5-30 mm material thickness)<br />

Connecting lead(5 m)<br />

Tool set<br />

Operation instructions<br />

Accessories<br />

Description Art-No Alternative No.<br />

Transformer 230 V /115 V 580000104014 90100<br />

Rail L600 580000117010 90234<br />

Rail L900 580000117011 90235<br />

Rail L1500 580000117012 90136<br />

Guide Rail L1200 580000117013 32027<br />

Guide Rail L1200<br />

39

IK-54D<br />

IK-54D<br />

Robust shape <strong>cutting</strong> machine<br />

The IK-54 D is a high quality <strong>and</strong> robust shape <strong>cutting</strong><br />

machine with high production accuracy. It allows to cut<br />

steel plates of a material thickness up to 100 mm. An<br />

extremely powerful permanent magnet guarantees a<br />

constant feed even when <strong>cutting</strong> difficult shapes. The<br />

magnet rolls (for sampling) have different diameter (8, 10,<br />

15 <strong>and</strong> 20 mm). By exchanging the magnet roll, various<br />

cut sizes with the same template are achieved.<br />

The low weight (33 kg) allows an easy transport of the<br />

machine from one site of operation to another.<br />

These features apply only to considerably more expensive<br />

<strong>cutting</strong> machines.<br />

n Cutting oxygen <strong>and</strong> feed are operated with<br />

easy-to-use control unit<br />

n Extreme powerful permanent magnet<br />

n S.C.R. control system for constant feed<br />

n Rotatable burner support<br />

n Circle <strong>cutting</strong> (up to 1700 mm) possible<br />

40

Technical specifications<br />

Cutting thickness<br />

Cutting circle<br />

Cutting Rectangle<br />

Cutting speed<br />

Type of drive<br />

Power supply<br />

Type of gas<br />

Machine height<br />

Weight<br />

3-100 mm<br />

30-700 mm, with device 600-1700 mm<br />

300-600 mm, with device 500-1200 mm<br />

100-1000 mm /min<br />

SCR control<br />

115 V AC<br />

Acetylene, propane, natural gas <strong>and</strong> mapp<br />

gas<br />

765 mm<br />

33,0 kg<br />

Circle <strong>cutting</strong> unit<br />

Types<br />

Description Art-No Alternative No.<br />

IK-54D, 115 V 580000118001 90051<br />

Please indicate type of gas with your order<br />

Scope of delivery<br />

Cutting machine IK-45 D<br />

Cutting nozzles (5-30 mm material thickness)<br />

Connecting lead<br />

Tool set<br />

Operation instructions<br />

Magnet roller, 6 mm<br />

Accessories<br />

Description Art-No Alternative No.<br />

Transformer 230 V /115 V 580000104014 90100<br />

Circle <strong>cutting</strong> unit 580000118010 30800<br />

Magnet roller, 6 mm 580000118011 30722<br />

Magnet roller, 8 mm 580000118012 30723<br />

Magnet roller, 15 mm 580000118013 30724<br />

Magnet roller, 20 mm 580000118014 30725<br />

41

IK-05 Lug-Cut<br />

IK-05 Lug-Cut<br />

Cutting machine for <strong>cutting</strong> lifting<br />

brackets<br />

The IK-05 Lug-Cut is a portable oxy-fuel <strong>cutting</strong> machine<br />

for <strong>cutting</strong> lifting brackets. The machine is mainly used<br />

everywhere where large plate- <strong>and</strong> construction parts are<br />

equipped with lifting brackets for transportation (e.g.<br />

bridge <strong>and</strong> ship building).<br />

The feed results from a unique spring drive-the machine<br />

does not need any power supply. The curved <strong>cutting</strong><br />

nozzles allow a separating cut of the lifting brackets very<br />

close to the work piece without damaging it. The separated<br />

lifting brackets can be reused. Varying material<br />

thicknesses can be cut with the same feed speed simply<br />

by changing the heating flames parameters..<br />

n Unique spring drive<br />

n Constant feed (400 mm /min)<br />

n Easy operation <strong>and</strong> low weight (5,9 kg)<br />

n Perfect quality of cuts (peerless to manual <strong>cutting</strong>)<br />

n Quick coupling device for burning gas,<br />

heating <strong>and</strong> <strong>cutting</strong> oxygen<br />

42

Technical specifications<br />

Cutting thickness<br />

Cutting speed<br />

Drive system<br />

Dimensions<br />

Type of gas<br />

Weight<br />

20-30 mm<br />

400 mm /min<br />

Spring drive<br />

Length of 740 mm, effective <strong>cutting</strong> length of<br />

380 mm<br />

Acetylene, propane<br />

5,9 kg<br />

Types<br />

Description Art-No Alternative No.<br />

IK-05 Lug-Cut 580000119000 61003848<br />

Please indicate type of gas with your order<br />

Scope of delivery<br />

Cutting machine IK-05 Lug-Cut<br />

Cutting nozzle (20-30 mm material thickness)<br />

Tool set<br />

Operation instructions<br />

43

IK-12 Max 3W<br />

IK-12 Max 3W<br />

Cutting <strong>and</strong> <strong>welding</strong> at highest<br />

quality<br />

The IK 12 Max 3W is the premium product of our<br />

assortment! This motorized h<strong>and</strong> <strong>cutting</strong> machine allows<br />

different types of oxy-fuel /plasma <strong>cutting</strong> <strong>and</strong> automated<br />

<strong>welding</strong>.<br />

There are three major parts to the system.The advanced<br />

motorized carriage, a <strong>cutting</strong> torch unit, the plate track <strong>and</strong><br />

accesories. All serving as independent units, the customer<br />

can choose the system for his specific requirements.<br />

The Speed Control utilizes an exclusive <strong>KOIKE</strong> Double<br />

Cone Stepless Speed System, which functions with a<br />

condensor motor rotating at regular speed to prevent heat<br />

<strong>and</strong> voltage problems. In addition, the condensor motor<br />

rotates at a constant low speed ( 1,500 rpm ), extending<br />

the service life of bearings.<br />

n Outst<strong>and</strong>ing performance<br />

n Unrivaled robust <strong>and</strong> heat-proof machine<br />

n Excellent traction<br />

n Steady drive by a well balanced centre of gravity<br />

n Very high number of operation hours (more than 5000 h)<br />

due to the doubled cone drive<br />

n High Speed (240-2400 mm /min.)<br />

n Heat protection shield on the <strong>cutting</strong> side <strong>and</strong> the base plate<br />

n Gas <strong>and</strong> plasma <strong>cutting</strong> as well as automated <strong>welding</strong><br />

n Easy maintenance<br />

44

Technical specifications<br />

Cutting Speed (High speed)<br />

Type of drive<br />

Power supply<br />

Total length<br />

Track width<br />

Weight<br />

240-2400 mm /min<br />

Double cone speed system, mechanical<br />

regulation<br />

115 V /230 V AC<br />

430 mm<br />

140 mm<br />

10,0 kg<br />

Types<br />

Description Art-No Alternative No.<br />

IK-12 MAX 3W, High Speed, 230 V 580000107003 90026<br />

IK-12 MAX 3W, High Speed, 115 V 580000107004 90057<br />

Rail f. straight <strong>cutting</strong> (1800 mm)<br />

Scope of delivery<br />

Base machine IK-12 Max 3W<br />

Connecting lead<br />

Operation instructions<br />

Accessories<br />

Description Art-No Alternative No.<br />

Transformer 230 V /115 V 580000104014 90100<br />

Rail f. straight <strong>cutting</strong> (1800 mm) 580000106010 30400<br />

Magnet to fix rail 580000107010 D6010<br />

Circle rail 580000107012 30410<br />

Circle cutt. attachment 580000107013 30389<br />

Control unit FR-3, 230 V 580000107040 61003427<br />

Control unit FR-3, 110 V 580000107041 BUB01553<br />

Torch set MP-100 ( Welding / 580000107043 31301<br />

Plasma )<br />

Weaving unit WU-2 580000107045 90219<br />

Circle rail<br />

Control unit FR-3, 230 V<br />

Weaving unit WU-2<br />

45

Wel-H<strong>and</strong>y-Multi<br />

Wel-H<strong>and</strong>y-Multi<br />

Automated <strong>welding</strong> portable<br />

The Koike Wel H<strong>and</strong>y Multi <strong>welding</strong> carriage is available in<br />

two basis models; st<strong>and</strong>ard <strong>and</strong> advance, with two main<br />

options to cover a wide range of <strong>welding</strong> positions <strong>and</strong><br />

applications, such as horizontal, vertical, tack, weaving<br />

etc. The Wel H<strong>and</strong>y Multi Models are all light, compact <strong>and</strong><br />

are equipped a 4WD. The magnetic force traction with low<br />

center of gravity which achieves the highest pulling power<br />

<strong>and</strong> stability in the market. In addition, vertical <strong>welding</strong> is<br />

possible for both Wel H<strong>and</strong>y Multi Models.<br />

Wel H<strong>and</strong>y Multi St<strong>and</strong>ard<br />

The Wel H<strong>and</strong>y Multi St<strong>and</strong>ard can be used for flat <strong>and</strong><br />

vertical <strong>welding</strong>. The Twin Torch option can easily be<br />

mounted on the Wel H<strong>and</strong>y Multi St<strong>and</strong>ard to increase<br />

productivity while decreasing heat distortion.<br />

Wel H<strong>and</strong>y Multi Advance<br />

The Wel H<strong>and</strong>y Multi Advance is equipped with true tack<br />

function for maximum productivity <strong>and</strong> weld quality. With<br />

the weaving option you can increase weldability <strong>and</strong><br />

quality in multi-pass <strong>welding</strong>. The Weaving option is only<br />

available for the Wel H<strong>and</strong>y Multi Advance. The Twin Torch<br />

or the Weaving option can easily be mounted on the Wel<br />

H<strong>and</strong>y Multi Advance.<br />

46

Technical specifications<br />

Welding speed<br />

150-1500 mm /min, left/right run<br />

Type of drive<br />

4 wheel drive with magnetic attraction<br />

system<br />

Traction power<br />

50,0 kg<br />

Burner support<br />

Vertical stroke <strong>and</strong> horizontal, 45 mm<br />

adjustable<br />

Guide roller Scanning height adjustable to 10, 20 <strong>and</strong> 38<br />

mm<br />

Auto stop function<br />

End limit with electric arc interruption<br />

Power supply<br />

42 V AC<br />

Machine dimensions (WxHxD) 262 mm x 265 mm x 260 mm<br />

Weight<br />

6,9 kg (St<strong>and</strong>ard) /6,8 kg (Advance)<br />

Twin torch option<br />

Types<br />

Description Art-No Alternative No.<br />

Wel-H<strong>and</strong>y Multi, 42 V 580000130001 90214<br />

Wel-H<strong>and</strong>y Multi Advance, 42 V 580000130002 90215<br />

Scope of delivery<br />

Welding portable Wel-H<strong>and</strong>y Multi<br />

Connection cable<br />

Tool set<br />

Operation manual<br />

Weaving unit<br />

Accessories<br />

Description Art-No Alternative No.<br />

Transformer 230 V /42 V 580000104013 222.002.207<br />

Twin torch option 580000130010 90216<br />

Weaving unit 580000130013 90217<br />

Holder f. curved torch 15-25 mm 580000130014 61000676<br />

Holder f. curved torch 15-25 mm<br />

47

SilverCut-250<br />

SilverCut-250<br />

H<strong>and</strong> <strong>cutting</strong> torch for gas mixing<br />

<strong>cutting</strong> nozzle<br />

The SilverCut-250 is a h<strong>and</strong> <strong>cutting</strong> torch for gas mixing<br />

<strong>cutting</strong> nozzles. This well balanced <strong>and</strong> safe h<strong>and</strong> torch<br />

utilizes a triangular tube configuration for greater strength.<br />

The <strong>KOIKE</strong> gas mixing nozzles reduce flashbacks <strong>and</strong><br />

protect the <strong>cutting</strong> torch from damages. By changing the<br />

<strong>cutting</strong> nozzles, the gas type can be changed (acetylene,<br />

propane, mapp gas or natural gas).<br />

n Gas mixing h<strong>and</strong> <strong>cutting</strong> torch<br />

n Rigid triangular tube configuration<br />

48

Technical specifications<br />

Cutting range<br />

Torch head 90°<br />

Total length<br />

Weight (kg)<br />

Type of gas<br />

3-250 mm<br />

495 mm<br />

1,0 kg<br />

Acetylene, propane, natural gas <strong>and</strong> mapp<br />

gas<br />

Types<br />

Description Art-No Alternative No.<br />

SilverCut-250 590000001000 80496<br />

Scope of delivery<br />

H<strong>and</strong> <strong>cutting</strong> torch<br />

Operation instructions<br />

Accessories<br />

Description Art-No Alternative No.<br />

Dual rollers guide 590000003000 80515<br />

Circle <strong>cutting</strong> bar d=100-900 mm 590000003001 80514<br />

49

MK-150<br />

MK-150<br />

Medium Pressure/Tip mixing type<br />

gas <strong>cutting</strong> torch MK-150<br />

The design of <strong>KOIKE</strong>'S MK-150 is rugged <strong>and</strong> simple. This<br />

also result in a fine balance that makes it very easy to use.<br />

And in line with Koike's policy of even greater safety, a<br />

three seat tip-mixing system has been employed. This is<br />

because the three seat tip-mixing system substantially<br />

reduces the risk of flashbacks occurring. And even if<br />

flashbacks occur, damage to the torch is reduced to the<br />

minimum. If you use <strong>KOIKE</strong> tips, you will have the benefit<br />

of an even greater safety margin, as <strong>KOIKE</strong> tips have a<br />

special design which makes it hard for any flashback to<br />

happen.<br />

50

Technical Specifications<br />

Cutting thickness<br />

Torch head angle 90°<br />

Torch length<br />

Weight<br />

Type of gas<br />

3-150 mm<br />

495 mm<br />

880g<br />

Acetylene, propane, natural gas <strong>and</strong> mapp<br />

gas<br />

Types<br />

Description Art-No Alternative No.<br />

MK-150 590000001001 80497<br />

Scope of delivery<br />

H<strong>and</strong> <strong>cutting</strong> torch<br />

Operation instructions<br />

Accessories<br />

Description Art-No Alternative No.<br />

Dual rollers guide 590000003000 80515<br />

Circle <strong>cutting</strong> bar d=100-900 mm 590000003001 80514<br />

51

MK-250<br />

MK-250<br />

H<strong>and</strong> <strong>cutting</strong> torch for gas mixing<br />

<strong>cutting</strong> nozzles<br />

The MK-250 is a h<strong>and</strong> <strong>cutting</strong> torch for gas mixing <strong>cutting</strong><br />

nozzles. This well balanced <strong>and</strong> safe h<strong>and</strong> torch utilizes a<br />

tube configuration for greater strength. The <strong>KOIKE</strong> gas<br />

mixing nozzles reduce flash backs <strong>and</strong> protect the <strong>cutting</strong><br />

torch from damages. By changing the <strong>cutting</strong> nozzles, the<br />

gas type can be changed (acetylene, propane, mapp gas<br />

or natural gas).<br />

n Well-balanced <strong>and</strong> robust<br />

n Gas mixing h<strong>and</strong> <strong>cutting</strong> torch<br />

n Gas guiding stainless steel pipes<br />

n Torch head in 90° <strong>and</strong> 75°<br />

52

Technical specifications<br />

Cutting range<br />

3-250 mm<br />

Torch head 75°/90°<br />

Total length<br />

Weight (kg)<br />

Type of gas<br />

525 mm (other lengths on request)<br />

1,5 kg<br />

Acetylene, propane, natural gas <strong>and</strong> mapp<br />

gas<br />

Types<br />

Description Art-No Alternative No.<br />

H<strong>and</strong> <strong>cutting</strong> torch MK250-90° 590000001002 80504<br />

H<strong>and</strong> <strong>cutting</strong> torch MK250-75° 590000001003 80503<br />

Scope of delivery<br />

H<strong>and</strong> <strong>cutting</strong> torch<br />

Operation instructions<br />

Accessories<br />

Description Art-No Alternative No.<br />

Dual rollers guide 590000003000 80515<br />

Circle <strong>cutting</strong> bar d=100-900 mm 590000003001 80514<br />

53

MK-300<br />

MK-300<br />

Robust h<strong>and</strong> <strong>cutting</strong> machine<br />

The MK-300 is a h<strong>and</strong> <strong>cutting</strong> torch for gas mixing <strong>cutting</strong><br />

nozzles. This well balanced <strong>and</strong> safe h<strong>and</strong> torch utilizes a<br />

tube configuration for greater strength. The <strong>KOIKE</strong> gas<br />

mixing nozzles reduce flash backs <strong>and</strong> protect the <strong>cutting</strong><br />

torch from damages. By changing the <strong>cutting</strong> nozzles, the<br />

gas type can be changed (acetylene, propane, mapp gas<br />

or natural gas).<br />

n Well-balanced <strong>and</strong> robust<br />

n Gas mixing h<strong>and</strong> <strong>cutting</strong> machine<br />

n Gas guiding pipes made of stainless steel<br />

n Torch head in 90° <strong>and</strong> 75°<br />

n Cutting capacity till 300 mm<br />

54

Technical specifications<br />

Cutting range<br />

3-300 mm<br />

Torch head 75°/90°<br />

Total length 661 mm ( other lengths on request )<br />

Weight (kg)<br />

Type of gas<br />

1,55 kg<br />

Acetylene, propane, natural gas <strong>and</strong> mapp<br />

gas<br />

Types<br />

Description Art-No Alternative No.<br />

H<strong>and</strong> <strong>cutting</strong> torch MK300-90° 590000001004 80508<br />

H<strong>and</strong> <strong>cutting</strong> torch MK300-75° 590000001005 80507<br />

Scope of delivery<br />

H<strong>and</strong> <strong>cutting</strong> torch<br />

Operation instructions<br />

Accessories<br />

Description Art-No Alternative No.<br />

Dual rollers guide 590000003000 80515<br />

Circle <strong>cutting</strong> bar d=100-900 mm 590000003001 80514<br />

55

Cutting nozzles<br />

Since its establishment in 1918, Koike has been committed<br />

to making full use of "gas energy” <strong>and</strong> by its dedicated efforts<br />

has become a voice of authority in machine tool circles <strong>and</strong> a<br />

prime mover in the advancement of this key industry. <strong>KOIKE</strong><br />

is a supplier of integrated total systems, from gases to related<br />

equipment, meeting the many <strong>and</strong> varied needs of its<br />

customers. The gases <strong>and</strong> gas-related equipment division<br />

manufactures <strong>and</strong> markets gases which are used in industry,<br />

medical treatment <strong>and</strong> daily life. Gas mixing <strong>cutting</strong> nozzles<br />

by <strong>KOIKE</strong> have an excellent reputation worldwide.<br />

The <strong>cutting</strong> nozzles can be applied with different <strong>cutting</strong> gases<br />

(acetylen, propan, mapp <strong>and</strong> natuaral gas) allowing to operate<br />

<strong>cutting</strong> machines <strong>and</strong> <strong>cutting</strong> equipment with different <strong>cutting</strong><br />

gases.<br />

n Straight <strong>and</strong> clean cut surface<br />

n Small kerf<br />

n No slagging<br />

n No partial melting of edges<br />

n High <strong>cutting</strong> speed<br />

n High operating safety<br />

n High service life<br />

n Low gas consumption<br />

57

Cutting nozzle 102 HC<br />

Gas mixing <strong>cutting</strong> nozzle<br />

Acetylene<br />

Des.<br />

Article<br />

no.<br />

Alternative<br />

No.<br />

Cutting<br />

range Cutting speed Pressure (bar) Consumption (m 3 /h)<br />

mm<br />

mm/min.<br />

Cutting<br />

O 2<br />

Heating<br />

O 2<br />

Acetylene<br />

Cutting<br />

O 2<br />

Kerf<br />

width<br />

Heating<br />

O 2 Acetylene mm<br />

00 590000005000 80011 0-5 660 1,5 1,5 0,2 0,69 0,41 0,37 1<br />

0 590000005001 80012 5-10 660-550 2 2 0,2 1,2 0,41 0,37 1,3-1,5<br />

1 590000005002 80013 10-15 550-490 2,5 2,5 0,2 2,1 0,48 0,43 1,7-1,8<br />

2 590000005003 80014 15-30 490-400 3 3 0,2 3,4 0,48 0,43 2,0-2,1<br />

3 590000005004 80015 30-40 400-350 3 3 0,2 4,3 0,48 0,43 2,3-2,4<br />

4 590000005005 80016 40-50 350-320 3,5 3,5 0,25 6,5 0,55 0,5 2,7-2,9<br />

5 590000005006 80017 50-100 320-200 4 4 0,3 11 0,69 0,63 3,4-3,5<br />

6 590000005007 80018 100-150 200-150 4 4 0,35 15 0,77 0,7 3,9-4,0<br />

7 590000005008 80019 150-250 150-80 4,5 4,5 0,4 22 1,06 0,96 4,4-5,1<br />

8 590000005009 80051 250-300 80-45 4,5 4,5 0,4 28 1,06 0,96 5,8-6,8<br />

Cutting nozzle 106 HC<br />

Gas mixing <strong>cutting</strong> nozzle<br />

Propane<br />

Des.<br />

Article<br />

no.<br />

Alternative<br />

No.<br />

Cutting<br />

range Cutting speed Pressure (bar) Consumption (m 3 /h)<br />

mm<br />

mm/min.<br />

Cutting<br />

O 2<br />

Heating<br />

O 2<br />

Propane<br />

Cutting<br />

O 2<br />

Kerf<br />

width<br />

Heating<br />

O 2 Propane mm<br />

00 590000005010 80041 0-5 660 1,5 1,5 0,2 0,69 1,18 0,31 1,2<br />

0 590000005011 80042 5-10 660-550 2 2 0,2 1,2 1,18 0,31 1,3-1,5<br />

1 590000005012 80043 10-15 550-490 2,5 2,5 0,2 2,1 1,18 0,31 1,7-1,8<br />

2 590000005013 80044 15-30 490-400 3 3 0,25 3,4 1,37 0,36 2,0-2,1<br />

3 590000005014 80045 30-40 400-350 3 3 0,25 4,3 1,37 0,36 2,3-2,4<br />

4 590000005015 80046 40-50 350-320 3,5 3,5 0,3 6,5 1,86 0,49 2,7-2,9<br />

5 590000005016 80047 50-100 320-200 4 4 0,3 11 1,86 0,49 3,4-3,5<br />

6 590000005017 80048 100-150 200-150 4 4 0,3 15 3,04 0,8 3,9-4,0<br />

7 590000005018 80049 150-250 150-80 4,5 4,5 0,4 22 3,72 0,98 4,4-5,1<br />

8 590000005019 80050 250-300 80-45 4,5 4,5 0,4 28 3,72 0,98 5,8-6,8<br />

58

Cutting nozzle 107 HC<br />

Gas mixing <strong>cutting</strong> nozzle<br />

Natural gas<br />

Des.<br />

Article<br />

no.<br />

Alternative<br />

No.<br />

Cutting<br />

range Cutting speed Pressure (bar) Consumption (m 3 /h)<br />

mm<br />

mm/min.<br />

Cutting<br />

O 2<br />

Heating<br />

O 2<br />

Natural<br />

gas<br />

Cutting<br />

O 2<br />

Heating<br />

O 2<br />

Natural<br />

gas<br />

00 590000005030 80061 0-5 660 1,5 1,5 0,15 0,69 1,22 0,74 1<br />

0 590000005031 80062 5-10 660-550 2 2 0,15 1,2 1,22 0,74 1,3-1,5<br />

1 590000005032 80063 10-15 550-490 2,5 2,5 0,15 2,1 1,22 0,74 1,7-1,8<br />

2 590000005033 80064 15-30 490-400 3 3 0,15 3,4 1,39 0,84 2,0-2,1<br />

3 590000005034 80065 30-40 400-350 3 3 0,15 4,3 1,39 0,84 2,3-2,4<br />

4 590000005035 80066 40-50 350-320 3,5 3,5 0,15 6,5 1,9 1,15 2,7-2,9<br />

5 590000005036 80067 50-100 320-200 4 4 0,15 11 1,9 1,15 3,4-3,5<br />

6 590000005037 80068 100-150 200-150 4 4 0,15 15 2,31 1,4 3,9-4,0<br />

7 590000005038 80069 150-250 150-80 4,5 4,5 0,15 22 2,31 1,4 4,4-5,1<br />

8 590000005039 80070 250-300 80-45 4,5 4,5 0,15 28 2,31 1,4 5,8-6,8<br />

Kerf<br />

width<br />

mm<br />

Cutting nozzle 402 ST<br />

St<strong>and</strong>ard <strong>cutting</strong> nozzle for IK-82 Series<br />

Acetylene<br />

Des.<br />

Article<br />

no.<br />

Alternative<br />

No.<br />

Cutting<br />

range Cutting speed Pressure (bar) Consumption (m 3 /h)<br />

mm<br />

mm/min.<br />

Cutting<br />

O 2<br />

Heating<br />

O 2<br />

Acetylene<br />

Cutting<br />

O 2<br />

Kerf<br />

width<br />

Heating<br />

O 2 Acetylene mm<br />

0 590000005040 80082 5-10 500-450 2 2 0,15 1,2 0,38 0,34 1,5<br />

1 590000005041 80083 10-15 450-400 2,5 2,5 0,15 2,1 0,485 0,44 1,8<br />

2 590000005042 80084 15-30 400-350 3 3 0,15 3,4 0,48 0,44 2,1<br />

3 590000005043 80085 30-40 350-300 3 3 0,15 4,3 0,55 0,5 2,4<br />

4 590000005044 80086 40-50 300-250 3,5 3,5 0,15 6,5 0,64 0,58 2,9<br />

5 590000005045 80087 50-100 250-200 4 4 0,15 11 0,73 0,66 3,5<br />

59

Cutting nozzle 406 NT<br />

St<strong>and</strong>ard <strong>cutting</strong> nozzle for IK-82 Series<br />

Propane<br />

Des.<br />

Article<br />

no.<br />

Alternative<br />

No.<br />

Cutting<br />

range Cutting speed Pressure (bar) Consumption (m 3 /h)<br />

mm<br />

mm/min.<br />

Cutting<br />

O 2<br />

Heating<br />

O 2<br />

Propane<br />

Cutting<br />

O 2<br />

Kerf<br />

width<br />

Heating<br />

O 2 Propane mm<br />

0 590000005050 80102 5-10 500-450 2 2 0,15 1,2 1,64 0,41 1,5<br />

1 590000005051 80103 10-15 450-400 2,5 2,5 0,15 2,1 1,64 0,41 1,8<br />

2 590000005052 80104 15-30 400-350 3 3 0,15 3,4 1,64 0,41 2,1<br />

3 590000005053 80105 30-40 350-300 3 3 0,15 4,3 1,64 0,41 2,4<br />

4 590000005054 80106 40-50 300-250 3,5 3,5 0,15 6,5 2,16 0,54 2,9<br />

5 590000005055 80107 50-100 250-200 4 4 0,15 11 2,16 0,54 3,5<br />

Cutting nozzle 102 Lug-Cut<br />

Gas mixing <strong>cutting</strong> nozzle for IK-05 Lug-Cut<br />

Acetylene<br />

Des.<br />

Article<br />

no.<br />

Alternative<br />

No.<br />

Cutting<br />

range Cutting speed Pressure (bar) Consumption (m 3 /h)<br />

Cutting Heating<br />

Cutting Heating<br />

mm mm/min. O 2 O 2 Acetylene O 2 O 2 Acetylene mm<br />

3 590000005070 DB91101F 30-40 400 3 3 0,2 4,3 0,48 0,43 2,4<br />

Kerf<br />

width<br />

60

Cutting nozzle 106 Lug-Cut<br />

Gas mixing <strong>cutting</strong> nozzle for IK-05 Lug-Cut<br />

Propane<br />

Des.<br />

Article<br />

no.<br />

Alternative<br />

No.<br />

Cutting<br />

range Cutting speed Pressure (bar) Consumption (m 3 /h)<br />

Cutting Heating<br />

Cutting Heating<br />

mm mm/min. O 2 O 2 Propane O 2 O 2 Propane mm<br />

3 590000005080 DB91401F 30-40 400 3 3 0,25 4,3 1,37 0,36 2,4<br />

Kerf<br />

width<br />

61

Cutting nozzle 102 D5<br />

Gas mixing machine <strong>cutting</strong> nozzle<br />

Acetylene<br />

Des.<br />

Article<br />

no.<br />

Alternative<br />

No.<br />

Cutting<br />

range Cutting speed Pressure bar Consumption (m 3 /h)<br />

mm<br />

mm/min.<br />

Cutting<br />

O 2<br />

Heating<br />

O 2<br />

Acetylene<br />

Cutting<br />

O 2<br />

Kerf<br />

width<br />

Heating<br />

O 2 Acetylene mm<br />

00 590000005090 80201 0-5 700 5 1,5 0,2 0,85 0,52 0,47 1,1<br />

0 590000005091 80202 5-10 700-625 5 2 0,2 1,6 0,52 0,47 1,2-1,4<br />

1 590000005092 80203 10-15 625-550 5 2,5 0,2 2,4 0,6 0,55 1,6-1,7<br />

2 590000005093 80204 15-30 550-475 5 3 0,2 3,6 0,6 0,55 1,9-2,0<br />

3 590000005094 80205 30-40 475-425 5 3 0,2 4,8 0,6 0,55 2,2-2,4<br />

4 590000005095 80206 40-50 425-350 5 3 0,2 5,6 0,75 0,68 2,5-2,7<br />

5 590000005096 80207 50-100 350-250 5 4 0,25 8,8 0,86 0,78 3,0-3,3<br />

6 590000005097 80208 100-150 250-175 5 4 0,3 13,5 0,95 0,86 3,6-4,2<br />

7 590000005098 80209 150-250 175-90 5 4,5 0,4 24 1,33 1,21 4,7-5,4<br />

8 590000005099 80210 250-300 90-60 5 4,5 0,4 31 1,6 1,45 5,5-6,4<br />

Cutting nozzle 102 D7<br />

Gas mixing machine <strong>cutting</strong> nozzle<br />

Acetylene<br />

Des.<br />

Article<br />

no.<br />

Alternative<br />

No.<br />

Cutting<br />

range Cutting speed Pressure (bar) Consumption (m 3 /h)<br />

mm<br />

mm/min.<br />

Cutting<br />

O 2<br />

Heating<br />

O 2<br />

Acetylene<br />

Cutting<br />

O 2<br />

Kerf<br />

width<br />

Heating<br />

O 2 Acetylene mm<br />

00 590000005100 80221 0-5 750 7 1,5 0,2 0,75 0,52 0,47 0,9<br />

0 590000005101 80222 5-10 750-680 7 2 0,2 1,1 0,52 0,47 1,0-1,2<br />

1 590000005102 80223 10-15 680-600 7 2,8 0,2 2,5 0,6 0,55 1,3-1,4<br />