a reliable wafer-level chip scale package (wlcsp) - AKRO Engineering

a reliable wafer-level chip scale package (wlcsp) - AKRO Engineering

a reliable wafer-level chip scale package (wlcsp) - AKRO Engineering

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

A RELIABLE WAFER-LEVEL CHIP SCALE<br />

PACKAGE (WLCSP) TECHNOLOGY<br />

Umesh Sharma, Ph.D., Philip Holland and Harry Gee<br />

California Micro Devices, Inc.<br />

Milpitas, CA, USA<br />

umeshs@cmd.com, philh@cmd.com, and harryg@cmd.com<br />

Metin Ozen, Ph.D. and Can Ozcan<br />

Ozen <strong>Engineering</strong>, Inc.<br />

Sunnyvale, CA, USA<br />

Metin@ozeninc.com and can@ozeninc.com<br />

ABSTRACT<br />

In conventional WLCSP process, after defining the under<br />

bump metal (UBM) layer, a solder ball is dropped in the<br />

UBM opening. A subsequent thermal reflow cycle melts the<br />

solder ball and cools it in a well defined shape on top of the<br />

UBM layer. One draw back of this technology is the fracture<br />

or cracking of passivation film that may occur during the<br />

solder ball reflow process. The cracks in the passivation<br />

expose the underlying semiconductor devices to the ambient<br />

environment. Such cracks result in long term reliability<br />

problems or complete failure depending on the extent of the<br />

exposure to harmful ambient.<br />

In this paper, we systematically analyze the problem of<br />

passivation cracking and present a WLCSP process that is<br />

resistant to cracking during solder flow and subsequent<br />

multiple reflow steps. ANSYS thermo-mechanical finite<br />

element modeling software is used to model the WLCSP<br />

structure and process flow to evaluate stress and<br />

deformation at various points across the device structure.<br />

Contour plots clearly highlight the high stress regions and<br />

pinpoint the potential failure region. The use of ANSYS<br />

software in optimizing process parameters, and predicting<br />

reliability is presented. The experimental results confirm<br />

our simulation results and we conclude by presenting an<br />

optimized process that is resistant to passivation cracking<br />

and resulting failures.<br />

Keywords: WLCSP, passivation cracks, re-passivation,<br />

ANSYS, simulations<br />

INTRODUCTION AND PROBLEM DESCRIPTION<br />

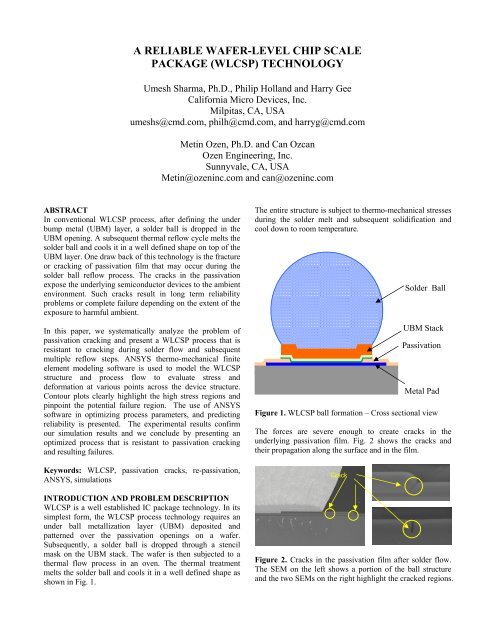

WLCSP is a well established IC <strong>package</strong> technology. In its<br />

simplest form, the WLCSP process technology requires an<br />

under ball metallization layer (UBM) deposited and<br />

patterned over the passivation openings on a <strong>wafer</strong>.<br />

Subsequently, a solder ball is dropped through a stencil<br />

mask on the UBM stack. The <strong>wafer</strong> is then subjected to a<br />

thermal flow process in an oven. The thermal treatment<br />

melts the solder ball and cools it in a well defined shape as<br />

shown in Fig. 1.<br />

The entire structure is subject to thermo-mechanical stresses<br />

during the solder melt and subsequent solidification and<br />

cool down to room temperature.<br />

Figure 1. WLCSP ball formation – Cross sectional view<br />

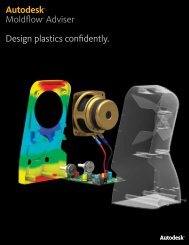

The forces are severe enough to create cracks in the<br />

underlying passivation film. Fig. 2 shows the cracks and<br />

their propagation along the surface and in the film.<br />

Crack<br />

Solder Ball<br />

UBM Stack<br />

Passivation<br />

Metal Pad<br />

Figure 2. Cracks in the passivation film after solder flow.<br />

The SEM on the left shows a portion of the ball structure<br />

and the two SEMs on the right highlight the cracked regions.

These cracks left in the passivation film expose the<br />

underlying structures to the harmful ambient environment. It<br />

is quite easy for moisture and other contaminants to<br />

penetrate the device structures through the cracks leading to<br />

circuit failure. Besides environmental damage, the primary<br />

catastrophic failure is caused when the IC is assembled on<br />

the PC board using conventional SMT techniques. Standard<br />

procedures for mounting the ICs on a PC board require<br />

application of a “flux” and then a thermal cycle to melt the<br />

solder. It is during the flux application process, we have<br />

seen the most damage done to the IC. Figure 3 clearly<br />

highlights this problem. The flux can easily migrate through<br />

the crack and attack the metal pad or the metal wiring.<br />

Typical chemicals used in the flux are strong enough to<br />

corrode the metal and etch away selected portions of metal<br />

lines as shown in the bottom SEM in Figure 3.<br />

crack formation. We combined theoretical simulations with<br />

experimental results on carefully designed daisy chain<br />

structures to develop the best WLCSP process. In the<br />

following paragraphs we describe our experimental methods<br />

and highlight our major findings.<br />

THEORETICAL ANALYSIS –ANSYS SIMULATIONS<br />

To aid design of experiments and develop a deeper<br />

understanding of the failure mechanism, we created a finite<br />

element model of a WLCSP ball structure. Figure 4 shows a<br />

unit cell of the WLCSP structure. Finite Element Model is<br />

generated using APDL(Ansys Parametric Design Language)<br />

parametrically such that the dimensions, material properties,<br />

and loading conditions can be changed for subsequent<br />

simulations. Periodic boundary conditions are applied on the<br />

finite element model boundaries to model physics with the<br />

representative model. Material models are assumed to be<br />

linear elastic and isotropic for this analysis. Material<br />

properties used in the model are taken from the available<br />

sources in the web[1],[2]. The material names, and<br />

properties are presented in Table 1. Deposition process of<br />

different layers are carried out using the EKILL and<br />

EALIVE commands in Ansys which allow turning-off and<br />

turning-on of the active elements during simulations. This<br />

capability allows the deposition modeling of different<br />

materials at different temperatures. Reference temperature is<br />

taken as 25°C for the model, but the materials are activated<br />

at the elevated deposition temperatures such that the stress<br />

free state is achieved at the time of deposition.<br />

Figure 3. The flux used during PCB mounting of the IC,<br />

flows through the cracks (top) and etches away the<br />

Aluminum pad (bottom).<br />

Figure 4. Finite Element Model of a 0.5mm pitch WLCSP<br />

structure. Periodic boundary conditions are assumed.<br />

The location, density, and size of the cracks in the<br />

passivation film are dependent on several critical parameters.<br />

The solder reflow temperature, the composition of the UBM<br />

material, composition of the passivation films, the vertical<br />

and horizontal geometries of the ball structure, etc., are<br />

some of the parameters that affect passivation cracking.<br />

In this work we embarked upon understanding the<br />

relationship between all of the above factors and the<br />

composite thermo-mechanical stress produced in the<br />

passivation film during solder reflow. The goal was to arrive<br />

at an optimum WLCSP process that would be resistant to<br />

Table I. Mechanical and thermal properties of the materials<br />

used in the WLCSP structure model.

The finite element analysis simulates the thermal cycle<br />

during the entire process. The most relevant information is<br />

the 1 st principal stress before and after the solder flow<br />

thermal cycle. Both the magnitude and location of the stress<br />

vectors are important. In the next few paragraphs, we<br />

present path plots in the passivation layer, around the edge<br />

to extract stresses along this critical path and compare<br />

results for various simulation conditions. The top view of<br />

the path location for the WLCSP structure is shown in<br />

Figure 5.<br />

For all thickness values, the maximum stress values are<br />

around the region where the circular metal pad connects to<br />

the metal interconnects. For thinner nitride films, the stress<br />

is highly non-uniform ranging from very high values near<br />

the interconnect regions versus very low values further<br />

away. As the thickness increases, the average stress rises<br />

throughout the film but the peak stress actually reduces.<br />

This is an important finding as it suggests a possibility of<br />

optimizing the stress <strong>level</strong> in the passivation film by<br />

choosing the right thickness.<br />

X<br />

Y<br />

<br />

Figure 5. Top view of the WLCSP structure. The dashed<br />

line shows the path of 1 st principal stress near the edge of<br />

the passivation layer.<br />

Simulations were performed in several batches, varying one<br />

process parameter at a time and evaluating the impact of the<br />

variation on the final stress. An example of such a<br />

simulation is the study of the effect of gradually increasing<br />

the nitride passivation thickness. The nitride thickness was<br />

varied from 8KÅ to 20KÅ in steps of 2KÅ. The results of<br />

the principal stress calculations are plotted in Fig. 6.<br />

Figure 7. Principal stress along the cracking path. As the<br />

path location (a) is varied, the stress increases or decreases<br />

depending on the location. Peak stress is observed at the<br />

pad connection to the metal lines. Average stress rises with<br />

film thickness but peak stress reduces with increasing<br />

thickness.<br />

We ran several simulations and were able to predict both<br />

qualitative and quantitative stress <strong>level</strong>s in the passivation<br />

film after completion of the WLCSP process. Results from<br />

key simulation runs are presented below in Figures. 8-11.<br />

Figure 8. Principal stress along the cracking path. In this<br />

experiment a dual dielectric passivation film (oxide +<br />

nitride) was chosen. The figure compares 4 different cases:<br />

1) original 12KÅ nitride, 2) Case-1 6K oxide + 6K nitride,<br />

3) Case-2 8KÅ oxide + 6KÅ nitride, and 4) Case-3 12KÅ<br />

oxide + 6KÅ nitride. Clearly, both peak and average stress<br />

values can be reduced by using a dual dielectric film of<br />

oxide + nitride instead of the nitride film alone.<br />

Figure 6. The stress in the passivation film is shown as a<br />

function of the nitride thickness. The stress value increases<br />

in the color coded charts from blue to red.

under the nitride, adding a polyimide layer on top of<br />

passivation or by carefully tailoring the design rules.<br />

Based on these findings and our anticipation that reduced<br />

cumulative stress would lead to less fatigue and eventually<br />

fewer cracks in the passivation film, we narrowed down our<br />

experimental matrix to just a few parameters. In the<br />

following section we discuss the experimental procedure<br />

and the results of various experiments.<br />

Figure 9. Principal stress along the cracking path. In this<br />

simulation run comparison is made between two WLCSP<br />

processes (0.4mm ball pitch vs. 0.5mm ball pitch). We<br />

observe higher peak stress for the 0.4mm ball pitch case.<br />

This suggests different optimizations for these two<br />

processes.<br />

EXPERIMENTAL PROCEDURES AND RESULTS<br />

Experimental Procedures<br />

To facilitate detailed study of this phenomenon and simply<br />

the analysis, we designed a 5x5 daisy chain with 5 rows and<br />

5 columns of I/Os linked with metal as shown in Figure 12.<br />

After WLCSP processing, the daisy chains were mounted<br />

on a FR-4 board designed to complete the electrical<br />

continuity between the two ends of the chain. Resistance<br />

was measured after mounting the parts on the board. A<br />

crack in the passivation layer would lead to flux going<br />

through the crack and attacking the metal lines underneath.<br />

Failed parts would typical register an “OPEN” or “High<br />

Resistance”.<br />

Figure 10. Principal stress along the cracking path. In this<br />

simulation run, the UBM opening and the metal pad<br />

diameter are varied to study the dependence on layout rules.<br />

Comparing 3 different cases: 1) Original UBM opening =<br />

240um + Pad size = 260um, 2) Case-1 UBM = 240um +<br />

Pad size = 290um, 3) Case-2 UBM = 210um + Pad size =<br />

260um. Peak stress is lower for Case-1 and Case-2.<br />

Figure 12. Daisy chain layout<br />

Figure 11. Principal stress along the cracking path. In this<br />

simulation, addition of a polyimide coat over the passivation<br />

layer is investigated. Stress can be reduced significantly by<br />

adding the polyimide layer. Three cases are considered: 1)<br />

original – no polyimide, 2) Case-1 10um of polyimide, and<br />

3) Case-2 3um of polyimide.<br />

The simulation results above point to a complex relationship<br />

between the passivation film stress and various process and<br />

layout parameters. In general, stress can be reduced by<br />

increasing the nitride thickness, adding a pad oxide layer<br />

In a typical 2-sided FR4 board mounting process the IC is<br />

subjected to 2 solder reflows. We also subjected a few parts<br />

to additional 3X reflows with the same temperature profile<br />

as the standard lead free WLCSP mount process. Daisy<br />

chains were visually examined before and after reflows for<br />

any signs of passivation cracks. Daisy chains were also<br />

electrically measured before and after reflows to examine<br />

metal continuity.<br />

Process Experiments<br />

Wafers were split into several groups. Main process<br />

experiments can be summarized as follows:<br />

1) Nitride thickness variation – 6KÅ, 9KÅ, 12KÅ,<br />

15KÅ, 18KÅ<br />

2) Nitride vs. Oxynitride – 12KÅ

3) Oxide + Nitride dual dielectric (6KÅ/6KÅ,<br />

6KÅ/12KÅ, 12KÅ/6KÅ)<br />

4) Deposition Tool A vs. Deposition Tool B (12KÅ<br />

nitride, 6KÅ oxide + 12KÅ nitride)<br />

5) No polyimide vs. Polyimide (10um)<br />

The primary goal of these experiments was to design a<br />

WLCSP vertical structure that is free of cracks in the<br />

passivation immediately after processing and can withstand<br />

3X thermal reflow cycles. After WLCSP processing, one<br />

<strong>wafer</strong> from every group was used for visual examination<br />

under a high power microscope. The solder balls were<br />

chemically removed from the <strong>wafer</strong> to allow observations of<br />

cracks in the passivation underneath the balls. Rest of the<br />

<strong>wafer</strong>s were diced and the individual ICs were mounted on<br />

the FR-4 board. The devices were then subjected to 3X<br />

reflows using the same temperature profile as the SMT<br />

assembly process. Daisy chains were electrically measured<br />

after completion of the 3X reflow.<br />

EXPERIMENTAL RESULTS<br />

Results after 3X reflow cycle provide the most dramatic<br />

contrast among various <strong>wafer</strong> groups. These results are<br />

summarized in Table 2.<br />

No. Passivation<br />

% Failed Pads<br />

After 3X Reflow<br />

1 6KÅ SiN 98.00%<br />

2 6 KÅ SiO2 + 6 KÅ SiN 39.60%<br />

3 12 KÅ SiO2 + 6 KÅ SiN 59.33%<br />

4 9 KÅ SiN 5.60%<br />

5 12k SiN 0.24%<br />

6 6 KÅ SiO2 + 12 KÅ SiN 0.02%<br />

7 15 KÅ SiN 8.80%<br />

8 18 KÅ SiN 0.22%<br />

9 12 KÅ SiON 96.40%<br />

10 6 KÅ SiO2 + 12 KÅ SiON 10.00%<br />

11 12 KÅ SiN(Deposition tool B) 0.02%<br />

12 6 KÅ SiO2+12 KÅ SiN 0%<br />

(Deposition Tool B )<br />

13 12 KÅ SiN + 10um Polyimide 0%<br />

14 6 KÅ SiO2+12 KÅ SiN + 0%<br />

10um Polyimide<br />

Table 2. Summary of experimental results<br />

Upon examining the table carefully we can draw the<br />

following conclusions:<br />

A) SiN passivation thickness: Examining <strong>wafer</strong><br />

groups 1, 4, 5, and 8, we can see a definite<br />

correlation with nitride thickness as predicted by<br />

the simulations. From Figure7, we observe a<br />

reduction in the peak stress with increasing nitride<br />

thickness. The experimental results are consistent<br />

with this observation. For 6KÅ nitride film, the<br />

failure rate is as high as 98% but for 18KÅ nitride<br />

film, the failure rate drops to 0.22%.<br />

B) Comparing SiN passivation with Oxynitride<br />

passivation: Group 5 and Group 9 comparison<br />

shows that a single oxynitride film is worse than<br />

the nitride film of same thickness.<br />

C) Dual Dielectric passivation film (SiO2 + SiN): A<br />

comparison of groups 2 and 3 shows that both<br />

groups have high failure rate. Thus, increasing the<br />

oxide thickness does not prevent cracking. But,<br />

comparing 2 and 3 with group 6 suggests the<br />

dramatic improvement in performance obtained by<br />

increasing the nitride film in the stack to 12KÅ.<br />

The failure rate for group 6 is only 0.02%. Using<br />

Oxynitride as the second film instead of nitride<br />

makes matters worse. The failure rate for group 10<br />

increases to 10%.<br />

D) Effect of nitride deposition tool: Experimental<br />

data show that Deposition Tool B is marginally<br />

better than Deposition Tool A as evidenced by<br />

comparing Group 5 and Group 12. This result is<br />

due to minor differences in deposition conditions<br />

such as gas flow, pressure, and chamber design.<br />

E) The Optimal results: From the table it is clear that<br />

the best results are for the case when the<br />

passivation film is a composite insulator consisting<br />

of 6KÅ SiO2 + 12KÅ SiN. The failure rate is zero<br />

(within statistical limits) for this combination,<br />

especially if the nitride is deposited using<br />

Deposition Tool B.<br />

We also investigated the effect of a 10um thick polyimide<br />

layer deposited on top of the passivation layer. This process<br />

is known in the industry as “Re-passivation WLCSP”<br />

process. Schematically, the resulting vertical ball structure is<br />

shown in Figure 13.<br />

Solder<br />

UBM<br />

Polyimide<br />

Passivation<br />

Metal<br />

Figure 13. “Re-passivation WLCSP” ball formation –<br />

Cross sectional view. A thick polyimide layer is added on<br />

top of the passivation film before ball drop.<br />

Addition of the thick polyimide layer completely prevents<br />

any failures due to thermo-mechanical stresses during<br />

processing or PC board assembly. Because polyimide has a<br />

higher coefficient of thermal expansion (52ppm/K) and

much lower Young’s modulus than either oxide or nitride<br />

films with a CTE of (0.75 – 2.8ppm/K) and Young’s<br />

modulus (68 – 290 GPa) (see Table 1), it provides larger<br />

elongation and therefore a “cushioning effect” during<br />

WLCSP process or subsequent reflow steps. Even if the<br />

passivation underneath cracks due to thermal fatigue, the<br />

polyimide film covers up all the cracks and seals all the<br />

cracks. In this manner, the corrosive flux or any other<br />

harmful ambient element are unable to enter the cracks and<br />

cause damage. The SEM shown in Figure 14, illustrates this<br />

result.<br />

Figure 14. Addition of a thick polyimide layer (top row) to<br />

prevent flux migration.<br />

CONCLUSIONS<br />

In this paper we discussed a commonly observed problem<br />

for all WLCSP products. Various compressive and tensile<br />

forces present during solder flow and subsequent cooling<br />

cycle cause cracks in the passivation film. These cracks<br />

expose the underlying circuitry to harmful ambient<br />

chemicals and volatile compounds during assembly process<br />

and can cause circuit failure.<br />

The best method of preventing assembly failures due to<br />

these cracks is to add a thick layer of polyimide on top of<br />

the passivation film. However, the polyimide layer increases<br />

the manufacturing cost. A second approach requires<br />

optimization of the composition, thickness, and deposition<br />

conditions of the passivation film. Passivation cracks can be<br />

minimized or completely eliminated by using a dual<br />

dielectric layer passivation consisting of oxide and nitride<br />

films. The best results are obtained by using a 6KÅ thick<br />

oxide layer followed by a 12KÅ thick nitride layer.<br />

ACKNOWLEDGEMENTS<br />

The authors would like to thank Sanyo Semiconductor, Inc. ,<br />

and JCAP, Inc., who were involved in supporting this study.<br />

The authors would also like to acknowledge the support of<br />

CMD management in this study, in particular Manny Mere<br />

and Bob Dickinson.<br />

REFERENCES<br />

[1] www.matweb.com.<br />

[2]http://www.flip<strong>chip</strong>.com/get_started/FCI_bump_design_<br />

guide.pdf

![Moldflow Adviser Giriş Eğitimi Broşürü [2 gün] - AKRO Engineering](https://img.yumpu.com/3939177/1/190x245/moldflow-adviser-giris-egitimi-brosuru-2-gun-akro-engineering.jpg?quality=85)