Justi_Resin_Cement_L.. - American Tooth Industries

Justi_Resin_Cement_L.. - American Tooth Industries

Justi_Resin_Cement_L.. - American Tooth Industries

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

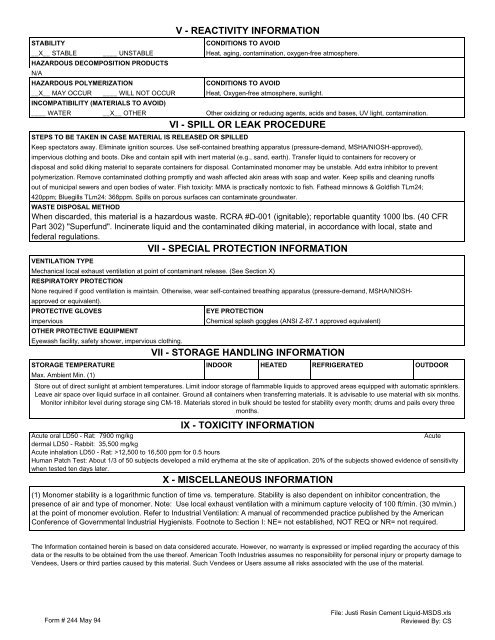

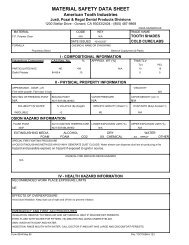

STABILITY<br />

__X__ STABLE ____ UNSTABLE<br />

HAZARDOUS DECOMPOSITION PRODUCTS<br />

N/A<br />

HAZARDOUS POLYMERIZATION<br />

__X__ MAY OCCUR ____ WILL NOT OCCUR<br />

INCOMPATIBILITY (MATERIALS TO AVOID)<br />

____ WATER __X__ OTHER<br />

V - REACTIVITY INFORMATION<br />

CONDITIONS TO AVOID<br />

Heat, aging, contamination, oxygen-free atmosphere.<br />

CONDITIONS TO AVOID<br />

Heat, Oxygen-free atmosphere, sunlight.<br />

Other oxidizing or reducing agents, acids and bases, UV light, contamination.<br />

VI - SPILL OR LEAK PROCEDURE<br />

STEPS TO BE TAKEN IN CASE MATERIAL IS RELEASED OR SPILLED<br />

Keep spectators away. Eliminate ignition sources. Use self-contained breathing apparatus (pressure-demand, MSHA/NIOSH-approved),<br />

impervious clothing and boots. Dike and contain spill with inert material (e.g., sand, earth). Transfer liquid to containers for recovery or<br />

disposal and solid diking material to separate containers for disposal. Contaminated monomer may be unstable. Add extra inhibitor to prevent<br />

polymerization. Remove contaminated clothing promptly and wash affected akin areas with soap and water. Keep spills and cleaning runoffs<br />

out of municipal sewers and open bodies of water. Fish toxicity: MMA is practically nontoxic to fish. Fathead minnows & Goldfish TLm24;<br />

420ppm; Bluegills TLm24: 368ppm. Spills on porous surfaces can contaminate groundwater.<br />

WASTE DISPOSAL METHOD<br />

When discarded, this material is a hazardous waste. RCRA #D-001 (ignitable); reportable quantity 1000 lbs. (40 CFR<br />

Part 302) "Superfund". Incinerate liquid and the contaminated diking material, in accordance with local, state and<br />

federal regulations.<br />

VII - SPECIAL PROTECTION INFORMATION<br />

VENTILATION TYPE<br />

Mechanical local exhaust ventilation at point of contaminant release. (See Section X)<br />

RESPIRATORY PROTECTION<br />

None required if good ventilation is maintain. Otherwise, wear self-contained breathing apparatus (pressure-demand, MSHA/NIOSHapproved<br />

or equivalent).<br />

PROTECTIVE GLOVES<br />

EYE PROTECTION<br />

impervious<br />

Chemical splash goggles (ANSI Z-87.1 approved equivalent)<br />

OTHER PROTECTIVE EQUIPMENT<br />

Eyewash facility, safety shower, impervious clothing.<br />

VII - STORAGE HANDLING INFORMATION<br />

STORAGE TEMPERATURE INDOOR HEATED REFRIGERATED OUTDOOR<br />

Max. Ambient Min. (1)<br />

Store out of direct sunlight at ambient temperatures. Limit indoor storage of flammable liquids to approved areas equipped with automatic sprinklers.<br />

Leave air space over liquid surface in all container. Ground all containers when transferring materials. It is advisable to use material with six months.<br />

Monitor inhibitor level during storage sing CM-18. Materials stored in bulk should be tested for stability every month; drums and pails every three<br />

months.<br />

IX - TOXICITY INFORMATION<br />

Acute oral LD50 - Rat: 7900 mg/kg<br />

Acute<br />

dermal LD50 - Rabbit: 35,500 mg/kg<br />

Acute inhalation LD50 - Rat: >12,500 to 16,500 ppm for 0.5 hours<br />

Human Patch Test: About 1/3 of 50 subjects developed a mild erythema at the site of application. 20% of the subjects showed evidence of sensitivity<br />

when tested ten days later.<br />

X - MISCELLANEOUS INFORMATION<br />

(1) Monomer stability is a logarithmic function of time vs. temperature. Stability is also dependent on inhibitor concentration, the<br />

presence of air and type of monomer. Note: Use local exhaust ventilation with a minimum capture velocity of 100 ft/min. (30 m/min.)<br />

at the point of monomer evolution. Refer to Industrial Ventilation: A manual of recommended practice published by the <strong>American</strong><br />

Conference of Governmental Industrial Hygienists. Footnote to Section I: NE= not established, NOT REQ or NR= not required.<br />

The Information contained herein is based on data considered accurate. However, no warranty is expressed or implied regarding the accuracy of this<br />

data or the results to be obtained from the use thereof. <strong>American</strong> <strong>Tooth</strong> <strong>Industries</strong> assumes no responsibility for personal injury or property damage to<br />

Vendees, Users or third parties caused by this material. Such Vendees or Users assume all risks associated with the use of the material.<br />

Form # 244 May 94<br />

File: <strong>Justi</strong> <strong>Resin</strong> <strong>Cement</strong> Liquid-MSDS.xls<br />

Reviewed By: CS