Pozzi_Ortho_Resin_Li.. - American Tooth Industries

Pozzi_Ortho_Resin_Li.. - American Tooth Industries

Pozzi_Ortho_Resin_Li.. - American Tooth Industries

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

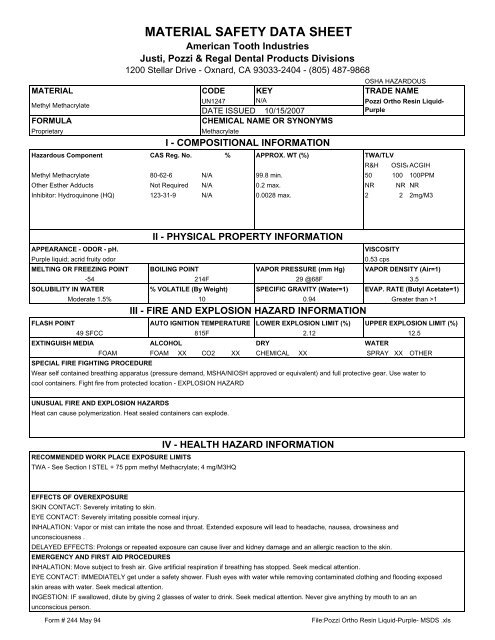

MATERIAL SAFETY DATA SHEET<br />

<strong>American</strong> <strong>Tooth</strong> <strong>Industries</strong><br />

Justi, <strong>Pozzi</strong> & Regal Dental Products Divisions<br />

1200 Stellar Drive - Oxnard, CA 93033-2404 - (805) 487-9868<br />

OSHA HAZARDOUS<br />

MATERIAL CODE KEY TRADE NAME<br />

Methyl Methacrylate<br />

UN1247 N/A<br />

<strong>Pozzi</strong> <strong>Ortho</strong> <strong>Resin</strong> <strong>Li</strong>quid-<br />

DATE ISSUED 10/15/2007<br />

Purple<br />

FORMULA<br />

CHEMICAL NAME OR SYNONYMS<br />

Proprietary<br />

Methacrylate<br />

I - COMPOSITIONAL INFORMATION<br />

Hazardous Component CAS Reg. No. % APPROX. WT (%)<br />

TWA/TLV<br />

R&H OSISAACGIH<br />

Methyl Methacrylate 80-62-6 N/A 99.8 min. 50 100 100PPM<br />

Other Esther Adducts Not Required N/A 0.2 max. NR NR NR<br />

Inhibitor: Hydroquinone (HQ) 123-31-9 N/A 0.0028 max. 2 2 2mg/M3<br />

II - PHYSICAL PROPERTY INFORMATION<br />

APPEARANCE - ODOR - pH.<br />

VISCOSITY<br />

Purple liquid; acrid fruity odor<br />

0.53 cps<br />

MELTING OR FREEZING POINT BOILING POINT VAPOR PRESSURE (mm Hg) VAPOR DENSITY (Air=1)<br />

-54 214F<br />

29 @68F 3.5<br />

SOLUBILITY IN WATER % VOLATILE (By Weight) SPECIFIC GRAVITY (Water=1) EVAP. RATE (Butyl Acetate=1)<br />

Moderate 1.5% 10 0.94 Greater than >1<br />

III - FIRE AND EXPLOSION HAZARD INFORMATION<br />

FLASH POINT AUTO IGNITION TEMPERATURE LOWER EXPLOSION LIMIT (%) UPPER EXPLOSION LIMIT (%)<br />

49 SFCC 815F 2.12 12.5<br />

EXTINGUISH MEDIA ALCOHOL DRY WATER<br />

FOAM FOAM XX CO2 XX CHEMICAL XX SPRAY XX OTHER<br />

SPECIAL FIRE FIGHTING PROCEDURE<br />

Wear self contained breathing apparatus (pressure demand, MSHA/NIOSH approved or equivalent) and full protective gear. Use water to<br />

cool containers. Fight fire from protected location - EXPLOSION HAZARD<br />

UNUSUAL FIRE AND EXPLOSION HAZARDS<br />

Heat can cause polymerization. Heat sealed containers can explode.<br />

RECOMMENDED WORK PLACE EXPOSURE LIMITS<br />

TWA - See Section I STEL + 75 ppm methyl Methacrylate; 4 mg/M3HQ<br />

IV - HEALTH HAZARD INFORMATION<br />

EFFECTS OF OVEREXPOSURE<br />

SKIN CONTACT: Severely irritating to skin.<br />

EYE CONTACT: Severely irritating possible corneal injury.<br />

INHALATION: Vapor or mist can irritate the nose and throat. Extended exposure will lead to headache, nausea, drowsiness and<br />

unconsciousness .<br />

DELAYED EFFECTS: Prolongs or repeated exposure can cause liver and kidney damage and an allergic reaction to the skin.<br />

EMERGENCY AND FIRST AID PROCEDURES<br />

INHALATION: Move subject to fresh air. Give artificial respiration if breathing has stopped. Seek medical attention.<br />

EYE CONTACT: IMMEDIATELY get under a safety shower. Flush eyes with water while removing contaminated clothing and flooding exposed<br />

skin areas with water. Seek medical attention.<br />

INGESTION: IF swallowed, dilute by giving 2 glasses of water to drink. Seek medical attention. Never give anything by mouth to an an<br />

unconscious person.<br />

Form # 244 May 94<br />

File:<strong>Pozzi</strong> <strong>Ortho</strong> <strong>Resin</strong> <strong>Li</strong>quid-Purple- MSDS .xls

V - REACTIVITY INFORMATION<br />

STABILITY<br />

CONDITIONS TO AVOID<br />

__X__ STABLE ____ UNSTABLE<br />

Heat, Aging, Contamination, Oxygen-Free atmosphere<br />

HAZARDOUS DECOMPOSITION PRODUCTS<br />

N/A<br />

HAZARDOUS POLYMERIZATION<br />

CONDITIONS TO AVOID<br />

__X__ MAY OCCUR ____ WILL NOT OCCUR Heat, Oxygen-Free atmosphere and sunlight<br />

INCOMPATIBILITY (MATERIALS TO AVOID)<br />

____ WATER __XX__ OTHER<br />

Other Oxidizing or reducing agents, acids and bases, UV light, contamination<br />

VI - SPILL OR LEAK PROCEDURE<br />

STEPS TO BE TAKEN IN CASE MATERIAL IS RELEASED OR SPILLED<br />

Keep spectators away. Eliminate ignition sources. Use self-contained breathing apparatus (pressure- demand, MSHA/NIOSH approved),<br />

impervious clothing and boots. Dike and contain spill with inert material (e.g. sand, earth). Transfer liquid to containers for recovery or disposal<br />

and solid diking material to separate containers for disposal. Contaminated monomer may be unstable. Add extra inhibitor to prevent<br />

polymerization. Remove contaminated clothing promptly and wash affected skin areas with soap and water. Keep spills and cleaning runoffs<br />

out of municipal sewers and open bodies of water. Spills on porous surfaces can contaminate groundwater.<br />

WASTE DISPOSAL METHOD<br />

When discarded, this material is a hazardous waste. RCRA #D-001 (ignitable); reportable quantity 1000 lbs. (40 CFR<br />

Part 302) "Superfund". Incinerate liquid and the contaminated diking material, in accordance with state and federal<br />

regulations.<br />

VII - SPECIAL PROTECTION INFORMATION<br />

VENTILATION TYPE<br />

MECHANICAL local exhaust ventilation at point of contaminant release. (See Section X)<br />

RESPIRATORY PROTECTION<br />

None required if good ventilation is maintained. Otherwise, wear self-contained breathing apparatus (pressure demand, MSHA/NIOSH<br />

approved or equivalent).<br />

PROTECTIVE GLOVES<br />

EYE PROTECTION<br />

Impervious<br />

Chemical splash goggles (AVSI Z-87.1 or approved equivalent)<br />

OTHER PROTECTIVE EQUIPMENT<br />

Eye wash facility, safety shower, imperious clothing.<br />

VII - STORAGE HANDLING INFORMATION<br />

STORAGE TEMPERATURE INDOOR HEATED REFRIGERATED OUTDOOR<br />

MAX. Ambient Min. (1)<br />

Store out of direct sunlight at ambient temperatures. <strong>Li</strong>mit indoor storage of flammable liquids to approved areas equipped with automatic sprinklers.<br />

Leave air space over liquid surface in all containers. Found all containers when transferring material. It is advisable to use material with in six months.<br />

Monitor inhibitor level during storage using CM-18. Materials stored in bulk should be tested for stability every month; drums and pails every three<br />

months.<br />

IX - TOXICITY INFORMATION<br />

Acute oral LD50 - Rat: 7900 mg/kg Acute dermal LD50 - Rabbit: 35,500 mg/kg Acute inhalation LD50 - Rat:> 12,500<br />

to 16, 500 ppm for 0.5 hours Human Patch Test: About 1/3 of 50 subjects developed a mild erythema at the site of<br />

application. 20% of subjects showed evidence of sensitivity when tested 10 test later.<br />

X - MISCELLANEOUS INFORMATION<br />

(1) Monomer stability is a logarithmic function of time vs. temperature. Stability is also dependent on inhibitor<br />

concentraion, the presence of air and type of monomer. NOTE: use local exhaust ventilation with a minimum capture<br />

velocity of 100ft/min. (30 m/min.) at the point of monomer evolution. FOOTNOTE TO SECTION I: NE = not established,<br />

NOT REQ or NR = not required.<br />

The Information contained herein is based on data considered accurate. However, no warranty is expressed or implied regarding the accuracy of this<br />

data or the results to be obtained from the use thereof. <strong>American</strong> <strong>Tooth</strong> <strong>Industries</strong> assumes no responsibility for personal injury or property damage to<br />

Vendees, Users or third parties caused by this material. Such Vendees or Users assume all risks associated with the use of the material.<br />

Form # 244 May 94<br />

File:<strong>Pozzi</strong> <strong>Ortho</strong> <strong>Resin</strong> <strong>Li</strong>quid-Purple- MSDS .xls