You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

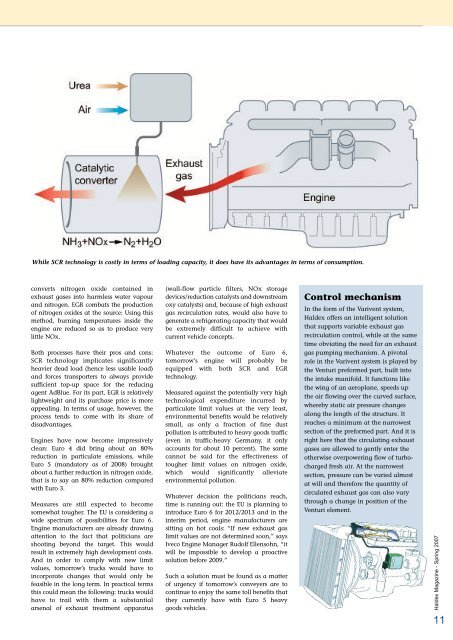

While SCR technology is costly in terms of loading capacity, it does have its advantages in terms of consumption.<br />

converts nitrogen oxide contained in<br />

exhaust gases into harmless water vapour<br />

and nitrogen. EGR combats the production<br />

of nitrogen oxides at the source: Using this<br />

method, burning temperatures inside the<br />

engine are reduced so as to produce very<br />

little NOx.<br />

Both processes have their pros and cons:<br />

SCR technology implicates significantly<br />

heavier dead load (hence less usable load)<br />

and forces transporters to always provide<br />

sufficient top-up space for the reducing<br />

agent AdBlue. For its part, EGR is relatively<br />

lightweight and its purchase price is more<br />

appealing. In terms of usage, however, the<br />

process tends to come with its share of<br />

disadvantages.<br />

Engines have now become impressively<br />

clean: Euro 4 did bring about an 80%<br />

reduction in particulate emissions, while<br />

Euro 5 (mandatory as of 2008) brought<br />

about a further reduction in nitrogen oxide,<br />

that is to say an 80% reduction compared<br />

with Euro 3.<br />

Measures are still expected to become<br />

somewhat tougher. The EU is considering a<br />

wide spectrum of possibilities for Euro 6.<br />

Engine manufacturers are already drawing<br />

attention to the fact that politicians are<br />

shooting beyond the target. This would<br />

result in extremely high development costs.<br />

And in order to comply with new limit<br />

values, tomorrow’s trucks would have to<br />

incorporate changes that would only be<br />

feasible in the long term. In practical terms<br />

this could mean the following: trucks would<br />

have to trail with them a substantial<br />

arsenal of exhaust treatment apparatus<br />

(wall-flow particle filters, NOx storage<br />

devices/reduction catalysts and downstream<br />

oxy catalysts) and, because of high exhaust<br />

gas recirculation rates, would also have to<br />

generate a refrigerating capacity that would<br />

be extremely difficult to achieve with<br />

current vehicle concepts.<br />

Whatever the outcome of Euro 6,<br />

tomorrow’s engine will probably be<br />

equipped with both SCR and EGR<br />

technology.<br />

Measured against the potentially very high<br />

technological expenditure incurred by<br />

particulate limit values at the very least,<br />

environmental benefits would be relatively<br />

small, as only a fraction of fine dust<br />

pollution is attributed to heavy goods traffic<br />

(even in traffic-heavy Germany, it only<br />

accounts for about 10 percent). The same<br />

cannot be said for the effectiveness of<br />

tougher limit values on nitrogen oxide,<br />

which would significantly alleviate<br />

environmental pollution.<br />

Whatever decision the politicians reach,<br />

time is running out: the EU is planning to<br />

introduce Euro 6 for 2012/2013 and in the<br />

interim period, engine manufacturers are<br />

sitting on hot coals: “If new exhaust gas<br />

limit values are not determined soon,” says<br />

Iveco Engine Manager Rudolf Ellensohn, “it<br />

will be impossible to develop a proactive<br />

solution before 2009.”<br />

Such a solution must be found as a matter<br />

of urgency if tomorrow’s conveyers are to<br />

continue to enjoy the same toll benefits that<br />

they currently have with Euro 5 heavy<br />

goods vehicles.<br />

Control mechanism<br />

In the form of the Varivent system,<br />

<strong>Haldex</strong> offers an intelligent solution<br />

that supports variable exhaust gas<br />

recirculation control, while at the same<br />

time obviating the need for an exhaust<br />

gas pumping mechanism. A pivotal<br />

role in the Varivent system is played by<br />

the Venturi preformed part, built into<br />

the intake manifold. It functions like<br />

the wing of an aeroplane, speeds up<br />

the air flowing over the curved surface,<br />

whereby static air pressure changes<br />

along the length of the structure. It<br />

reaches a minimum at the narrowest<br />

section of the preformed part. And it is<br />

right here that the circulating exhaust<br />

gases are allowed to gently enter the<br />

otherwise overpowering flow of turbocharged<br />

fresh air. At the narrowest<br />

section, pressure can be varied almost<br />

at will and therefore the quantity of<br />

circulated exhaust gas can also vary<br />

through a change in position of the<br />

Venturi element.<br />

<strong>Haldex</strong> Magazine - Spring 2007<br />

11