WIBObarrier® OCS - Open Containment Systems WIBObarrier ...

WIBObarrier® OCS - Open Containment Systems WIBObarrier ...

WIBObarrier® OCS - Open Containment Systems WIBObarrier ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

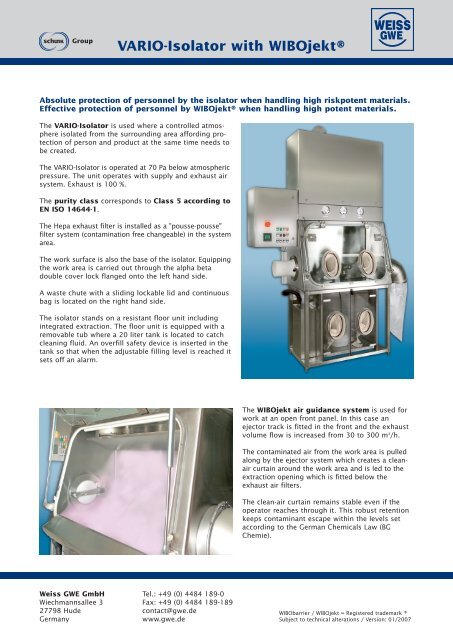

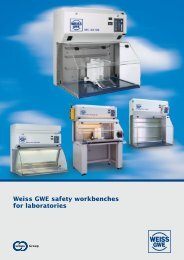

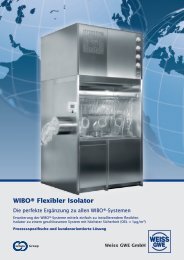

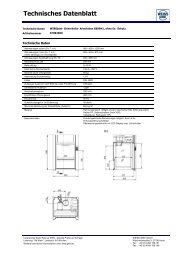

VARIO-Isolator with WIBOjekt®<br />

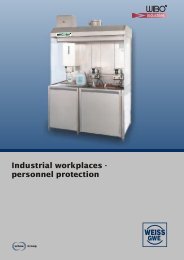

Absolute protection of personnel by the isolator when handling high riskpotent materials.<br />

Effective protection of personnel by WIBOjekt® when handling high potent materials.<br />

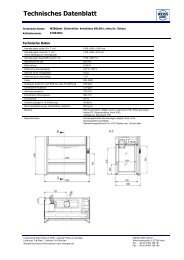

The VARIO-Isolator is used where a controlled atmosphere<br />

isolated from the surrounding area affording protection<br />

of person and product at the same time needs to<br />

be created.<br />

The VARIO-Isolator is operated at 70 Pa below atmospheric<br />

pressure. The unit operates with supply and exhaust air<br />

system. Exhaust is 100 %.<br />

The purity class corresponds to Class 5 according to<br />

EN ISO 14644-1.<br />

The Hepa exhaust filter is installed as a "pousse-pousse"<br />

filter system (contamination free changeable) in the system<br />

area.<br />

The work surface is also the base of the isolator. Equipping<br />

the work area is carried out through the alpha beta<br />

double cover lock flanged onto the left hand side.<br />

A waste chute with a sliding lockable lid and continuous<br />

bag is located on the right hand side.<br />

The isolator stands on a resistant floor unit including<br />

integrated extraction. The floor unit is equipped with a<br />

removable tub where a 20 liter tank is located to catch<br />

cleaning fluid. An overfill safety device is inserted in the<br />

tank so that when the adjustable filling level is reached it<br />

sets off an alarm.<br />

Weiss GWE GmbH<br />

Wiechmannsallee 3<br />

27798 Hude<br />

Germany<br />

Tel.: +49 (0) 4484 189-0<br />

Fax: +49 (0) 4484 189-189<br />

contact@gwe.de<br />

www.gwe.de<br />

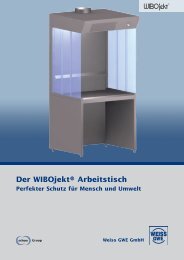

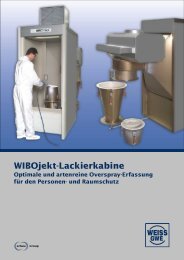

The WIBOjekt air guidance system is used for<br />

work at an open front panel. In this case an<br />

ejector track is fitted in the front and the exhaust<br />

volume flow is increased from 30 to 300 m 3 /h.<br />

The contaminated air from the work area is pulled<br />

along by the ejector system which creates a cleanair<br />

curtain around the work area and is led to the<br />

extraction opening which is fitted below the<br />

exhaust air filters.<br />

The clean-air curtain remains stable even if the<br />

operator reaches through it. This robust retention<br />

keeps contaminant escape within the levels set<br />

according to the German Chemicals Law (BG<br />

Chemie).<br />

<strong>WIBObarrier</strong> / WIBOjekt = Registered trademark ®<br />

Subject to technical alterations / Version: 01/2007