WIBObarrier® OCS - Open Containment Systems WIBObarrier ...

WIBObarrier® OCS - Open Containment Systems WIBObarrier ...

WIBObarrier® OCS - Open Containment Systems WIBObarrier ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

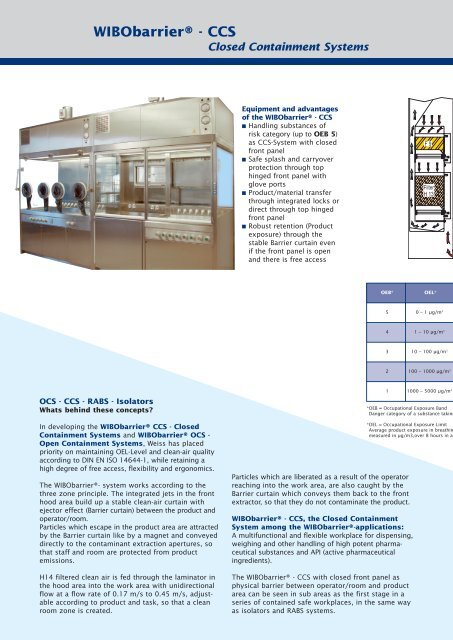

<strong><strong>WIBObarrier</strong>®</strong> - CCS<br />

Closed <strong>Containment</strong> <strong>Systems</strong><br />

<strong>OCS</strong> - CCS - RABS - Isolators<br />

Whats behind these concepts?<br />

In developing the <strong><strong>WIBObarrier</strong>®</strong> CCS - Closed<br />

<strong>Containment</strong> <strong>Systems</strong> and <strong><strong>WIBObarrier</strong>®</strong> <strong>OCS</strong> -<br />

<strong>Open</strong> <strong>Containment</strong> <strong>Systems</strong>, Weiss has placed<br />

priority on maintaining OEL-Level and clean-air quality<br />

according to DIN EN ISO 14644-1, while retaining a<br />

high degree of free access, flexibility and ergonomics.<br />

The <strong><strong>WIBObarrier</strong>®</strong>- system works according to the<br />

three zone principle. The integrated jets in the front<br />

hood area build up a stable clean-air curtain with<br />

ejector effect (Barrier curtain) between the product and<br />

operator/room.<br />

Particles which escape in the product area are attracted<br />

by the Barrier curtain like by a magnet and conveyed<br />

directly to the contaminant extraction apertures, so<br />

that staff and room are protected from product<br />

emissions.<br />

H14 filtered clean air is fed through the laminator in<br />

the hood area into the work area with unidirectional<br />

flow at a flow rate of 0.17 m/s to 0.45 m/s, adjustable<br />

according to product and task, so that a clean<br />

room zone is created.<br />

Equipment and advantages<br />

of the <strong><strong>WIBObarrier</strong>®</strong> - CCS<br />

■ Handling substances of<br />

risk category (up to OEB 5)<br />

as CCS-System with closed<br />

front panel<br />

■ Safe splash and carryover<br />

protection through top<br />

hinged front panel with<br />

glove ports<br />

■ Product/material transfer<br />

through integrated locks or<br />

direct through top hinged<br />

front panel<br />

■ Robust retention (Product<br />

exposure) through the<br />

stable Barrier curtain even<br />

if the front panel is open<br />

and there is free access<br />

Particles which are liberated as a result of the operator<br />

reaching into the work area, are also caught by the<br />

Barrier curtain which conveys them back to the front<br />

extractor, so that they do not contaminate the product.<br />

<strong><strong>WIBObarrier</strong>®</strong> - CCS, the Closed <strong>Containment</strong><br />

System among the <strong><strong>WIBObarrier</strong>®</strong>-applications:<br />

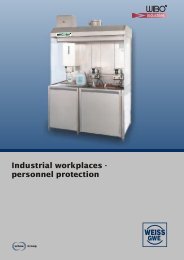

A multifunctional and flexible workplace for dispensing,<br />

weighing and other handling of high potent pharmaceutical<br />

substances and API (active pharmaceutical<br />

ingredients).<br />

The <strong><strong>WIBObarrier</strong>®</strong> - CCS with closed front panel as<br />

physical barrier between operator/room and product<br />

area can be seen in sub areas as the first stage in a<br />

series of contained safe workplaces, in the same way<br />

as isolators and RABS systems.<br />

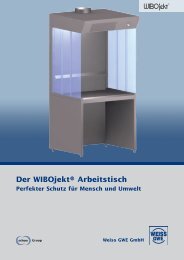

F 9<br />

Filter<br />

H 13<br />

OEB* OEL*<br />

5 0 – 1 µg/m 3<br />

4 1 – 10 µg/m 3<br />

3 10 – 100 µg/m 3<br />

2 100 – 1000 µg/m 3<br />

1 1000 – 5000 µg/m 3<br />

*OEB = Occupational Exposure Band<br />

Danger category of a substance taking<br />

*OEL = Occupational Exposure Limit<br />

Average product exposure in breathin<br />

measured in µg/m3,over 8 hours in a