WIBObarrier® OCS - Open Containment Systems WIBObarrier ...

WIBObarrier® OCS - Open Containment Systems WIBObarrier ...

WIBObarrier® OCS - Open Containment Systems WIBObarrier ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

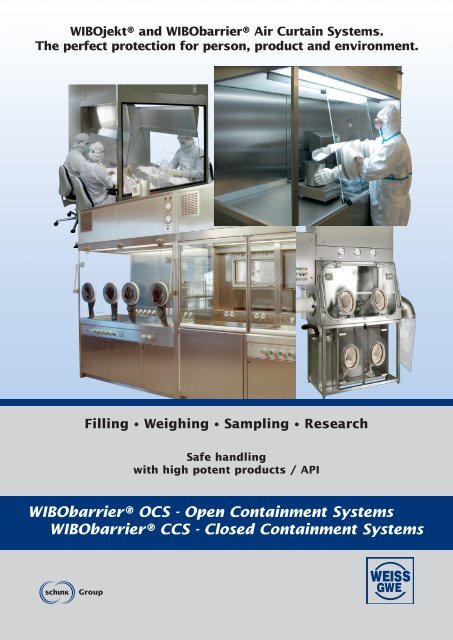

WIBOjekt® and <strong><strong>WIBObarrier</strong>®</strong> Air Curtain <strong>Systems</strong>.<br />

The perfect protection for person, product and environment.<br />

Filling • Weighing • Sampling • Research<br />

Safe handling<br />

with high potent products / API<br />

<strong><strong>WIBObarrier</strong>®</strong> <strong>OCS</strong> - <strong>Open</strong> <strong>Containment</strong> <strong>Systems</strong><br />

<strong><strong>WIBObarrier</strong>®</strong> CCS - Closed <strong>Containment</strong> <strong>Systems</strong>

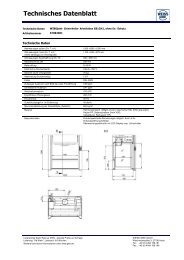

<strong><strong>WIBObarrier</strong>®</strong> - Duo<br />

<strong>Open</strong> <strong>Containment</strong> <strong>Systems</strong><br />

<strong><strong>WIBObarrier</strong>®</strong> - Duo<br />

as a seated workplace for four workers, used in a<br />

microbiological laboratory.<br />

Ventilation technology<br />

H14<br />

Air guidance principle<br />

<strong><strong>WIBObarrier</strong>®</strong>- Duo<br />

<strong><strong>WIBObarrier</strong>®</strong>- Duo<br />

The Barrier fulfils the requirements of exposure<br />

limit and protection of person according to DIN EN<br />

12469,C3 with both sides free front opening 300<br />

mm high and a product protection/clean room<br />

class ISO 5 according to EN ISO 14644-1 within<br />

the working area.<br />

<strong><strong>WIBObarrier</strong>®</strong> - Duo<br />

A safe workplace for sampling packages containing<br />

high potent steroid agents and/or APIs (active<br />

pharmaceutical ingredients).<br />

Integrated in a pallet conveying system which passes<br />

through the Barrier. The sampling is carried out from<br />

two sides to ensure that the person does not have to<br />

bend over the packages during sampling.<br />

Priority is given to the protection of person with a<br />

maximum product exposure of OEL 1-10 µg/m 3<br />

and the product protection/clean-room quality ISO 7<br />

according to EN ISO 14644-1 above the product.

<strong><strong>WIBObarrier</strong>®</strong> - Horizontal<br />

<strong>Open</strong> <strong>Containment</strong> <strong>Systems</strong><br />

The reliable air guidance system for<br />

modern filling technology.<br />

The system consists of two modules, a transmitter and a<br />

receiver,which are positioned vertically opposite each<br />

other. The filling and emptying station for packages, big<br />

bags, containers and so forth are located between them.<br />

H14 filtered air flows through the transmitter laminator<br />

horizontally over the filling/emptying station towards<br />

the receiver unit. The air curtain which builds up<br />

through the vertical and horizontal transmitter unit<br />

ejectors supports and stabilises this clean air curtain.<br />

In addition, a stable clean-airflow is drawn in by the<br />

receiver unit and is built up through the filling/<br />

emptying station ensuring that the emissions emanating<br />

from the filling/emptying station are contained within<br />

the protected area and are safely conveyed to the extraction<br />

unit. At the same time penetration of emissions emanating<br />

from personnel or from the room into the product<br />

area are prevented.<br />

Cross contaminations which could result from there being<br />

a number of filling/emptying stations with different products<br />

in one room, are prevented by the high directional<br />

stability of the airflow.<br />

Flow technology settings enable prioritisation of<br />

personnel or product protection.<br />

<strong>WIBObarrier</strong> Horizontal<br />

Abluft<br />

exhaust air<br />

Zuluft<br />

supply air<br />

Barrier<br />

Stabilisator<br />

stabilizer<br />

Air guidance principle<br />

<strong><strong>WIBObarrier</strong>®</strong>- Horizontal<br />

Advantages<br />

■ Protection factor > 100,000, possible for<br />

both personnel and product protection<br />

■ Product exposure for personnel and room<br />

according to OEL 10-30 µg/m 3 achievable<br />

■ Air quality up to ISO 7 according to EN ISO<br />

14644-1 when set up in the" black" area<br />

■ No product removal as a result of low air speeds<br />

with high directional stability<br />

■ Free access from three sides makes integration<br />

of filling/emptying equipment and materials<br />

handling possible<br />

■ Modular construction means configuration as<br />

either stationary or mobile units is possible<br />

■ Also available in an acid resistant plastic version<br />

<strong>WIBObarrier</strong> ® - Horizontal

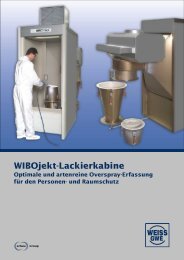

VARIO-Isolator with WIBOjekt®<br />

Absolute protection of personnel by the isolator when handling high riskpotent materials.<br />

Effective protection of personnel by WIBOjekt® when handling high potent materials.<br />

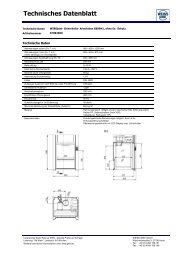

The VARIO-Isolator is used where a controlled atmosphere<br />

isolated from the surrounding area affording protection<br />

of person and product at the same time needs to<br />

be created.<br />

The VARIO-Isolator is operated at 70 Pa below atmospheric<br />

pressure. The unit operates with supply and exhaust air<br />

system. Exhaust is 100 %.<br />

The purity class corresponds to Class 5 according to<br />

EN ISO 14644-1.<br />

The Hepa exhaust filter is installed as a "pousse-pousse"<br />

filter system (contamination free changeable) in the system<br />

area.<br />

The work surface is also the base of the isolator. Equipping<br />

the work area is carried out through the alpha beta<br />

double cover lock flanged onto the left hand side.<br />

A waste chute with a sliding lockable lid and continuous<br />

bag is located on the right hand side.<br />

The isolator stands on a resistant floor unit including<br />

integrated extraction. The floor unit is equipped with a<br />

removable tub where a 20 liter tank is located to catch<br />

cleaning fluid. An overfill safety device is inserted in the<br />

tank so that when the adjustable filling level is reached it<br />

sets off an alarm.<br />

Weiss GWE GmbH<br />

Wiechmannsallee 3<br />

27798 Hude<br />

Germany<br />

Tel.: +49 (0) 4484 189-0<br />

Fax: +49 (0) 4484 189-189<br />

contact@gwe.de<br />

www.gwe.de<br />

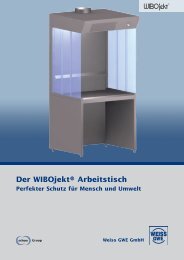

The WIBOjekt air guidance system is used for<br />

work at an open front panel. In this case an<br />

ejector track is fitted in the front and the exhaust<br />

volume flow is increased from 30 to 300 m 3 /h.<br />

The contaminated air from the work area is pulled<br />

along by the ejector system which creates a cleanair<br />

curtain around the work area and is led to the<br />

extraction opening which is fitted below the<br />

exhaust air filters.<br />

The clean-air curtain remains stable even if the<br />

operator reaches through it. This robust retention<br />

keeps contaminant escape within the levels set<br />

according to the German Chemicals Law (BG<br />

Chemie).<br />

<strong>WIBObarrier</strong> / WIBOjekt = Registered trademark ®<br />

Subject to technical alterations / Version: 01/2007

<strong><strong>WIBObarrier</strong>®</strong>- CCS<br />

as weighing and dispensing table for API<br />

■ Infinitely adjustable sliding front panel<br />

with glove ports<br />

■ Material air locks on both sides for<br />

removal and target package<br />

■ Lift and tilt table for removal packages<br />

■ Integrated label printer<br />

2 <strong><strong>WIBObarrier</strong>®</strong>- CCS<br />

installed in sequence<br />

■ <strong>Open</strong> reach through in the Barrier<br />

work areas<br />

■ Infinitely adjustable front panels with<br />

glove ports<br />

■ Integrated media connections<br />

<strong><strong>WIBObarrier</strong>®</strong>- combined with<br />

WIBOjekt®- table<br />

as laboratory workplace for high potent API<br />

<strong><strong>WIBObarrier</strong>®</strong>- CCS<br />

■ Double leaf front door with horizontally<br />

sliding safety glass front panel<br />

■ Drum location station over the whole width<br />

■ Integrated media connections<br />

■ Transfer hatch to the second <strong><strong>WIBObarrier</strong>®</strong><br />

<strong><strong>WIBObarrier</strong>®</strong>- CCS<br />

■ Table top over the whole width with integrated<br />

waste chute<br />

■ Top hinged front panel with glove ports<br />

WIBOjekt®- table<br />

■ Drum station<br />

■ Double leaf front door in safety glass with<br />

glove ports<br />

■ Transfer hatch to the second <strong><strong>WIBObarrier</strong>®</strong><br />

CCS – Configurations<br />

<strong><strong>WIBObarrier</strong>®</strong>- CCS<br />

as weighing and dispensing table for API<br />

■ Front door with glove ports<br />

■ Drum station<br />

Cleaning lock<br />

■ Transfer hatch with pneumatic<br />

shutter to the Barrier<br />

■ Compressed air for cleaning inliners<br />

■ Inliner welding gun<br />

■ Front door with glove ports<br />

Loading lock<br />

■ Front door with glove ports<br />

■ Conveyor for dispatch packages at<br />

ground level, equipped with lifting<br />

table<br />

■ Table top with opening for dispatch<br />

inliner<br />

Transfer trolley between Barrier<br />

and locks

<strong><strong>WIBObarrier</strong>®</strong> - CCS<br />

Closed <strong>Containment</strong> <strong>Systems</strong><br />

<strong>OCS</strong> - CCS - RABS - Isolators<br />

Whats behind these concepts?<br />

In developing the <strong><strong>WIBObarrier</strong>®</strong> CCS - Closed<br />

<strong>Containment</strong> <strong>Systems</strong> and <strong><strong>WIBObarrier</strong>®</strong> <strong>OCS</strong> -<br />

<strong>Open</strong> <strong>Containment</strong> <strong>Systems</strong>, Weiss has placed<br />

priority on maintaining OEL-Level and clean-air quality<br />

according to DIN EN ISO 14644-1, while retaining a<br />

high degree of free access, flexibility and ergonomics.<br />

The <strong><strong>WIBObarrier</strong>®</strong>- system works according to the<br />

three zone principle. The integrated jets in the front<br />

hood area build up a stable clean-air curtain with<br />

ejector effect (Barrier curtain) between the product and<br />

operator/room.<br />

Particles which escape in the product area are attracted<br />

by the Barrier curtain like by a magnet and conveyed<br />

directly to the contaminant extraction apertures, so<br />

that staff and room are protected from product<br />

emissions.<br />

H14 filtered clean air is fed through the laminator in<br />

the hood area into the work area with unidirectional<br />

flow at a flow rate of 0.17 m/s to 0.45 m/s, adjustable<br />

according to product and task, so that a clean<br />

room zone is created.<br />

Equipment and advantages<br />

of the <strong><strong>WIBObarrier</strong>®</strong> - CCS<br />

■ Handling substances of<br />

risk category (up to OEB 5)<br />

as CCS-System with closed<br />

front panel<br />

■ Safe splash and carryover<br />

protection through top<br />

hinged front panel with<br />

glove ports<br />

■ Product/material transfer<br />

through integrated locks or<br />

direct through top hinged<br />

front panel<br />

■ Robust retention (Product<br />

exposure) through the<br />

stable Barrier curtain even<br />

if the front panel is open<br />

and there is free access<br />

Particles which are liberated as a result of the operator<br />

reaching into the work area, are also caught by the<br />

Barrier curtain which conveys them back to the front<br />

extractor, so that they do not contaminate the product.<br />

<strong><strong>WIBObarrier</strong>®</strong> - CCS, the Closed <strong>Containment</strong><br />

System among the <strong><strong>WIBObarrier</strong>®</strong>-applications:<br />

A multifunctional and flexible workplace for dispensing,<br />

weighing and other handling of high potent pharmaceutical<br />

substances and API (active pharmaceutical<br />

ingredients).<br />

The <strong><strong>WIBObarrier</strong>®</strong> - CCS with closed front panel as<br />

physical barrier between operator/room and product<br />

area can be seen in sub areas as the first stage in a<br />

series of contained safe workplaces, in the same way<br />

as isolators and RABS systems.<br />

F 9<br />

Filter<br />

H 13<br />

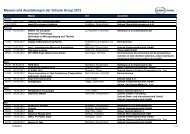

OEB* OEL*<br />

5 0 – 1 µg/m 3<br />

4 1 – 10 µg/m 3<br />

3 10 – 100 µg/m 3<br />

2 100 – 1000 µg/m 3<br />

1 1000 – 5000 µg/m 3<br />

*OEB = Occupational Exposure Band<br />

Danger category of a substance taking<br />

*OEL = Occupational Exposure Limit<br />

Average product exposure in breathin<br />

measured in µg/m3,over 8 hours in a

Laminator for unidirectional airflow<br />

Air guidance principle<br />

<strong><strong>WIBObarrier</strong>®</strong>- CCS / <strong>OCS</strong><br />

WIBO®-system solution<br />

BDK-Isolator<br />

<strong><strong>WIBObarrier</strong>®</strong>-CCS<br />

<strong><strong>WIBObarrier</strong>®</strong>-CCS<br />

<strong><strong>WIBObarrier</strong>®</strong>-<strong>OCS</strong><br />

<strong><strong>WIBObarrier</strong>®</strong>-Horizontal<br />

<strong><strong>WIBObarrier</strong>®</strong>-<strong>OCS</strong><br />

<strong><strong>WIBObarrier</strong>®</strong>-Horizontal<br />

<strong><strong>WIBObarrier</strong>®</strong>-<strong>OCS</strong><br />

<strong><strong>WIBObarrier</strong>®</strong>-Horizontal<br />

WIBOjekt®<br />

<strong><strong>WIBObarrier</strong>®</strong>-<strong>OCS</strong><br />

<strong><strong>WIBObarrier</strong>®</strong>-Horizontal<br />

WIBOjekt®<br />

toxicity into account<br />

g area of operator,<br />

40 hour, five day week.<br />

Light<br />

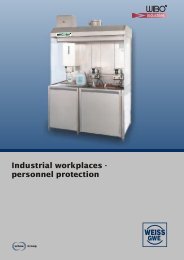

<strong><strong>WIBObarrier</strong>®</strong> - <strong>OCS</strong><br />

<strong>Open</strong> <strong>Containment</strong> <strong>Systems</strong><br />

Equipment and advantages<br />

of the <strong>WIBObarrier</strong> - CCS<br />

■ Handling substances of risk<br />

category (up to OEB 4)<br />

■ Splash and carryover protection<br />

through horizontally sliding<br />

protection glass pane<br />

for the protection of person,<br />

equipped with glove ports<br />

■ Unrestricted transfer of product<br />

and material directly<br />

through the front opening<br />

■ Reaching through protection<br />

for risk areas (Crusher /<br />

mills) by means of controllable<br />

light grids<br />

■ Robust retention (Product<br />

exposure) through the stable<br />

Barrier curtain despite free<br />

access, even without front<br />

panel<br />

When handling less dangerous substances the front<br />

panel is clipped open or swung up and the Barrier<br />

can be freely accessed and used as <strong>OCS</strong>.<br />

<strong><strong>WIBObarrier</strong>®</strong> - <strong>OCS</strong>, the <strong>Open</strong> <strong>Containment</strong><br />

System among the <strong><strong>WIBObarrier</strong>®</strong>-applications:<br />

An ergonomic workplace for the protection of operator,<br />

room and product with integrated clean-room<br />

zone up to ISO 5, for dispensing and filling, refining<br />

and sampling.<br />

Its patented air guidance system guarantees a robust<br />

retention, despite the very gentle airflow, following<br />

EN 14175-3, with free open front up to 1,000 mm<br />

high. Splash and carryover protection can be provided by<br />

installing a front panel, easy to be slid horizontally, available<br />

even with glove ports.<br />

Isolators, which guarantee the highest safety level<br />

as far as personnel and product protection are concerned<br />

are not always economically appropriate or necessary<br />

because of the limited access in the product area<br />

and the legal air and cleaning regulations at the<br />

increasing flexibility requirements for production<br />

processes.<br />

Advanced development of the CCS/RABS (Restricted<br />

Access Barrier <strong>Systems</strong>) means that the requirements<br />

of increasing production flexibility in contained workplaces<br />

have already been taken into account. RABS<br />

are used primarily in aseptic filling.<br />

In contrast to the isolator, RABS systems achieve only<br />

a partial separation between sterile operations and<br />

work area. This is possible without sacrificing quality<br />

and safety limitations, because the operator is always<br />

working in a clean room Class ISO 7 and ISO 5 is provided<br />

in the product area of the RABS. In contrast to<br />

isolators, RABS need not be operated in controlled<br />

pressure areas and do not need to be hermetically<br />

sealed.<br />

<strong><strong>WIBObarrier</strong>®</strong> - CCS is also available in RABS configuration.

<strong><strong>WIBObarrier</strong>®</strong>- <strong>OCS</strong><br />

as weighing station for API<br />

■ Horizontally sliding front panel<br />

with glove ports<br />

■ Table surface with weighing plate<br />

■ Drum station<br />

■ Lifting column, 200 kg capacity<br />

■ Material lock with active cleaning<br />

■ Transfer trolley from production<br />

room up to lifting column<br />

<strong><strong>WIBObarrier</strong>®</strong>- <strong>OCS</strong><br />

as sampling station<br />

■ Lift turntable for pallets<br />

■ Transverse carriage for lift turntable<br />

■ Pneumatic lift gates<br />

■ Integrated pallet transport<br />

<strong>OCS</strong> – Configurations<br />

<strong><strong>WIBObarrier</strong>®</strong>- <strong>OCS</strong><br />

as dispensing and laboratory workplace<br />

■ Drum station<br />

■ Lift and tilt column with drum turning<br />

device 120 kg capacity<br />

■ Weighing plate in the table surface<br />

■ Spot extraction for container interiors<br />

■ Catch tub with perforated plate cover<br />

<strong><strong>WIBObarrier</strong>®</strong>- <strong>OCS</strong><br />

as weighing station for API<br />

■ Horizontally sliding front panel<br />

with glove ports<br />

■ Drum location station with floor<br />

weighing machine<br />

■ Articulated arm with weighing<br />

terminal<br />

<strong><strong>WIBObarrier</strong>®</strong>- <strong>OCS</strong><br />

as dispensing station for API<br />

■ Lift and tilt column with floor<br />

weighing machine,150 kg capacity<br />

■ Drum turning device<br />

■ Drum location station for target<br />

package with floor weighing<br />

machine