Download - hdgasa

Download - hdgasa

Download - hdgasa

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Masts and poles<br />

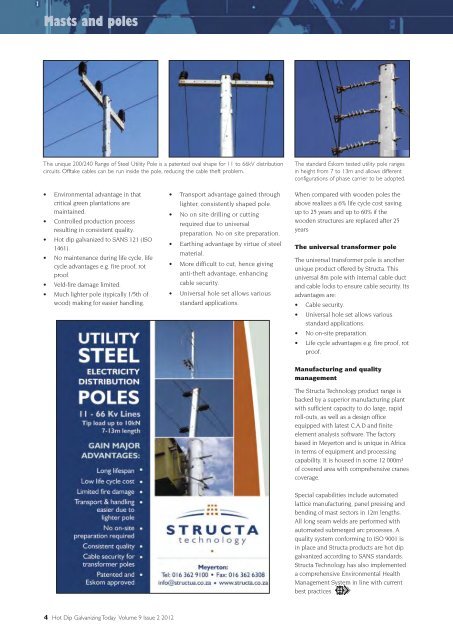

This unique 200/240 Range of Steel Utility Pole is a patented oval shape for 11 to 66kV distribution<br />

circuits. Offtake cables can be run inside the pole, reducing the cable theft problem.<br />

The standard Eskom tested utility pole ranges<br />

in height from 7 to 13m and allows different<br />

configurations of phase carrier to be adopted.<br />

• Environmental advantage in that<br />

critical green plantations are<br />

maintained.<br />

• Controlled production process<br />

resulting in consistent quality.<br />

• Hot dip galvanized to SANS 121 (ISO<br />

1461).<br />

• No maintenance during life cycle, life<br />

cycle advantages e.g. fire proof, rot<br />

proof.<br />

• Veld-fire damage limited.<br />

• Much lighter pole (typically 1/5th of<br />

wood) making for easier handling.<br />

• Transport advantage gained through<br />

lighter, consistently shaped pole.<br />

• No on site drilling or cutting<br />

required due to universal<br />

preparation. No on site preparation.<br />

• Earthing advantage by virtue of steel<br />

material.<br />

• More difficult to cut, hence giving<br />

anti-theft advantage, enhancing<br />

cable security.<br />

• Universal hole set allows various<br />

standard applications.<br />

When compared with wooden poles the<br />

above realizes a 6% life cycle cost saving<br />

up to 25 years and up to 60% if the<br />

wooden structures are replaced after 25<br />

years<br />

The universal transformer pole<br />

The universal transformer pole is another<br />

unique product offered by Structa. This<br />

universal 8m pole with internal cable duct<br />

and cable locks to ensure cable security. Its<br />

advantages are:<br />

• Cable security.<br />

• Universal hole set allows various<br />

standard applications.<br />

• No on-site preparation.<br />

• Life cycle advantages e.g. fire proof, rot<br />

proof.<br />

Manufacturing and quality<br />

management<br />

The Structa Technology product range is<br />

backed by a superior manufacturing plant<br />

with sufficient capacity to do large, rapid<br />

roll-outs, as well as a design office<br />

equipped with latest C.A.D and finite<br />

element analysis software. The factory<br />

based in Meyerton and is unique in Africa<br />

in terms of equipment and processing<br />

capability. It is housed in some 12 000m²<br />

of covered area with comprehensive cranes<br />

coverage.<br />

Special capabilities include automated<br />

lattice manufacturing, panel pressing and<br />

bending of mast sectors in 12m lengths.<br />

All long seam welds are performed with<br />

automated submerged arc processes. A<br />

quality system conforming to ISO 9001 is<br />

in place and Structa products are hot dip<br />

galvanized according to SANS standards.<br />

Structa Technology has also implemented<br />

a comprehensive Environmental Health<br />

Management System in line with current<br />

best practices.<br />

4 Hot Dip Galvanizing Today Volume 9 Issue 2 2012