Davis & Harrison & Kim.Jacobs.Wastewater Treatment for Enhanced ...

Davis & Harrison & Kim.Jacobs.Wastewater Treatment for Enhanced ...

Davis & Harrison & Kim.Jacobs.Wastewater Treatment for Enhanced ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

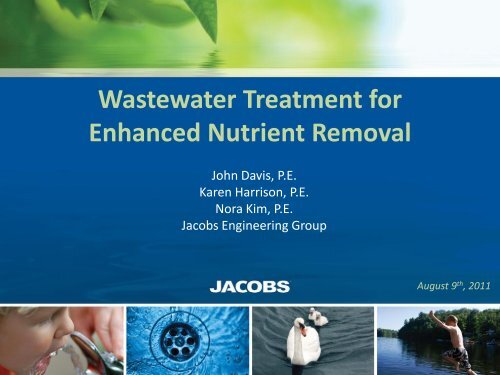

<strong>Wastewater</strong> <strong>Treatment</strong> <strong>for</strong><br />

<strong>Enhanced</strong> Nutrient Removal<br />

John <strong>Davis</strong>, P.E.<br />

Karen <strong>Harrison</strong>, P.E.<br />

Nora <strong>Kim</strong>, P.E.<br />

<strong>Jacobs</strong> Engineering Group<br />

August 9 th , 2011

Outline<br />

• What is enhanced nutrient removal (ENR)?<br />

• Why is it required?<br />

• Where has it been required?<br />

• How is it accomplished?<br />

• Issues, lessons, and observations <strong>for</strong> two key<br />

processes:<br />

– Three-stage treatment<br />

– Simultaneous nitrification/denitrification (SND)

What is ENR?<br />

<strong>Treatment</strong> Level<br />

Typical Effluent<br />

Nutrient Levels<br />

Typical Process<br />

Nutrient<br />

Removal<br />

<strong>Enhanced</strong><br />

Nutrient<br />

Removal<br />

Wow!<br />

You’re Serious?<br />

Nutrient Removal<br />

8 mg/L TN<br />

and/or<br />

1 mg/L TP<br />

3 mg/L TN<br />

and/or<br />

0.1 mg/L TP<br />

1 mg/L TN<br />

and/or<br />

Why is ENR Required?<br />

Nitrogen and phosphorus<br />

waste loads in streams,<br />

lakes, and coastal estuaries<br />

can cause algae<br />

proliferation,<br />

eutrophication, & low<br />

oxygen levels.

Where has ENR been Required?<br />

• For Nitrogen<br />

– Typically coastal regions<br />

– Groundwater recharge<br />

– Chesapeake Bay<br />

– Florida<br />

– Long Island Sound<br />

• For Phosphorus<br />

– Typically upstream of freshwater lakes<br />

– Throughout U.S.

How is ENR accomplished?<br />

Sample of Low Nitrogen Plants<br />

<strong>Treatment</strong> Plant Process Supplement<br />

Carbon<br />

95 th %tile<br />

TN, mg/L<br />

Average<br />

TN, mg/L<br />

Truckee Meadows WRF, NV Fixed Film Nit/Denit & Filters Yes 2.5 1.7<br />

River Oaks WWTP, FL Separate Sludge & Filters Yes 2.3 1.5<br />

Howard F. Curran WWTP, FL Nitrification & Denit Filters Yes 3.0 NA<br />

WSSC Western Branch WWTP, MD Separate Sludge & Filters Yes 2.2 1.5<br />

Scituate WWTP, MA Nitrification & Denit Filters Yes 3.8 2.4<br />

Eastern WRF, FL Bardenpho & Filters No 6.7 4.3 (Median)<br />

WSSC Parkway WWTP, MD Bardenpho Yes 5.1 3.1<br />

Fiesta Village, FL Simult Nit/Denit & Denit Filters Yes 2.2 1.1<br />

Kalaska CWP, MI Ox Ditch Bardenpho No 2.8 2.2<br />

Iron Bridge WRF, FL Ox Ditch Bardenpho & Filters No 2.4 1.9<br />

WSSC Piscataway, WWTP, MD Step Feed & Filters No 7.2 3.1<br />

Ten Bardenpho Plants, FL Bardenpho & Filters Yes 3.5 2.4<br />

Five 3-Stage with Denite Filters, FL 3-Stage & Denit Filters Yes 3.0 2.1<br />

Source: WERF/WEF Real World LOT Nutrient Removal: Achievable Limits and Statistical Reliability Workshop,<br />

October 11, 2009

How is ENR accomplished <strong>for</strong><br />

Low Nitrogen?<br />

• Typical Processes<br />

– Separate Sludge<br />

– Attached-Growth Denitrification<br />

– Bardenpho<br />

– Simultaneous Nitrification/Denitrification (SND)<br />

PLUS<br />

• Chemical Addition<br />

– Methanol, Acetic Acid, Other Carbon Source

How is Nitrogen Removal<br />

Accomplished?<br />

A Basin Meeting Three Main Requirements<br />

1. Nitrified Influent<br />

2. Anoxic Conditions<br />

3. Carbon Source

Separate Sludge<br />

Supplemental<br />

Carbon<br />

Nitrification<br />

Stage<br />

1 st Stage<br />

Clarifiers<br />

De-Nitrification<br />

Stage<br />

2 nd Stage<br />

Clarifiers<br />

• Common in earliest low TN applications (70s and 80s)<br />

• Effective<br />

• High cost <strong>for</strong> capital and chemical

Attached-Growth Denitrification<br />

Supplemental<br />

Carbon<br />

Anaerobic<br />

Stage<br />

Anoxic<br />

Stage<br />

Aerobic<br />

Stage<br />

Clarifiers<br />

Denitrifying<br />

Filters<br />

• Combined with upstream activated sludge<br />

• TN removal with upstream nitrification<br />

• TN polishing with upstream 3-stage process

Bardenpho<br />

Supplemental<br />

Carbon<br />

Anaerobic<br />

Stage<br />

1 st Anoxic<br />

Stage<br />

1 st Aerobic<br />

Stage<br />

2 nd Anoxic<br />

Stage<br />

2 nd Aerobic<br />

Stage<br />

Clarifiers<br />

Filters<br />

• Responds well to flow and load changes<br />

• Limits supplemental carbon need<br />

• Has become very common <strong>for</strong> low TN applications

Simultaneous<br />

Nitrification/Denitrification (SND)<br />

• More of an operational method than a<br />

process configuration<br />

• DO = 0.3 to 0.7 mg/L Nitrify & Denitrify<br />

• Used in many process configurations<br />

• Key is maintaining DO in low, narrow range<br />

– DO too high exceed on TN<br />

– DO too low exceed on NH 3 -N<br />

• Supplemental carbon may not be needed

SND Mechanism<br />

O 2<br />

Aerobic<br />

CO 2<br />

Anoxic<br />

N 2<br />

Ammonia<br />

NO 2<br />

NO 3<br />

BOD

How is ENR accomplished?<br />

Sample of Low Phosphorus Plants<br />

<strong>Treatment</strong> Plant BioP ChemP 95 th %tile<br />

TP, mg/L<br />

Average TP,<br />

mg/L<br />

Clark County, NV Yes Pre & Post 0.153 0.086<br />

Rocky Creek, OR Yes Pre & Post 0.151 0.067<br />

Blue Plains, DC Yes Pre & Co 0.161 0.067<br />

Iowa Hill WRF, CO Yes Post 0.031 0.013<br />

F. Wayne Hill, Gwinnett County, GA Yes Post 0.090 0.044<br />

Cauley Creek, Fulton County, GA Yes Co (MBR) 0.116 0.077<br />

Alexandia Sanitation Authority WWTP, VA Some Co & Post 0.101 0.046<br />

Pinery WWTP, CO Yes Post 0.042 0.023<br />

WSSC Piscataway, WWTP, MD Some Post 0.178 0.087<br />

Kalispell AWWTP, MT Yes No 0.168 0.110<br />

Kelowna WWTF, BC Yes Co 0.217 0.160<br />

Source: WERF/WEF Real World LOT Nutrient Removal: Achievable Limits and Statistical Reliability Workshop,<br />

October 11, 2009

How is ENR accomplished <strong>for</strong><br />

• Typical Processes<br />

Low Phosphorus?<br />

– Post-precipitation with tertiary clarifiers followed<br />

by filters<br />

– Co-precipitation in a Membrane Bioreactor (MBR)<br />

– Upstream biological phosphorus removal is<br />

warranted to save on chemical costs

Post-Precipitation<br />

Alum or<br />

Ferric<br />

Alum or<br />

Ferric<br />

Anaerobic<br />

Stage<br />

Anoxic<br />

Stage<br />

Aerobic<br />

Stage<br />

Clarifiers<br />

Chemical<br />

Clarifiers<br />

Chemical<br />

Filters<br />

• Need two sets of clarifiers plus filters<br />

• Multiple chemical feed points are common<br />

• Georgia has many examples on Lake Lanier, Chattahoochee

Co-Precipitation with MBR<br />

Alum or<br />

Ferric<br />

Anaerobic<br />

Stage<br />

Anoxic<br />

Stage<br />

Aerobic<br />

Stage<br />

RAS DeOx<br />

Tank<br />

Membrane<br />

Tank<br />

• Membranes replace two sets of clarifiers, and media filters<br />

• Air Scour DO can interfere with anaerobic/anoxic treatment<br />

• Georgia has many examples on Lake Lanier, Chattahoochee

Minimizing Chemical Costs<br />

As ENR standards become more common two<br />

process approaches will standout as keys to<br />

limiting chemical costs:<br />

– 3-Stage <strong>Treatment</strong><br />

• Example: Mauldin Road WWTP<br />

– Simultaneous Nitrification/Denitrification<br />

• Example: Yulee/Nassau Regional WRF

3-Stage <strong>Treatment</strong> – Mauldin Rd WWTP<br />

Anaerobic<br />

Stage<br />

Anoxic<br />

Stage<br />

Aerobic<br />

Stage<br />

Clarifiers<br />

Filters<br />

• Removes N and P to degree possible w/o chemicals<br />

• Can achieve low TN if extended into Bardenpho or followed<br />

by denitrifying filters<br />

• Can achieve < 1 mg/L TP w/o chemicals

TN, mg/L<br />

TP, mg/L<br />

3-Stage Process - SRT Sweet Spot<br />

30<br />

25<br />

20<br />

5<br />

4.5<br />

4<br />

3.5<br />

3<br />

15<br />

10<br />

5<br />

0<br />

0 10 20 30 40 50 60<br />

Sludge Retention Time (SRT), days<br />

2.5<br />

2<br />

1.5<br />

1<br />

0.5<br />

0<br />

TN Results<br />

TP Results

3-Stage Process – Other Observations<br />

• Phosphorus accumulating organisms (PAOs) and<br />

denitrifying organisms compete <strong>for</strong> carbon<br />

• Primary clarifiers will be counter-productive<br />

• Biologically fixed phosphorus must be removed with<br />

sludge<br />

• Long SRTs due to low plant loading will interfere with<br />

phosphorus removal<br />

• If denitrification is carbon-limited, more nitrified<br />

recycle won’t help TN removal.<br />

• DO and NO 3 in RAS can interfere with<br />

PAOs/phosphorus removal

SND - Yulee/Nassau Regional WRF<br />

Recycle<br />

Influent<br />

Flow<br />

Discharge<br />

Screening and Flow<br />

Split<br />

Anoxic Aerobic Anoxic MBR<br />

UV<br />

Disinfection

Effluent Limits<br />

Parameter<br />

cBOD 5<br />

Total Suspended Solids (TSS)<br />

Ammonia-Nitrogen (NH 3 -N)<br />

Total Nitrogen (TN)<br />

Total Phosphorus (TP)<br />

Limit<br />

5 mg/L<br />

5 mg/L<br />

1 mg/L<br />

3 mg/L<br />

1 mg/L

Process Highlights<br />

• SymBio® Process<br />

– Simultaneous nitrification-denitrification (SND)<br />

– Operates at low dissolved oxygen (0.2 – 0.5 mg/L)<br />

• Alum feed <strong>for</strong> P removal<br />

• Kubota flat plate membranes

Process Modeling<br />

• BioWin model used as operational tool<br />

• BioWin switching functions require<br />

adjustment<br />

• Jimenez (2010) research on SND switching<br />

functions

Concentration, mg/L<br />

Original Operation<br />

8<br />

7<br />

Nov 2006 to Jan 2007 Effluent Data<br />

Effluent TN<br />

Effluent TP<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0

Recommended Modifications<br />

• Added new aeration blower with VFD – 400 to<br />

1300 scfm capacity<br />

• Aeration tank minimum air reduced from 600<br />

scfm to 400 scfm<br />

• Operation of fewer trains at low loads<br />

• Consulted membrane vendor and reduced<br />

minimum scour air from 1400 to 700 scfm per<br />

membrane tank

Concentration, mg/L<br />

Modified Operation<br />

2010 Effluent Data<br />

7<br />

6<br />

Effluent TN<br />

Effluent TP<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0

Questions?<br />

john.davis@jacobs.com

![VIA CERTIFIED MAIL (Return Receipt Requested) [DATE] Ms ...](https://img.yumpu.com/43063436/1/190x245/via-certified-mail-return-receipt-requested-date-ms-.jpg?quality=85)