Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

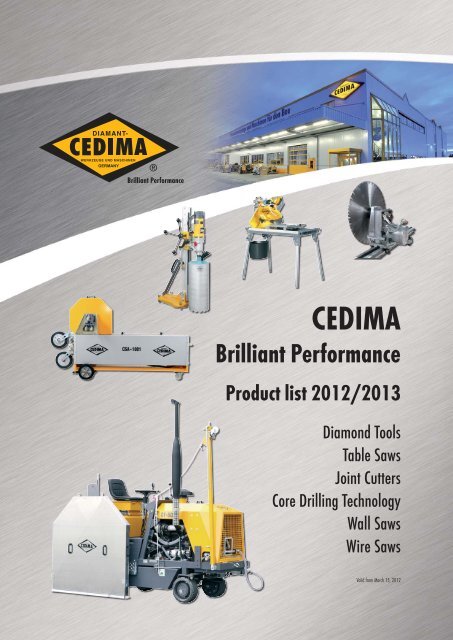

Brilliant Performance<br />

CEDIMA<br />

Brilliant Performance<br />

Product list 2012/2013<br />

Diamond Tools<br />

Table Saws<br />

Joint Cutters<br />

Core Drilling Technology<br />

Wall Saws<br />

Wire Saws<br />

Valid from March 15, 2012<br />

1

Brilliant Performance<br />

CEDIMA - Diamond Tools and Machines for the Construction Industry<br />

With the customer, for the customer! Since 1984 CEDIMA GmbH in Celle has been<br />

developing and distributing diamond tools and machines for the construction industry.<br />

Having cumulated know-how over many years, we now have a variety of diamond<br />

tools and machines at our disposal, which offer our customers an unequalled range of<br />

benefi ts. Quality is CEDIMA’s most important maxim. As a consequence of our quality<br />

assurance efforts, we have been awarded the DIN ISO 9001 certifi cate as early as 1997.<br />

CEDIMA exports to more than 50 countries world wide. Our international distribution and<br />

service partners contribute in our keeping delivery and service lead times to a minimum.<br />

A powerful internal sales team assures that every customer need is taken care of.<br />

Our most important resource is our highly skilled service team. This team demonstrates<br />

our commitment to our customers at home and abroad. Any kind of problem is<br />

professionally analysed, and in many cases, immediately solved. Our ability to offer a<br />

full range of diamond tools, machines and services, makes us the right partner for the<br />

concrete drilling and sawing industry.<br />

How to order!<br />

by telefax: +49 (0)5141-86427<br />

by e-mail:<br />

verkauf@cedima.com<br />

by telephone: +49 (0)5141/8854-580<br />

-581<br />

for repairs +49 (0)5141/8854-15<br />

for all technical queries on<br />

diamond tools +49 (0)5141/8854-544<br />

machines +49 (0)5141/8854-365<br />

- 241<br />

Our office hours are Monday to Friday from 7:30 a.m. to 5:00 p.m.<br />

Otherwise an answering unit will take your call.<br />

2

TABLE OF CONTENTS<br />

Brilliant Performance<br />

Diamond tools 6 - 12<br />

Diamond saw blades 6 - 9<br />

Diamond tools for special application • grinding disc • slot cutters • mortar reamer • diamond ring saw blades 9 - 12<br />

Table saws 13 - 22<br />

Table saws and accessories 19<br />

Diamond saw blades for table saws 20 - 22<br />

Joint cutters 23 - 42<br />

Joint cutters and accessories 23 - 35<br />

Diamond saw blades for joint cutters 36 - 42<br />

Core drilling technology 43 - 72<br />

Drill columns 43 - 53<br />

Drill motors 54 - 56<br />

Drill trailers 57<br />

Accessories 58 - 59<br />

Diamond drill bits 61 - 72<br />

Wall saws 73 - 82<br />

Wall saws and accessories 73 - 80<br />

Diamond saw blades for wall saws 81 - 82<br />

Wire saw technology 83 -94<br />

Automatic wire saws 83 - 89<br />

Circular saws 90<br />

Diamond wires 91<br />

Accessories 92 - 94<br />

Hydraulic power packs 95<br />

High-frequency drives and control technology 96 - 97<br />

Special machines 98 - 108<br />

Electric hand-held cut-off saw SM-410 99<br />

High-frequency electric chain saw CKR-1016 HF 100<br />

High-frequency electric chain saw CKE-943 HF F4 101<br />

Brushing machine CBM-35 B/ D 102<br />

Milling machine CRF-60.1 B 103<br />

Surface milling machine CF-245 104<br />

Reinforced concrete breaker SBB-2000 105<br />

Chamfering machine CF-206.2 105<br />

Concrete slurry separators 106 - 107<br />

Bump Cutter 108<br />

3

HOW TO WORK WITH THIS PRICE LIST<br />

Brilliant Performance<br />

colour guidance<br />

system<br />

data of tools<br />

designation of tool<br />

CEDIMA DIAMANTTRENNSCHEIBEN<br />

CA-ECO ASPHALT (LASER)<br />

Bestell-Nr.<br />

Ø Segment Anzahl Bohrung<br />

mm B x H x L mm Segmente mm<br />

Preis €<br />

12 - 02 66 115 2,1 x 10 x 32 9 22,23 23,-<br />

12 - 02 67 125 2,1 x 10 x 32 10 22,23 24,-<br />

12 - 02 68 150 2,2 x 10 x 31 12 22,23 29,-<br />

12 - 02 69 180 2,3 x 10 x 33 14 22,23 39,-<br />

12 - 02 70 230 2,4 x 10 x 40 14 22,23 45,-<br />

12 - 02 72 300 2,8 x 10 x 40 18 20 68,-<br />

12 - 02 73 300 2,8 x 10 x 40 18 25,4 68,-<br />

12 - 02 74 350 3,2 x 10 x 40 21 20 102,-<br />

12 - 02 75 350 3,2 x 10 x 40 21 25,4 102,-<br />

12 - 02 76 400 3,2 x 10 x 40 24 20 135,-<br />

12 - 02 77 400 3,2 x 10 x 40 24 25,4 135,-<br />

12 - 02 78 450 3,6 x 10 x 40 26 25,4 177,-<br />

12 - 02 79 500 4,2 x 10 x 40 30 25,4 227,-<br />

12 - 02 80 600 4,2 x 10 x 40 36 25,4 308,-<br />

• Asphalt, Kalksandstein und anderen abrasiven Materialien<br />

• hohe Standzeit<br />

• mit Schutzsegmenten<br />

+<br />

Brillante Leistung<br />

mode of operation*<br />

dry cutting<br />

wet cutting<br />

description and detailed<br />

choice of material to be cut<br />

for operation with type of machine<br />

CA-3 STANDARD MIT SCHUTZSEGMENTEN<br />

+<br />

Bestell-Nr.<br />

Ø Segment Anzahl Bohrung<br />

mm B x H x L mm Segmente mm<br />

Preis €<br />

12 - 01 95 115 2,0 x 9 x 32 9 22,23 32,-<br />

12 - 01 96 125 2,0 x 9 x 32 10 22,23 34,-<br />

12 - 01 97 150 2,0 x 9 x 32 12 22,23 49,-<br />

12 - 01 98 180 2,4 x 9 x 32 14 22,23 58,-<br />

12 - 01 99 230 2,4 x 9 x 40 16 22,23 67,-<br />

12 - 02 00 300 3,0 x 9 x 40 18 25,4/20 137,-<br />

12 - 02 01 350 3,2 x 9 x 40 20 25,4/20 165,-<br />

12 - 02 02 400 3,6 x 9 x 40 24 25,4/20 206,-<br />

12 - 02 03 450 3,6 x 9 x 40 27 25,4/20 254,-<br />

12 - 02 04 500 3,6 x 9 x 40 30 25,4/20 373,-<br />

12 - 02 05 600 4,2 x 9 x 40 36 25,4/20 483,-<br />

TSCE-POROTON-KS<br />

• Abrasive Materialien wie Asphalt, Estrich, Kalksandstein (Rohdichte < 2),<br />

Poroton, Feuerfestmaterial porös, Gasbeton, Sandstein, Tonziegel<br />

* It is principally possible to use dry<br />

cutting tools in wet cutting mode; this<br />

will increase the life of your<br />

CEDIMA diamond tool. But please<br />

always observe the safety instructions<br />

of your machine manufacturer.<br />

• Poroton, Gasbeton, hochverdichteter Kalksandstein, abrasive Natursteine<br />

• Universal-Tischsägeblatt für abrasive Materialien<br />

Bestell-Nr.<br />

Ø Segment Anzahl Bohrung<br />

mm B x H x L mm Segmente mm<br />

Preis €<br />

12 - 17 19 650 3,6 x 10 x 40 36 35/25,4 254,-<br />

12 - 17 24 700 3,6 x 10 x 40 36 60/55 385,-<br />

12 - 17 22 900 4,4 x 10 x 38 52 60/55 406,-<br />

pictograms<br />

saw blades<br />

grinding discs<br />

petrol-driven<br />

cut-off saws<br />

table saws<br />

joint cutters<br />

core drilling<br />

technology<br />

wire saw technology<br />

hydraulic<br />

power packs<br />

angle grinders<br />

block saws<br />

wall saws<br />

hand-held machines<br />

!<br />

The drawings in this price list partially do not correspond to the actual scope of delivery. They only serve as a survey on the products.<br />

Some of the machines are shown with accessories that require an extra charge.<br />

Safety fi rst! Always wear your personal protection equipment when working with diamond tools.<br />

CEDIMA reserves the right of further development and modifi cations of the products specifi ed in this price list without prior notice. CEDIMA is not obliged to make corresponding modifi cations of products already<br />

supplied. Also CEDIMA reserves the right to delete products from her delivery programme. Without written approval by CEDIMA GmbH it is not allowed to reproduce any part of this price list by reprint, photocopy,<br />

microfi lm or other methods or by storage in electronic systems. Amendments and modifi cations are not permitted. All the prices and particulars are non-binding and without engagement.<br />

4

RECOMMENDATIONS FOR THE USE OF CEDIMA DIAMOND TOOLS<br />

Brilliant Performance<br />

AR-Standard<br />

AR-Super<br />

A1-Super-<br />

Turbo<br />

Syncro<br />

Granit<br />

Turbo 2009 CA-series TSCE-Proton<br />

Fliese<br />

Premium<br />

AR-DUAL BCE-series ACE-series FBC-J3 HGT-J3<br />

wall saw<br />

blades<br />

stoneware<br />

tiles, glazed tiles,<br />

slabs of natural stone<br />

vitreous refractory material<br />

hard clinkers, paving stones<br />

glazed stone ware tubes<br />

heavy ceramics<br />

natural stone (granite,<br />

gneiss etc.)<br />

artifi cial stone, polymer<br />

concrete<br />

reinforced concrete<br />

cured concrete<br />

washed-out concrete<br />

curb stones<br />

paving concrete<br />

concrete full brick<br />

high density lime sand-stone<br />

lime stone<br />

(marble,terrazzo etc.)<br />

roof tiles<br />

slate<br />

fi bre-glas plastics<br />

plaster board<br />

clay bricks<br />

aerated concrete<br />

refractory material, porous<br />

lime sand-stone,<br />

gross density < 2<br />

poroton<br />

sand-stone<br />

fl oor fi nish<br />

mortar<br />

asphalt<br />

green concrete<br />

grey cast iron<br />

profi le sheets<br />

♦<br />

♦<br />

♦<br />

♦<br />

♦<br />

♦<br />

♦<br />

♦<br />

♦<br />

♦<br />

♦ ♦ ♦ ♦ ♦<br />

♦ ♦ ♦ ♦ ♦<br />

♦ ♦ ♦ ♦ ♦ ♦ ♦<br />

♦ ♦ ♦ ♦ ♦ ♦ ♦<br />

♦ ♦ ♦ ♦ ♦ ♦ ♦<br />

♦ ♦ ♦ ♦ ♦ ♦<br />

♦ ♦ ♦ ♦ ♦ ♦<br />

♦ ♦ ♦ ♦ ♦ ♦<br />

♦ ♦ ♦ ♦ ♦ ♦<br />

♦ ♦ ♦ ♦<br />

♦ ♦ ♦ ♦ ♦<br />

♦ ♦ ♦<br />

♦ ♦ ♦<br />

♦ ♦ ♦<br />

♦ ♦ ♦ ♦ ♦ ♦<br />

♦ ♦ ♦<br />

dry/<br />

wet<br />

dry/<br />

wet<br />

dry/<br />

wet<br />

♦ ♦ ♦ ♦<br />

♦ ♦ ♦ ♦<br />

♦<br />

♦ ♦ ♦<br />

♦ ♦ ♦<br />

♦ ♦ ♦ ♦<br />

♦ ♦ ♦<br />

♦<br />

♦<br />

♦ ♦ ♦ ♦ ♦<br />

♦ ♦ ♦<br />

dry/<br />

wet<br />

dry/<br />

wet<br />

dry/<br />

wet<br />

dry/<br />

wet<br />

wet wet wet<br />

♦ very applicable ♦ well applicable ♦ conditionally applicable sub-optimally suited<br />

5

CEDIMA DIAMOND SAW BLADES<br />

Brilliant Performance<br />

Colour guidance system+ application description<br />

In order to facilitate the suitable diamond tool, the application area is classifi ed in colours. The colour marking immediately shows the<br />

particular used fi elds of application for diamond tools. (differing fi elds of application see page 5).<br />

concrete/ reinforced concrete<br />

clinkers/ natural stone<br />

asphalt / poroton/ lime sand-stone<br />

tiles<br />

AR-STANDARD GENERATION 2<br />

+<br />

order-No.<br />

Ø<br />

segment No. of bore hole<br />

mm W x H x L mm segments mm<br />

10000034 115 2,2 x 10 x 31 9 22,23<br />

10000047 125 2,2 x 10 x 31 10 22,23<br />

10000057 150 2,4 x 10 x 32 12 22,23<br />

10000063 180 2,4 x 10 x 33 14 22,23<br />

10000073 230 2,4 x 10 x 38 16 22,23<br />

10000097 300 2,8 x 10 x 40 20 20/25,4<br />

10000115 350 3,2 x 10 x 40 24 20/25,4<br />

10000136 400 3,6 x 10 x 38 28 20/25,4<br />

10000142 450 3,6 x 10 x 38 32 25,4<br />

10000148 500 3,6 x 10 x 38 36 25,4<br />

10000154 600 4,2 x 10 x 38 42 25,4<br />

10000158 700 4,2 x 10 x 38 42 25,4<br />

• concrete, reinforced concrete, washed-out concrete, artifi cial and<br />

natural stone, concrete full brick, curb stones, paving concrete<br />

• universal blade with high cutting speed and long life<br />

AR-SUPER GENERATION 2<br />

+<br />

•concrete, reinforced concrete, washed-out concrete, artifi cial and natural stone, concrete full brick, curb stones, paving concrete<br />

• premium blade with very high cutting speed and very long life<br />

order-No.<br />

Ø segment No. of bore hole<br />

mm W x H x L mm segments mm<br />

10000074 230 2,4 x 12 x 36 16 22,23<br />

10000084 250 2,4 x 12 x 36 18 25,4<br />

10000098 300 2,8 x 12 x 40 20 20/25,4<br />

10000124 350 3,2 x 12 x 38 24 20/25,4<br />

10000137 400 3,6 x 12 x 38 28 20/25,4<br />

10000143 450 3,6 x 12 x 38 32 25,4<br />

10000149 500 3,6 x 12 x 38 36 25,4<br />

10000155 600 4,2 x 12 x 38 42 25,4<br />

6

CEDIMA DIAMOND SAW BLADES<br />

Brilliant Performance<br />

A1-SUPER TURBO<br />

+<br />

• concrete, reinforced concrete, artifi cial stone, natural stone,<br />

hard clinkers, grey cast iron<br />

•premium blade with very high cutting speed<br />

order-No.<br />

Ø<br />

segment No. of bore hole<br />

mm W x H x L mm segments mm<br />

10000029 115 2,4 x 12 x 31 9 22,23<br />

10000043 125 2,4 x 12 x 31 10 22,23<br />

10000048 150 2,4 x 12 x 32 12 22,23<br />

10000059 180 2,4 x 12 x 33 14 22,23<br />

10000019 230 2,6 x 12 x 40 16 22,23<br />

10000102 300 2,8 x 12 x 40 20 25,4/20<br />

10000127 350 3,2 x 12 x 40 24 25,4/20<br />

10000140 400 3,6 x 12 x 40 28 25,4/20<br />

10000141 450 3,6 x 12 x 40 32 25,4<br />

10000150 500 3,6 x 12 x 38 36 25,4<br />

10000157 600 4,2 x 12 x 38 42 25,4<br />

SYNCRO GRANIT<br />

+<br />

• main application: granite of all sorts<br />

concrete, reinforced concrete, concrete products, clinkers, general construction materials<br />

•premium-saw blade with very high cutting speed<br />

•noise damped<br />

NEW!<br />

order-No.<br />

Ø<br />

segment No. of bore hole<br />

mm W x H x L mm segments mm<br />

10000202 115 2,2 x 10 x 32 9 22,23<br />

10000209 125 2,2 x 10 x 32 10 22,23<br />

10000225 180 2,2 x 10 x 32 12 22,23<br />

10000238 230 2,2 x 10 x 32 14 22,23<br />

10000244 300 2,6 x 10 x 40 16 20/25,4<br />

10000259 350 3,2 x 10 x 40 20 20/25,4<br />

10000265 400 3,2 x 10 x 40 23 25,4<br />

10000266 450 3,2 x 10 x 40 27 25,4<br />

10000272 500 3,6 x 10 x 40 30 25,4<br />

10000274 600 3,6 x 10 x 40 36 25,4<br />

TURBO 2009 „EXTRA THIN“<br />

+<br />

• concrete, hard clinkers, hard natural and artifi cial stones,<br />

profi le sheets, ceramics, vitreous refractory material<br />

•universal blade with very high cutting speed<br />

order-No.<br />

Ø<br />

segment<br />

bore hole<br />

mm W x H x L mm<br />

mm<br />

10000027 115 1,2 x 10 turbo ring 22,23<br />

10000041 125 1,2 x 10 turbo ring 22,23<br />

10000053 150 1,4 x 10 turbo ring 22,23<br />

10000062 180 1,6 x 10 turbo ring 22,23<br />

10000072 230 1,8 x 10 turbo ring 22,23<br />

10000086 250* 1,8 x 10 turbo ring 22,23<br />

10000085 250* 1,8 x 10 turbo ring 25,4<br />

10000091 300* 2,0 x 10 turbo ring 20/25,4<br />

10000105 350* 2,2 x 10 turbo ring 20/25,4<br />

*not for hand-held machines<br />

7

CEDIMA DIAMOND SAW BLADES<br />

Brilliant Performance<br />

CA-ECO ASPHALT (LASER)<br />

+<br />

order-No.<br />

Ø<br />

segment No. of bore hole<br />

mm W x H x L mm segments mm<br />

10000033 115 2,1 x 10 x 32 9 22,23<br />

10000046 125 2,1 x 10 x 32 10 22,23<br />

10000056 150 2,2 x 10 x 31 12 22,23<br />

10000065 180 2,3 x 10 x 33 14 22,23<br />

10000078 230 2,4 x 10 x 40 16 22,23<br />

10000089 300 2,8 x 10 x 40 18 20/25,4<br />

10000119 350 3,2 x 10 x 40 21 20/25,4<br />

10000138 400 3,2 x 10 x 40 24 20/25,4<br />

10000146 450 3,6 x 10 x 40 26 25,4<br />

10000152 500 4,2 x 10 x 40 30 25,4<br />

10000156 600 4,2 x 10 x 40 36 25,4<br />

• asphalt, lime sand-stone and other abrasive materials<br />

• long life<br />

• with diamond protective segments<br />

CA-3 STANDARD WITH DIAMOND PROTECTIVE SEGMENTS<br />

+<br />

order-No.<br />

Ø<br />

segment No. of bore hole<br />

mm W x H x L mm segments mm<br />

10000030 115 2,0 x 9 x 32 9 22,23<br />

10000044 125 2,0 x 9 x 32 10 22,23<br />

10000054 150 2,0 x 9 x 32 12 22,23<br />

10000055 180 2,4 x 9 x 32 14 22,23<br />

10000075 230 2,4 x 9 x 40 16 22,23<br />

10000094 300 3,0 x 9 x 40 18 25,4/20<br />

10000110 350 3,2 x 9 x 40 20 25,4/20<br />

10000132 400 3,6 x 9 x 40 24 25,4/20<br />

10000144 450 3,6 x 9 x 40 27 25,4<br />

10000151 500 3,6 x 9 x 40 30 25,4<br />

10000153 600 4,2 x 9 x 40 36 25,4<br />

• abrasive materials like asphalt, fl oor fi nsch, lime sand stone<br />

(gross density < 2), Poroton, refractory material porous,<br />

aerated concrete, sand stone, clay bricks<br />

TSCE-POROTON-KS<br />

• poroton, aerated concrete, high density lime sand-stone, abrasive natural stones<br />

• universal blade for table sawing for abrasive materials<br />

order-No.<br />

Ø<br />

segment No. of bore hole<br />

mm W x H x L mm segments mm<br />

10000013 650 3,6 x 10 x 40 36 35/25,4<br />

10000015 700 3,6 x 10 x 40 36 60/55<br />

10000017 900 4,4 x 10 x 38 52 60/55<br />

10000343 1000 4,4 x 10 x 40 56 60/55<br />

8

CEDIMA DIAMOND SAW BLADES<br />

Brilliant Performance<br />

FLIESE PREMIUM (CONTINUOUS CUTTING RIM)<br />

• tiles, glazed tiles, ceramics, stoneware, refractory material vitreous<br />

• premium blade with very good cutting speed and excellent quality of<br />

cutting edges<br />

order-No.<br />

Ø<br />

segment bore hole<br />

mm<br />

W x H mm<br />

mm<br />

10000020 110 1,5 x 5,5 22,23<br />

10000021 115 1,5 x 7 22,23<br />

10000036 125 1,5 x 7 22,23<br />

10000050 150 1,6 x 7 22,23<br />

10000058 180 1,6 x 7 22,23<br />

10000066 200 1,6 x 7 22,23<br />

10000079 230 1,7 x 7 22,23<br />

10000083 250 1,8 x 7 25,4<br />

10000087 300 2,0 x 7 25,4<br />

10000103 350 2,2 x 7 25,4<br />

+<br />

AR-DUAL<br />

+<br />

• concrete and asphalt, other hard or abrasive materials<br />

• universal blade with high cutting speed and life<br />

• with diamond protective segments<br />

order-No.<br />

Ø<br />

segment No. of bore hole<br />

mm W x H x L mm segments mm<br />

10000100 300 3,2 x 10 x 50 16 20/25,4<br />

10000120 350 3,2 x 10 x 50 19 20/25,4<br />

10000139 400 3,6 x 10 x 50 22 20/25,4<br />

REDUCER RINGS FOR DIAMOND SAW BLADES<br />

order-No. outer-Ø mm inner-Ø mm width mm<br />

10001104 22,23 20 1,6<br />

10001102 25,4 20 2,0<br />

10001103 25,4 20 2,4<br />

10001107 25,4 20 9,0<br />

order-No. outer-Ø mm inner-Ø mm width mm<br />

10001105 25,4 22,23 1,6<br />

10001109 30 25,4 2,8<br />

10001106 35 25,4 2,8<br />

10001110 35 25,4 3,5<br />

9

Brilliant Performance<br />

CEDIMA DIAMOND TOOLS<br />

special applications<br />

CST-SATURN STANDARD<br />

order-No.<br />

Ø<br />

mm<br />

No. of<br />

segments<br />

bore hole<br />

mm<br />

10003564 100 16 22,23<br />

10003567 115 15 22,23<br />

10003571 125 16 22,23<br />

10003577 180 24 22,23<br />

• for grinding and smoothing of concrete, clinkers,<br />

natural stone and other hard surfaces<br />

• grinding disc with large suction openings and<br />

long life<br />

CST-SATURN SUPER<br />

order-No.<br />

Ø<br />

mm<br />

segment<br />

version<br />

No. of<br />

segments<br />

bore hole<br />

mm<br />

10003562 100 turbo layer 2 x 23 22,23<br />

10003566 115 turbo layer 2 x 26 22,23<br />

10003569 125 turbo layer 2 x 28 22,23<br />

10003576 180 turbo layer 2 x 40 22,23<br />

•for grinding and smooting of concrete, clinkers,<br />

natural stone and other hard surfaces<br />

• grinding disc with 2 segment layers and very<br />

long life<br />

CST-SATURN<br />

order-No.<br />

Ø<br />

mm<br />

segment<br />

W x H x L mm<br />

No. of<br />

segments<br />

bore hole<br />

mm<br />

10003596 115 5,5 x 7 x 30 18 22,23<br />

10003599 125 5,0 x 7 x 30 20 22,23<br />

10003605 180 5,5 x 7 x 35 22 22,23<br />

• for grinding and smooting of concrete, clinkers,<br />

natural stone and other hard surfaces<br />

• grinding disc in double row version<br />

CST-SATURN ABRASIV (2-ROWS)<br />

order-No.<br />

Ø<br />

mm<br />

segment<br />

W x H x L mm<br />

No. of<br />

segments<br />

bore hole<br />

mm<br />

10003563 100 5,0 x 7 x 30 12 22,23<br />

10003568 115 5,5 x 7 x 30 18 22,23<br />

10003572 125 5,0 x 7 x 30 20 22,23<br />

10003578 180 5,5 x 7 x 35 22 22,23<br />

• for grinding and smoothing of fl oor fi nish<br />

and other abrasive surfaces<br />

10

CEDIMA DIAMOND TOOLS<br />

special applications<br />

Brilliant Performance<br />

CST-POLYMER<br />

• for grinding of polymer coatings and other hard surfaces<br />

Ø<br />

segment No. of bore hole<br />

order-No.<br />

mm W x H x L mm segments mm<br />

10003570 125 7 x 5 x 20 10 22,23<br />

CST-MERKUR (MOUNTING TYPE H)<br />

•for grinding and smoothing of concrete, clinker, natural stone and other abrasive surfaces<br />

•machine mounting type H with 19 mm centre bore and 5 secondary holes<br />

order-No.<br />

Ø<br />

mm<br />

10003575 150<br />

segment<br />

W x H x L mm<br />

7,5 x 6,5 x 35<br />

7,5 x 6,5 x 15<br />

No. of<br />

segments<br />

10<br />

10<br />

bore hole<br />

mm<br />

19 + 5-Loch<br />

CST-MERKUR ABRASIV (MOUNTING TYPE H)<br />

•for grinding and smoothing of fl oor fi nish and other abrasive surfaces<br />

•machine mounting type H with 19 mm centre bore and 5 secondary holes<br />

order-No.<br />

Ø<br />

mm<br />

10003574 150<br />

segment<br />

W x H x L mm<br />

7,5 x 6,5 x 35<br />

7,5 x 6,5 x 15<br />

No. of<br />

segments<br />

10<br />

10<br />

bore hole<br />

mm<br />

19 + 5-Loch<br />

CNF-ASPHALT<br />

•for creating grooves in asphalt surfaces<br />

order-No. Ø mm No. of segments bore hole mm<br />

10003552 150 20 25,4<br />

11

Brilliant Performance<br />

CEDIMA DIAMOND TOOLS<br />

special applications<br />

CR-STANDARD<br />

• for widening unintentional cracks in concrete, with hand-held machines<br />

order-No.<br />

Ø<br />

mm<br />

segment<br />

W x L x H mm<br />

No. of<br />

segments<br />

bore hole<br />

mm<br />

10003548 110 9,5 x 12 x 30 8 22,23<br />

CMR-STANDARD<br />

•for removing mortar out of wall joints, high feed speed, with hand-held machines<br />

order-No.<br />

Ø<br />

mm<br />

segment<br />

W x L x H mm<br />

No. of<br />

segments<br />

bore hole<br />

mm<br />

10003547 115 6,4 x 10 x 16 12 22,23<br />

10003549 125 6,4 x 10 x 16 14 22,23<br />

DIAMOND CUTTING RINGS AND ACCESSORIES FOR RING SAWS<br />

concrete, reinforced concrete, asphalt, aerated concrete, masonry<br />

order-No. type application in<br />

30000448 red abrasive materials such as asphalt, aerated concrete or masonry<br />

30000449 blue<br />

concrete and reinforced concrete with soft aggregates<br />

and low shares of reinforcement<br />

30000450 yellow<br />

concrete and reinforced concrete with medium-hard<br />

aggregates and high shares of reinforcement<br />

70006970 drive wheel for K-3500<br />

70009072 drive wheel for K-3600<br />

drive wheel K-3600<br />

drive wheel K-3500<br />

12

13<br />

Table saws

CEDIMA- TABLE SAWS<br />

Brilliant Performance<br />

CTS-56 and CTS-57 G are table saws for cutting quickly and precisely concrete, bricks, clinkers, natural stone and similar materials.<br />

The combination of stability and technical details make them ideal equipment for daily use.<br />

CTS-56<br />

order-No. 30000207<br />

CTS-57 G<br />

order-No. 30000208<br />

• powerful blade drive motors<br />

• fi xable swivel cutting head, adjustable for mitre cuts<br />

from 0° to 45°<br />

• smooth-running roller table with adjustable lateral stop<br />

• supply with cooling water by electrical water pump and<br />

simple cleaning by combination of water container with<br />

overfl ow plug and bucket<br />

• easy transport and loading by removable plug-in feet,<br />

transport rollers, carrying handles and crane eyes<br />

technical data CTS-56* CTS-57 G*<br />

max. cutting depth mm 130 125<br />

max. cutting length mm 600 600<br />

max. blade-Ø mm 400 400<br />

bore hole of blade mm 25,4 25,4<br />

speed of cutting shaft rpm 2770 2770<br />

drive motor kW/V/Hz 2,2/230/50 2,2/230/50<br />

protective system - IP54 IP54<br />

contents water container/bucket litres 35 35<br />

dimensions L/W/H mm 1180/600/600 1140/580/730<br />

weight kg 70 74<br />

sound pressure level db(A) 69,8 69,8<br />

sound power level db(A) 88,5 88,5<br />

*400 V version on request<br />

Loading and transport<br />

For transport unlatch the feet and swivel them<br />

up below the water container. For simple loading<br />

in a vehicle, place the wheels into the provided<br />

receptacles at the cross bar.<br />

Thus the saw can be placed onto the loading<br />

platform and pushed without diffi culty.<br />

14

CEDIMA-TABLE SAWS<br />

Brilliant Performance<br />

CTS-175.1 (230 V)<br />

order-No. 30000217<br />

230 V drive motor<br />

•powerful drive motor with 230<br />

•infi nitely height-adjustable and lockable cutting head<br />

•smooth-running roller table with measuring scala<br />

and adjustable lateral stop<br />

• fold-away feet, handles on both sides<br />

•ring eyes and transport rollers<br />

•water pump in bucket or water container with overfl ow plug<br />

technical data CTS-175.1 (230 V) CTS-200 (400 V)<br />

max. cutting depth mm 175 200<br />

max. cutting length mm 610 610<br />

blade-Ø max. mm 450 500<br />

bore hole of blade mm 25,4 25,4<br />

speed of cutting shaft rpm 1980 1935<br />

drive motor kW/V/Hz 3,0/230/50 4,0/400/50<br />

protective system - IP54 IP54<br />

contents water container/bucket litres 35/ 20 35/ 20<br />

dimensions L/W/H mm 1180/600/600 1180/600/600<br />

weight kg 85 85<br />

sound pressure level db(A) 69,8 69,8<br />

sound power level db(A) 88,5 88,5<br />

CTS-200<br />

order-No. 30000239<br />

400 V drive motor<br />

• Mounting of saw blades up to 500 mm blade diameter<br />

for cutting depth to 200 mm<br />

•powerful drive motor with 400 V<br />

•presice, infi nitely adjustable swivel cutting head<br />

•smooth-running roller table with measuring scale and adjustable lateral stop<br />

• fold-away feet, handles on both sides<br />

•ring eyes and transport rollers<br />

•water pump in bucket or water container with overfl ow plug<br />

NEW!<br />

15

CEDIMA- TABLE SAWS<br />

Brilliant Performance<br />

CTS-26 CTS-26 L CTS-26 XL<br />

order-No. 30000206 order-No. 30000204 order-No. 30000205<br />

Table Saws of CTS-26 series are very robust and durable cutting machines for the application in tiles, glazed tiles or thin natural stone plates.<br />

The XL-version enables the cutting of large glazed tiles up to 80 x 80 cm feed size without any problems.<br />

•insertable table with rubber mat<br />

•precise sliding cutting head<br />

•adjustable guide rail for mitre cuts from 0° to 45°<br />

•water pump in water container or bucket<br />

•splash guard at 3 sides of the machine<br />

•easy transport due to removable slide-in feet<br />

•l ateral side table for cutting of long work pieces is<br />

optionally available<br />

technical data CTS-26 CTS-26 L CTS-26 XL<br />

max. cutting depth mm 65 65 65<br />

max. cutting length mm 650 850 1150<br />

max. blade-Ø mm 250 250 250<br />

bore hole of blade mm 25,4 25,4 25,4<br />

speed of cutting shaft rpm 2770 2770 2770<br />

drive motor kW/V/Hz 1,1/ 230/50 1,1/230/50 1,1/230/50<br />

protective system - IP54 IP54 IP54<br />

contents water container litres 18/20 20/20 25/20<br />

dimensions L/W/H mm 1040/480/480 1240/480/480 1530/480/480<br />

weight kg 58 70 76<br />

sound pressure level db(A) 78 78 78<br />

sound power level db(A) 96 96 96<br />

16<br />

All prices ex works Celle

CEDIMA-TABLE SAWS<br />

Brilliant Performance<br />

CTS-81* CTS-81 L* CTS-81 XL*<br />

order-No. 30000213 order-No. 30000214 order-No. 30000215<br />

Table saws of CTS-81 series universal cutting machines for job sites. With their infi nitely adjustable, precise and smooth-running swivel cutting heads they<br />

guarantee fatigue-free working. For mitre cuts the guide rail of the saws can be adjusted infi nitely from 0° to 45°. Due to the large cutting length the<br />

saws are especially suitable for cutting large-sized stone slabs<br />

•adjustable guide rail for mitre cuts<br />

•precise, infi nitely adjustable swivel cutting head<br />

•handles and removable slide-in feet<br />

•insertable table with rubber mats<br />

•splash guard at 3 sides of the machine<br />

•fi nal stop and adjustable lateral stop<br />

• lateral side table for cutting of long work pieces is<br />

optionally available<br />

technical data CTS-81 CTS-81 L CTS-81 XL<br />

max. cutting depth mm 130 130 110<br />

max. cutting length mm 850 1250 1640<br />

max. blade-Ø mm 400 400 350<br />

bore hole of blade mm 25,4 25,4 25,4<br />

speed of cutting shaft rpm 2770 2770 2770<br />

drive motor kW/V/Hz 2,2/230/50 2,2/230/50 2,2/230/50<br />

protective system - IP54 IP54 IP54<br />

contents water container litres 25/20 35/20 45/20<br />

dimensions L/W/H mm 1150/670/(610/1270) 1550/670/(610/1270) 1950/670/(610/1270)<br />

weight kg 78 94 110<br />

sound pressure level db(A) 81,4 81,4 81,4<br />

sound power level db(A) 96,5 96,5 96,5<br />

technical data<br />

All prices ex works Celle<br />

17

CEDIMA- TABLE SAWS<br />

Brilliant Performance<br />

Block saws are designed for cutting large-sized blocks made of concrete, Poroton or lime sand-stone.<br />

With the models CTS-265 and CTS-375.2 CEDIMA enables the operator on the job site to separate stones quickly and precisely.<br />

CTS-265<br />

order-No. 30000224<br />

CTS-265<br />

•powerful three-phase motor<br />

•swivel cutting head<br />

•removable water container of stainless steel, easy cleaning<br />

•roller table with feed bar<br />

•water pump in water container<br />

•splash guard<br />

•lockable steering wheels and extra large running wheels for easy transport<br />

•ring eyes for easy relocation on the job site<br />

CTS-375.2<br />

order-No. 30000227<br />

CTS-375.2<br />

•infi nitely height-adjustable and lockable cutting head<br />

•feed by lateral hand wheel for comfortable handling<br />

•removable water container, easy cleaning<br />

•lockable steering wheels<br />

•splash guard<br />

•galvanised steel water container<br />

•ring eyes for easy relocation on the job site<br />

•angular stop<br />

•ball bearing swivel head<br />

technical data CTS-265 CTS-375.2<br />

max. cutting depth mm 265 425<br />

max. cutting length mm 500 960<br />

max. blade-Ø mm 650 1000<br />

bore hole of blade mm 25,4 60<br />

speed of cutting shaft rpm 1420 1072<br />

drive motor kW/V/Hz 5,5/400/50 7,5/400/50<br />

protective system - IP54 IP54<br />

contents water container litres 50 110<br />

L/W/H mm 1700/800/1520 1800/1100/1500<br />

weight kg 200 300<br />

sound pressure level db(A) 87 86<br />

sound power level db(A) 104,9 111<br />

18

ACCESSORIES FOR TABLE SAWS<br />

Brilliant Performance<br />

jolly table for mitre cuts angle stop with scale prism for cutting round objects<br />

CEP- electric immersion pump<br />

auxiliary table with rubber mat<br />

order-No. operation with description<br />

30000228 CTS-56, CTS-175.1, CTS-200 jolly table for mitre cuts, pivoting by 45° on both sides, with angle scale<br />

30000201<br />

CTS-56, CTS-57 G,<br />

CTS-26 series, CTS-81 series,<br />

CTS-175.1, CTS-200<br />

angle stop with scale<br />

30000225<br />

CTS-56, CTS-57 G,<br />

CTS-81, CTS-175.1, CTS-200<br />

30000202 CTS-26, CTS-81 Serie<br />

prism for cutting round objects, with rubber mat against torsion<br />

auxiliary table with rubber mat for cutting long objects, 614 x 586 mm,<br />

with lay-on edge and slide-in feet<br />

70008154<br />

CTS-56, CTS-57 G,<br />

CTS-26 series, CTS-81 series,<br />

CTS-175.1, CTS-200<br />

electric immersion pump CEP-700 (without connecting plug*)<br />

technical details: 230 V; 50 Hz; 0,4 AMP; 50 W; • protective system: ISO-F IP X8<br />

feed rate: 11,6 l/min • lifting height: 1,5 m<br />

length of supply: 4 m • dimensions: 71 x 95 x 108 mm<br />

70008155 CTS-265, CTS-375.2<br />

electric immersion pump CEP-1600 (without connecting plug*)<br />

technical details: 230 V; 50 Hz; 0,7 AMP; 60 W • protective system: ISO-F IP X8<br />

feed rate: 25 l/min • lifting height: 2,5 m<br />

length of supply: 4 m • dimensions: 71 x 95 x 123 mm<br />

*connecting plug only to be attached by a qualifi ed employee<br />

19

Brilliant Performance<br />

DIAMOND SAW BLADES<br />

for table saws<br />

Recommendation:<br />

CEDIMA offers a wide range of optimal diamond saw blades for the use on CEDIMA-table saws.<br />

In the following you fi nd a selected list for the use of most suitable diamond saw blades.<br />

AR-STANDARD GENERATION 2<br />

• concrete, reinforced concrete, washed-out concrete, artifi cial and<br />

natural stone, concrete full brick, curb stones, paving concrete<br />

• universal blade with high cutting speed and long life<br />

order-No.<br />

Ø<br />

segment No. of bore hole<br />

mm W x H x L mm segments mm<br />

10000097 300 2,8 x 10 x 40 20 20/25,4<br />

10000115 350 3,2 x 10 x 40 24 20/25,4<br />

10000136 400 3,6 x 10 x 38 28 20/25,4<br />

10000142 450 3,6 x 10 x 38 32 25,4<br />

10000148 500 3,6 x 10 x 38 36 25,4<br />

+<br />

AR-SUPER GENERATION 2<br />

•concrete, reinforced concrete, washed-out concrete, artifi cial and<br />

natural stone, concrete full brick, curb stones, paving concrete<br />

• premium blade with very high cutting speed and very long life<br />

order-No.<br />

Ø<br />

segment No. of bore hole<br />

mm W x H x L mm segments mm<br />

10000084 250 2,4 x 12 x 36 18 25,4<br />

10000098 300 2,8 x 12 x 40 20 20/25,4<br />

10000124 350 3,2 x 12 x 38 24 20/25,4<br />

10000137 400 3,6 x 12 x 38 28 20/25,4<br />

10000143 450 3,6 x 12 x 38 32 25,4<br />

10000149 500 3,6 x 12 x 38 36 25,4<br />

+<br />

A1-SUPER TURBO<br />

+<br />

•concrete, reinforced concrete, artifi cial stone, natural stone, hard clinkers, grey cast iron<br />

•premium blade with very high cutting speed<br />

order-No.<br />

Ø<br />

segment No. of bore hole<br />

mm W x H x L mm segments mm<br />

10000102 300 2,8 x 12 x 40 20 20/25,4<br />

10000127 350 3,2 x 12 x 40 24 20/25,4<br />

10000140 400 3,6 x 12 x 40 28 20/25,4<br />

10000141 450 3,6 x 12 x 40 32 25,4<br />

10000150 500 3,6 x 12 x 38 36 25,4<br />

20

DIAMOND SAW BLADES<br />

for table saws<br />

Brilliant Performance<br />

SYNCRO GRANIT<br />

order-No.<br />

Ø<br />

segment No. of bore hole<br />

mm W x H x L mm segments mm<br />

10000244 300 2,6 x 10 x 40 16 20/25,4<br />

10000259 350 3,2 x 10 x 40 20 20/25,4<br />

10000265 400 3,2 x 10 x 40 23 25,4<br />

10000266 450 3,2 x 10 x 40 27 25,4<br />

10000272 500 3,6 x 10 x 40 30 25,4<br />

• main application: granite of all sorts - concrete, reinforced concrete,<br />

concrete products, clinkers, general construction materials<br />

•premium-saw blade with very high cutting speed<br />

•noise damped<br />

+<br />

NEW!<br />

TURBO 2009 „EXTRA THIN“<br />

+<br />

order-No.<br />

Ø segment<br />

bore hole<br />

mm W x H x mm<br />

mm<br />

10000086 250* 1,8 x 10 turbo ring 22,23<br />

10000085 250* 1,8 x 10 turbo ring 25,4<br />

10000091 300* 2,0 x 10 turbo ring 25,4/20<br />

10000105 350* 2,2 x 10 turbo ring 25,4/20<br />

*not for hand-held machines<br />

• concrete, hard clinkers, hard natural and artifi cial stones, profi le<br />

sheets, ceramics, vitreous refractory material<br />

•universal blade with very high cutting speed<br />

FLIESE PREMIUM (CONTINUOUS CUTTING RIM)<br />

order-No. Ø mm segment W x H mm bore hole mm<br />

10000083 250 1,8 x 7 25,4<br />

10000087 300 2,0 x 7 25,4<br />

10000103 350 2,2 x 7 25,4<br />

• tiles, glazed tiles, ceramics, stoneware, refractory material vitreous<br />

• premium blade with very good cutting speed and excellent quality of<br />

cutting edges<br />

+<br />

AR-DUAL<br />

order-No.<br />

Ø<br />

segment No. of bore hole<br />

mm W x H x L mm segments mm<br />

10000100 300 3,2 x 10 x 50 16 20/25,4<br />

10000120 350 3,2 x 10 x 50 19 20/25,4<br />

10000139 400 3,6 x 10 x 50 22 20/25,4<br />

• concrete and asphalt, other hard or abrasive materials<br />

• universal blade with high cutting speed and life<br />

• with diamond protective segments<br />

+<br />

21

Brilliant Performance<br />

DIAMOND SAW BLADES<br />

für table saws<br />

CA-ECO ASPHALT (LASER)<br />

• asphalt, lime sand-stone and other abrasive materials<br />

• long life<br />

• with diamond protective segments<br />

order-No.<br />

Ø<br />

segment No. of bore hole<br />

mm W x H x L mm segments mm<br />

10000088 300 2,8 x 10 x 40 18 20<br />

10000089 300 2,8 x 10 x 40 18 25,4<br />

10000113 350 3,2 x 10 x 40 21 20<br />

10000119 350 3,2 x 10 x 40 21 25,4<br />

10000134 400 3,2 x 10 x 40 24 20<br />

10000138 400 3,2 x 10 x 40 24 25,4<br />

10000146 450 3,6 x 10 x 40 26 25,4<br />

10000152 500 4,2 x 10 x 40 30 25,4<br />

+<br />

CA-3 STANDARD WITH DIAMOND PROTECTIVE SEGMENTS<br />

+<br />

• abrasive materials like asphalt, fl oor fi nisch, lime sand stone (gross density < 2), Poroton,<br />

refractory material porous, aerated concrete, sand stone, clay bricks<br />

order-No.<br />

Ø<br />

segment No. of bore hole<br />

mm W x H x L mm segments mm<br />

10000094 300 3,0 x 9 x 40 18 25,4/20<br />

10000110 350 3,2 x 9 x 40 20 25,4/20<br />

10000132 400 3,6 x 9 x 40 24 25,4/20<br />

10000144 450 3,6 x 9 x 40 27 25,4<br />

10000151 500 3,6 x 9 x 40 30 25,4<br />

TSCE-POROTON-KS<br />

• poroton, aerated concrete, high density lime sand-stone, abrasive natural stones<br />

• universal blade for table sawing for abrasive materials<br />

order-No.<br />

Ø<br />

segment No. of bore hole<br />

mm W x H x L mm segments mm<br />

10000013 650 3,6 x 10 x 40 36 35/25,4<br />

10000015 700 3,6 x 10 x 40 36 60/55<br />

10000017 900 4,4 x 10 x 38 52 60/55<br />

10000343 1000 4,4 x 10 x 40 56 60/55<br />

22

Joint Cutters

CEDIMA-JOINT CUTTERS<br />

Brilliant Performance<br />

CEDIMA Joint Cutters<br />

You will come across joint cutters made by CEDIMA in road and highway construction or<br />

in the restoration of industrial fl oors. They are essential for cutting fl oors and ceilings<br />

made of concrete or asphalt by means of diamond saw blades. For many years CEDIMA<br />

joint cutters have been proving their effi ciency on many national and international<br />

construction sites. A wide range of different types of machines and motors ensure the<br />

best possible technical equipment for any kind of cutting operation. Joint cutters are<br />

driven either by powerful petrol, diesel or electric motors. Drive output is fi tted to the<br />

maximum cutting depth and the diamond tools.<br />

CEDIMA is always working to optimize and expand the technical performance of joint<br />

cutters in order to guarantee the operator comfortable working with excellent results.<br />

Therefore our qualifi ed staff check and control constantly the cutting performance on<br />

our test course.<br />

Cutting depth overview on Cedima-joint cutters<br />

dieseldriven joint cutters<br />

petroldriven joint cutters<br />

CF-2015 B<br />

240<br />

CF-3100 D<br />

500<br />

CF-1010 B<br />

200<br />

CF-6020<br />

480<br />

CF-2500 D<br />

350<br />

CF-13 B<br />

170<br />

CF-2116 D<br />

300<br />

CF-7.1 B<br />

150<br />

CF-2011 DE<br />

240<br />

0 50 100 150 200 250 300<br />

electrically operated joint cutters<br />

CF-1010 D<br />

200<br />

CF-50.2 E<br />

500<br />

CF-2800 D<br />

170<br />

green concrete<br />

CF-2015 E<br />

350<br />

CF-2500 D<br />

170<br />

green concrete<br />

CF-22 E<br />

270<br />

CF-13 D<br />

170<br />

CF-13 E<br />

170<br />

0 100 200 300 400 500 600<br />

CF-13 E-TR<br />

120<br />

0 100 200 300 400 500 600<br />

24

CEDIMA-JOINT CUTTERS<br />

small range<br />

Brilliant Performance<br />

CF-7.1 B CF-13 B CF-13 D<br />

order-No. 30000032 order-No. 30000949 order-No. 30000950<br />

New feature of CF-13 B/D:<br />

Saw blade mounting possible<br />

on both sides<br />

Due to its compact construction and low weight the<br />

CF-7.1 B is especially suitable for cutting jobs in narrow<br />

surroundings or areas diffi cult to access.<br />

• low-speed motor layout for large cutting depth<br />

(150 mm with blade-Ø 400 mm)<br />

• very easy transport due to compact design and<br />

low weight<br />

• possibility of mounting a second water container<br />

directly over the cutting shaft, thereby up to 44 l<br />

cooling water for extra long cutting periods<br />

The joint cutters CF-13 B and CF-13 D are prefarably used in landscape gardening or for easy<br />

tasks in road construction. Its simple handling and compact size recommend the machine for<br />

rental business. The adjustment of cutting depth is regulated by hand wheel, lifting by a lowmaintenance<br />

balance. The operating handle is rubber mounted and especially low in vibration.<br />

The large water container of pressurized water provide the supply of water.<br />

•modern cyclone air fi lter for long maintenance rates<br />

•large water container with ergonomic recessed grip<br />

•ring eye for loading<br />

•extendable handle for relocating the machine manually<br />

•adjustable cutting depth indicator and locking brake<br />

technical data CF-7.1 B CF-13 B CF-13 D<br />

max. cutting depth mm 150 170 170<br />

blade-Ø from - to mm 350 - 400 300 - 450 300 - 450<br />

bore hole of blade mm 25,4 25,4 25,4<br />

blade mounting lateral left right or left right or left<br />

max. mounting width mm 10 13 13<br />

speed of cutting shaft rpm 2240 2400 2360<br />

motor output (net) kW 4,1 8,7 4,6<br />

motor type petrol Honda GX-200 Honda GX-390 -<br />

motor type diesel - - Hatz 1B30<br />

motor starter - reversing start reversing start reversing start<br />

cutting depth adjustment - lever hand crank hand crank<br />

feed - manual manual manual<br />

contents water container l 22 23 23<br />

dimensions L/W/H mm 1050/520/800 820/520/870 820/520/870<br />

weight kg 61 93 106<br />

sound pressure level dB (A) 85,6 94 94,5<br />

sound power level dB (A) 102 110 111<br />

25

Brilliant Performance<br />

CEDIMA-JOINT CUTTERS<br />

small range<br />

CF-1010 B<br />

CF-1010 D<br />

order-No. 30000044 order-No. 30000047<br />

Despite their compact dimensions the joint cutters CF-1010 B and CF-1010 D are able to achieve a cutting depth up to 200 mm. Due to the extremely low<br />

assembly position of the drive motor the balance point of the machines has strongly been relocated downwards, thus achieving a high steadiness.<br />

•200 mm cutting depth with blade-Ø 500 mm<br />

•Honda GX- 390 with oil-shortage switch and cyclone fi lter (CF-1010 B)<br />

•high manoeuvrability due to extra large running wheels (Ø 200 mm)<br />

•high steadiness due to extremely deep balance point<br />

• water container to be swivelled aside for fi lling in fuel<br />

•removable water container with extra large fi lling opening<br />

•well dimensioned hand wheel for precise cutting depth adjustment<br />

•mounting of saw blade on right or left side<br />

•comfortable blade mounting by hinged blade guard<br />

• ergonomically designed and height-adjustable machine<br />

handle of low vibrations<br />

technical data CF-1010 B CF-1010 D<br />

max. cutting depth mm 200 200<br />

blade-Ø from - to mm 500 500<br />

bore hole of blade mm 25,4 25,4<br />

blade mounting lateral right or left right or left<br />

max. mounting width mm 20 20<br />

speed of cutting shaft rpm 2115 2115<br />

motor output (net) kW 8,7 7,3<br />

motor type petrol Honda GX-390 -<br />

motor type diesel - Hatz 1B40<br />

motor starter - reversing start reversing start<br />

cutting depth adjustment - hand wheel hand wheel<br />

feed - manual manual<br />

contents water container l 30 30<br />

dimensions L/W/H mm 1204/560/890 1204/560/890<br />

weight kg 121 117<br />

sound pressure level dB (A) 92,2 96,6<br />

sound power level dB (A) 107,4 114,5<br />

26

CEDIMA-JOINT CUTTERS<br />

medium range<br />

Brilliant Performance<br />

The joint cutters of series 2000 are equipped with a hydrostatic drive, ensuring a constant feed of the machines during cutting operations and also making<br />

the operator‘s job easier. The large water container (35 l) and the economic water supply to the blade via the cutting shaft (CF-2015 B, CF-2011 DE)<br />

guarantee long working periods free of interruptions.<br />

CF-2015 B<br />

order-No. 30000049<br />

CF-2011 DE<br />

order-No. 30000050<br />

•hydrostatic drive<br />

•height-adjustable handles<br />

•water supply via cutting shaft<br />

•well dimensioned water container<br />

•adjustable cutting depth indicator<br />

•lifting of saw blade via a balance<br />

technical data CF-2015 B CF-2011 DE<br />

max. cutting depth mm 240 240<br />

blade-Ø from - to mm 650 650<br />

bore hole of blade mm 25,4 25,4<br />

blade mounting lateral right or left right or left<br />

max. mounting width mm 20 20<br />

speed of cutting shaft rpm 1930 1710<br />

motor output (net) kW 15 ,5 11<br />

motor type petrol Honda GX-630 -<br />

motor type diesel - Hatz 1D81<br />

motor starter - electric electric<br />

cutting depth adjustment - hand crank hand crank<br />

feed - hydrostatic hydrostatic<br />

contents water container l 35 35<br />

dimensions L/W/H mm 1700/750/1050 1700/750/1050<br />

weight kg 256 314<br />

sound pressure level dB (A) 89,4 94<br />

sound power level dB (A) 110 114<br />

27

Brilliant Performance<br />

CEDIMA-JOINT CUTTERS<br />

medium range<br />

CF-2116 D<br />

order-No. 30000051<br />

CF-2116 D<br />

•hydrostatic drive<br />

•height-adjustable handles<br />

•well dimensioned water container<br />

•adjustable cutting depth indicator<br />

•electro-hydraulic lifting of saw blade via a balance<br />

CF-2500 D<br />

order-No. 30000054<br />

CF-2500 D<br />

•powerful drive motor for best possible cutting performance<br />

•mounting of saw blade on right or left side of machine<br />

•hydraulic cutting depth adjustment via balance<br />

•hydrostatic travel drive and large running wheels<br />

•ring eye for transporting and relocating the machine<br />

•adjustable cutting depth indicator<br />

•hinged blade guard for cuts rigth to wall and edges<br />

•well visible and solid pointer device with 2 points<br />

•height-adjustable handles of low vibrations<br />

technical data CF-2116 D CF-2500 D<br />

max. cutting depth mm 300 350<br />

blade-Ø mm 600 - 800 600 - 900<br />

bore hole of blade mm 25,4 35<br />

blade mounting lateral right or left right or left<br />

max. mounting width mm 20 20<br />

speed of cutting shaft rpm 1400 1250<br />

motor output kW 15,4 23<br />

motor type diesel Hatz 2G40 Deutz D 2011/2<br />

motor starter - electric electric<br />

cutting depth adjustment - electroc-hydraulic electroc-hydraulic<br />

feed - hydrostatic hydrostatic<br />

contents water container l 35 (with water pump) electric impeller pump<br />

dimensions L/W/H mm 1800/750/1050 1660/1020/1430<br />

weight kg 340 656<br />

sound pressure level dB (A) 96 93<br />

sound power level dB (A) 114 114<br />

28

CEDIMA-JOINT CUTTERS<br />

application in green concrete<br />

Brilliant Performance<br />

CF-2500 D green concrete<br />

CF-2800 D green concrete<br />

order-No. 30000117 order-No. 30000060<br />

•rpm adjusted to the operating purpose<br />

•mounting of saw blade on right or left side of machine<br />

•hydraulic cutting depth adjustment via balance<br />

•hydrostatic travel drive and large wheels<br />

•ring eye for easy relocation and transporting of the machine<br />

•hinged blade guard for cuts right to walls and edges<br />

• well visible and solid pointer device with 2 points<br />

•mounting of saw blade on right-hand side of the machine<br />

•adjustable rear axle for precise cut<br />

•water supply from pressure main or water container by self-suction,<br />

electric water pump<br />

•saw blade drive and attachment for slurry suction electrically controllable<br />

•hydrostatic drive and large running wheels<br />

•stationary attachment for slurry suction 4.1<br />

technical data CF-2500 D green concrete CF-2800 D green concrete<br />

max. cutting depth mm 170 170<br />

blade-Ø mm 450 - 500* 350 - 520<br />

bore hole of blade mm 35 25,4<br />

blade mounting lateral right or left right or left<br />

max. mounting width mm 20 20<br />

speed of cutting shaft rpm 2215 2600<br />

motor output kW 23 24,3<br />

motor type diesel Deutz D 2011/2 Hatz 2M 41 Z<br />

motor starter - Elektrostart Elektrostart<br />

cutting depth adjustment - 43 42<br />

feed - hydraulic hydraulic<br />

contents water container l hydrostatic hydrostatic<br />

dimensions L/W/H mm electric impeller pump electric impeller pump<br />

weight kg 1400/1020/1430 1800/1100/1650<br />

sound pressure level dB (A) 638 900<br />

sound power level dB (A) 93 97<br />

Schallleistungspegel dB (A) 114 123<br />

*on customer request available for blade Ø 350 - 400 mm (art.-no. for conversion kit: 3242217550)<br />

The joint cutters CF-2500 D and 2800 D<br />

green concrete are especially designed for<br />

their operating purpose with their shaft<br />

speed (rpm) adapted to the usual small<br />

diameter of green concrete saw blades.<br />

29

Brilliant Performance<br />

CEDIMA-JOINT CUTTERS<br />

large range<br />

CF-3100 D<br />

order-No. 30000957<br />

digital cutting depth display<br />

ergonomically designed,<br />

user friendly cockpit<br />

3-speed gearbox<br />

NEW<br />

steerable rear axles<br />

blade-Ø up to 1200 mm<br />

max. cutting depth up to 500 mm<br />

LED-headlamps<br />

technical data<br />

max. cutting depth:<br />

blade-Ø from - up to:<br />

bore hole of blade:<br />

blade mounting:<br />

speed of cutting shaft:<br />

motor starter:<br />

saw blade drive:<br />

cutting depth:<br />

motor output/ motor type:<br />

feed:<br />

water pump:<br />

dimensions L/W/H:<br />

weight:<br />

500 mm<br />

500 - 1200 mm<br />

35 mm + 6-hole<br />

right or left<br />

940/1380/1940 rpm<br />

electric<br />

hydraulically switchable<br />

hydraulic<br />

49 kW/ Kubota V2607 (diesel)<br />

hydraulic<br />

elektric impeller pump<br />

1600/1200/1100 mm<br />

appor. 1110 kg<br />

The joint cutter CF-3100 D is equipped with the latest technology<br />

and stands for an unique design. The machine can be equipped with a<br />

blade diameter of up to 1200 mm and achieves the enormous cutting<br />

depth of 500 mm.<br />

The full machine coverage achieves a considerable reduction of the sound<br />

level so that comfortable working is guaranteed.<br />

30<br />

All prices ex works Celle

CEDIMA-JOINT CUTTERS<br />

large range<br />

Brilliant Performance<br />

CF-6020<br />

order-No. 30000065<br />

The fully-hydraulic joint cutter CEDIMA CF-6020 is the multi-purpose machine of our joint cutters, characterised by excellent reliability, maximum utility of<br />

power and high operational comfort. For special applications there are various attachments available for cutting joints in asphalt or concrete (refer to next<br />

page). All working functions such as drive of saw blade, cutting depth adjustment, travel drive and steering are carried out by a powerful hydraulic system.<br />

technical data<br />

CF-6020<br />

max. cutting depth mm 480<br />

blade-Ø mm 300 - 1200<br />

bore hole of blade mm 35 + 6-Loch<br />

blade mounting lateral right or left<br />

max. mounting width mm 13<br />

speed of cutting depth rpm 930 - 3000 infi netely<br />

motor output (net) kW 62<br />

motor type diesel Perkins 804-D-33 T<br />

motor starter - electric<br />

max. travel speed m/min 60<br />

cutting depth adjustment - hydraulic<br />

feed - hydraulic<br />

water pump - electric impeller pump<br />

dimensions L/W/H mm 2550/950/1550<br />

weight kg 1300<br />

sound pressure level dB (A) 96<br />

sound power level dB (A) 113<br />

•fully-hydraulic drive of all working functions (drive of cutting shaft,<br />

cutting depth adjustment, feed drive, steering)<br />

•infi nitely adjustable speed of cutting shaft<br />

•various attachments for special applications available<br />

•ergonomically and clearly arranged control elements<br />

•change of blade mounting side by swivelling the cutting shaft motor<br />

to the other side<br />

•serial auxiliary hydraulic for driving an attachment for slurry removal<br />

All prices ex works Celle<br />

31

Brilliant Performance<br />

CEDIMA-JOINT CUTTERS<br />

attachments<br />

Attachments for CF-6020<br />

The fully-hydraulic joint cutter CF-6020 off ers a great variety of<br />

attachments. Seperating cuts and deep cuts or cuts in green concrete<br />

are just as well possible as horizontal cuts, cutting of grooves<br />

(grooving) or core drillings up to 600 mm diameter.<br />

suction plant type 6.2<br />

CF-6020 with grooving attachment<br />

longitudinal attachment LS-2<br />

core drilling machine attachment<br />

order-No.<br />

30000007<br />

30000002<br />

30000010<br />

30000070<br />

30000008<br />

30000006<br />

description<br />

Longitudinal attachment LS-2<br />

For cutting very long joints (centre longitudinal joints) in green concrete up to a cutting depth of 160 mm in one work step. Two saw blades are<br />

mounted one after the other in one line: The fi rst, Ø 350 mm, for the initial cut and/or expanding the joint, the second saw blade, Ø 500 mm,<br />

for the fi nal cut.<br />

Green concrete attachment<br />

For cutting expansion joints, especially transverse joints in green concrete. Blade and blade drive can be moved along the joint cutter beyond the axle<br />

base, thus enabling cuts beyond the edge of the roadway.<br />

Core drilling machine attachment<br />

Hydraulically driven core drilling machine for max. drill-Ø 600 mm. The drill bit‘s speed is infi nitely adjustable; the max. lifting comes up to 600 mm.<br />

Special versions on request.<br />

45°- diagonal cutting attachment<br />

Saw blade to be infi nitely pivoted to both sides from the vertical position up to 45°, max. blade-Ø 1000 mm, max. cutting depth 380 mm at vertical<br />

blade position - 270 mm at 45°- position<br />

Grooving attachment<br />

For cutting grooves in roadways to prevent aquaplaning. The cutting shaft is mounted with saw blades side by side up to a total width of 600 mm.<br />

Washers provide the necessary distance between the blades. For milling operations the cutting shaft is densely mounted with up to 210 diamond saw<br />

blades. (spacers not included in the scope of delivery)<br />

Suction plant type 6.2 hydaulic<br />

Suction plant type 6.2 with hydraulic drive<br />

30000003 Suction blade guard for grooving attachment<br />

- Washers for cutting shaft of grooving attachment (thickness as per specifi cation up to 30 mm) for creating different grooving profi les<br />

32

CEDIMA-JOINT CUTTERS<br />

electric range<br />

Brilliant Performance<br />

Electrically driven joint cutters are suitable for indoor cutting operations where it is not permitted to use machines with combustion motors due<br />

to regulations regarding emission and/or noise protection. The compact construction of these small electric joint cutters is ideal for the transport to<br />

areas diffi cult to access.<br />

CF-13 E<br />

CF-13 E-TR<br />

order-No. 30000951 order-No. 30000952<br />

New feature of CF-13 B/D:<br />

Saw blade mounting possible<br />

on both sides<br />

CF-13 E<br />

•small joint cutter for renovation works especially in halls<br />

•powerful drive motor with 7,5 kW<br />

•crane eye for loading<br />

•extendable handle for relocating the machine<br />

manually<br />

•adjustable cutting depth indicator and locking brake<br />

CF-13 E-TR<br />

The modifi ed version especially designed for dry cutting is the ideal machine for cutting<br />

jobs in areas where the cooling of the diamond saw blade with water is not permitted or<br />

possible.<br />

The joint cutter works in counter direction. The cut material will be ejected out of the cut<br />

and removed via the suction blade guard. Vacuum cleaner with air quantity of at least<br />

250 m³/h and a fi lter surface of 1,5 m² required (not included in the CEDIMA programme).<br />

CF-22 E<br />

order-No. 30000055<br />

The modular construction of the CF-22 E enables the assembly of the joint cutter<br />

directly on the work place.<br />

•hinged blade guard for cuts directly to the wall<br />

•large cutting depth despite compact dimensions<br />

•modular constructions in 3 parts for easy transport<br />

(frame: 30 kg, balance: 60 kg, blade guard: 20 kg)<br />

technical data: CF-13 E CF-13 E-TR CF-22 E<br />

max. cutting depth mm 170 120 270<br />

max. blade-Ø mm 450 350 700<br />

bore hole of blade mm 25,4 25,4 25,4<br />

blade mounting lateral right od left right right or left<br />

max. mounting width mm 15 15 6<br />

speed of cutting shaft rpm 2250 3160 1630<br />

motor output kW 7,5 7,5 7,5<br />

voltage V/Hz 400/50 400/50 400/50<br />

amperage A 16 16 16<br />

protective system - IP54 IP54 IP54<br />

cutting depth adjustment - hand crank hand crank hand crank<br />

feed - manual manual manual<br />

dimensions L/W/H mm 820/520/870 820/520/870 1350/660/930<br />

weight kg 106 106 110<br />

sound pressure level dB (A) 83 83 78<br />

sound power level dB (A) 103 103 98<br />

33

Brilliant Performance<br />

CEDIMA-JOINT CUTTERS<br />

electric range<br />

CF-2015 E<br />

CF-50.2 E<br />

order-No. 30000052 order-No. . 30000067<br />

CF-2015 E<br />

•compact electric joint cutter with large cutting depth<br />

•hinged blade guard for cuts directly to the wall<br />

•drive of cutting shaft to be operated for displacing the machine on the job site<br />

•economic supply of cooling water via blade fl anges<br />

•lifting of saw blade in case of emergency by hydraulic manual pump<br />

CF-50.2 E<br />

•hinged blade guard for cuts directly to the wall<br />

•amperage switchable between 32 and 63 A<br />

•drive of cutting shaft to be operated separately for<br />

displacing the machine on the job site<br />

•supply of cooling water via blade guard<br />

•adjustable rear axle for an optimal straight cut<br />

•assembly set for water pump available<br />

The powerful CEDIMA joint cutters CF-50.2 E and CF-2015 E are<br />

primarily used for the extension and renovation of hall fl oors.<br />

technical data CF-2015 E CF-50.2 E<br />

max. cutting depth mm 350 500<br />

blade-Ø mm 600 - 900 800 - 1200<br />

bore hole of blade mm 25,4 35<br />

blade mounting lateral right or left right or left<br />

max. mounting width mm 20 5<br />

speed of cutting shaft rpm 1290 1000<br />

motor output kW 15 15/22 switchable<br />

voltage V/Hz 400/50 400/50<br />

amperage A 32 32/63 switchable<br />

protective system - IP54 IP54<br />

cutting depth adjustment - electro-hydraulic electro-hydraulic<br />

feed - hydrostatic hydrostatic<br />

dimensions L/W/H mm 1700/750/1050 1550/940/1200<br />

weight kg 342 580<br />

sound pressure level dB (A) 86 81<br />

sound power level dB (A) 112 107<br />

34

ACCESSORIES FOR JOINT CUTTERS<br />

Brilliant Performance<br />

Blade guards<br />

Suctions plants<br />

order-No. for description<br />

30000123 CF-2500 D standard blade guard for saw blade-Ø 700 mm<br />

30000086 CF-6020 standard blade guard for saw blade-Ø 600 mm<br />

30000017 CF-6020 standard blade guard for saw blade-Ø 800 mm<br />

30000087 CF-6020 standard blade guard for saw blade-Ø 1000 mm<br />

30000013 CF-6020 suction blade guard for saw blade-Ø 600 mm<br />

30000078 CF-6020 suction blade guard for saw blade-Ø 800 mm<br />

30000014 CF-6020 suction blade guard for saw blade-Ø 1000 mm<br />

30000015 CF-6020 suction blade guard for saw blade-Ø 1200 mm<br />

30000003 CF-6020 suction blade guard for grooving attachment<br />

order-No. for type<br />

30000006 CF-6020 type 6.2 (hydraulic)<br />

Conversion kits for cutting operations in green concrete<br />

order-No. for description<br />

30000053 CF-2116 D<br />

green concrete conversion kit for saw blade-Ø 400 mm<br />

Consisting of:<br />

1 x belt pulley for cutting shaft<br />

4 x V-belts<br />

1 x blade guard 400 mm, foldable<br />

suction plant type 6.2<br />

Further accessories<br />

order-No. for description<br />

30000021 CF-6020 set of lamps, 2 head lights<br />

30000022 CF-6020 warning beacon<br />

35

Brilliant Performance<br />

DIAMOND SAW BLADES<br />

for joint cutters<br />

Diamond saw blades for use on joint cutters<br />

Joint cutters are used in different areas of application so that the material to be cut can vary accordingly. To guarantee an optimum cutting result in the<br />

following please fi nd a choice of diamond saw blade for various applications of CEDIMA-joint cutters.<br />

APPLICATION: CURED CONCRETE<br />

AR-STANDARD GENERATION 2<br />

+<br />

order-No.<br />

Ø<br />

segment No. of bore hole<br />

mm W x H x L mm segments mm<br />

10000097 300 2,8 x 10 x 40 20 20/25,4<br />

10000115 350 3,2 x 10 x 40 24 20/25,4<br />

10000136 400 3,6 x 10 x 38 28 20/25,4<br />

10000142 450 3,6 x 10 x 38 32 25,4<br />

10000148 500 3,6 x 10 x 38 36 25,4<br />

10000154 600 4,2 x 10 x 38 42 25,4<br />

10000158 700 4,2 x 10 x 38 42 25,4<br />

•concrete, reinforced concrete, washed-out concrete, artifi cial and<br />

natural stone, concrete full brick, curb stones, paving concrete<br />

•universal blade with high cutting speed and long life<br />

AR-SUPER GENERATION 2<br />

order-No.<br />

Ø<br />

segment No. of bore hole<br />

mm W x H x L mm segments mm<br />

10000098 300 2,8 x 12 x 40 20 20/25,4<br />

10000124 350 3,2 x 12 x 38 24 20/25,4<br />

10000137 400 3,6 x 12 x 38 28 20/25,4<br />

10000143 450 3,6 x 12 x 38 32 25,4<br />

10000149 500 3,6 x 12 x 38 36 25,4<br />

10000155 600 4,2 x 12 x 38 42 25,4<br />

• concrete, reinforced concrete, washed-out concrete, artifi cial and<br />

natural stone, concrete full brick, curb stones, paving concrete<br />

• premium blade with very high cutting speed and very long life<br />

+<br />

A1-SUPER TURBO<br />

order-No.<br />

Ø<br />

segment No. of bore hole<br />

mm W x H x L mm segments mm<br />

10000102 300 2,8 x 12 x 40 20 20/25,4<br />

10000127 350 3,2 x 12 x 40 24 20/25,4<br />

10000140 400 3,6 x 12 x 40 28 20/25,4<br />

10000141 450 3,6 x 12 x 40 32 25,4<br />

10000150 500 3,6 x 12 x 38 36 25,4<br />

10000157 600 4,2 x 12 x 38 42 25,4<br />

•concrete, reinforced concrete, artifi cial stone, natural stone, hard<br />

clinkers, grey cast iron<br />

•premium blade with very high cutting speed<br />

+<br />

36

DIAMOND SAW BLADES<br />

for joint cutters<br />

Brilliant Performance<br />

For the application of joint cutters in cured concrete Cedima presents the BCE series of diamond saw blades:<br />

•innovative sandwich segments with height of segment 12 mm<br />

• very high cutting speed and very long life<br />

•lasered, by request soldered<br />

hardness grade concrete BCE-52 SA BCE-53* SA BCE-54.1 SA BCE-55* SA BCE-56 SA BCE-57* SA BCE-58* SA BCE-59 SA<br />

soft concrete > 45 kW >25 kW > 15 kW > 7 kW<br />

medium concrete > 60 kW > 45 kW > 30 kW > 25 kW > 20 kW > 15 kW > 11 kW<br />

hard concrete > 60 kW > 45 kW > 30 kW > 25 kW > 20 kW > 15 kW<br />

* available on request<br />

DIAMOND SAW BLADE BCE-52 SA<br />

• suitable for joint cutters of 45 kW<br />

order-No.<br />

Ø<br />

segment No. of bore hole+<br />

mm W x H x L mm segments mm<br />

10001147 500 4,4 x 12 x 20 56 35/25,4<br />

10001158 600 4,4 x 12 x 20 68 35/25,4<br />

10001171 700 4,4 x 12 x 20 80 35/25,4<br />

10001179 800 4,4 x 12 x 20 92 35/25,4<br />

10001186 900 4,4 x 12 x 20 104 35/25,4<br />

10001192 1000 4,4 x 12 x 20 108 35/25,4<br />

10001198 1200 4,4 x 12 x 20 128 35/25,4<br />

DIAMOND SAW BLADE BCE-54.1 SA<br />

• suitable for joint cutters of 25 kW<br />

order-No.<br />

Ø<br />

segment No. of bore hole+<br />

mm W x H x L mm segments mm<br />

10001146 500 4,4 x 12 x 20 56 35/25,4<br />

10001156 600 4,4 x 12 x 20 68 35/25,4<br />

10001169 700 4,4 x 12 x 20 80 35/25,4<br />

10001177 800 4,4 x 12 x 20 92 35/25,4<br />

10001184 900 4,4 x 12 x 20 104 35/25,4<br />

10001190 1000 4,4 x 12 x 20 108 35/25,4<br />

10001196 1200 4,4 x 12 x 20 128 35/25,4<br />

DIAMOND SAW BLADE BCE-56 SA<br />

• suitable for joint cutters of 15 kW<br />

order-No.<br />

Ø<br />

segment No. of bore hole+<br />

mm W x H x L mm segments mm<br />

10001389 500 4,4 x 12 x 20 56 35/25,4<br />

10001157 600 4,4 x 12 x 20 68 35/25,4<br />

10001170 700 4,4 x 12 x 20 80 35/25,4<br />

10001178 800 4,4 x 12 x 20 92 35/25,4<br />

10001185 900 4,4 x 12 x 20 104 35/25,4<br />

10001191 1000 4,4 x 12 x 20 108 35/25,4<br />

10001197 1200 4,4 x 12 x 20 128 35/25,4<br />

*with 6 additional mointing holes for fullly-hydraulic CEDIMA joint cutters<br />

37

Brilliant Performance<br />

DIAMOND SAW BLADES<br />

for joint cutters<br />

DIAMOND SAW BLADES BCE-59 SA<br />

• suitable for joint cutters of 7,5 kW<br />

order-No.<br />

Ø<br />

segment No. of bore hole+<br />

mm W x H x L mm segments mm<br />

10001148 500 4,4 x 12 x 20 56 35/25,4<br />

10001159 600 4,4 x 12 x 20 68 35/25,4<br />

10001172 700 4,4 x 12 x 20 80 35/25,4<br />

10001180 800 4,4 x 12 x 20 92 35/25,4<br />

10001187 900 4,4 x 12 x 20 104 35/25,4<br />

10001193 1000 4,4 x 12 x 20 108 35/25,4<br />

10001199 1200 4,4 x 12 x 20 128 35/25,4<br />

DIAMOND SAW BLADE BCE-23.2<br />

• cured concrete, reinforced concrete, washed-out concrete, curb stones<br />

• suitable for joint cutters of 10 kW - 22 kW<br />

order-No.<br />

Ø<br />

segment No. of bore hole<br />

mm W x H x L mm segments mm<br />

10001139 450 4,4 x 10 x 40 26 35/25,4<br />

10001154 600 4,4 x 10 x 40 34 35/25,4<br />

10001161 650 4,4 x 10 x 40 36 35/25,4<br />

10001167 700 3,6 x 10 x 40 40 35/25,4<br />

10001166 700 4,4 x 10 x 40 40 35/25,4<br />

10001174 800 4,4 x 10 x 40 46 35/25,4<br />

10001182 900 4,4 x 10 x 40 52 35/25,4<br />

10001188 1000 4,4 x 10 x 40 54 35/25,4<br />

DIAMOND SAW BLADE BCE-SYNCRO<br />

•hard concrete with hard aggregates, excellent cutting behaviour in reinforced concrete with high and very high shares of reinforcement<br />

•suitable for joint cutters of 7,5 kW till 15 kW<br />

•very high cutting speed and very long life •optimal cutting behaviour by V-form of segments<br />

order-No.<br />

Ø<br />

segment<br />

bore hole<br />

No. of segments<br />

mm W x H x L mm<br />

mm<br />

10001534 600 4,0 x 10 x 40 36 35/25,4<br />

10001535 600 4,4 x 10 x 40 36 35/25,4<br />

10001536 700 4,0 x 10 x 40 42 35/25,4<br />

10001537 700 4,4 x 10 x 40 42 35/25,4<br />

10001538 750 4,0 x 10 x 40 46 35/25,4<br />

10001539 750 4,4 x 10 x 40 46 35/25,4<br />

10001540 800 4,0 x 10 x 40 50 35/25,4<br />

10001541 800 4,4 x 10 x 40 50 35/25,4<br />

10001542 900 4,4 x 10 x 40 56 35/25,4<br />

*with 6 additional mounting holes for fully-hydraulic CEDIMA joint cutters<br />

38

DIAMOND SAW BLADES<br />

for joint cutters<br />

Brilliant Performance<br />

APPLICATION AREA: ASPHALT<br />

petrol- and diesel joint cutters<br />

engine power<br />

diamond saw blade type<br />

9 - 22 kW ACE-22<br />

ab 18 kW<br />

ACE-44<br />

ab 20 kW<br />

ACE-52.3<br />

ab 25 kW<br />

ACE-50<br />

electric joint cutters<br />

engine power<br />

diamond saw blade type<br />

9 - 22 kW ACE-22<br />

ab 18 kW<br />

ACE-44<br />

CA-ECO ASPHALT (Laser)<br />

• asphalt, lime sand-stone and other abrasive materials<br />

• long life<br />

• with diamond protective segments<br />

order-No.<br />

Ø<br />

segment No. of bore hole<br />

mm W x H x L mm segments mm<br />

10000088 300 2,8 x 10 x 40 18 20<br />

10000089 300 2,8 x 10 x 40 18 25,4<br />

10000113 350 3,2 x 10 x 40 21 20<br />

10000119 350 3,2 x 10 x 40 21 25,4<br />

10000134 400 3,2 x 10 x 40 24 20<br />

10000138 400 3,2 x 10 x 40 24 25,4<br />

10000146 450 3,6 x 10 x 40 26 25,4<br />

10000152 500 4,2 x 10 x 40 30 25,4<br />

10000156 600 4,2 x 10 x 40 36 25,4<br />

+<br />

CA-3 STANDARD with diamond protective segments<br />

• abrasive materials like asphalt, fl oor fi nish, lime sand stone<br />

(gross density < 2), poroton, refractory material porous,<br />

aerated concrete, sand stone, clay bricks<br />

order-No.<br />

Ø<br />

segment No. of bore hole<br />

mm W x H x L mm segments mm<br />

10000094 300 3,0 x 9 x 40 18 25,4/20<br />

10000110 350 3,2 x 9 x 40 20 25,4/20<br />

10000132 400 3,6 x 9 x 40 24 25,4/20<br />

10000144 450 3,6 x 9 x 40 27 25,4<br />

10000151 500 3,6 x 9 x 40 30 25,4<br />

10000153 600 4,2 x 9 x 40 36 25,4<br />

+<br />

AR-DUAL<br />

• concrete and asphalt, other hard or abrasive materials<br />

• universal blade with high cutting speed and life<br />

• with diamond protective segments<br />

order-No.<br />

Ø<br />

segment No. of bore hole<br />

mm W x H x L mm segments mm<br />

10000100 300 3,2 x 10 x 50 16 20/25,4<br />

10000120 350 3,2 x 10 x 50 19 20/25,4<br />

10000139 400 3,6 x 10 x 50 22 20/25,4<br />

+<br />

39

Brilliant Performance<br />

DIAMOND SAW BLADES<br />

for joint cutters<br />

DIAMOND SAW BLADE ACE-22 with protective segments<br />

• application in asphalt and fl oor fi nish with soft to medium-hard aggregates<br />

• suitable for joint cutters of 10 kW -22 kW<br />

order-No.<br />

Ø<br />

segment No. of bore hole<br />

mm W x H x L mm segments mm<br />

10001200 450 3,6 x 10 x 40 26 25,4<br />

10001206 600 4,2 x 10 x 40 36 25,4<br />

10001213 650 4,4 x 10 x 40 36 35/25,4<br />

10001215 700 4,4 x 10 x 40 40 35/25,4<br />

10001220 800 4,4 x 10 x 40 46 35/25,4<br />

10001225 900 4,4 x 10 x 40 52 35/25,4<br />

Diamond saw blade ACE-44 with diamond protective segments<br />

• application in asphalt with medium-hard aggregates, high feed, fast cutting<br />

• suitable for joint cutters of 18 kW<br />

order-No.<br />

Ø<br />

segment No. of bore hole+<br />

mm W x H x L mm segments mm<br />

10001202 500 3,6 x 10 x 40 28 35/25,4<br />

10001203 500 4,4 x 10 x 40 28 35/25,4<br />

10001209 600 3,6 x 10 x 40 34 35/25,4<br />

10001208 600 4,4 x 10 x 40 34 35/25,4<br />