Wire saw technology

Wire saw technology

Wire saw technology

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Wire</strong> <strong>saw</strong> <strong>technology</strong>

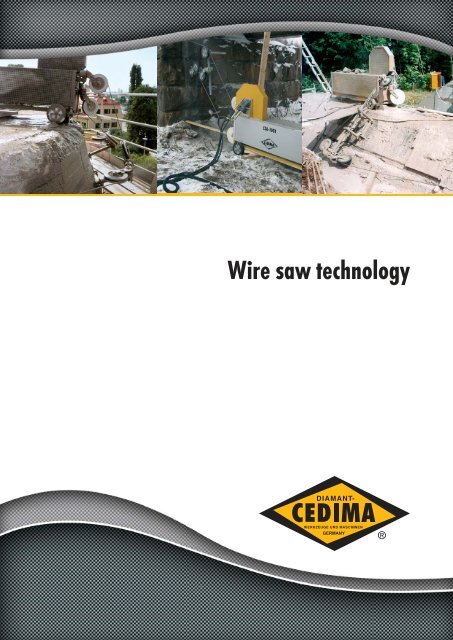

CEDIMA WIRE SAW TECHNOLOGYup and below: automatic wire <strong>saw</strong> CSA-1001 creating separation cutsToday the <strong>saw</strong>ing with diamond wires offers almost unlimited possibilities toprofessional users. Thanks to modern wire <strong>saw</strong> <strong>technology</strong> it is no problem anylonger to cut conrete, reinforced conrete of masonry which before was a task ofhigh complexity. By using swivel rolls and wire guide pulleys cuts in any directionand of any kind become possible. Also in places diffi cult to access and in extremelynarrow areas where a wall <strong>saw</strong> cannot be used the wire <strong>saw</strong> <strong>technology</strong> can beapplied without any problems.CEDIMA disposes of many years of experience in the development and theconstruction of powerful wire <strong>saw</strong>ing machines that meet all requirements on jobsites. From the automatic wire <strong>saw</strong> CSA-100 for small to medium surfaces to theCSA-1001 with a wire storage capacity of 21 m for large surfaces we offer you thesuitable machine for each <strong>saw</strong>ing application.All the CEDIMA automatic wire <strong>saw</strong>s are equipped with an automatic cuttingforce control that provides constantly the correct wire tension while cutting. Thisensures a permanent maximum output at the lowest possible tool costs. Due to theextensively automated cutting operation the operator‘s job is effectively eased andpossible mistakes due to mishandling are widely avoided.According to your requirements and preferences hydraulic wire drives or drives withmodern, powerful high-frequency electric motors are available.The construction of the automatic wire <strong>saw</strong>s allows looping of a maximum wirelength around the drive wheel, this involving a high power transmission.The modular design of the machines and the wide range of accessories enable youto compose your wire <strong>saw</strong>ing equipment according to your special requirements.We shall be glad to offer you the appropriate wire for each material.••••••••Compact dimensions at high wire storage capacityLight, modular aluminium constructionHighest daily output by hydraulic feed control and automatic cutting forcecontrolCentral wire guidance (in and out) with swivel rollsDue to large wire storage capacities no change of wire necessary in case ofdifferent cutting surfacesShort set-up timesHigh fl exibility due to hydraulic of high-frequency electric drivesCompletely encapsulated systems for maximum operator‘s safety(wire guard system)Wide range of accessories•2

CEDIMA WIRE SAW TECHNOLOGY! ImportantWhile using wire <strong>saw</strong> <strong>technology</strong> the safety of your operators as well as theCE-conformity of the equipment can only be guaranteed if the machines areoperated according to the attached operating manuals.automatic wire <strong>saw</strong> CSA-1001: horizontal cut of a bridge pierautomatic wire <strong>saw</strong> CSA-1001 H: vertical cut through a bridge cheekfi xing of mini wire <strong>saw</strong> CSA-100 H for a horizontal cut directly to a concrete pierMounted on a special platform the CSA-1001 H separates an industrial chimney by horizontal cuts.Including platform the separated piece is lifted by a crane.3

AUTOMATIC WIRE SAWSThe wire storage compartments of the CEDIMA automatic wire <strong>saw</strong>s have been designed as alight aluminium construction and despite the low weight a high resilience is achieved.The connections for the feed are equipped with quick couplings.A high-solid, durable hydraulic cylinder in the interior keeps a constant tenseness of the wireand retracts the free wire as per requirement.The drive can easily be converted from hydraulic to electric by changing the drive panel(CSA-1001) or the drive motor (CSA-100).CSA-1001The wire storage rolls made of aluminium are equipped with a rubber bandagefor the wire guidance. In case of wear the bandage can be replaced without anyproblems. Thus the costs for storage rolls are considerably reduced.CSA-100technical data CSA-1001 CSA-100dimensions and weights of the automatic wire <strong>saw</strong>stransport dimensions L x W x H mm 1950 x 600 x 550 1050 x 300 x 460weight of basic machine without drive kg 130 54weight of hydraulic drive panel with drive wheel kg 50 -weight of hydraulic motor HM-19 kg - 6,8operational weight hydraulic without wire kg 180 60,8weight of electric drive panel with drive wheel kg 55,5 -weight of high-frequency electric motor HFM-18.1 with 10 m motor cable kg 19,5 19,5operational weight electric without wire kg 205 73,5required hydraulic connecting valuesoil quantity for feed l/min 1 - 15 1 - 15max. operating pressure of feed bar 100 1004

OPERATING MODE OF WIRE STORAGECSA-1001 with10 storage rollsThe functionality of the wire storage is similar to achain-block. In the interior the diamond wire is laid inan endless loop around 2 packages of rolls. The rearpackage of rolls can be moved hydraulically.For the starting position the 2 packages of rolls aredirectly adjoined. The diamond wire has to be mountedon at least 2 rolls of package. While cutting, the rearpackage of rolls is moved backwards. This way, the wireset free during the <strong>saw</strong>ing process is pulled into themachine.When reaching the fi nal stop, the cutting operating isinterrupted by the operator, the rear package of rollsis moved forward again and the wire set free is loopedaround the remaining storage rolls. This procedure canbe repeated until all the storage rolls are lined with wire.Due to this operating mode large cutting surfacescan be implemented without repositioningthe machine or shortening the wire.CSA-100110 storage rollsCSA-100114 storage rollsCSA-1008 storage rollsmin. wire lengthin the machineposition of the packages of rolls in the wire storage compartmentwith different cutting surfaces and identical wire lengthmax. wire lengthin the machinemax. available wirestorage capacity6,5 m 20,5 m 14,0 m6,5 m 27,5 m 21,0 m4,0 m 10,5 m 6,5+1,5* m* by displacing the machine on the guiding tubecutting surface5

HYDRAULIC DRIVESPowerful hydraulic motors are available for the drive of CEDIMA automatic wire <strong>saw</strong>s. Already existing hydraulic components, e.g. of the CEDIMA wall <strong>saw</strong>, can be usedwithout prior alterations.••••••powerful drive panels with axial piston motors (45 und 63 cm³) for CSA-1001 Hgearwheel motors HM-19 or HM-23 for CSA-100 Havailable components of the CEDIMA wall <strong>saw</strong> <strong>technology</strong>, such as hydraulic power packs, control panels or hydraulic motor HM-23 (only for CSA-100 H) can be usedwithout prior alterationshydraulic power packs with an output from 10 to 24 kW are applicableconnection by drop-free quick-couplings, sets of hoses with pressure reliefwire drive wheels made of aluminium with interchangeable rubber bandagestechnical data of hydraulic drives CSA-1001 H CSA-100 Hmax. output of hydraulic motors kW 24 20oil quantity of hydraulic drive l/min 30 - 54 25 - 40max. operating pressure of drive bar 250 250Hydraulic power packs•••••triple gear pump for 3 oil circuits (HAG-324 and HAG-12.20)tandem gear pump for 2 oil circuits (HAG-12.10)control panel for feed of wire <strong>saw</strong>s CSA-100 H and CSA-1001 H orfully-hydraulic wall <strong>saw</strong> (HAG-324 and HAG-12.20)water-oil coolerremovable electric motor for easy transporthydraulic power pack HAG-12.10 with control panel HSP-12 for wire <strong>saw</strong>s andfully-hydraulic wall <strong>saw</strong> WS-451 Hhydraulic power pack HAG-12.20 with control panel forfeed of wire <strong>saw</strong>s and fully hydraulic wall <strong>saw</strong> WS-451 Htype HAG-12.10 HAG-12.20 HAG-324output electric motor S1/S6 15/20 kW 15/20 kW 18,5/24 kWvoltage/amperage 400 V/50 Hz/32 A 400 V/50 Hz/32 A 400 V/50 Hz/35 Ahydraulic pump tandem wheel gear triple wheel gear triple wheel gearoil fl ow capacity operating circuit 30/44 l/min 30/44 l/min 40/54 l/minoil fl ow capacity control circuit 14 l/min* 6 l/min 6 l/minoperating pressure 250 bar 250 bar 250 barsolenoid valve yes no yeshydraulic control panel - yes accessoryoil quantity in tank 11 l 11 l 11 lweight of electric motor 62 kg 62 kg 71 kgtotal weight 130 kg 130 kg 137 kgdimensions L/W/H 640/560/970 mm 640/560/970 mm 640/560/1000 mm* using control circuit: in operating circuit 30l/min available6

HYDRAULIC DRIVESset of hoses 3-partsExamples for connection• CSA-1001 H + HAG-12.10 + hydraulic control panel HSP-12• CSA-100 H + HAG-12.20 with additional control panel for feedoil flow wire driveoil flow feedset of hoses 3-partsset of hoses 2-partsHSP-12set of hoses 2-partsNecessary components for the operation of CSA-1001 H CSA-100 HCSA-1001 automatic wire <strong>saw</strong> with 2 swivel rolls and 10 storage rolls, without wire drive unit and wire drive wheel X- - - wire drive unit for CSA-1001 H with hydraulic motor (45 oder 63 cm³) and drive wheel guard X- - - wire drive wheel Ø 600 mm with interchangeable bandage XCSA-100 automatic wire <strong>saw</strong> with 2 mini swivel rolls, 8 storage rolls and ground mouting foot, without wire drive motor XHM-19/23 hydraulic motor (19 or 23 cm³) for drive of drive wheel X- - - set of hoses 3-parts, 10 m long, for drive of drive wheel X Xfor the operation of HAG-12.10 and control panel HSP-12HAG-12.10 hydraulic power pack; 15 kW/400 V; 30/44 l/min; 250 bar X XHSP-12 hydraulic control panel X X- - - set of hoses 2-parts, 10 m long, for feed at drilling and wire <strong>saw</strong>ing X Xfor the operation of HAG-324 or HAG-12.20 with control panel for feedHAG-324 hydraulic power pack; 18,5 kW/400 V; 40/54 l/min; 250 bar XHAG-12.20 hydraulic power pack; 15 kW/400 V; 30/44 l/min; 250 bar X X- - - hydraulic control panel HAG-324 for feed control X X- - - set of hoses 2-parts, 10 m long, for feed at wire <strong>saw</strong>ing with HAG-324 and HAG-12.20 X X7

HIGH-FREQUENCY ELECTRIC DRIVESThe modern high-frequency electric drives for CEDIMA automatic wire <strong>saw</strong>s offer an almost loss-free availability of output at the wire drive wheel. The wire speed can beregulated infi nitely by means of the universal control box (also available as remote control).• high-frequency electric motor HFM-18.1 with 18 kW output, connection: CSA-100 E directly, CSA-1001 E by special motor console• wire drive wheels made of aluminium with exchangeable rubber bandageselectrique drive console with HFM-18.1 at CSA-1001 Ehigh-frequency electric motor HFM-18.1 at CSA-100 EThe high-frequency drives are controlled by means of the powerful universal control HF-27.1. With its peakcapacity of 27 kW the control performs a future-proof investment in the modern high-frequency <strong>technology</strong>. Theautomatic machine identifi cation assures that the required commands are loaded directly on connection. All thefunctions can be carried out by means of a light universal control box.mini hydraulique power pack HAG-2 for feedtechnical dataHAG-2motor output S1 kW 0,25voltage/amperage V/Hz/A 230/50/16oil fl ow capacity l/min 1,2operating pressure bar 95oil quantity in tank l 1,2total weight with oil kg 23,5dimensions L/W/H mm 415/235/340universal high-frequency controle HF-27.1and universal remote controletechnical dataHF-27.1output S1/S6 kW 18,5/27frequency range Hz 0 – 310dimensions LxWxH mm 590/290/375weight kg 278

HIGH-FREQUENCY ELECTRIC DRIVESThe CEDIMA high-frequency electric components are characterised by their versatile applicability at drilling or <strong>saw</strong>ing concrete. With the help of the high-frequency universalcontrol HF-27.1 you can, already today, drive all the electrical automatic wire <strong>saw</strong>s as well as the wall <strong>saw</strong>s WS-290 and WS-450 EE.The high-frequency electric motor HFM-18.1 is suited for powering wire <strong>saw</strong>s as well as wall <strong>saw</strong> WS-451 EE.The mini hydraulic power pack HAG-2, providing the wire feed when wire <strong>saw</strong>ing, serves as automatic drill feed when diamond drilling <strong>technology</strong> is used.connecting schemaCSA-1001 E and CSA-100 Eset of hoses 2-partsoperating current wire driveoil flow feedelectric control linenecessary components for the operation of CSA-1001 E CSA-100 ECSA-1001 automatic wire <strong>saw</strong> with 2 swivel rolls and 10 storage rolls, without wire drive unit and wire drive wheel X- - - wire drive unit with high-frequency electric motor HFM.18.1 with drive wheel guard (without motor) X- - - wire drive wheel Ø 600 mm with interchangeable bandage XCSA-100 automatic wire <strong>saw</strong> with 2 mini swivel rolls, 8 storage rolls and ground mouting foot, without wire drive motor XHFM-18.1 high-frequency electric motor, 18.1 kW, with 10 m cable X XHAG-2 power pack for hydraulic feed; 230 V/50 Hz, 1,2 l/min, 0 - 95 bar X XHF-27.1 high-frequency universal control, 27 kW, 400 V/32 A X X- - - set of hoses 2-parts, 10 m long, for feed at drilling and wire <strong>saw</strong>ing X X- - - connecting cable HF-27.1 to HAG-2 X X- - - universal control box with 10 m cable X X- - - universal remote control box (alternatively to universal control box) X X9

MINI AUTOMATIC WIRE SAW CSA-100The mini automatic wire <strong>saw</strong> CSA-100 has especially been developed for medium and small separating cutswith diamond wires. Despite the considerably compact dimensions the machine allows a wire storage of up to6,5 m. There are additional 1,5 m wire by displacing the machine on the mounting tube.•••••••••consequent implementation of the one-man-principle by modular construction,no single component weighs more than 21 kghigh output of up to 20 kWpatented protective <strong>technology</strong>either hydraulic drive (HM-19/23) or high-frequency electric drive HFM-18.1variable wire speed 0 - 27 m/s with high-frequncy electric driveautomatic feed for relieving the operatorextremely easy transport and mountinghigh-grade storage-rolls and guide pulleys made of aluminium with interchangeable rubber bandageswide range of accessoriesCSA-100 E with footMF-6000 for wall or groundmoutingposition for vertical cutposition for horizontal cutThe CSA-100 automatic wire <strong>saw</strong> can be operatedwith a precision swivel foot that allows themachine to turn steplessly around its longitudinalaxis.By this it becomes possible with only two dowelfi xings to cut an opening without additional wireguide pulleys.The operation of the machine is exclusively permitted with mountedwire guard.10

CIRCULAR SAW CAZ-3200Circular wire <strong>saw</strong> CAZ-3200 for cutting openings in walls or ceilings.• for cutting large-sized, circular openings in concrete of masonry of diametresbetween 0,52 and 3,2* m at a maximum wall thickness of 1,1* m.• fl ush cutting possible at a diametre of at least Ø 1,3 m• short set-up times and easy handling• automatic cutting force control• wire tensioning roll to compensate varying wire loads• drive by hydraulic power packs of 10 - 30 kW output, e.g. HAG-12.10* enlargement possible by extension of guiding tubesOperational method of the circular <strong>saw</strong> CAZ-3200A core drilling of 120 mm diametre is created in the centre of the circle to be cut.This hole serves to mount the circular <strong>saw</strong> and to guide the diamond wire on theopposite side. <strong>Wire</strong> guide pulleys lead the wire to the cut.A hydraulic motor drives the endlessly looped diamond wire. Driven hydraulically,the circular <strong>saw</strong> revolves the central point and a circular opening is being cut.circular <strong>saw</strong> CAZ-3200 cutting an opening into a concrete tubetechnical data of circular <strong>saw</strong> CAZ-3200dimensions and weightsweight of central drive unit kg 42total weight kg 108required hydraulic connecting valuesrequired oil quantity for hydraulic drive l/min 30max. operating pressure of hydraulic drive bar 250required oil quantity for feed l/min 1 - 15operating pressure of feed bar 10011

WIRE GUARD SET WITH WATER COLLECTION FUNCTIONIn order to increase the safety for your operating staff CEDIMA has developed highly effective wire guard systems that will reduce considerably the risk of injury following awire breakage (fl ying beads and whip-lashing diamond wire).31223CSA-100 (1) with mounted wire guard system (2) and wire guiding devices (3)The CEDIMA wire guard systems is a simple possibility to cover completely the freely running wire parts thatrepresent potential danger.U-profi les made of aluminium are put on the wire and fi xed with rubbers. These profi les are available invarious lengths. On both ends the wire guard profi les are fi tted to the swivel rolls that continue to rotateunimpaired. The closed back side of the profi le is mounted in the direction the wire could possibly swing out.The wire guard profi les are available for all CEDIMA automatic wire <strong>saw</strong>s. For the CSA-100 the system isequipped with an additional water collection function. By means of the sealing elements and end caps thatbelong to the set most of the slurry can be collected and suctioned.long wire guiding device with lang with mini swivel roll and guide pulleywire guard profi le - aluminium- with end cap,suction connection and end cap GEKAholder for wire guard profi le fordirect mounting to the wallquick-mounting holder for wire guardprofi le for operation with wire guidingdevice<strong>Wire</strong> guard equipmentitem for operation with description25 CSA-1001wire guard set consisting of: wire guard profi le made of aluminium (5 x 2,3 m; 4 x 1,15 m; 3 x 0,76 m),4 end caps made of aluminium for wire guard profi le, 6 clamping yokes for mounting the wire guard profi les directly to the wall, fi xing material25 CSA-100wire guard and water collecting set consisting of: wire guard profi le made of aluminium (1 x 3 m; 1 x 2,5 m; 1 x 2 m; 1 x 1,5 m; 1 x 1 m; 2 x 0,75 m; 1 x 0,5m),2 end caps PUR for wire guard profi le, 3 x end caps for GEKA-connection, 1 x suction connection GEKA, 6 clamping yokes for mounting the wire guard profi lesdirectly to the wall, fi xing/sealing material26 CSA-1001 retrofi tting set for mounting wire guard profi le to swivel rolls Ø 270 mm without holder27 all types CSA quick-mounting holder wire guard profi le for the operation with wire guiding devices12

DIAMOND WIREStypeorange 10,5 mmblue 11,0 mmred 10,5 mmblack 8,8 mmblack 10,5 mmblack 8,8 mmapplicationconcrete with up to 3 % shares of reinforcement and soft to hard aggregatesconcrete with up to 3-8 % shares of reinforcement and hard to extremely hard aggregatesabrasive materialsfi nal cut in soft to hard materials with up to 6 % shares of reinforcementsteel, stainless steel, fi bre plastics, hard natural stones, glass, ceramics, special applicationsfi nal cut in steel, stainless steel, fi bre plastics, hard naturals stones, glass, ceramics, special applicationsHandling of diamond wiresTo guarantee the undisturbed function and the longest possible life of your CEDIMA diamond wire you are kindlyrequested to observe the following recommendationsfi g. 1 fi g. 2fi g. 3Turning in the diamond wire before closingIn order to prevent a one-sided wear of the wire it has to be turned in around its longitudinal axis before being closed. This produces a tension that makes the wire turningwhile cutting, thus an even wear of the diamond wire is obtained.After having laid on the diamond wire in the storage compartment and around the workpiece to be cut, take the end of the wire coming out of the machine and form a loop(fi g. 1). Now continue to turn the wire in its twisting direction (fi g. 2).As guiding value we recommend 1 to 1,5 complete turns per metre diamond wire, i.e. 20 to 30 turns for 20 m wire length.Closing the diamond wireFor closing the diamond wire remove the rubber coating at both ends as well as the spring very close to the diamond bead as shown in fi g.2. Insert the steel core in both sidesof the steel wire clamp. Make sure that the clamp is not positioned too close to the diamond beads as shown in fi g. 3 below. To guarantee the best possible fl exibility of thewire, 2-3mm steel core should be left free on both sides (fi g. 3 centre). Now press the steel wire clamp with an appropriate hydraulic jointing clamp (available at CEDIMA),thus creating a tensile strength connection (fi g. 3 above). When using articulated joints please act accordingly. Using screw-type connectors, make sure that the sleeve of theconnector is mounted at the towing side of the diamond wire. The running direction of the diamond wire is indicated by arrows on the rubber coating.Opening the diamond wire / repair after a wireFor opening the diamond wire and for the repair after a wire breakage please proceed as described in the „Product recommendations for handling and repair of CEDIMA diamondwires“, attached to each wire delivery. Here you will also fi nd safety recommendations for the use. Please observe the safety recommendations for a safe and effectiveworking with CEDIMA diamond wires.13

WIRE SAW TECHNOLOGY ACCESSORIES<strong>Wire</strong> drive wheels and storage rollsitem operation with description1 CSA-1001 wire drive wheel Ø 600 mm with interchangeable bandage2 CSA-1001 bandage for wire drive wheel Ø 600 mm3 CSA-1001 additional rolls Ø 300 mm for increasing wire storage capacity- CSA-100/1001 CSA-1001: bandage for storage roll Ø 300 mm / CSA-100: bandage for wire drive wheel<strong>Wire</strong> guidance and water supply to the wireitem operation with description4 all CSA wire guide pulley Ø 270 mm with hard rubber contact surface and assembly tube5 CSA-1001 swivel roll Ø 270 mm with interchangeable bandage and mounting device CSA-1001- CSA-1001 bandage for swivel roll Ø 270 mm6 CSA-100 mini swivel roll Ø 200 mm with interchangeable hard rubber bandage and mounting device for wire guard set CSA-100- CSA-100 bandage for mini swivel roll Ø 200 mm7 all CSA wire guiding device short with wire guide pulley (ca. 300 mm)8 all CSA wire guidance device long with mini swivel roll and guide roll (ca. 900 mm)9 all CSA immersion column with immersion roll Ø 230 mm for cuts in blind holeØ 250 mm, length 2,5 m, with suction hose, without swivel roll and mounting foot10 all CSA wire guide pulley for fl ush cutting Ø 300 mm, with holder11 all CSA fl exible jet with GEKA-coupling12 all CSA water lance with GEKA-coupling- all CSA throttle-check-valve - starting aid CSA-1001 and CSA-100 (supports starting the wire under complicated conditions)Mounting accessoriesitem for operation with description13 CSA-100 MF-6000, foot for mounting to wall and ground with mounting tube, 0-45° titable14 CSA-100 precision swivel foot with mounting tube, pivoting by 360°15 all CSA mounting foot for fi xing the mounting tubes and immersion column16 all CSA mounting tube 1 m long16 all CSA mounting tube 2 m long17 all CSA T-mounting tube for fi xing of swivel rolls18 all CSA rigid scaffold coupling19 all CSA rotating scaffold coupling<strong>Wire</strong> guard equipmentitem description20 steel wire clamps for closing diamond wires 10,5 and 11 mm20 steel wire clamps for closing diamond wires of 8,8 mm21 articulated joints for closing and opening of diamond wires 10,5 and 11 mm- spare pin for articulated joints22 device for opening and closing of articulated joints23 hydraulic jointing clamp with press chucks for closing diamond wires of 10,5 and 11 mm- press chucks for closing of diamond wires of 8,8 mm24 fi bre cutting discs for separating diamond wire15

EXAMPLES FOR WIRE SAWING OPERATIONSCutting a wall openingFor making a rectangular opening four steps are necessary. Thewire is led through two prepared core drilling holes at the cornersof the area to be cut. <strong>Wire</strong> guide pulleys and swivel rolls lead thediamond wire from the machine to the cut.assembly of a wire <strong>saw</strong> for vertical cutsFor horizontal cuts the diamond wire can be guided on itsshortest way to a horizontal cutting position by means of parallelpositioned swivel rolls.assembly of a wire <strong>saw</strong> for horizontal cuts(seen from an upper position)The wire <strong>saw</strong> operating as an immersion <strong>saw</strong>If the diamond wire connot be led around the material to be cutdue to structural reasons the wire <strong>saw</strong> is operated with the help ofimmersion columns. Two immersion rolls are placed into correspondingblind hole drillings.The wire „immerses“ into the material to be cut.immersion columns with prepared slurry removalmax. immersion depth 2500 mmblind hole drilling Ø 250 mm<strong>Wire</strong> <strong>saw</strong>ing in narrow areasBy means of swivel rolls the diamond wire can be led to the cutthrough cramped areas of narrow passages.CEDIMA ® Diamantwerkzeug- und Maschinenbaugesellschaft mbHLärchenweg 3 • 29227 Celle/DeutschlandTel. +49 (0)51 41 / 88 54 - 0 • Fax +49 (0)51 41 / 86 42 7Internet: www.cedima.com • E-Mail: info@cedima.com16